Raw material processing technology for smelting ferrosilicon in submerged arc furnace

A raw material processing and submerged arc furnace technology, which is applied in the field of ferroalloy production and the pretreatment of raw materials for ferrosilicon alloy production, can solve the problems of inability to guarantee the content of silicon dioxide, unsuitable for ferrosilicon raw materials, poor electrical conductivity, etc., so as to speed up the compound reaction Speed, improving market competitiveness, and powerful forming pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and the embodiments given by the applicant.

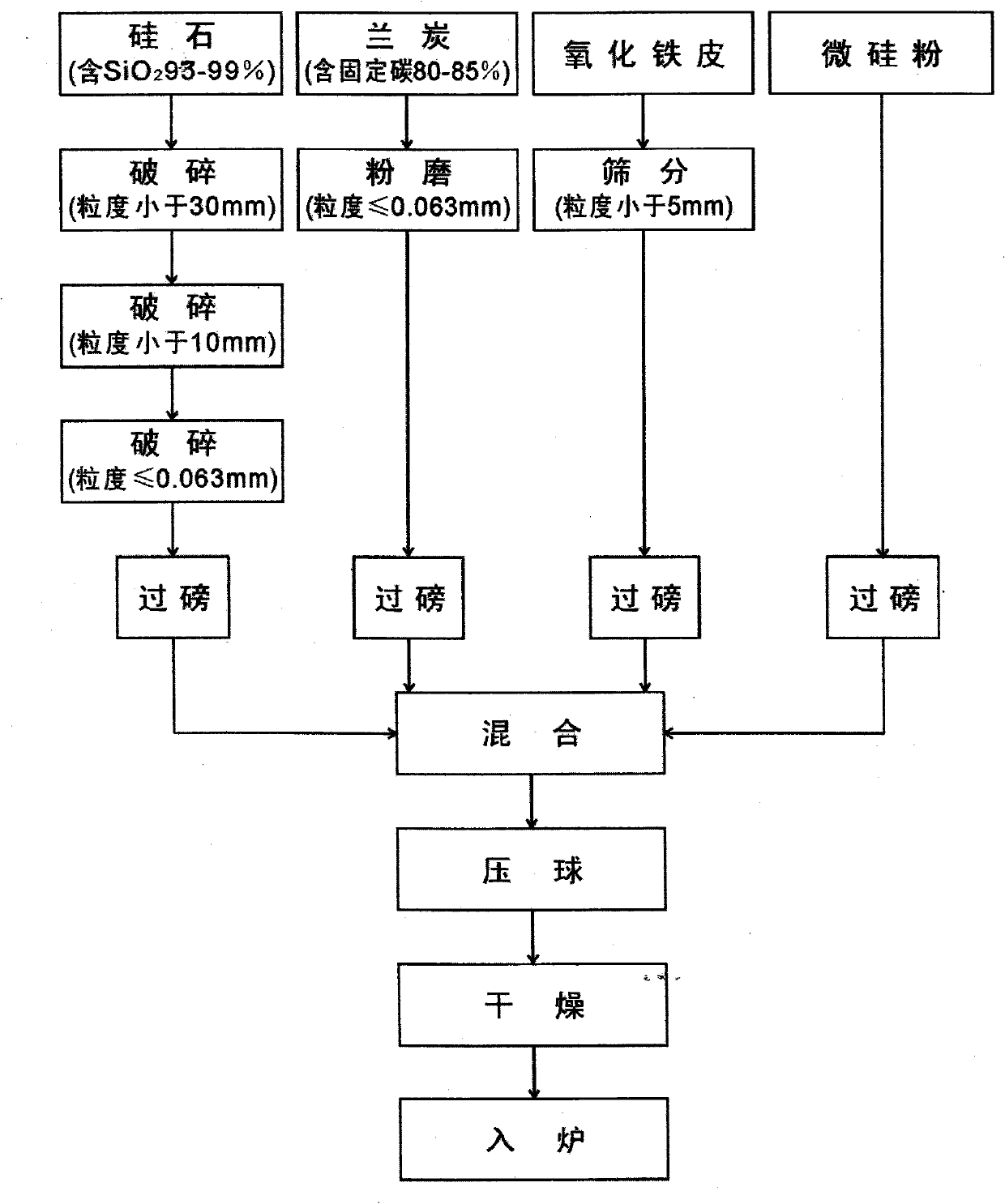

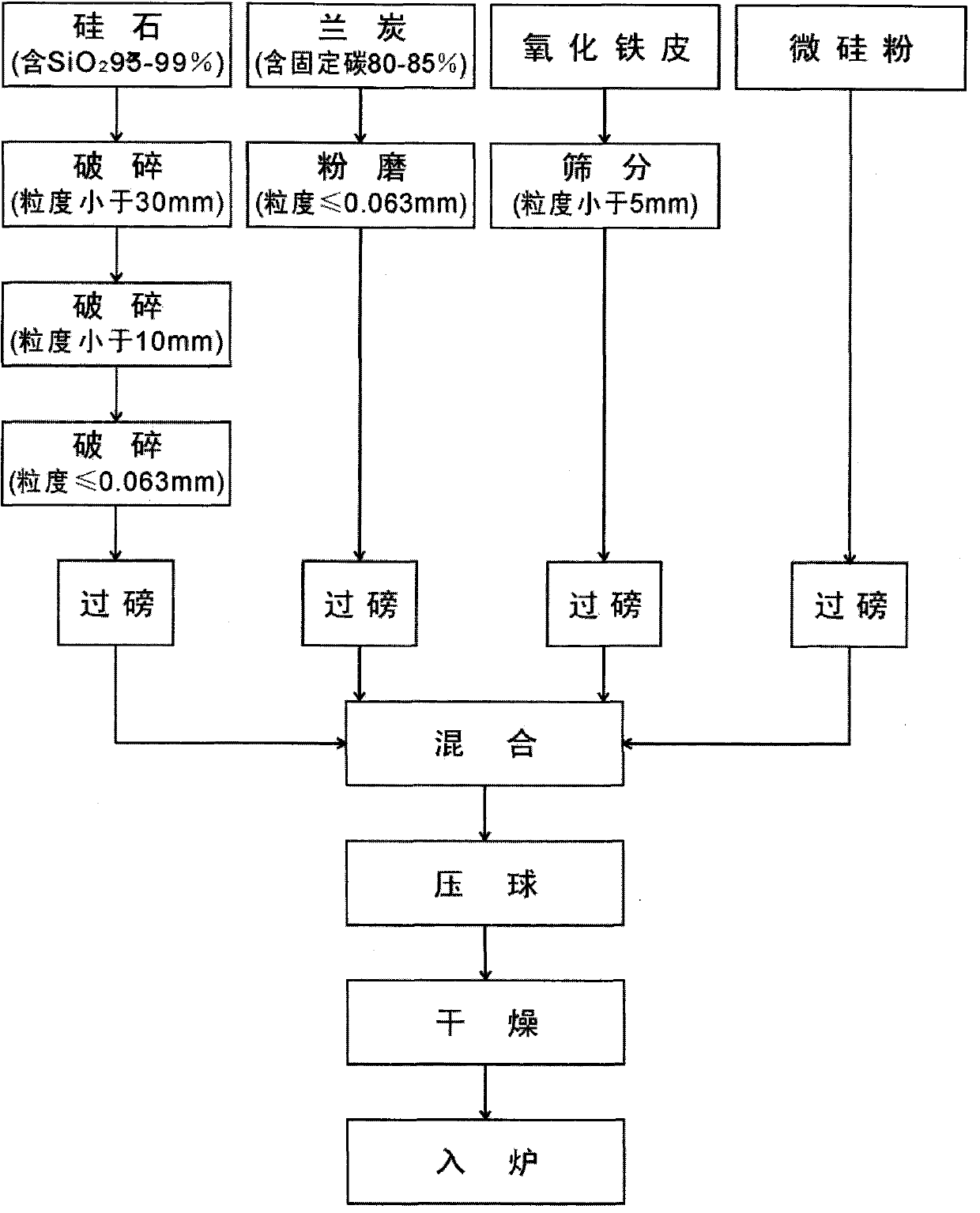

[0014] First of all, put the purchased raw silica with a particle size of 30-180mm and the composition is qualified, put it into a jaw crusher and crush it to a particle size below 30mm, then put it into a hammer crusher to crush it to a particle size below 10mm, and then put it into Raymond mill Grind to powder with a particle size of ≤0.063mm and put it into an independent silo. Then the purchased semi-coke with a particle size of 5-18mm is directly fed into the Raymond mill to grind the powder noodles with a particle size below 0.063mm, and also enters an independent silo. Sieve the purchased iron oxide scales, and those with a particle size of 5 mm or more are directly sent to an independent silo for temporary preparation of low-grade ferrosilicon according to the formula, and then directly p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com