Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

198results about How to "Not easy to introduce" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

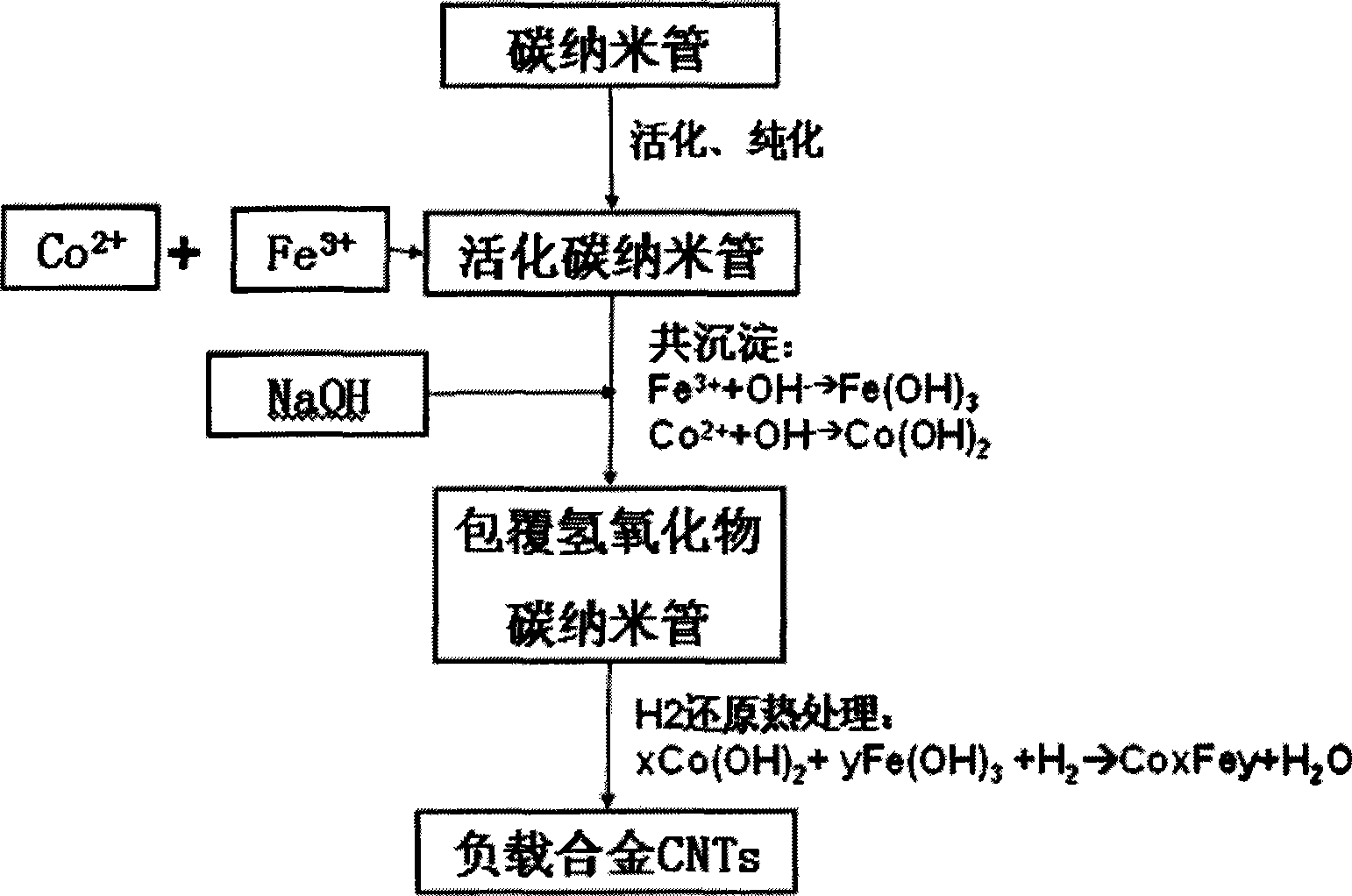

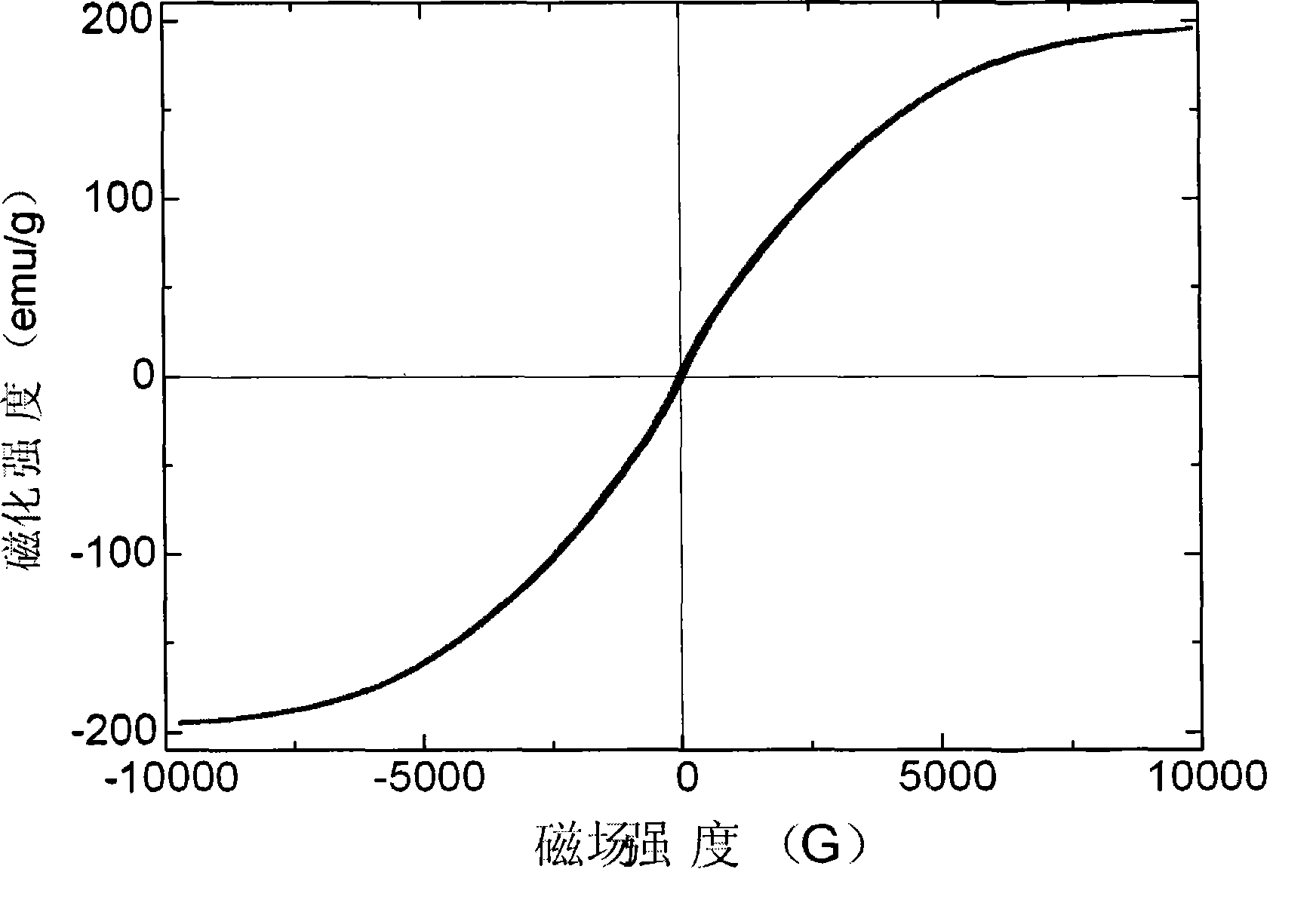

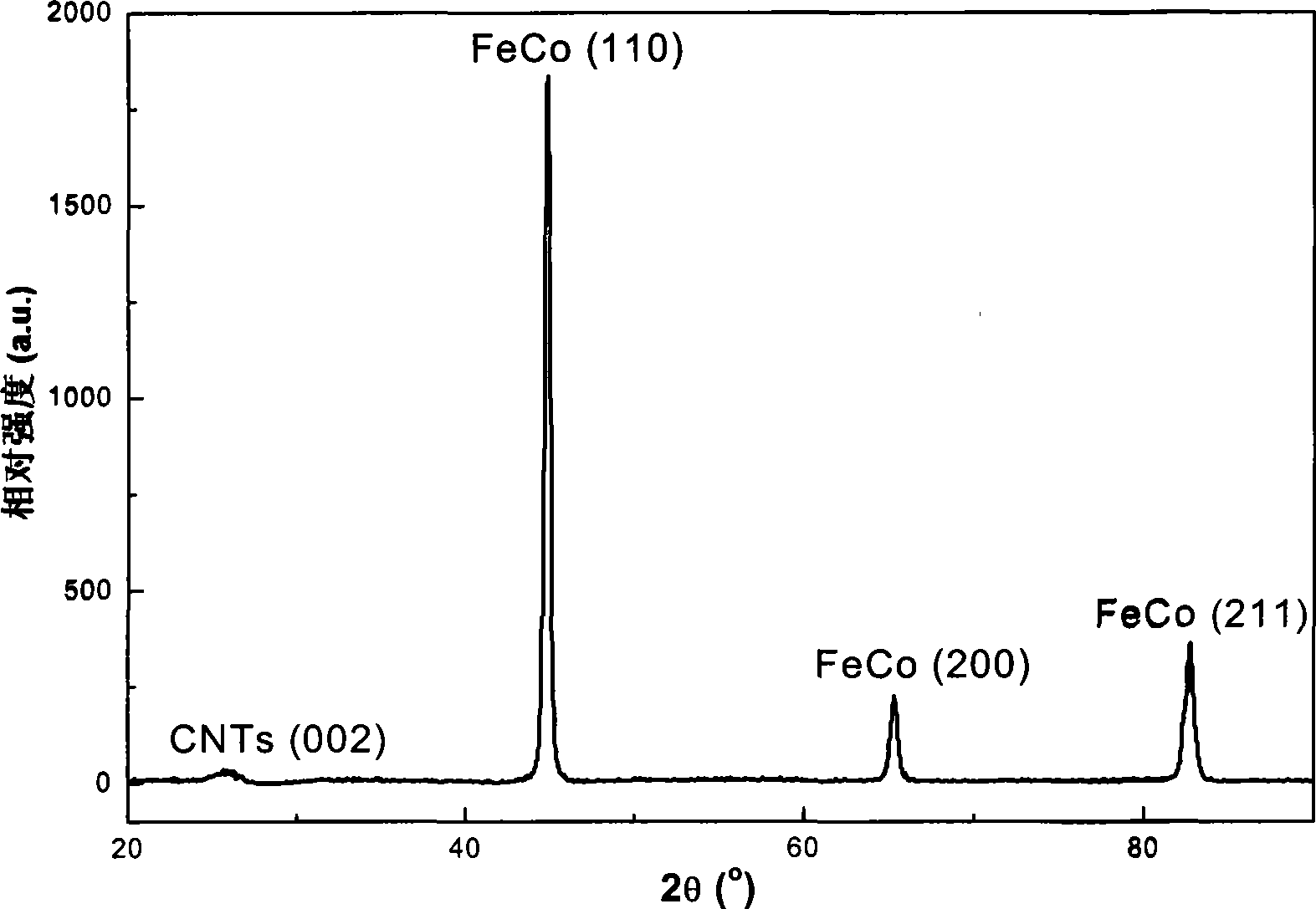

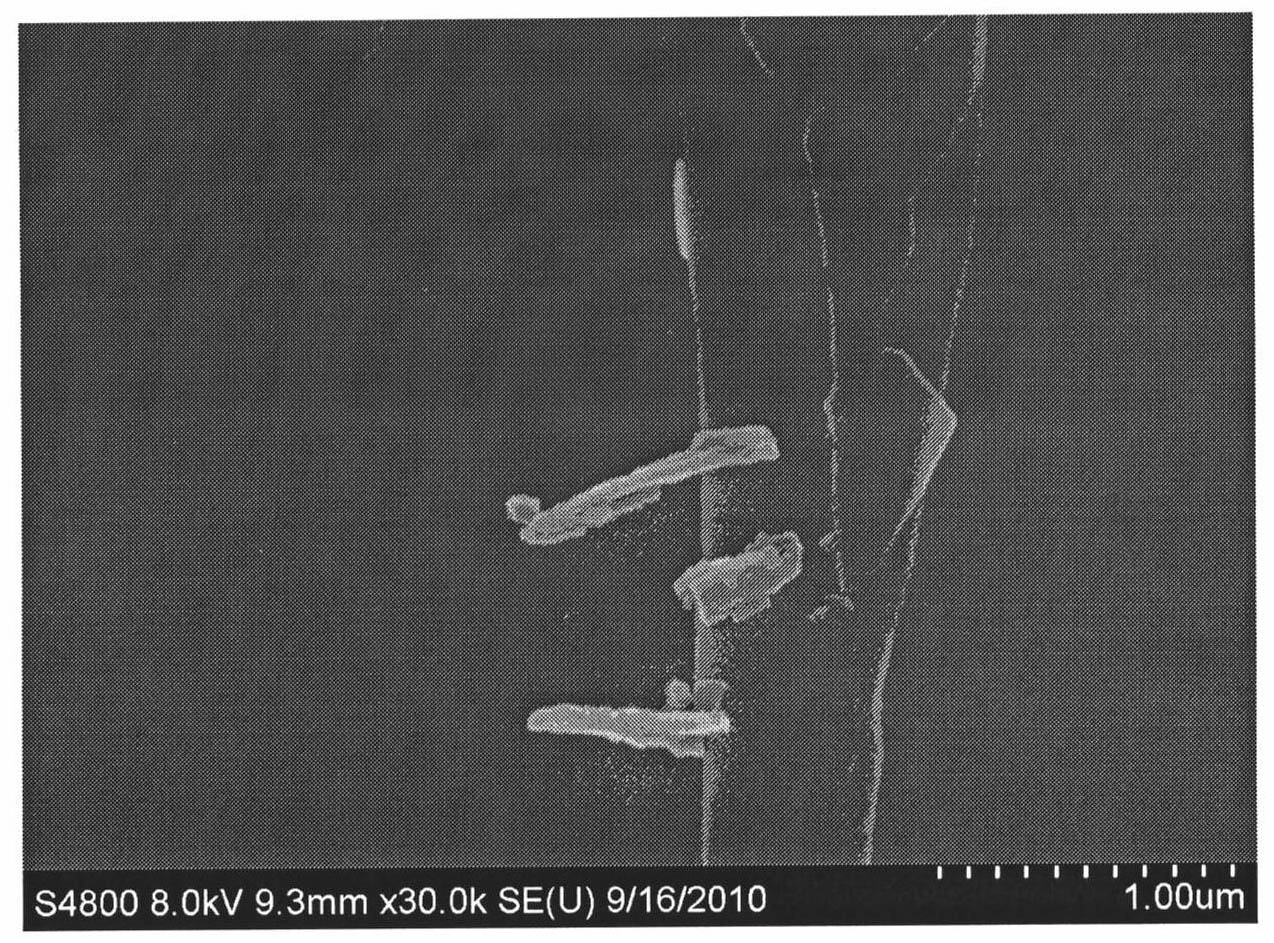

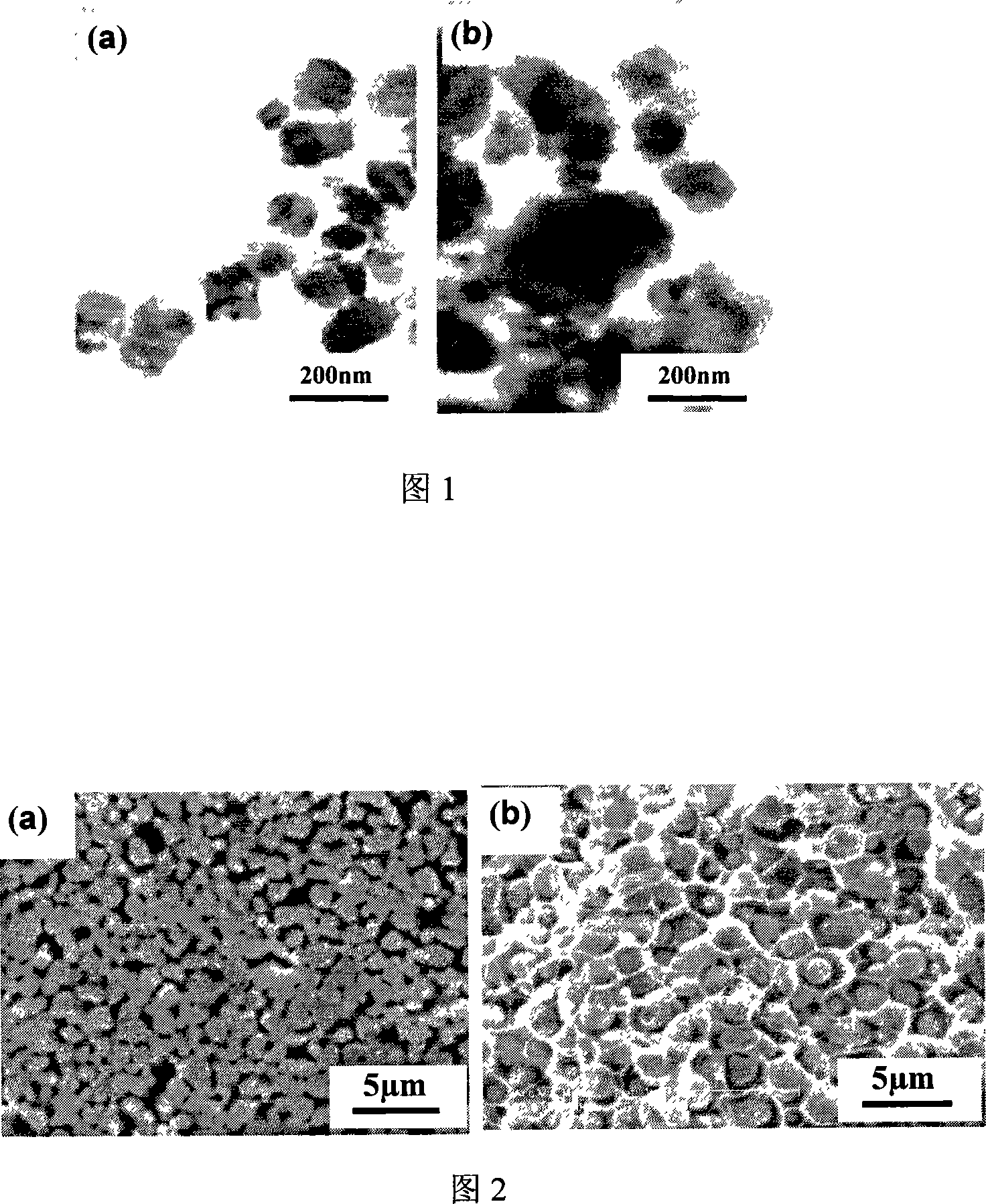

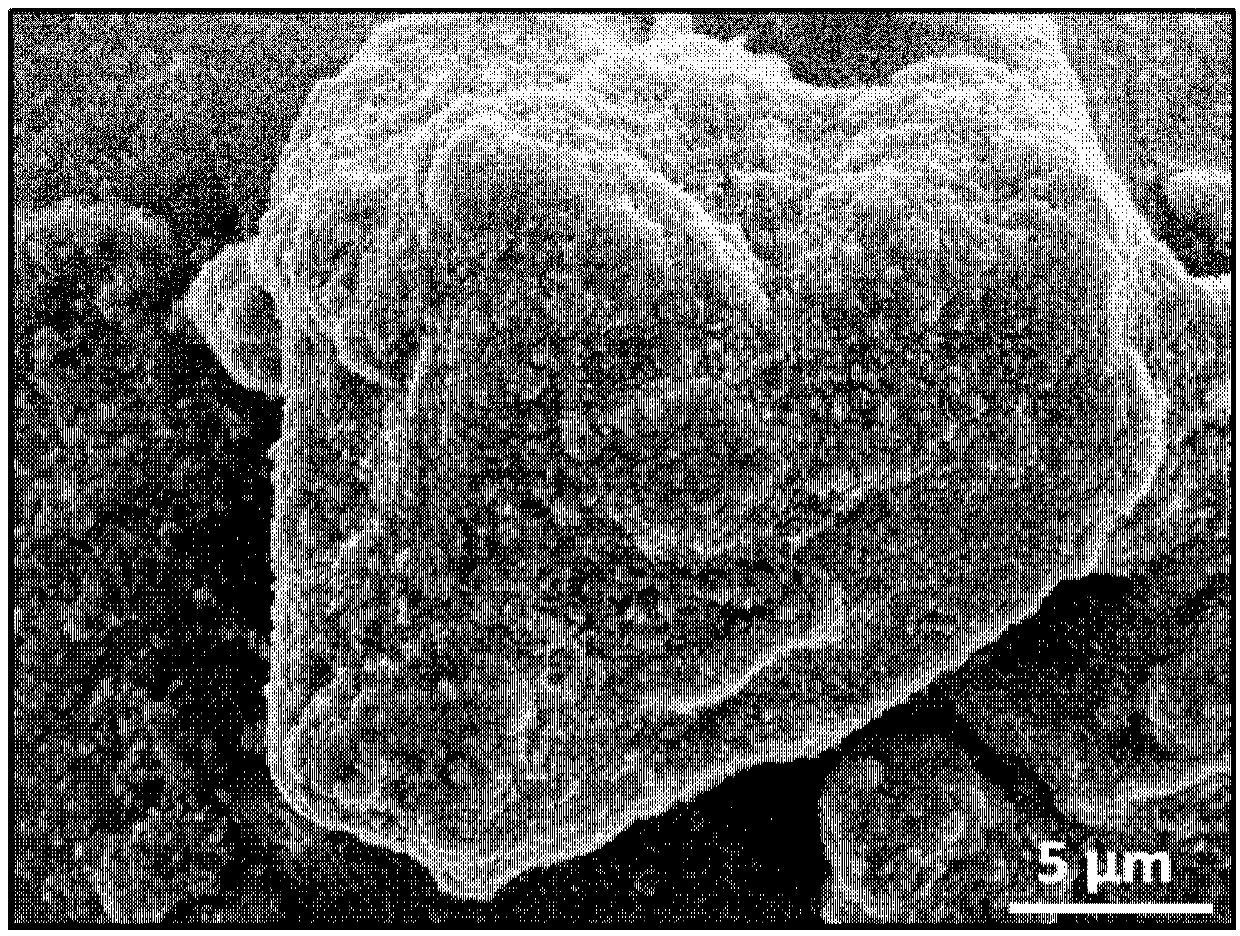

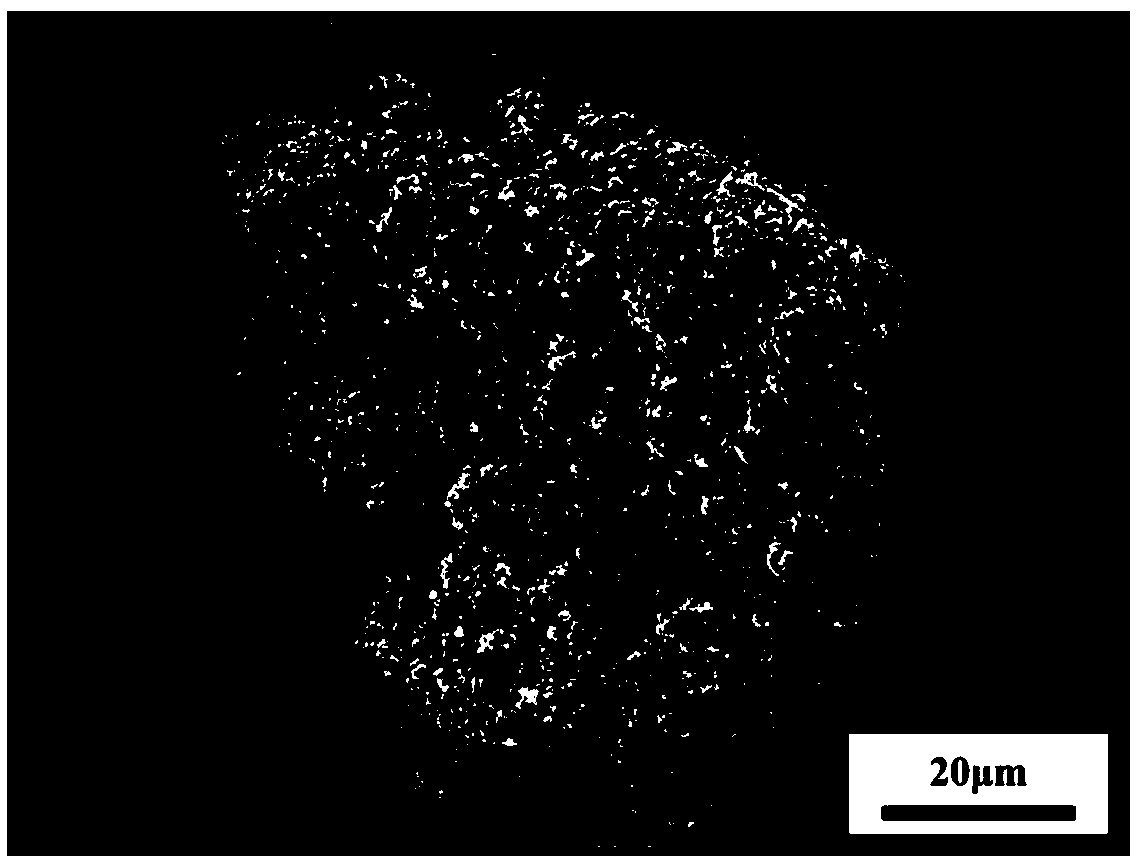

Preparation of surface load magnetic alloy particle carbon nano-tube composite material

InactiveCN101503579AGood electromagnetic performanceCrystallization intactOther chemical processesPigment physical treatmentCarbon nanotubeCrystallinity

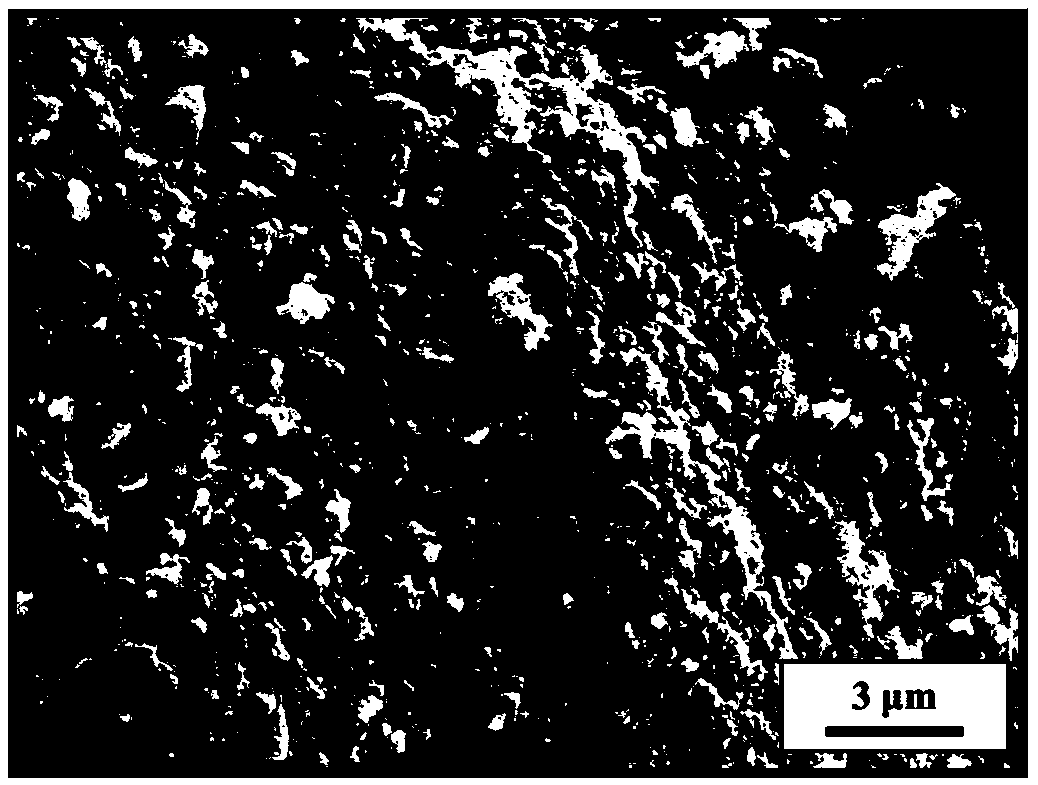

The invention discloses a preparation method for carbon nano tube surface loaded magnetic alloy nano particle composite material, which belongs to the field of electromagnetic wave absorbing material preparation. The preparation method comprises the following steps: after purifying and activating a carbon nano tube, evenly dispersing the carbon nano tube to chloride salt solution of iron, cobalt and nickel, slowing adding an alkali solution dropwise into the solution in the fierce agitation process, and regulating the pH value of the solution and making iron ions, cobalt ions and nickel ions be coprecipitated onto the surface of the carbon nano pipe in the form of hydroxide according to the alloy proportion set when the solution is prepared; taking out a deposit by centrifugation or filtering; and after drying the deposit, carrying out the heat treatment of the deposit in the reducing atmosphere to obtain the carbon nano tube composite material loaded with magnetic alloy particles. The preparation method adopts a simple process. As no impurity element is introduced into the preparation process, the obtained magnetic alloy particles have high degree of crystallinity and excellent magnetic properties. In addition, the method has easy regulation of the alloy components. The composite material prepared by the method is significantly applied in the fields of electromagnetic interference resistance, stealth, microwave darkrooms, and the like.

