Double-stator permanent-magnet vernier wind driven generator

A wind turbine and double stator technology, applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problem of low utilization rate of windings, achieve improved torque density, and increase the sine degree of air-gap magnetic density waveform Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

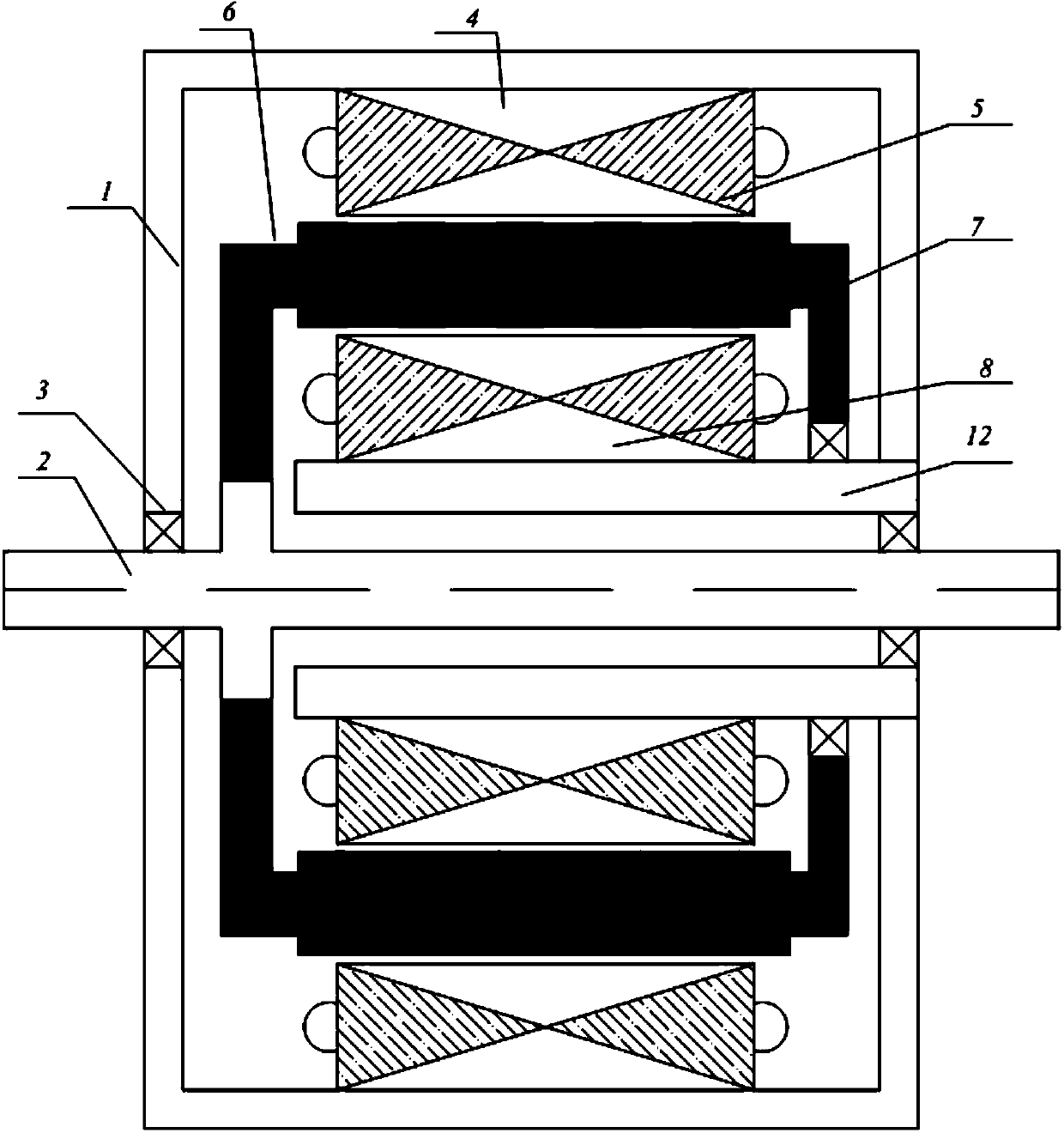

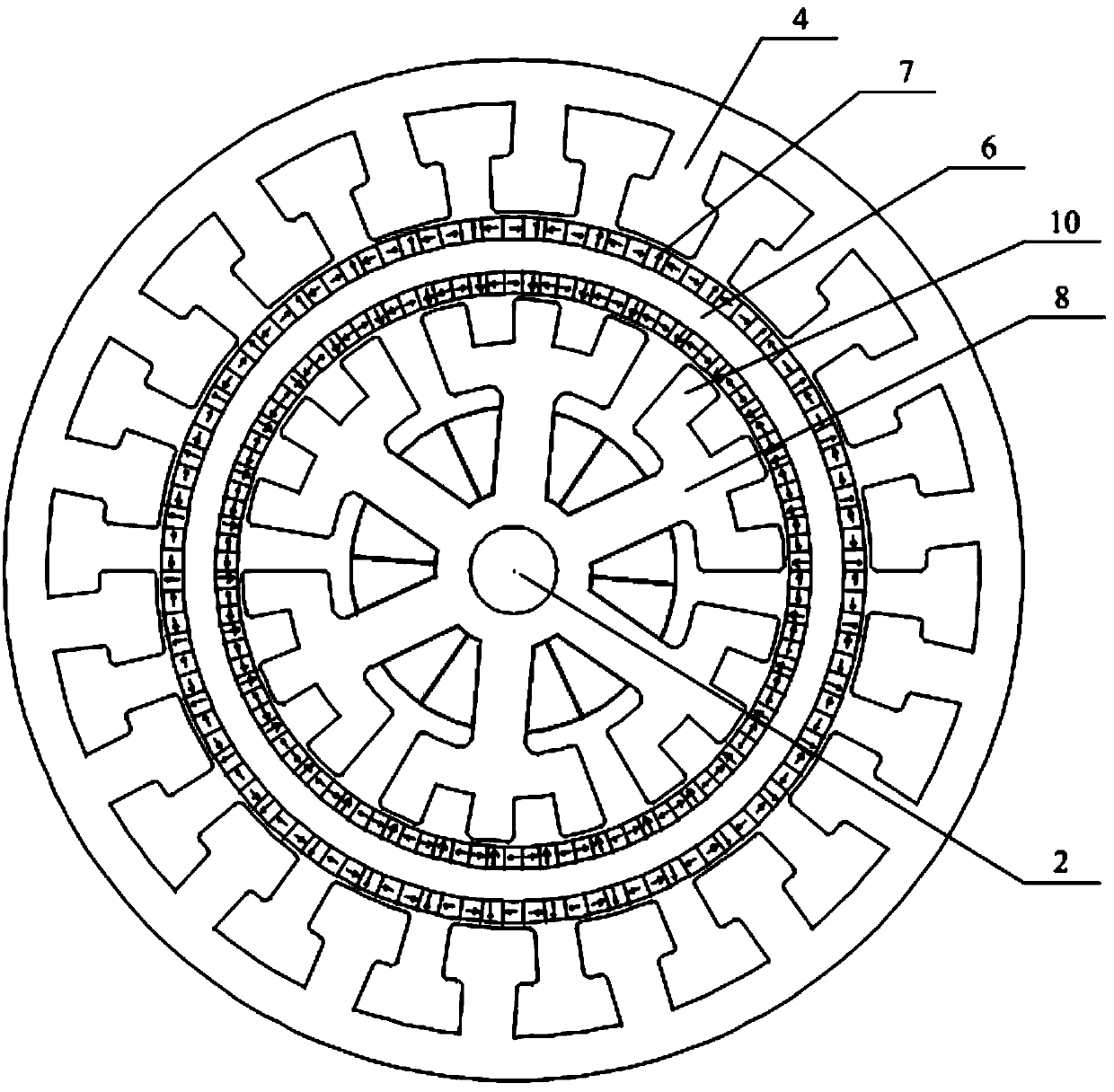

[0036] A double stator permanent magnet vernier wind generator, such as figure 1 As shown, it includes an outer stator 4, an inner stator 8 and a rotor 6; the outer stator 4 and the inner stator 8 are different in size, and the outer stator 4 and the inner stator 8 are coaxially arranged on the inner and outer sleeves, and the rotor 6 is set Between the outer stator 4 and the inner stator 8, and the outer stator 4, the inner stator 8 and the rotor 6 are concentrically distributed:

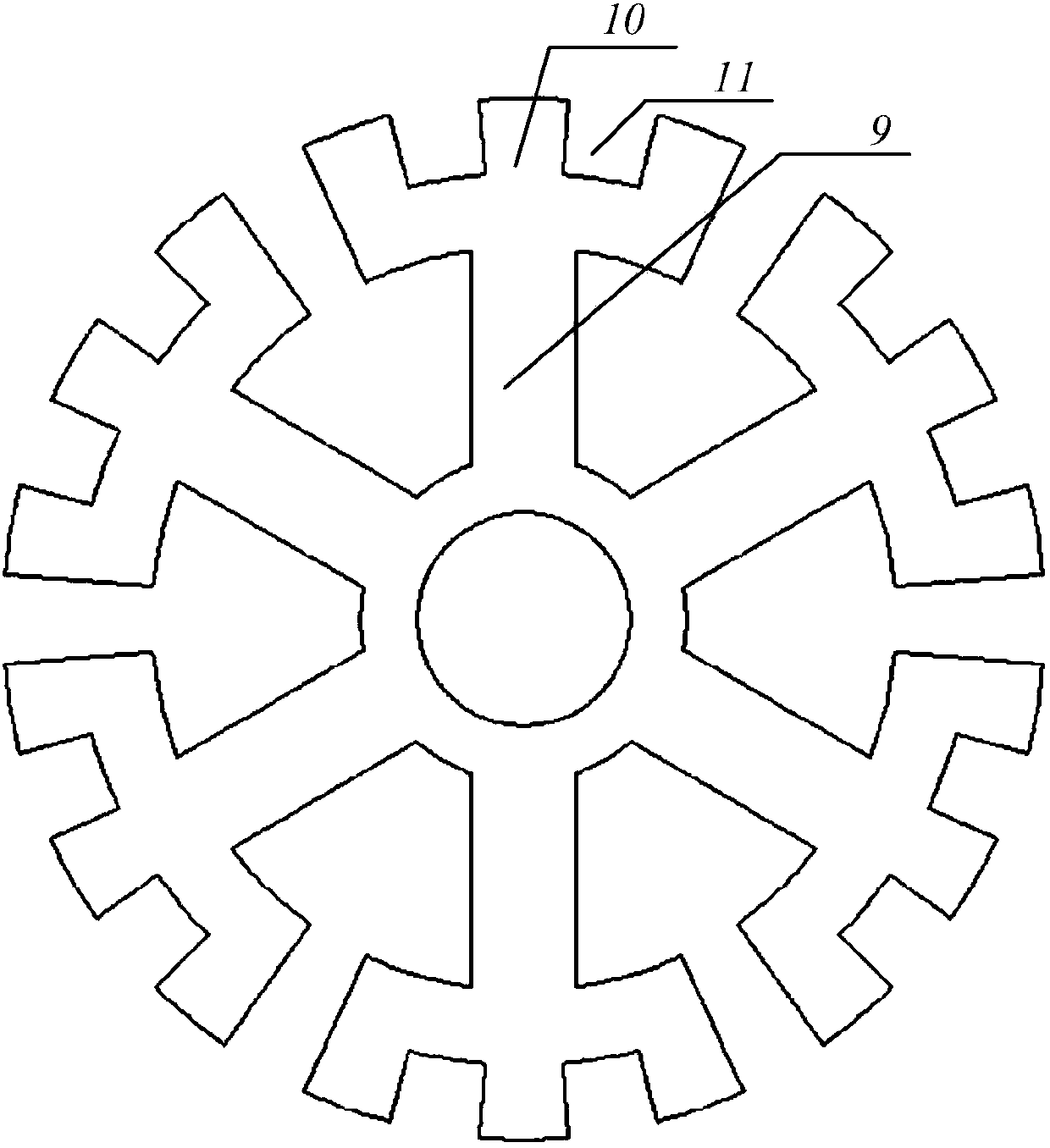

[0037] The motor of the example of the present invention has a double-layer air-gap topological structure, the outer stator 4 is cylindrical, and a pear-shaped slot is opened inside it along the circumferential direction, and the first three-phase armature winding is placed in the pear-shaped slot. Between adjacent slots is the first stator tooth;

[0038] The inner stator 8 is a cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com