Integrated thermal cycling system of electric vehicle

A technology of circulation system and electric vehicle, which is applied in the layout, circuit, and electrical components of the power plant's cooling combination. Consistency and other issues to achieve the effect of satisfying cooling and heating, improving overall efficiency, and improving life and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

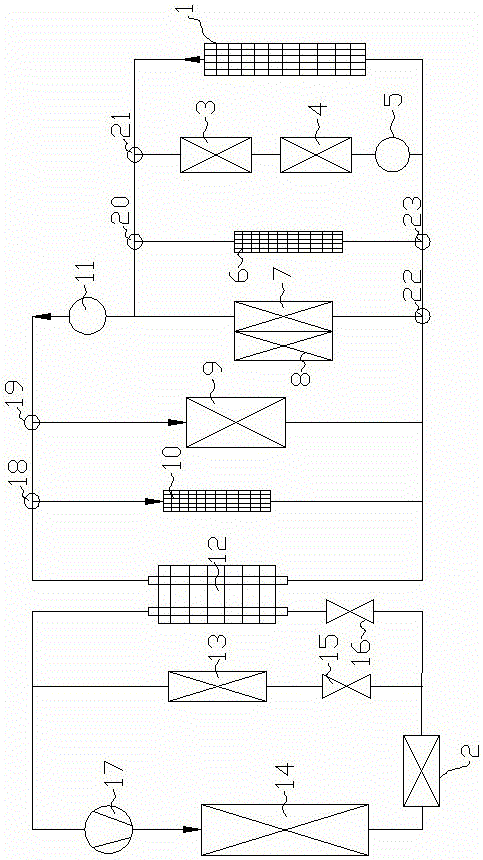

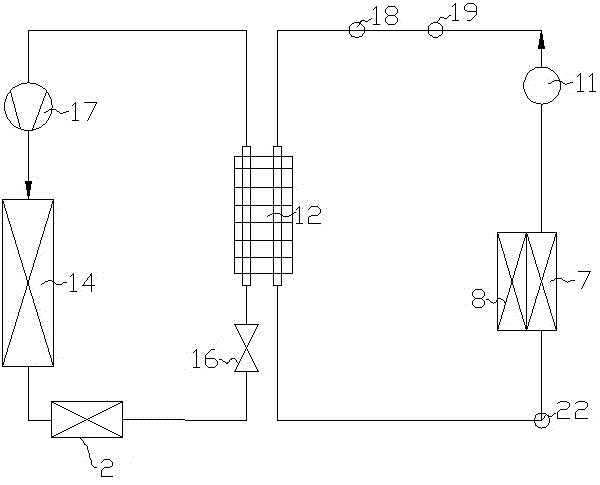

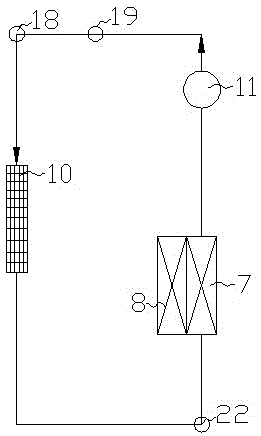

[0028] like figure 1 As shown, a comprehensive thermal cycle system for electric vehicles includes a motor system radiator 1, a motor 3, a motor controller 4, an air conditioning system, a first water pump 5, a heater 6, a water cooling jacket 7, a battery pack 8, and a heater 9. The battery pack radiator 10, the second water pump 11, the heat exchanger 12 and the evaporator 13; the heat exchanger 12 is connected with a refrigerant pipeline and a water pipeline, and the water cooling jacket 7 is installed on the battery pack 8 , the motor system radiator 1, the first water pump 5, the motor controller 4, and the motor 3 that are connected sequentially according to the circulating water flow form a motor cooling cycle;

[0029] The refrigerant pipeline of the heat exchanger 12 is connected in series with the second expansion valve 16, the evaporator 13 is connected in series with the first expansion valve 15, the first expansion valve 15 and the second expansion valve 16 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com