Owner:TSINGHUA UNIV

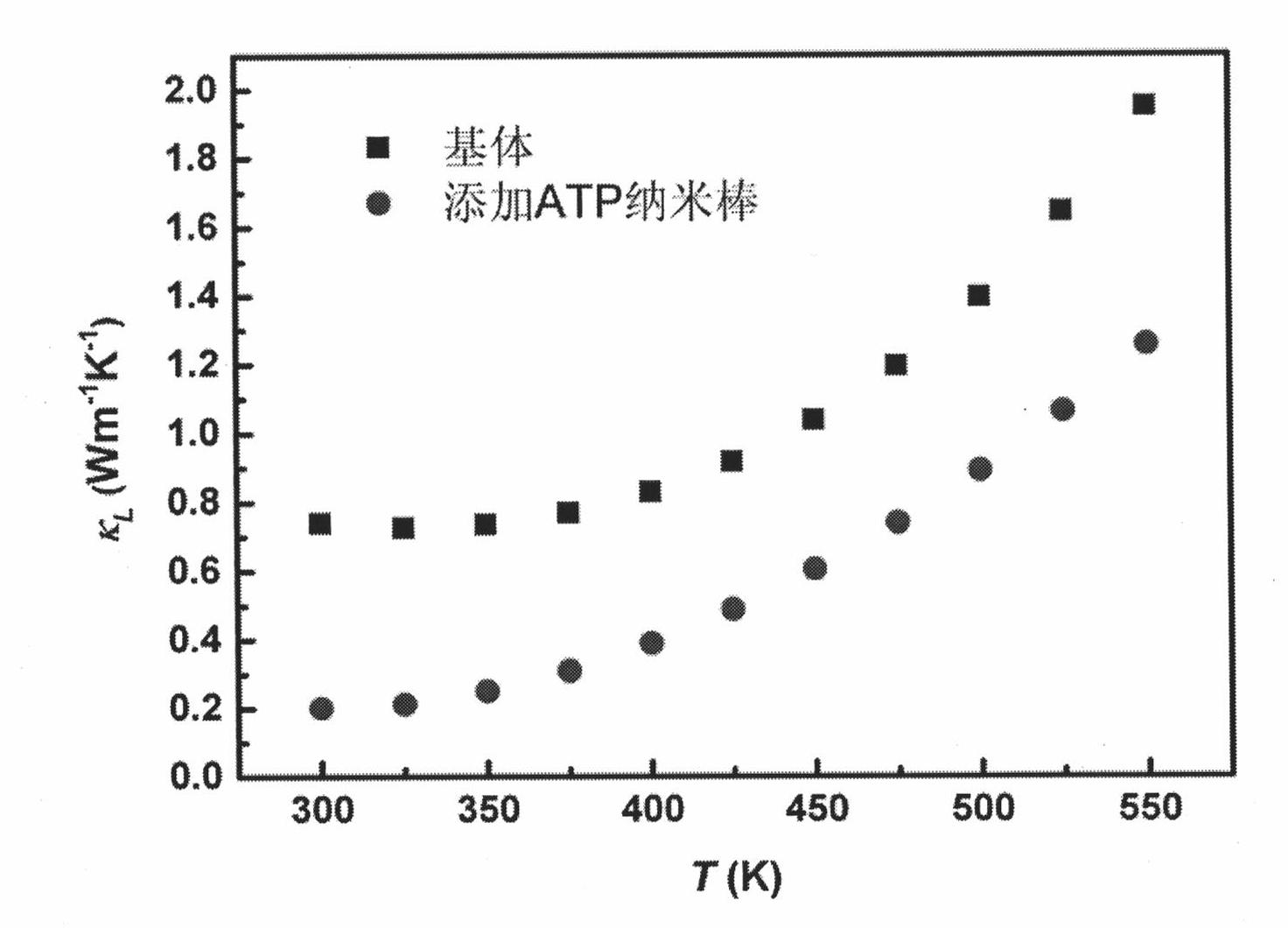

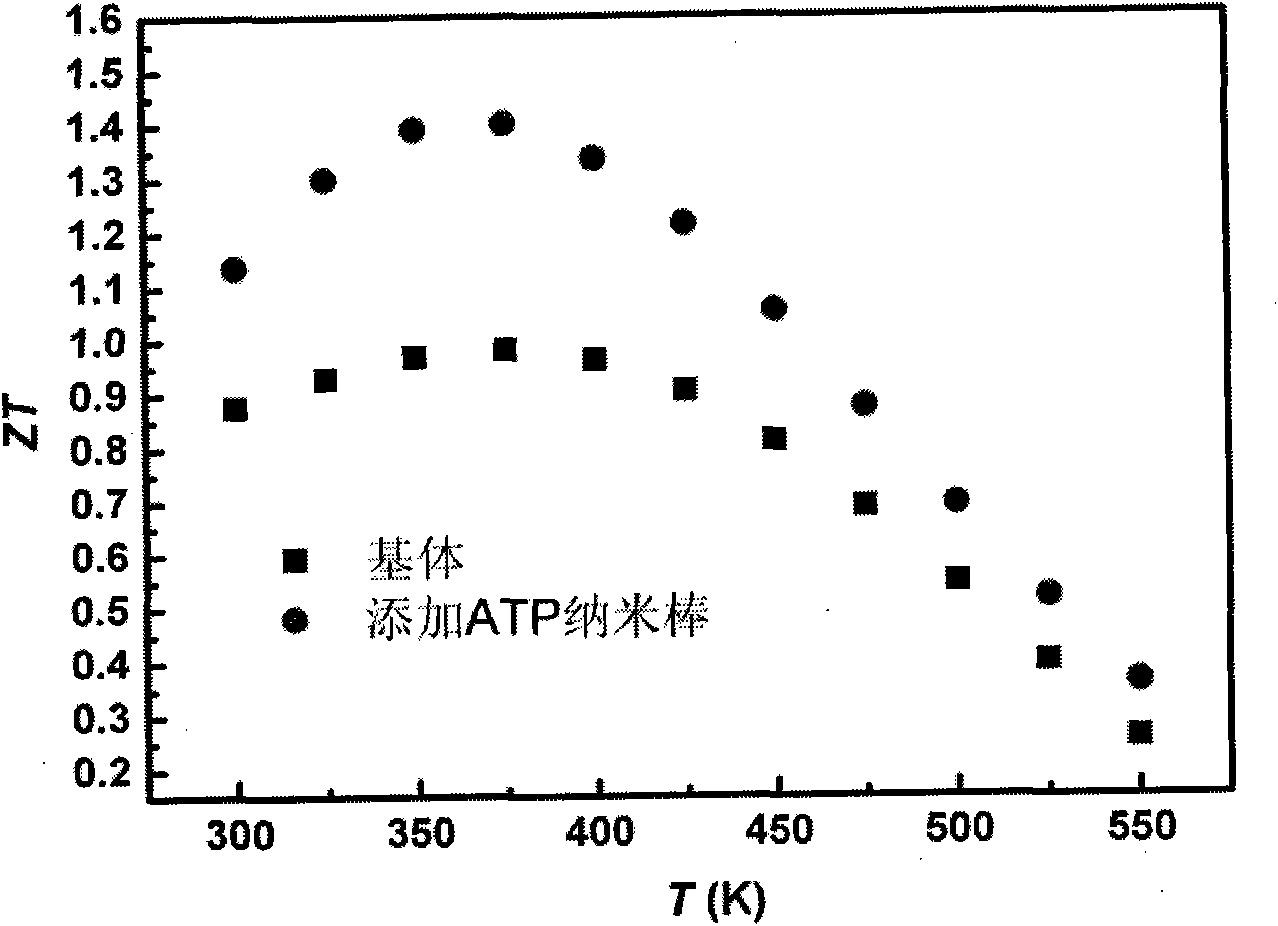

Nanophase doped bismuth telluride-based thermoelectric material and preparation method thereof

ActiveCN101994155ALower lattice thermal conductivityReduced lattice thermal conductivity κ

<sub>L</sub>Polycrystalline material growthBy zone-melting liquidsBismuth tellurideCarbon nanotube

The invention discloses a nanophase doped bismuth telluride-based thermoelectric material and a preparation method thereof. The bismuth telluride-based thermoelectric material is characterized in taking the bismuth telluride-based thermoelectric material containing a tellurium element, a bismuth element and a doped chemical element, as a matrix. The doped nanophase is a one-dimensional nanophase,and the weight of the one-dimensional nanophase accounts for 0.01-5 percent of the weight of the matrix. Attapulgite or a zinc oxide nanowire or a single-wall carbon nanotube or a multi-wall carbon nanotube is preferable to the one-dimensional nanophase. Compared with the prior art, in the bismuth telluride-based thermoelectric material, the lattice heat conductivity within the whole temperature zone range is reduced, thereby a ZT value is greatly improved and the thermoelectric performance of the bismuth telluride-based thermoelectric material is improved. The preparation method is simple and easy to implement, and compared with other methods of balling milling or liquid phase and the like, impurities are not easy to introduce in the preparation method so that the one-dimensional nanophase is evenly staggered and distributed in the matrix and the mechanical property of the material is effectively improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

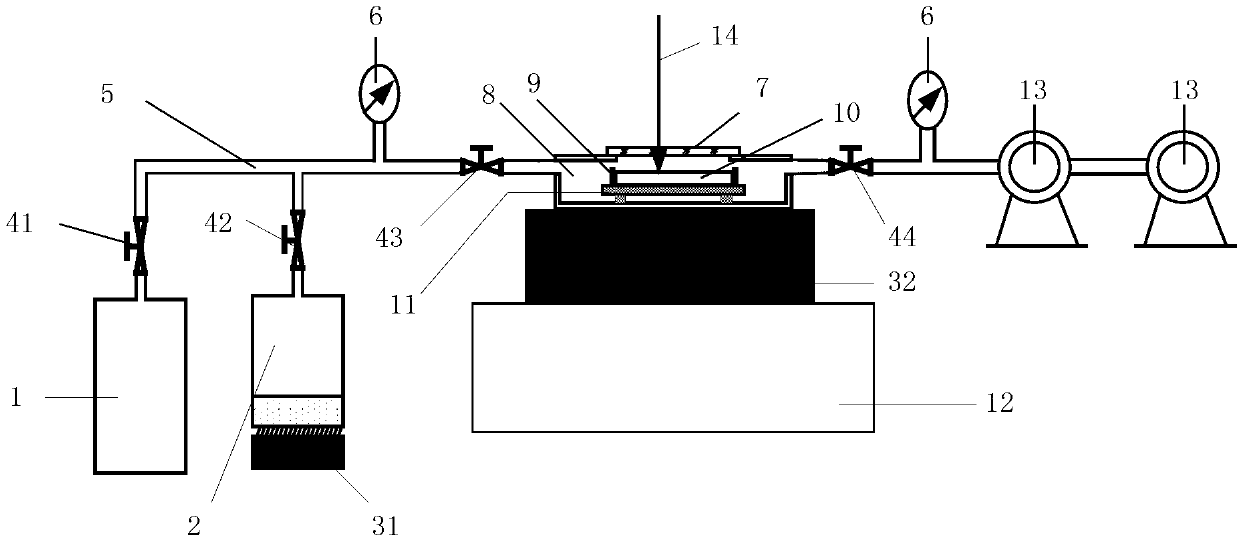

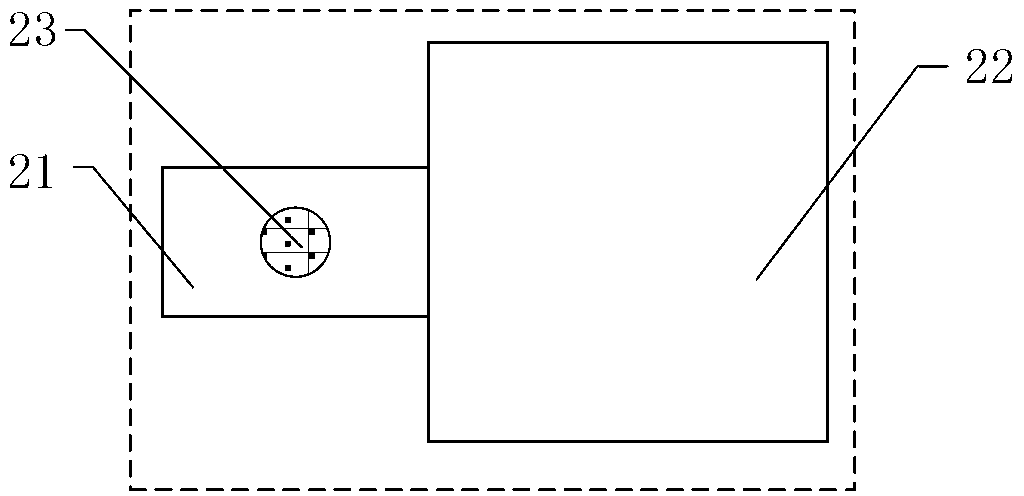

System and method for aerating and plugging alkali metal steam chamber of mini type CPT atomic clock

