Adjustable ultra-fine atomizing nozzle for titanium and titanium alloy melt

A technology of atomizing nozzles and titanium alloys, which is applied in the field of nozzles, can solve the problems of atomization mechanism, nozzle powder performance, tissue structure and gas consumption, and there are few research reports, so as to increase flexibility, reduce atomization costs, and improve the atomization process. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

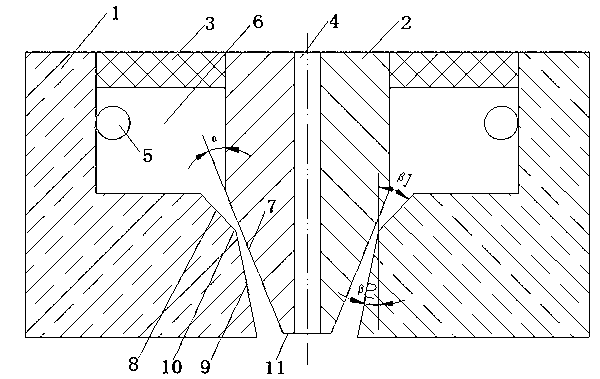

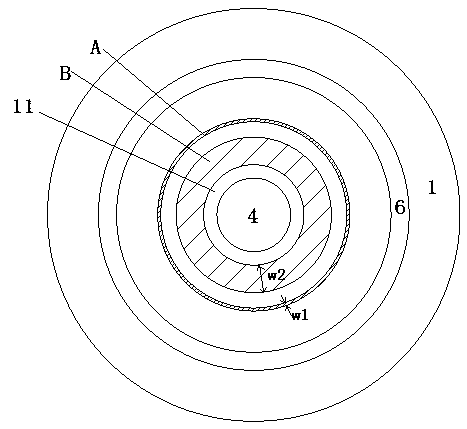

[0023] Example: An adjustable titanium and titanium alloy melt ultra-fine atomization nozzle, such as figure 1 , 2 As shown, it includes a nozzle cover 1, a titanium liquid guide tube 2 and a positioning bolt 3. The nozzle cover 1 is made of titanium alloy, and the titanium liquid guide tube 2 and the positioning bolt 3 are made of tungsten alloy. The titanium liquid guide tube 2 runs through the titanium liquid channel 4 along the axis, and the nozzle cover 1 is fixed on one end of the titanium liquid guide tube 2 through the positioning bolt 3, and the outer wall of the titanium liquid guide tube 2 and the nozzle cover are separated by the positioning bolt 3 A high-pressure gas source chamber 6 with a high-pressure gas source inlet 5 is formed between the inner walls of 1. The other end of the titanium liquid guide pipe 2 gradually converges, and the inner wall of the nozzle jacket 1 opposite to the gradually convergent surface 7 includes two slopes: the inlet Surface 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com