Multifunctional environmentally-friendly BSK sintering technology shaft kiln and use method thereof

An environmentally friendly and multi-functional technology, applied in the direction of furnace type, treatment of discharged materials, waste heat treatment, etc., to achieve high output, good product quality and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

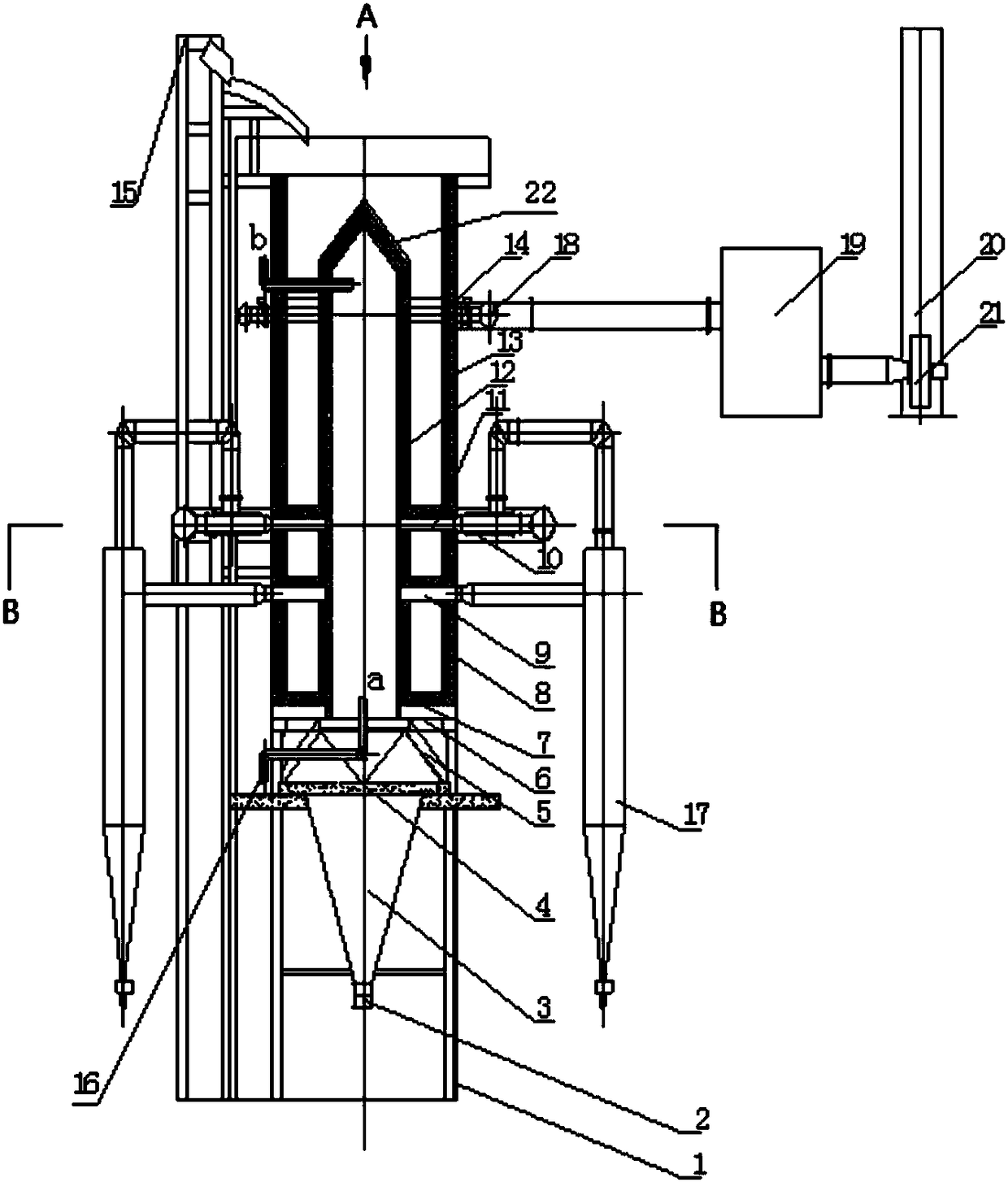

[0028] Refer to attached Figure 1-Figure 6 As shown, the multifunctional environment-friendly BSK sintering technology shaft kiln of the present invention includes an inner collar cooler 16, an inner collar tray 6, an inner collar 12, an outer collar 8, a kiln shell 13, a cooling air supply fire bridge 7, Hot air is discharged from the fire bridge 9, combustion products are fed into the fire bridge 11, a burner with a combustion channel 10, a ring-type gravity gas powder separator 17, a multi-pipe smoke exhauster 18, a feeding rack 15, etc. The specific structure is as follows:

[0029] Under the support of the steel structure 1, the inner collar tray support frame 5 is set through the foundation 4 on the steel structure 1, the inner collar tray 6 is set on the top of the inner collar tray support frame 5, and the inner sleeve is set on the inner col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com