ActiveCN103342335ANot easy to introduceNo frequency driftDecorative surface effectsChemical vapor deposition coatingGas cylinderEngineering

The invention relates to a system and a method for aerating and plugging an alkali metal steam chamber of a mini type CPT atomic clock. The system mainly comprises a buffer gas storing bottle, an alkali metal steam gas storing bottle, a vacuum chamber, an MEMS (micro-electromechanical systems) wafer supporting table, a vacuum pump and a laser plugging device. A manufacture method of an MEMS wafer of the alkali metal steam chamber comprises the following steps of: manufacturing an on-silicon alkali metal steam chamber on a silicon wafer, simultaneously forming an in-silicon vent groove in the silicon wafer by means of dry etching or wet etching, forming in-glass aerating holes in a glass material by means of mechanical holing or laser holing and the like, manufacturing on-glass aerating micro-channels on the glass material by means of the wet etching, and manufacturing the alkali metal steam chamber of the mini type CPT atomic clock by means of anodic bonding. The CO2 laser beam penetrates through an optical window of a vacuum chamber to melt alkali metal steam chamber chips on the MEMS wafer one by one to plug the glass aerating holes or aerating micro-channels. According to the system and the method provided by the invention, the alkali metal steam chamber of the mini type CPT atomic clock has the advantages that the alkali metal steam chamber is simply operated, impurities are hardly introduced, the alkali metal steam chamber is conveniently manufactured in batches, and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

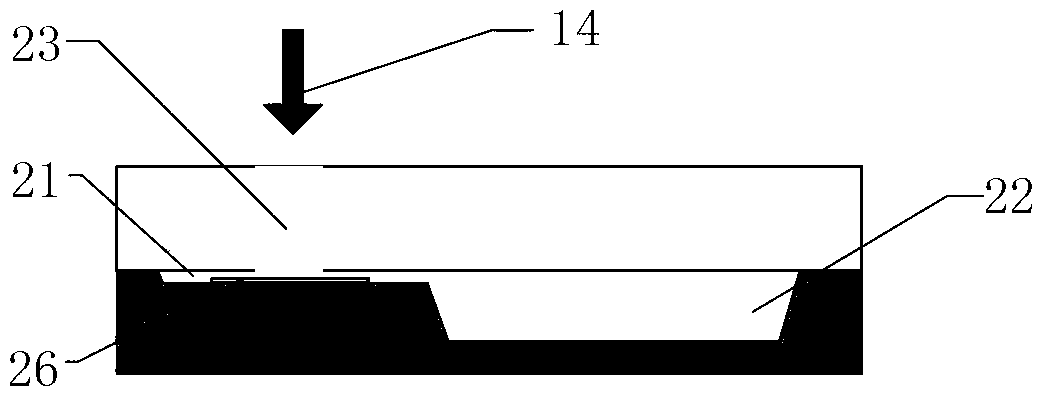

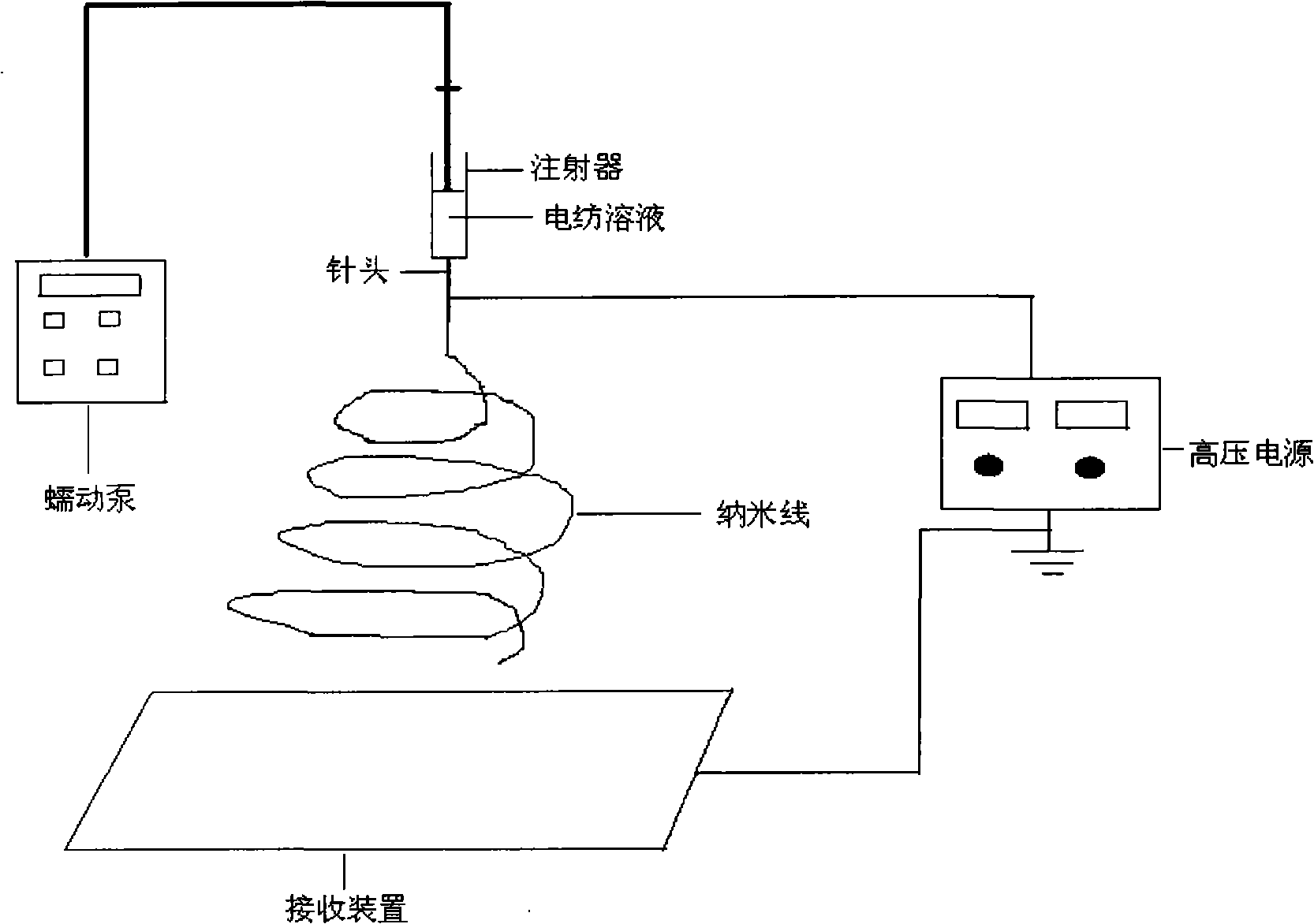

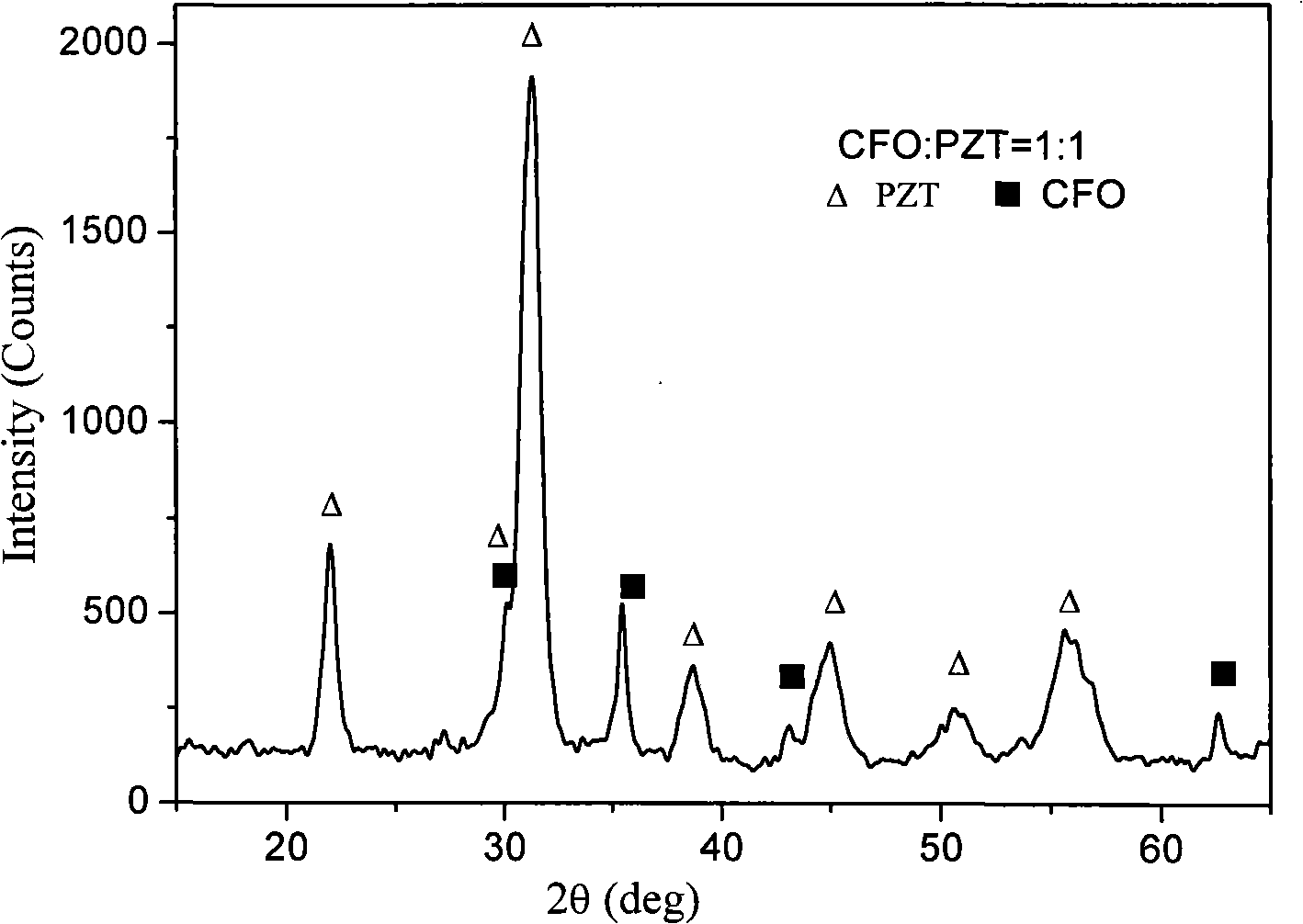

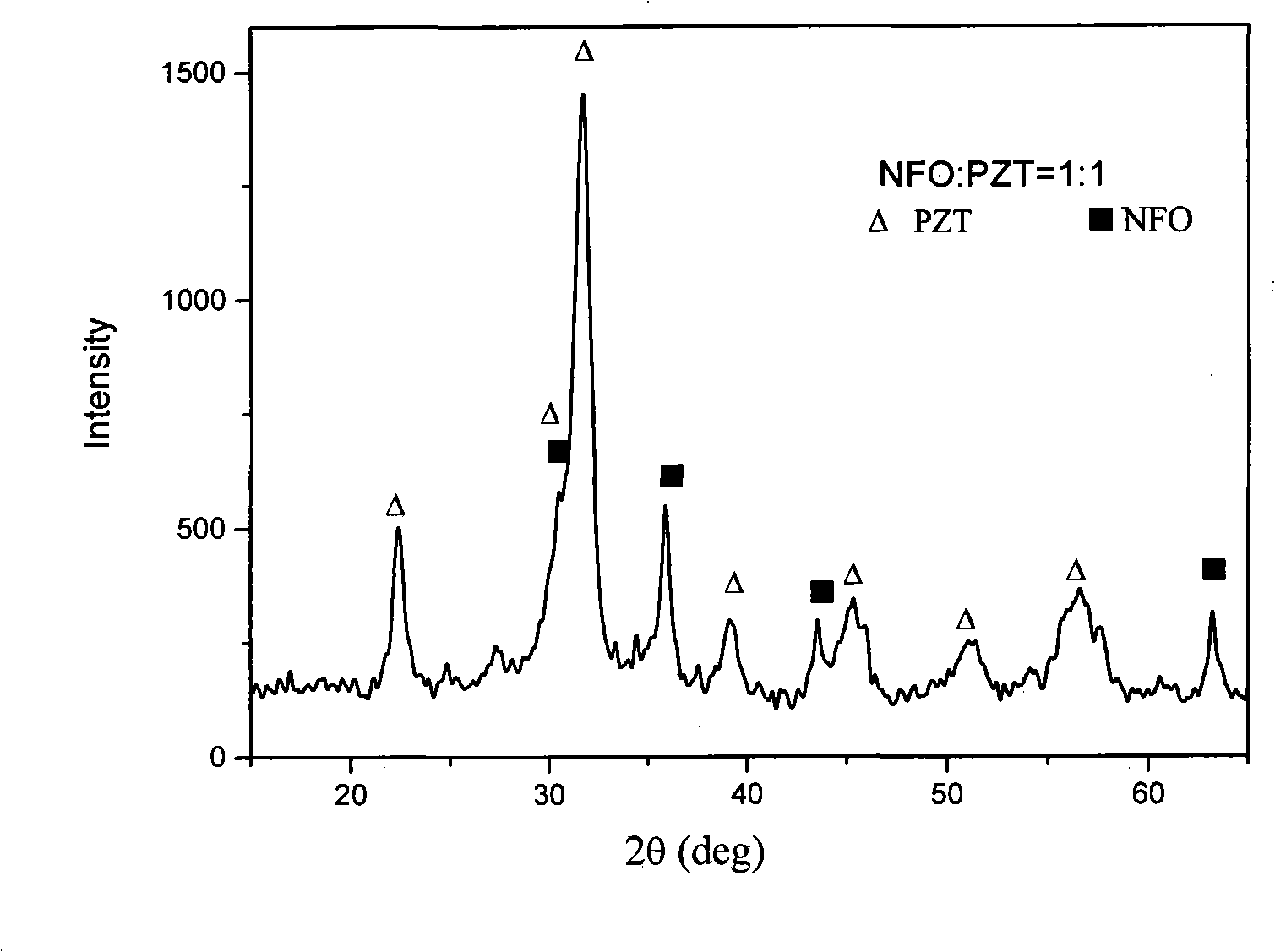

Preparation for ferroelectric-ferromagnetic composite nano-fiber

InactiveCN101274844ASimple processEasy to operateFilament/thread formingSpinning solutions preparationFiberElectrospinning

