A kind of low-sulfur marine fuel oil production method

A production method and fuel oil technology, which are applied in the field of refining and chemical industry, can solve the problems of complex blending components, the sulfur content cannot meet the new index requirements, and the solid content is high, and achieve the advantages of low cost, cheap source of raw materials, and reduced viscosity and impurity content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

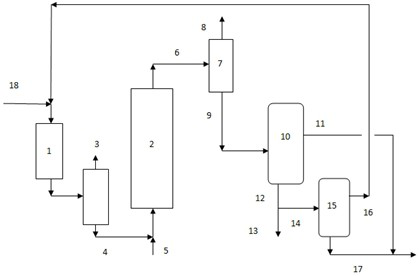

Method used

Image

Examples

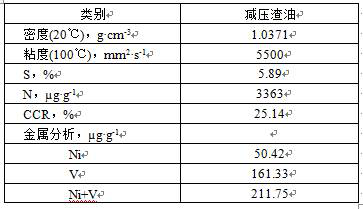

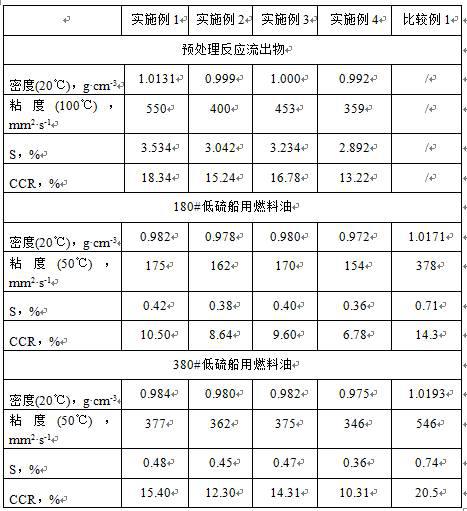

Embodiment 1

[0041] Embodiment 1 takes vacuum residue oil as raw material, adopts residue oil pretreatment method of the present invention, vacuum residue oil first enters pretreatment reactor to carry out pretreatment reactor, and the reaction conditions of pretreatment reactor are: reaction temperature: 360℃, reaction pressure 0.65MPa, volume space velocity 1.5h -1 , and then through gas-liquid separation, the liquid phase enters the hydrogenation reactor for deep decontamination reaction. The reaction conditions in the hydrogenation reaction zone are: reaction temperature: 390 ℃, reaction pressure 14MPa, volume space velocity 0.45h -1 , the volume ratio of hydrogen to oil is 800. Part of the hydrogenation reaction product is obtained by atmospheric fractionation as 180# low-sulfur marine fuel oil, and the other part is obtained by vacuum distillation to obtain vacuum distillate oil and tail oil. The blended mass ratio of tail oil and light distillate oil is 10:1, which is directly used ...

Embodiment 2

[0043] Compared with Example 1, it is basically the same, except that the vacuum distillate oil is recycled back to the pretreatment reactor, and the weight ratio of the vacuum distillate oil to the low-quality heavy oil feedstock is 1:5. The reaction results are shown in Table 2.

Embodiment 3

[0045] Basically the same as Example 1, the difference is that the second gas phase material is recycled back to the pretreatment reactor, and the reaction results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com