Lithium ion battery cathode material prepared by blue carbon solid waste, and preparation method of lithium ion battery cathode material

A lithium-ion battery, solid waste technology, applied in battery electrodes, carbon preparation/purification, circuits, etc., can solve the problems of high cost, complicated material preparation process, unfavorable commercialization, etc., and achieve low cost and good cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Select semi-coke powder with particle size below 3 mm, and ball mill it in an agate ball mill jar for 5 hours according to the mass ratio of ball to material 4:1. A part of the ball-milled powder was mixed with NaOH at a mass ratio of 1:1 and then calcined at 850°C for 1.5 hours under the protection of argon, then rinsed with hot deionized water until neutral and then dried at 60°C. The content of impurities before and after roasting is shown in Table 1, and the content of SiO2 is significantly reduced after roasting.

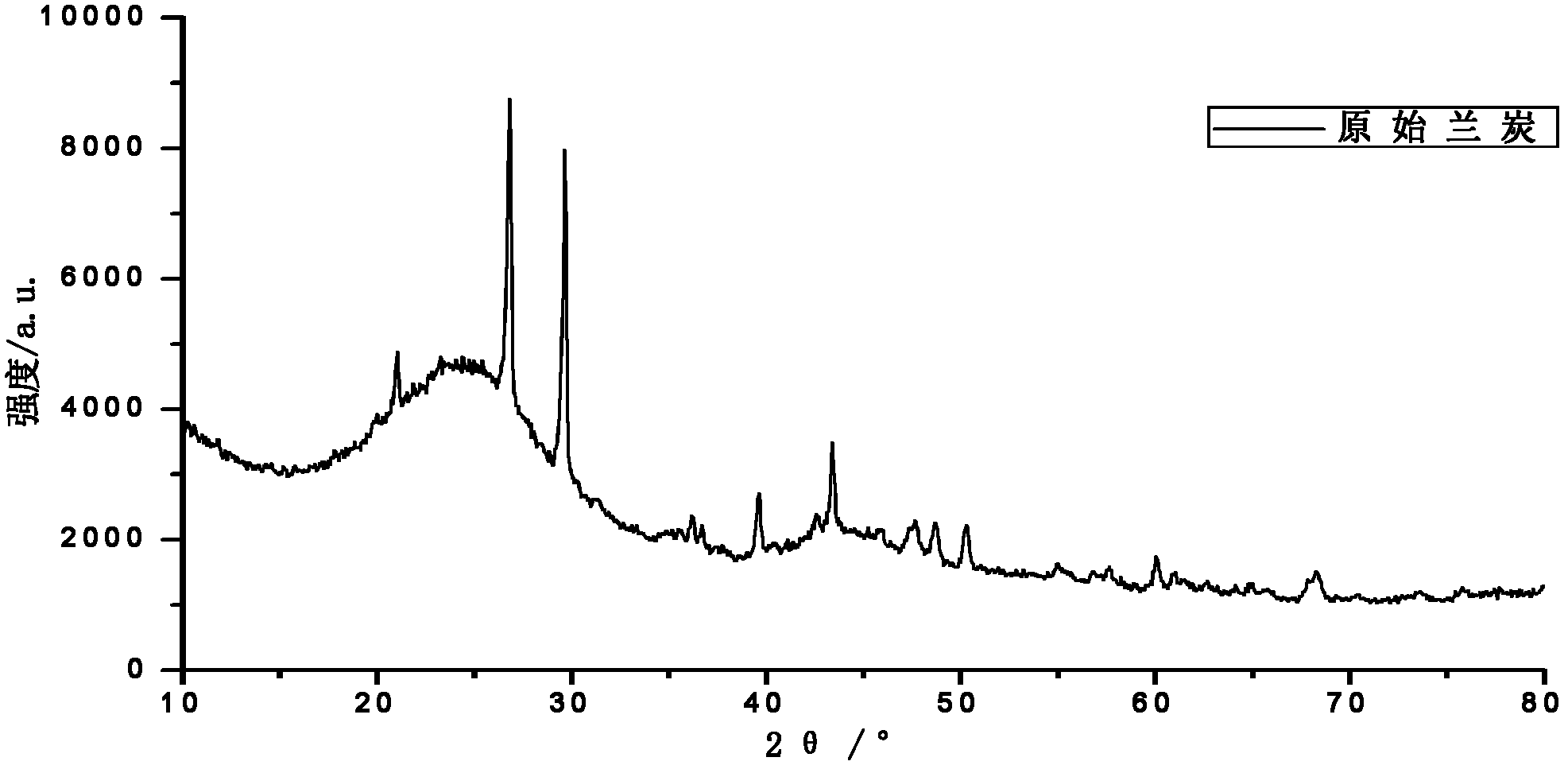

[0037] Alkali-roasted and unroasted semi-coke powders are respectively doped with a certain amount of boron powder and then heat-treated in a high-temperature furnace. figure 1 It is the XRD pattern of original blue carbon. It can be seen from the curve that there is a large peak package at about 25° in the original blue carbon XRD pattern, indicating that blue carbon is amorphous carbon. At the same time, the XRD pattern contains a large number of impur...

Embodiment 2

[0039] Add 6% conductive agent Super-p (conductive carbon black) to the high-temperature-treated blue carbon powder and mix it with the binder PVDF (polyvinylidene fluoride) according to the mass ratio of 84:6:10 to prepare a slurry (viscosity The binder PVDF is pre-dissolved in N-methylpyrrolidone before use, and is configured as a 2% solution), and evenly coated on the copper foil, and then dried in a vacuum environment at 70 ° C for 24 hours to prepare a negative electrode for lithium-ion batteries pole piece. With lithium sheet as the counter electrode, 1mol / L LiPF 6 The EC (hexyl carbonate) + DMC (dimethyl carbonate) (volume ratio 1:1) solution was used as the electrolyte, and the battery separator model celgard2400 was assembled into a button battery in a glove box filled with argon.

[0040] Figure 3(a) and (b) are the electrochemical performance curves of the battery assembled with blue carbon after simple ball milling. Its initial capacity is high, and the lithium in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com