The invention provides a method that can successively produce ferroelectric and ferromagnetic composite nano fiber, is simple, convenient and low in cost and comprises the following processing steps: (1) ferroelectric precursor solution is prepared; (2) ferromagnetic precursor solution is prepared; (3) ferroelectric and ferromagnetic composite solution is prepared; (4) electrostatic spinning is adopted to prepare the ferroelectric and ferromagnetic composite nano fiber; (5) roasting is carried out to obtain the ferroelectric and ferromagnetic composite nano fiber with stable performances. The ferroelectric and ferromagnetic composite nano fiber provided by the invention can ensure uniform composition of ferroelectric phase and ferromagnetic phase in the molecular scale and even in the atomic scale and greatly increase contact area, thus resulting in higher magneto-electric coupling coefficient; the technique of the invention has broad application prospects in fields such as a convertor, an attenuator, a filter, a probe, a spin valve and a biconditional storage unit, etc.

Owner:XIANGTAN UNIV

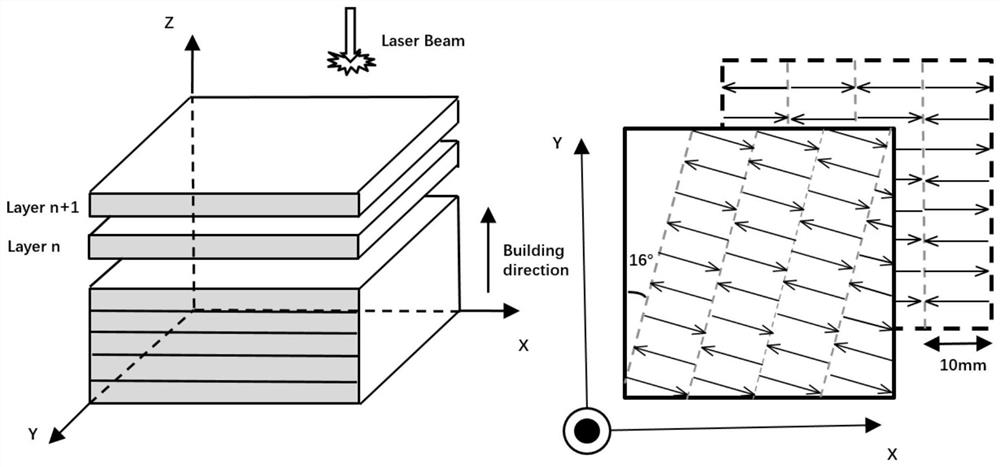

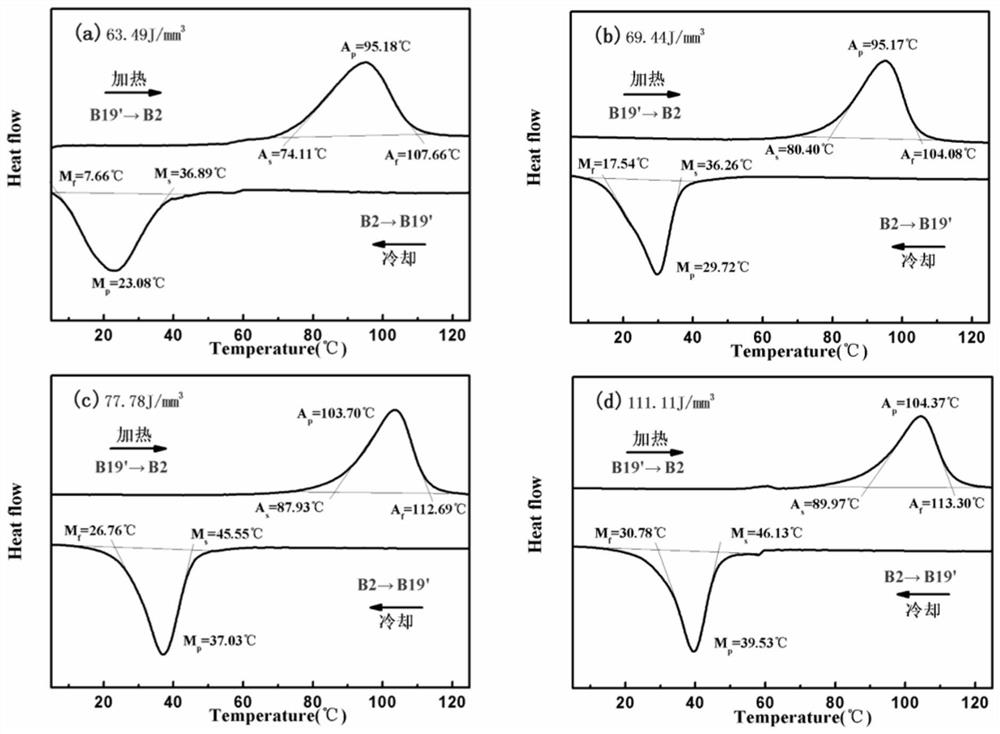

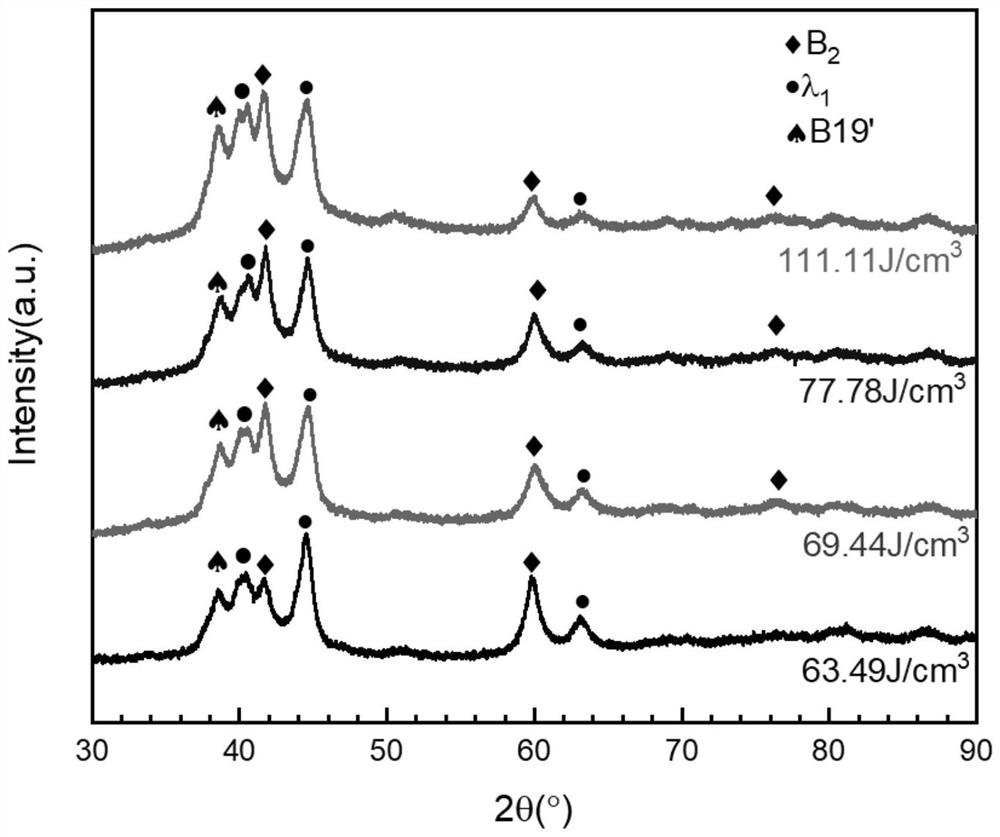

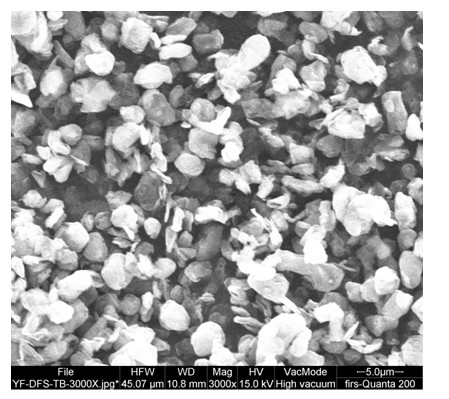

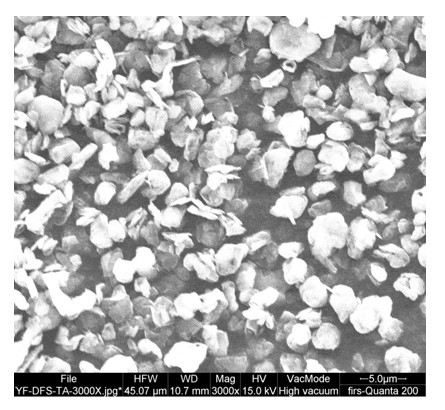

4D printing method of nickel-titanium-based ternary shape memory alloy

InactiveCN111842888AHas shape memory effectRaise the transition temperatureAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingBinary alloy

The invention belongs to the technical field of 4D printing additive manufacturing, and discloses a 4D printing method of a nickel-titanium-based ternary shape memory alloy. The 4D printing method ischaracterized in that a selective laser melting technology is adopted for printing gas atomized prefabricated NiTiZr ternary alloy powder, and a component obtained through printing has the shape memory function; and the laser energy density is changed by changing the technological parameters adopted in the selective laser melting technology, and therefore the changes of the structure and performance of the printed piece are regulated and controlled. According to the 4D printing method, the ternary component Zr is introduced into an existing nickel-titanium binary alloy, the martensite phase transformation temperature is obviously increased, the selective laser melting technology is adopted for forming, and complex parts uniform in structure and high in density can be obtained while the excellent shape memory performance and mechanical performance are guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

Infrared radiation material, high-temperature infrared coating and production process thereof

The invention provides an infrared radiation material. In the infrared radiation material, a high-concentration crystal defect spinel structure compound is synthesized at high temperature by using various transitional metal oxides and rare earth metal oxides as raw materials. The infrared radiation material has the advantages of high high-temperature stability and high emissivity. The invention also provides high-temperature infrared coating produced by using the infrared radiation material. The high-temperature infrared coating comprises the following components in part by mass: 67 to 73 parts of acidic silicon sol, 0.005 to 0.02 part of ammonium polyacrylate and 28 to 32 parts of mixed powder, wherein the mixed powder comprises the following components in part by mass: 48 to 52 parts of fused quartz, 32 to 37 parts of cordierite, 1 to 3 parts of boron nitride and 10 to 14 parts of the infrared radiation material. The high-temperature infrared coating has high adhesive property, high surface drying speed, low-temperature sintering property and high temperature resistance. The invention further provides a production process of the infrared radiation material and a production process of the high-temperature infrared coating. The production processes are easy and convenient in operation.

