A cooling and purification system for semi-coke tail gas

A purification system and semi-coke tail gas technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of complex operation and high purification cost, and achieve the effect of low purification cost, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

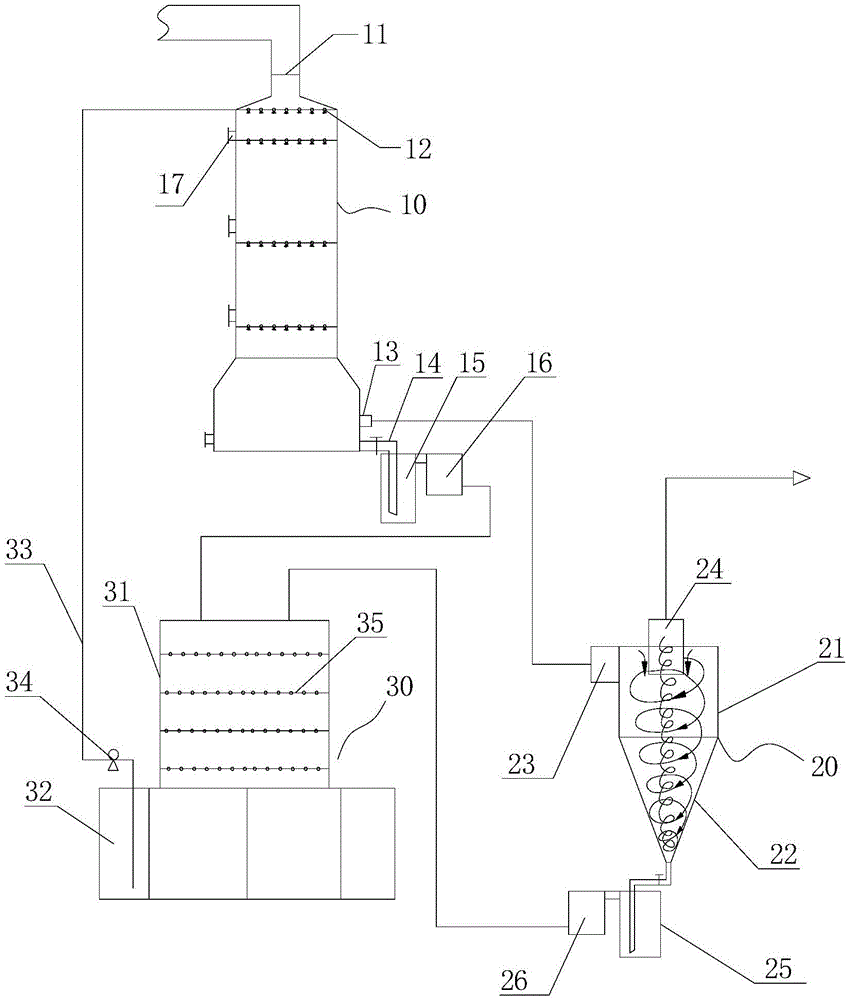

[0031] Such as figure 1 As shown, the described semi-coke tail gas cooling and purification system includes a spray tower 10, a spiral forced landing dehumidifier 20 and a return water cooling pool 30;

[0032] The top of the spray tower is provided with an air inlet 11, the air inlet 11 is connected with the gas-collecting pipeline, and a spray plate 12 is arranged in the spray tower 10 below the air inlet 11, and the spray plate 12 below the spray plate 12 A screen plate is arranged in the shower tower; the spray plate 12 includes a fixed frame and a spiral spray pipe, the spiral spray pipe is fixed on the fixed frame, and the fixed frame is installed in the spray tower 10; the bottom of the spray tower 10 An air outlet 13 is provided, and a water outlet is provided on the spray tower wall below the air outlet 13. The water outlet is connected to a water outlet pipe 14, and a first water seal groove 15 is arranged below the water outlet pipe 14, and the lower end of the wate...

Embodiment 2

[0038] On the basis of the above-mentioned embodiment 1, further, the number of the screen plates is more than 2. By setting up multiple screens, increasing the surface area of water, increasing the contact area between water and gas, and speeding up the purification and cooling speed, the impurities and soluble substances in the tail gas can be washed and settled quickly.

Embodiment 3

[0040]On the basis of the above-mentioned embodiment 1 or 2, a water inlet (not shown) is set on the tower wall of the spray tower corresponding to the spray plate; the return water cooling pool 30 is provided with an outlet pipe 33, and the outlet pipe 33 Connect with water inlet. Preferably, the outlet pipe 33 is provided with a pressure pump 34 . Through this scheme, the water in the backwater cooling pool can be pumped into the spray tower for reuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com