A method for recovering waste gas during regenerative process of filtering adsorption material

A waste gas recovery and regeneration process technology, applied in the direction of filter regeneration, filtration separation, separation methods, etc., can solve the problems of affecting the performance of filter adsorbents and reducing the adsorption capacity of filter adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

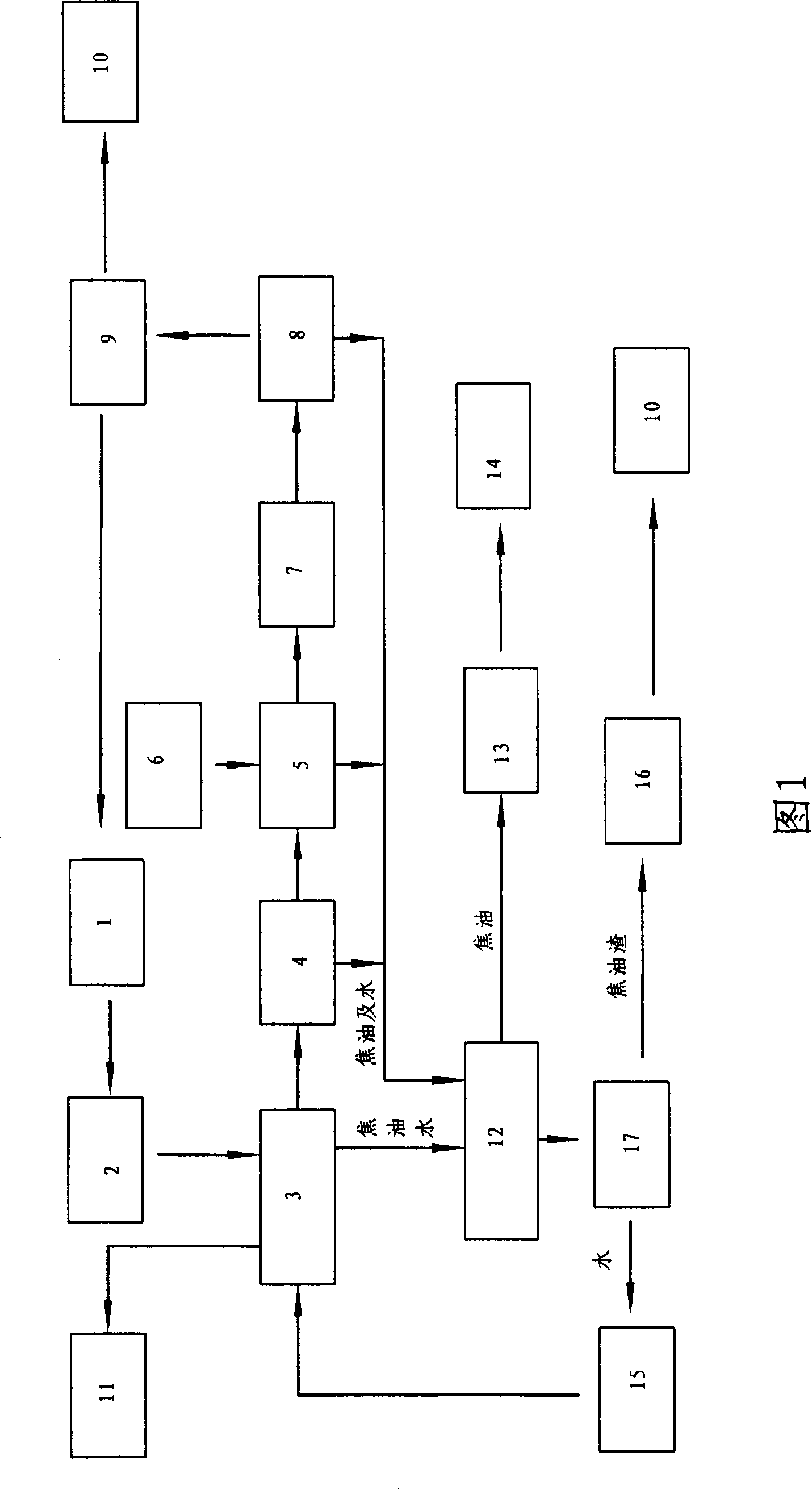

[0034] as the picture shows:

[0035] When the filter adsorption material is thermally regenerated in the regeneration furnace (1), the organic matter in the filter adsorption material is volatilized and decomposed after being heated, and a mixed gas composed of methane, ethane, ethylene, tar vapor, carbon dioxide, carbon monoxide and other components is produced. , calorific value 1,100-2,500kcal / m 3 . When the regeneration furnace (1) is in operation, the mixed gas produced by the volatilization and decomposition of the organic matter in the internal filter adsorption material after being heated can be utilized in two ways of recovering coal tar or not recovering coal tar.

[0036] The mixed gas utilization method for recovering coal tar is as follows;

[0037] When the regeneration furnace (1) is in operation, the mixed gas produced by the volatilization and decomposition of the organic matter in the internal filter adsorption material is processed by the cyclone dust col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com