Owner:官明智

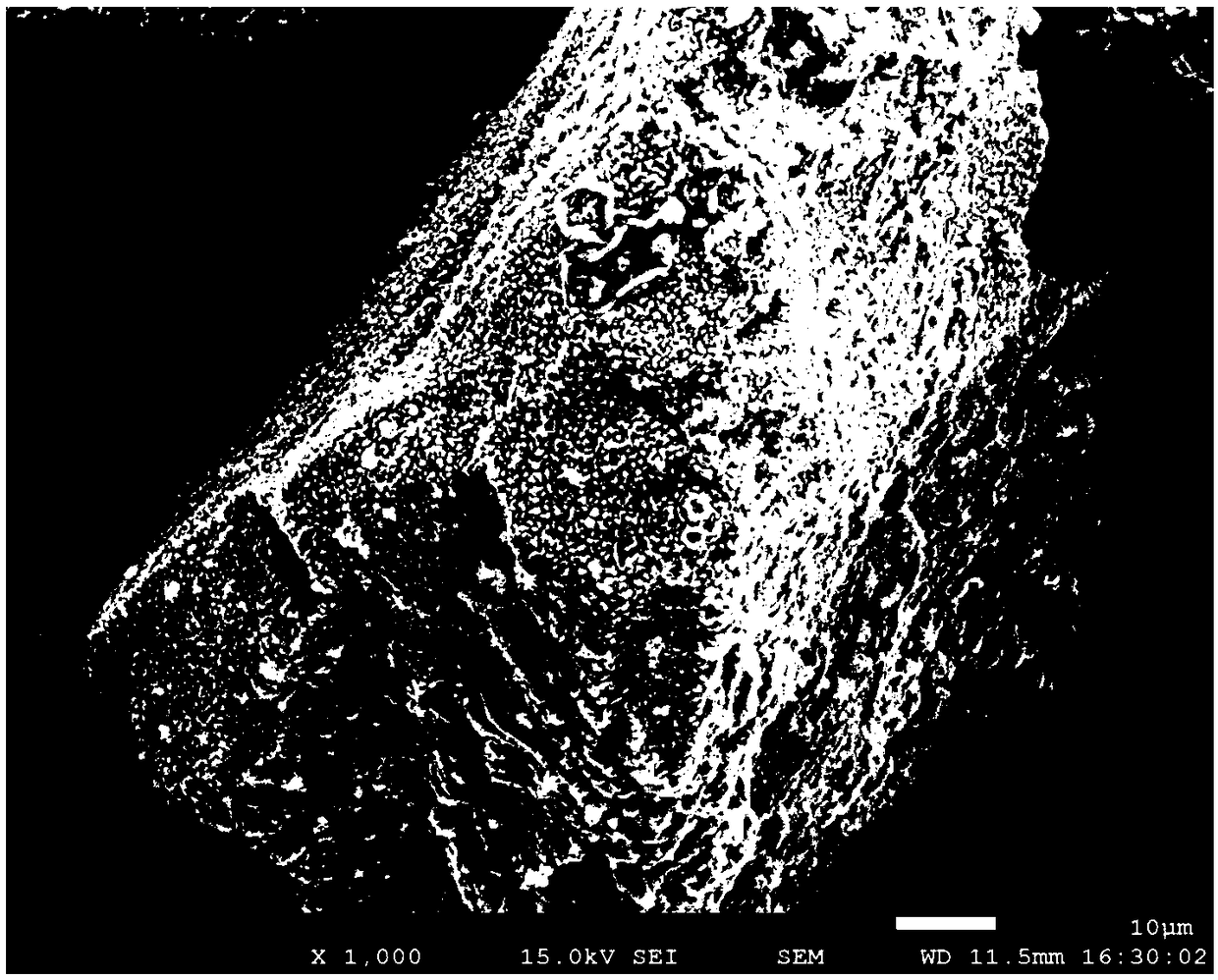

Pretreatment method of oil sludge obtained after neodymium-iron-boron material grinding through machine tool

The invention relates to a pretreatment method of oil sludge obtained after neodymium-iron-boron material grinding through a machine tool, belonging to the technical field of rare earth recovery. The pretreatment method comprises the following steps of: evenly dissolving oil sludge obtained after neodymium-iron-boron materials are ground, conducting distillation, keeping distillation temperature to be 50-100DEG C, rotating speed to be 10-300rpm (revolutions per minute) and atmospheric pressure to be 0.01-0.1MPa, and finally conducting acid dissolution, impurity removal, extraction separation, settlement and burning to residual products obtained after distillation to obtain rare earth oxides. By using the pretreatment method, the oil sludge is not needed to be oxidized and roasted during pretreatment, atmospheric pollution caused by dust is avoided and environmental protection is facilitated.

Owner:BEIJING UNIV OF TECH

High-temperature infrared radiant coating used for industrial furnace and preparation method thereof

The invention discloses a high-temperature infrared radiant coating used for an industrial furnace and a preparation method thereof. The high-temperature infrared radiant coating is mainly prepared from an infrared radiant base material, a high-temperature thermal expansivity regulator and a binder by direct ball-milling and mixing, wherein the infrared radiant base material has a stable spinel structure; the high-temperature thermal expansivity regulator is selected from micro silicon dioxide powder; the binder is one or two selected from the group consisting of high-temperature sol and micro oxide powder; and the infrared radiant base material is prepared by high-temperature sintering of transition metal oxides prepared by proportioning and mixing of MnO2, industrial grade chrome green, Co2O3, Ni2O3, CuO, Fe2O3, TiO2 and ZrO2. According to the invention, infrared radiance of the coating can be improved; stability of the infrared radiance of the coating can be guaranteed; meanwhile, the service life is enhanced; the process is simple and has no pollution to products in a furnace; and strong bonding strength and thermal shock resistance are achieved.

Owner:ZHEJIANG UNIV

Chromium corundum material and production method thereof

The invention relates to a chromium corundum material and a production method thereof. The chromium corundum material consists of 90wt%-94.5wt% of aluminum oxide, 3wt%-8wt% of chromic oxide and less than and equal to 2.5wt% of total impurities. The production method comprises the steps of uniformly mixing aluminum-chromium slag having a particle size less than and equal to 20mm, aluminum oxide having a particle size less than and equal to 1mm, petroleum coke having a particle size less than and equal to 20mm and aluminum fluoride, heating bitumen and spraying to the mixture, pressing into ball materials, drying, and adding the dried ball materials to an electric-arc furnace; smelting, pouring smelted liquid in a slag pot, removing the calcium fluoride floating on the upper part of the liquid material and standing; and separating from the slag pot, crushing, selecting chromium metal reduced by carbon and finishing to obtain the chromium corundum material. The chromium corundum material has the advantages that the problem of aluminum chromium slag solid waste is solved by taking aluminum chromium slag as raw materials, environmental friendliness is achieved, the raw material cost is lowered, the contents of Al2O3 and Cr2O3 are improved and the high-temperature performance, slag resistance and corrosion resistance of the chromium corundum material are ensured.

Owner:锦州集信高温材料有限公司

Method for preparing ultra-fine tungsten-copper composite powder

The superfine tungsten copper complex powder is made of tungsten and copper oxidization mixing with organic monomer and coupling water solution grind ball to trigger radiation and forming high polymer moisture gel, dehydration for calcining in 600-800deg.C with the yield recovered in hydrogen environment. The complex powder is evenly scattered with W and Cu, with grain size of 200-300 mu m, getting superfine complex material of 2-3 mu m sintering lower than 1200deg.C, with relative density higher than 99%. It has good electronic and dynamic feature, meeting requirement of relative high feature components.

Owner:HEFEI UNIV OF TECH

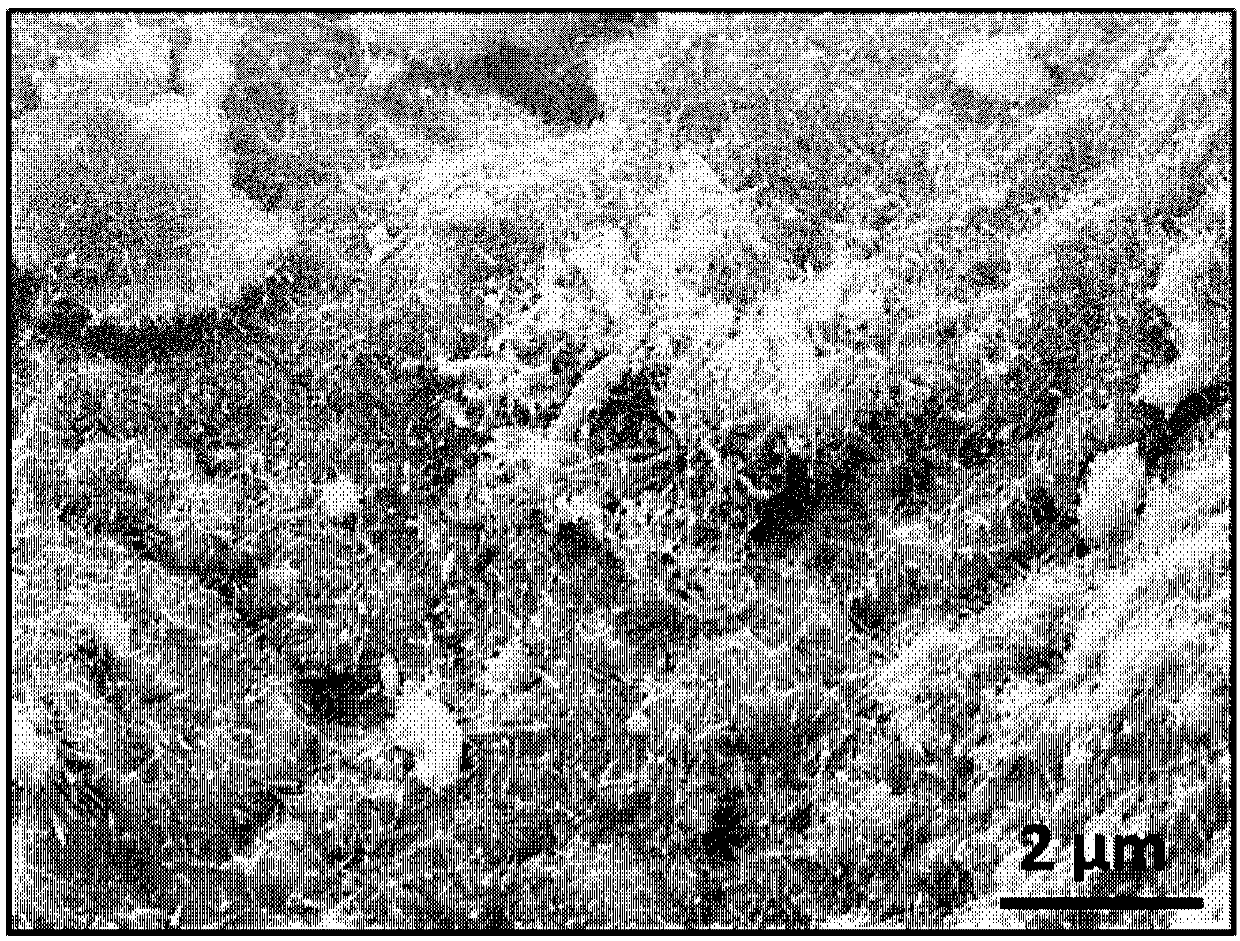

Core-shell structure carbon-coated titanium and titanium alloy composite powder and preparation method thereof

ActiveCN107824786AImprove bindingEvenly distributedTransportation and packagingMetal-working apparatusTitanium matrix compositesCarbon coating

The invention discloses core-shell structure carbon-coated titanium and titanium alloy composite powder and a preparation method thereof. The composite powder takes titanium or titanium alloy powder as a core and takes one or more than one carbon substances including graphite particles, carbon nano-tubes, carbon nano-rods and amorphous carbon as a shell. The preparation method of the composite powder disclosed by the invention is implemented through a fluidized bed chemical vapor deposition technology; and the composite powder body has the advantages that a product is pure and low in impuritycontent, a carbon coating layer has a high binding force with a titanium substrate and is not prone to dropping, carbon substances are uniformly distributed on the surface of the powder, and the content is controllable. The composite powder can be directly used as a production raw material for a carbon-reinforced titanium-based composite material and can solve the problems that a traditional powder metallurgical technology for preparing a titanium-based composite material causes uneven distribution of carbon-rich phases, the number density is difficult to control, and the impurity content is too high.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

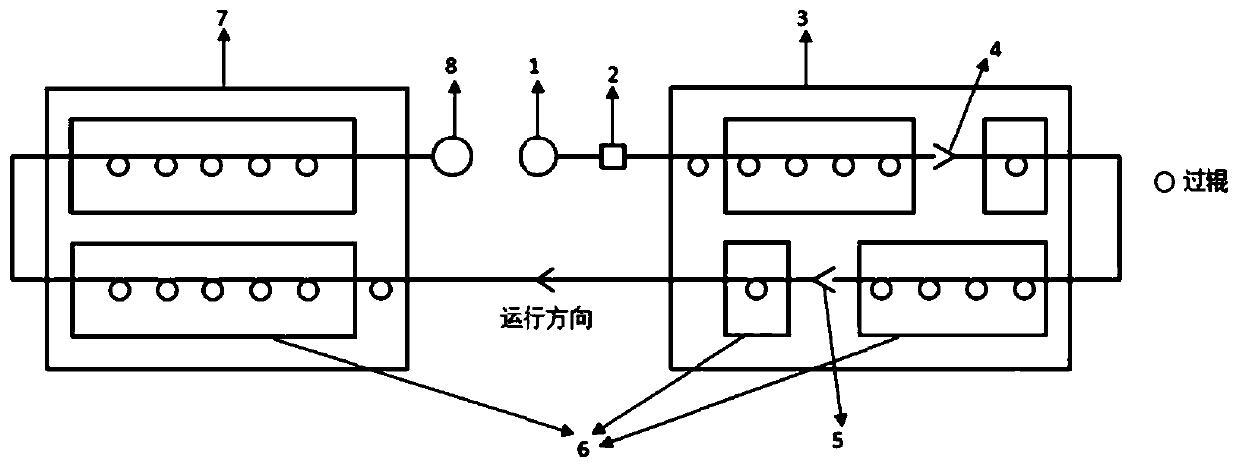

Preparation method of high-safety and high-performance lithium battery negative electrode

InactiveCN109817895AImprove surface roughnessGood coating effectElectrode manufacturing processesSecondary cells servicing/maintenancePole pieceSlurry

The invention relates to a preparation method of a high-safety and high-performance lithium battery negative electrode. The method comprises the following steps that A, copper foil is led out throughan unwinding unit (1); B, the copper foil is subjected to surface treatment through a corona surface treatment unit (2); C, coating the copper foil with silicon-carbon negative electrode slurry to obtain a coated pole piece; D, baking the pole piece in a baking oven, punching micropores in the surface of a pole piece dressing area through a laser mechanism (4), and E, conducting coating with a certain component of ceramic and binder mixed slurry through an intaglio coating mechanism (7) after a porous silicon carbon negative pole piece is formed, and drying the pole piece to obtain the high-safety and high-performance lithium battery negative electrode. The capacity and cycle life of the battery are improved, and the safety is improved.

