Method for producing vanadium pentoxide by utilizing vanadium slag

A technology of vanadium pentoxide and vanadium slag, which is applied in the direction of vanadium oxide, etc., and can solve the problems of complex process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

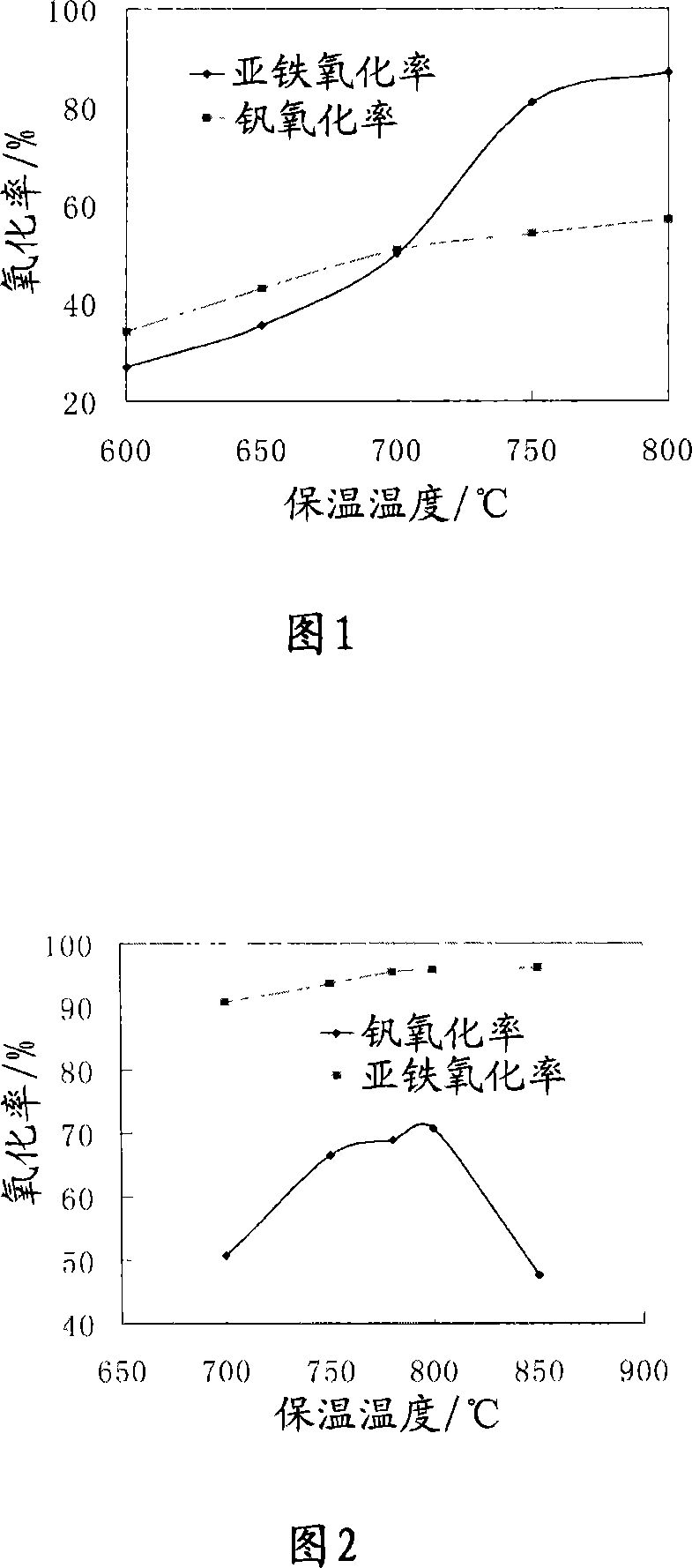

Examples

Embodiment 1

[0054] Weigh 2000g of 1# vanadium slag and 110g of sodium chloride and mix them well, put them into two 1000ml porcelain bowls; Insulate at 820°C for 60 minutes; take it out of the furnace and cool it quickly, grind it slightly and then soak it in water, and adjust the pH value of the water soaking to 9.0; filter; add calcium chloride to the filtrate, heat to completely precipitate the impurities, and then filter; adjust the pH value of the filtrate to 1.8, Heating to 80°C to boiling, adding ammonium sulfate with 1.4 times the mass of vanadium element to precipitate vanadium for 60 minutes, cooling for 60 minutes, and filtering to obtain ammonium polyvanadate filter cake; calcining the ammonium polyvanadate filter cake at a temperature of 500°C for 60 minutes to obtain GB3283-87 standard vanadium pentoxide is 33.9g, the grade is 98.5%, the amount of residual vanadium pentoxide in the waste residue is 0.55%, and the total yield of vanadium is 72.59%.

Embodiment 2

[0056] Weigh 1000g of 2# vanadium slag and 100g of sodium carbonate, mix well and put it into a 1000ml porcelain bowl; place it in a roasting furnace at 400°C, raise the temperature to 700°C in 10 minutes, raise the temperature to 750°C in 60 minutes, and then raise the temperature to 760°C in 80 minutes Keep warm for 50 minutes; cool down quickly after being out of the oven, and soak in water after a little grinding. Filtrate; adjust the pH value of the filtrate to 1.8, heat to 80°C until boiling, add ammonium sulfate with 1.4 times the mass of vanadium element to precipitate vanadium for 60 minutes, cool for 60 minutes, and filter to obtain ammonium polyvanadate filter cake; The ammonium acid filter cake was calcined for 60 minutes to obtain 39.3 g of vanadium pentoxide conforming to the GB3283-87 standard, with a grade of 98.6%, the amount of residual vanadium pentoxide in the waste residue was 0.90%, and the total vanadium yield was 76.73%.

Embodiment 3

[0058] Weigh 1000g of 2# vanadium slag, 50g of sodium carbonate and 55g of sodium chloride, mix them well, put them into a 1000ml porcelain bowl; put them in a roasting furnace at 500°C, heat up to 700°C in 10 minutes, and rise to 750°C in 80 minutes, then use Heat up to 800°C for 90 minutes and keep warm for 30 minutes, then cool down quickly after being out of the oven, grind it slightly, and soak in water, the pH of water immersion is 8.4; filter; add a little alkali to the filtrate to adjust the pH to 9.0, then add calcium chloride to the filtrate, heat to make The impurities are completely precipitated, and then filtered; adjust the pH value of the filtrate to 1.8, heat to 80°C until boiling, add ammonium sulfate with 1.4 times the mass of vanadium element to precipitate vanadium for 60 minutes, cool for 60 minutes, and filter to obtain ammonium polyvanadate filter cake; at 500°C The ammonium polyvanadate filter cake was calcined for 60min at high temperature to obtain 40....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com