Formula of culture medium for industrial production of sparasis crispa and production process

A production process and cultivation substrate technology, applied in horticulture, botanical equipment and methods, applications, etc., can solve problems such as difficulty in artificial cultivation, scarcity of hydrangea resources, etc., and achieve good factory production benefits, shorten production cycles, and mushrooms. body whitening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] According to the dry weight percentage, the cultivation substrate formula of the present invention is: pine sawdust 70%, chaff 15%, potato flour 7%, flour 6%, peptone 0.3%, ammonium sulfate 0.1%, brown sugar 1.6%.

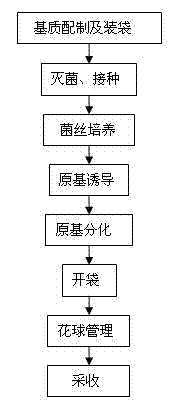

[0031] The hydrangea industrial production process of the present invention includes cultivation substrate preparation and bagging, sterilization and inoculation, hyphae cultivation, primordium induction, primordium differentiation, bag opening, curd management, and harvesting, and is characterized in that:

[0032] (1) Cultivation substrate preparation and bagging: Mix the above-mentioned medium with water at a ratio of 1: 1.3-1.5, then put it into a polypropylene plastic bag (17cm×33cm×0.005cm), and control the pH between 4-6 During the period, the mycelium grows the fastest, and the water content is controlled at about 63% to 65%. Each bag of dry material is 350g, press it while loading, tighten the top and loosen the bottom, tighten the outside and loose...

Embodiment 2

[0041] According to the dry weight percentage, the cultivation substrate formula of the present invention is: pine sawdust 75%, chaff 10%, potato flour 10%, flour 3%, peptone 0.4%, ammonium sulfate 0.1%, brown sugar 1.5%.

[0042] The hydrangea industrial production process of the present invention includes cultivation substrate preparation and bagging, sterilization and inoculation, hyphae cultivation, primordium induction, primordium differentiation, bag opening, curd management, and harvesting, and is characterized in that:

[0043] (1) Cultivation substrate preparation and bagging: mix the above-mentioned medium with water at a ratio of 1: 1.3 to 1.5, then put it into a polypropylene plastic bag (17cm×33cm×0.005cm), and control the water content at 63%~ About 65%. Each bag of dry material is 350g, press it while loading, tighten up and loosen down, and loosen outside and inside. Use a tapered wooden stick with a diameter of 2-2.5cm to punch holes in the middle of the culti...

Embodiment 3

[0052] According to the dry weight percentage, the cultivation substrate formula of the present invention is: pine sawdust 65%, chaff 20%, potato flour 5%, flour 8%, peptone 0.5%, ammonium sulfate 0.1%, brown sugar 1.4%.

[0053] The hydrangea industrial production process of the present invention includes cultivation substrate preparation and bagging, sterilization and inoculation, hyphae cultivation, primordia induction, primordium differentiation, bag opening, curd management and harvesting, the production process Specific steps are as follows:

[0054] (1) Cultivation substrate preparation and bagging: Mix the culture medium of the above cultivation substrate formulation, mix it with water at a weight ratio of 1: 1.3 to 1.5, and put it into a cultivation bag. The pH is controlled at 4 to 6, and the water content is controlled. At 63% to 65%; press while loading, tighten up and loosen at the bottom, tighten outside and loose inside, use a tapered wooden stick with a diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com