Owner:湖北锂诺新能源科技有限公司

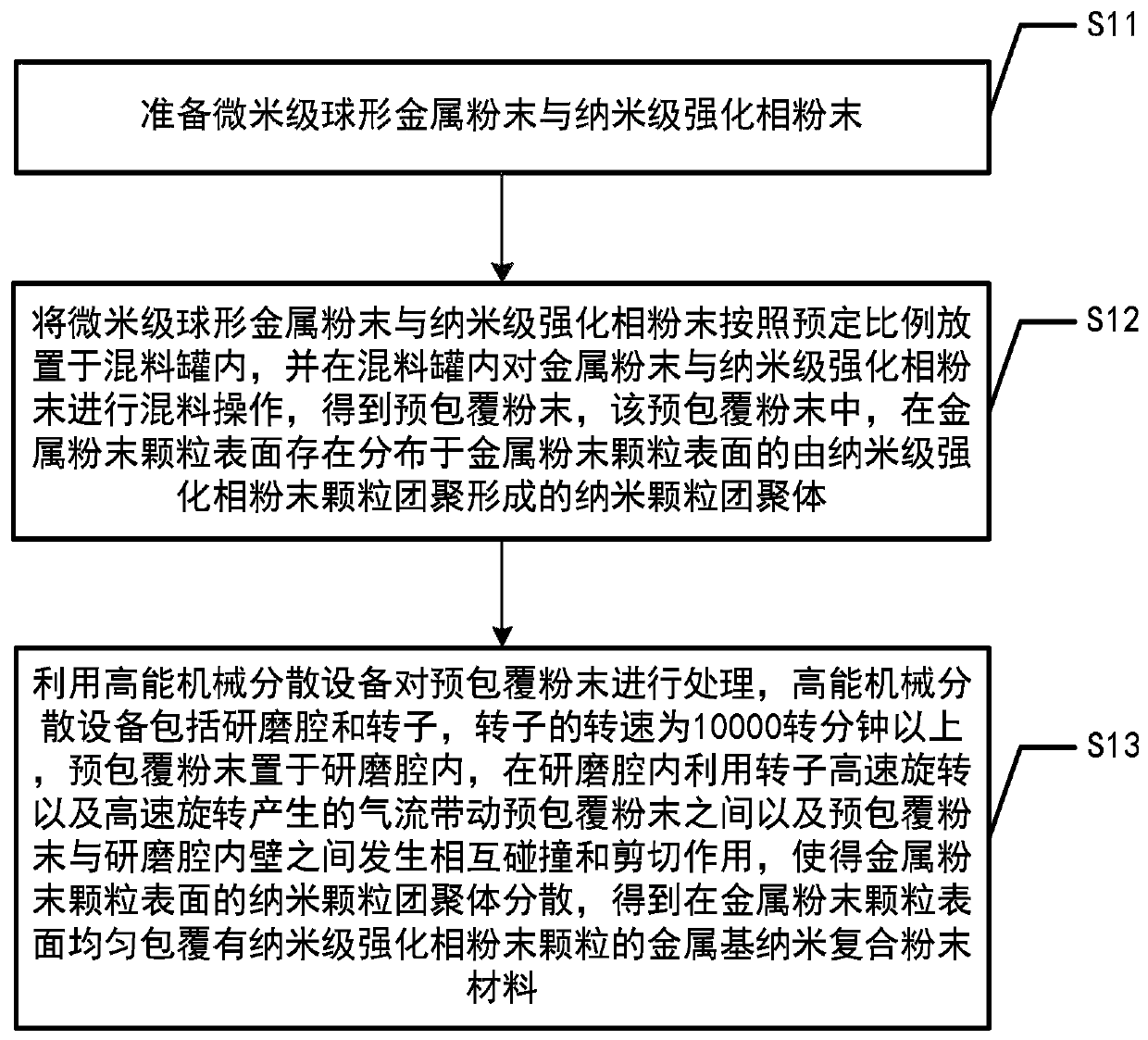

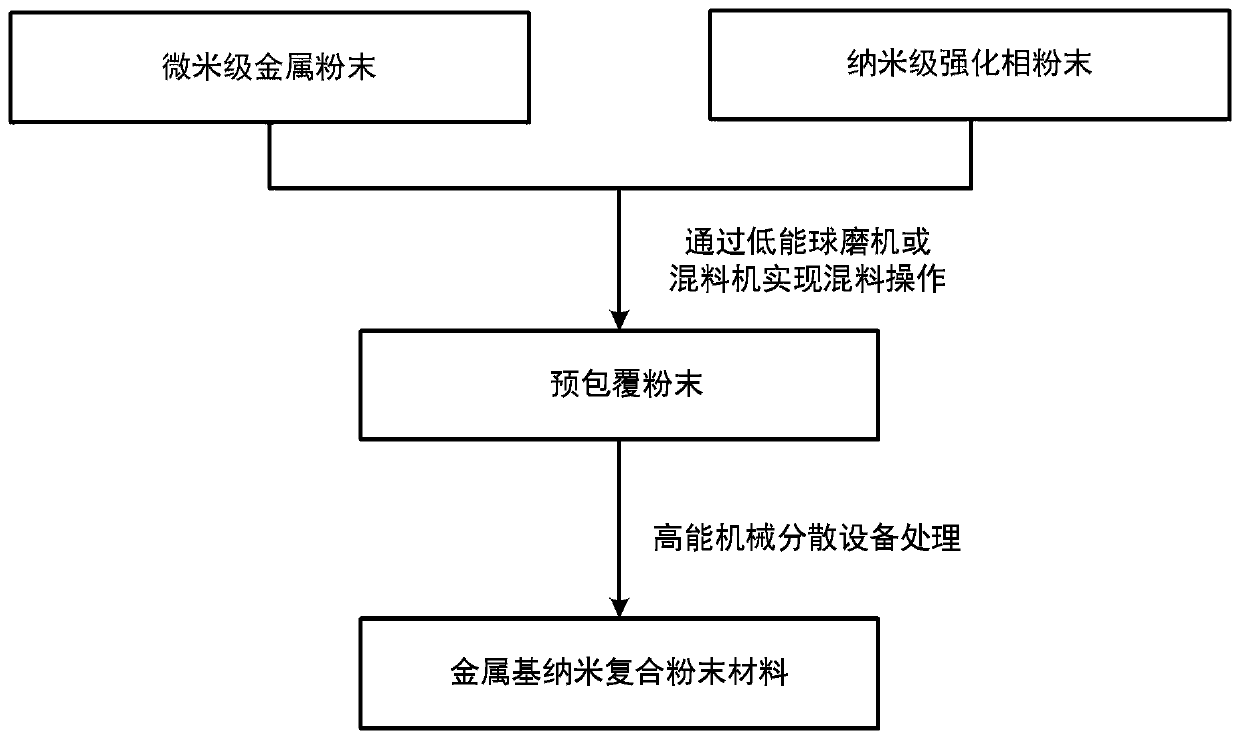

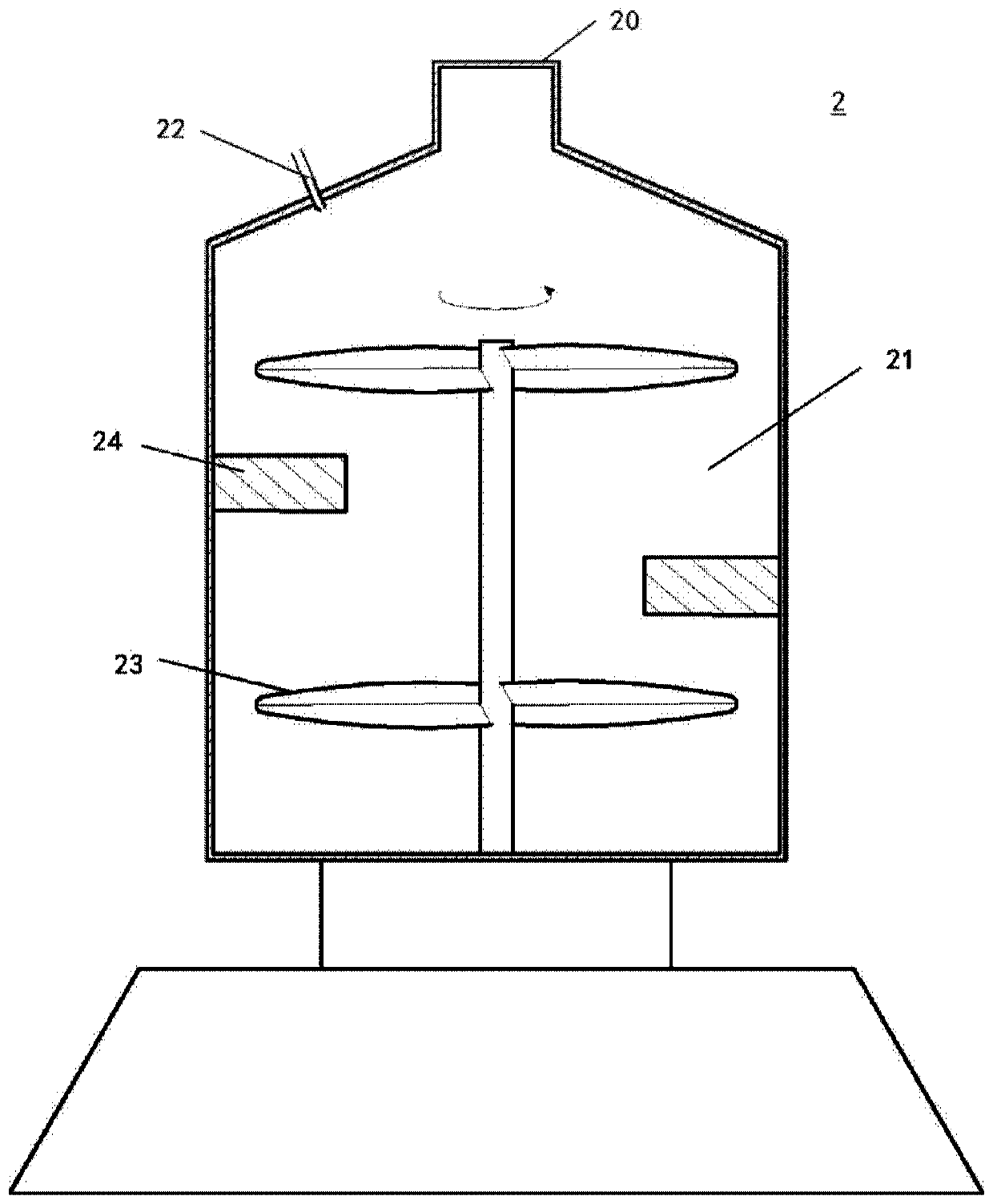

Metal-based nano composite powder material, preparation method and application thereof

ActiveCN111230098AImprove liquidityHigh bulk densityAdditive manufacturing apparatusTransportation and packagingNanoparticleMetal powder

The invention provides a metal-based nano composite powder material, a preparation method and application thereof. The preparation method comprises the following steps of preparing micron-sized spherical metal powder and nano-sized strengthening phase powder, and placing the micron-sized spherical metal powder and the nano-sized strengthening phase powder in a mixing tank according to a predetermined proportion for mixing operation to obtain pre-coated powder with a preliminary coating effect; and treating the pre-coated powder by using high-energy mechanical dispersion equipment, wherein thehigh-energy mechanical dispersion equipment comprises a grinding cavity and a rotor with a rotating speed of 104 revolutions per minute or above, the high-speed rotation of the rotor and the airflow generated by the rotor are used in the grinding cavity to drive the pre-coated powder to collide with each other and shear, and the nano-particle agglomeration on the surface of the pre-coated powder is released to obtain the metal-based nano composite powder material with the nano-sized strengthening phase powder particles uniformly coated on the surfaces of the metal powder particles. The composite powder material has good fluidity, high apparent density and mature and stable process, is suitable for large-scale industrial production, and can be applied to the fields of metal additive manufacturing, powder injection molding and the like.

Owner:PEKING UNIV

Method for producing sintering brown fused alumina

The invention discloses a method used to manufacture sintering brown alumina. The sintering brown alumina adopts high-alumina bauxite raw ore with a loose structure and aluminum oxide as raw materials and is made through steps such as material proportioning, grinding, forming, drying and burning. Compared with the prior fused brown alumina, the sintering brown alumina has equivalent aluminum content and excellent thermal shock stability, and the cost of the sintering brown alumina is only 37 percent that of the fused brown alumina; moreover, the main crystal phase of the sintering brown alumina is Alpha-Al2O3 and the section of the sintering brown alumina is black; meanwhile, the sintering brown alumina, which has compact texture and regular crystal grain development with most crystal grain more than 10 micron, is a top quality fireproof raw material.

Owner:PUYANG REFRACTORIES GRP CO LTD

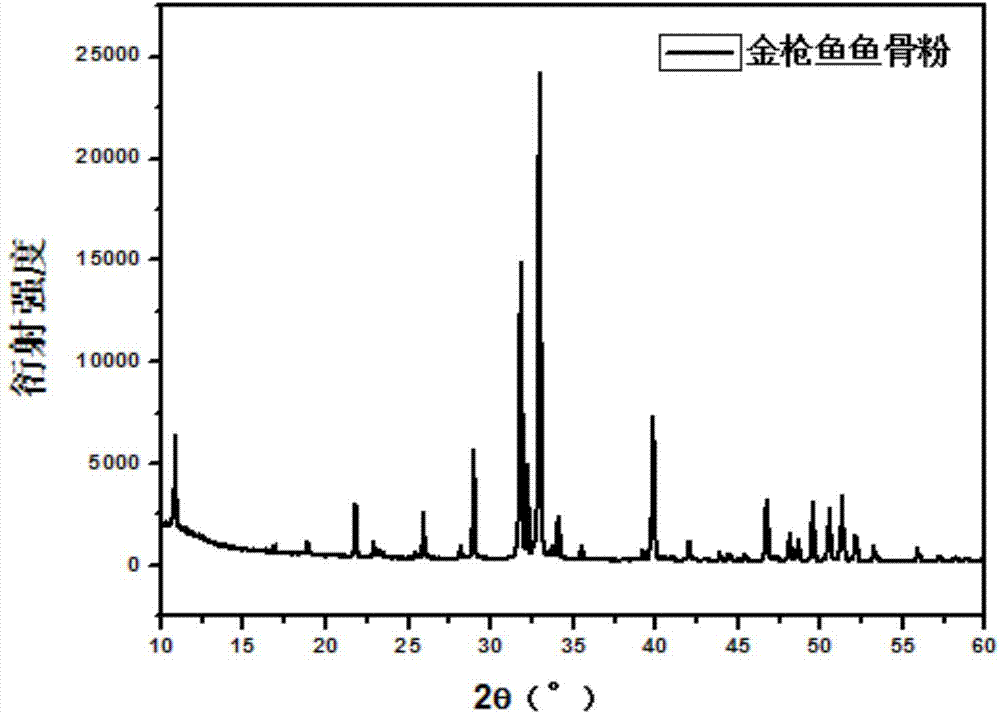

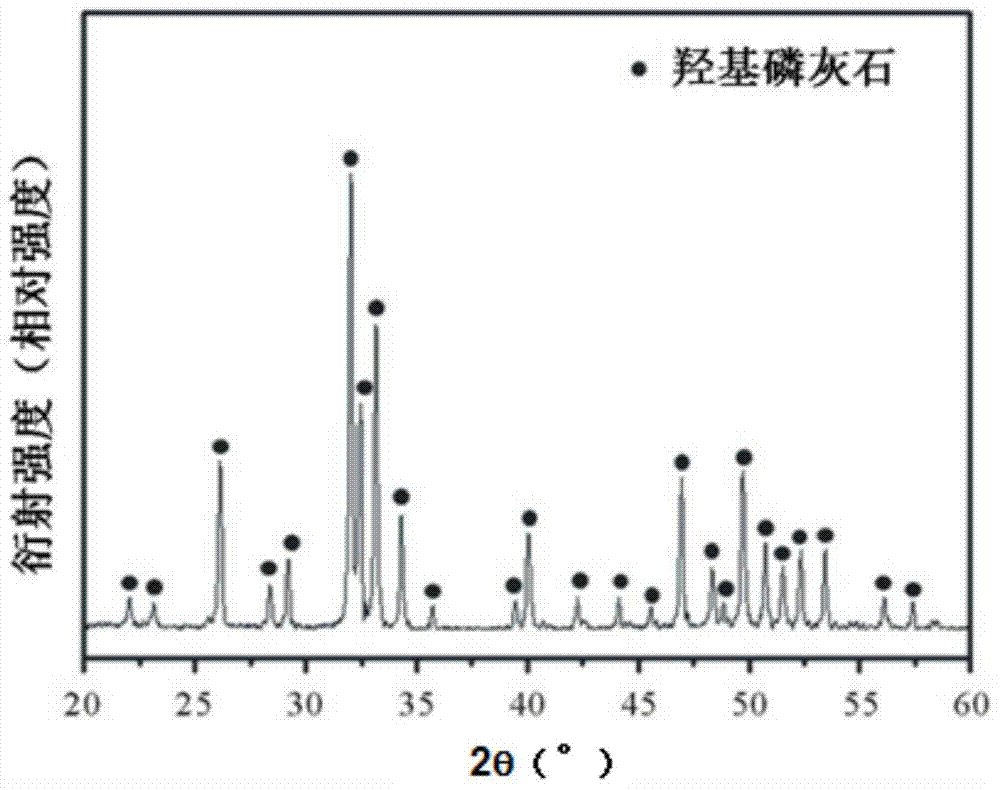

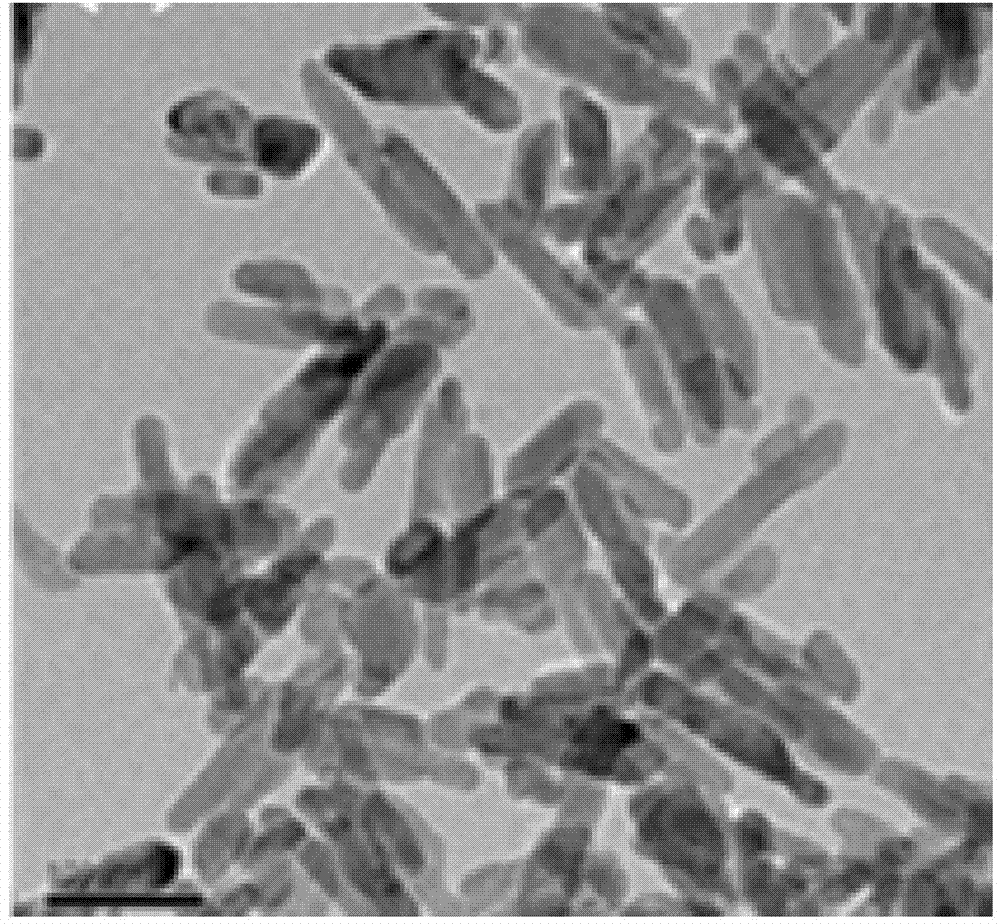

Tuna fishbone meal material, preparation method and application thereof

ActiveCN104841016AQuality is easy to controlEasy to introduceProsthesisDental filling materialsHydrogen

The invention provides a tuna fishbone meal material, a preparation method and application thereof. The preparation method of the tuna fishbone meal material provided by the invention includes: conducting preliminary crushing on tuna fishbone to obtain a fishbone preliminary material, cooking the fishbone preliminary material at 90-100DEG C and under 1.0-1.1bar for 1-4h to obtain a fishbone initial material; soaking the fishbone initial material in a sodium hydrogen sulfite buffer solution with a mole concentration of 4-7% for 2-4h, then conducting calcinations at 800-1000DEG C for 4-10h to obtain a fishbone material, and then carrying out crushing and sieving treatment to obtain fishbone meal material with different particle size ranges. The invention additionally provides the tuna fishbone meal material prepared by the method. The invention also provides application of the tuna fishbone material as a medical orthopaedic filling material. The tuna fishbone material can be used as an individual bone filling material and dental filling material, and also can be compounded with other materials into widely applied biomedical materials.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

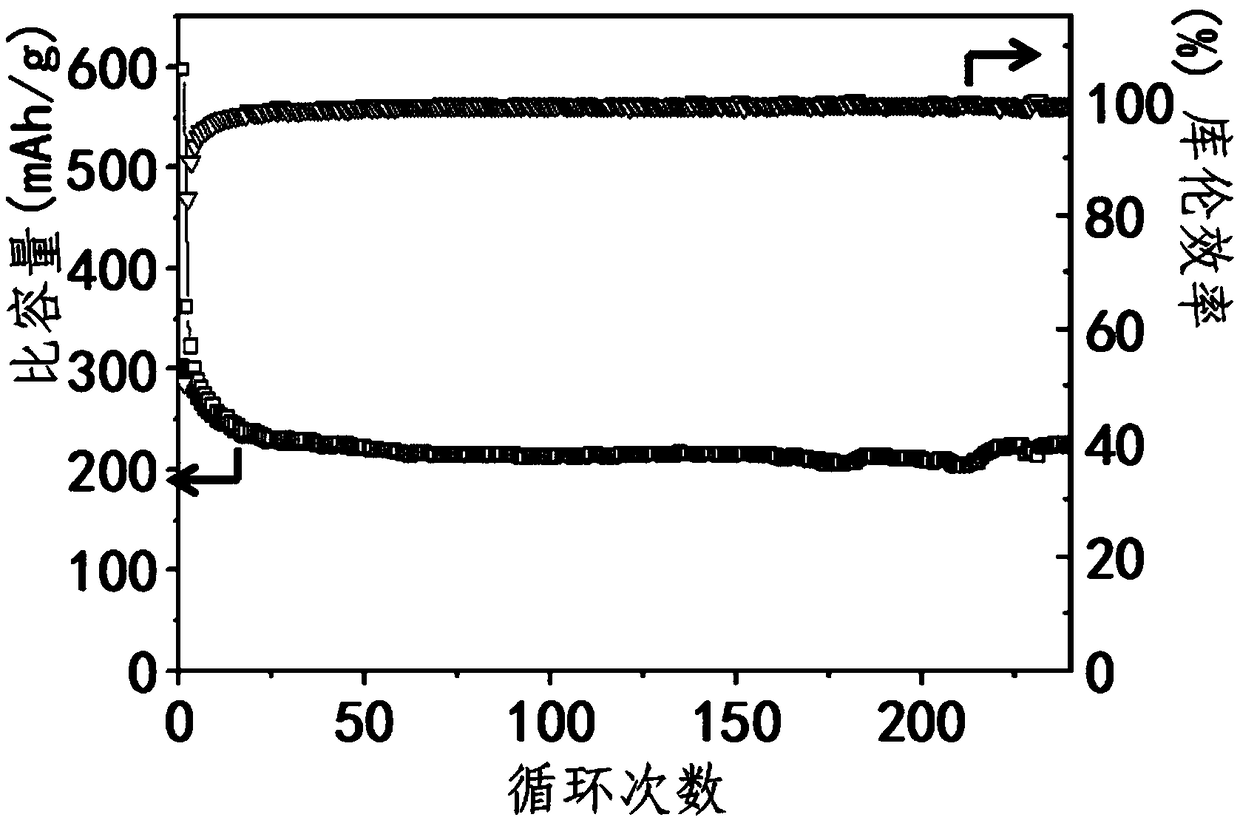

Preparation method of hollow porous TiO2 nanocubic material and application thereof

InactiveCN109286015ALow costEasy to prepareMaterial nanotechnologyCell electrodesN dimethylformamideTitanium isopropoxide

The invention discloses a preparation method of a hollow porous TiO2 nanocubic material. The method firstly mixes titanium isopropoxide and methanol, adds into a mixture of 2-aminoterephthalic acid and N,N-dimethylformamide for a reaction, obtains an amino-modified Ti-MIL-125 nanocube material, conducts stirring for the reaction after water, sodium hydroxide and absolute ethanol are added, obtainsa nano-precursor material, and finally conducts heat-treating to obtain the hollow porous TiO2 nanocubic material; the invention discloses application of the hollow porous TiO2 nanocubic material ina lithium ion battery. The method utilizes the characteristics that acidic ligands constituting the amino-modified Ti-MIL-125 nanometer material are not stable under the alkaline condition to conductself-etching, thereby ensuring the stability of the structure and performance; the hollow porous TiO2 nanocubic material is applied to the lithium ion battery to increase the specific capacity of thelithium ion battery.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Alfalfa seed pretreatment method for improving vigor of seedlings and saline-alkali resistance

InactiveCN102204439AIncrease resistanceIncreased resistance to osmotic stressSeed and root treatmentPretreatment methodSilica gel

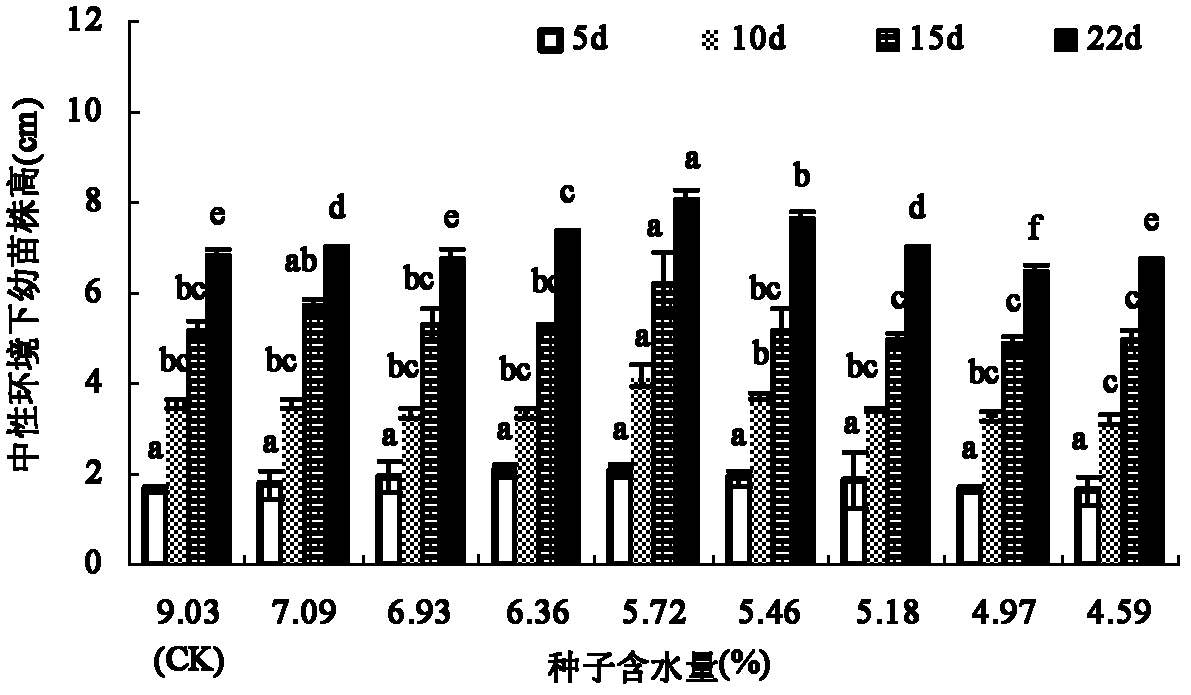

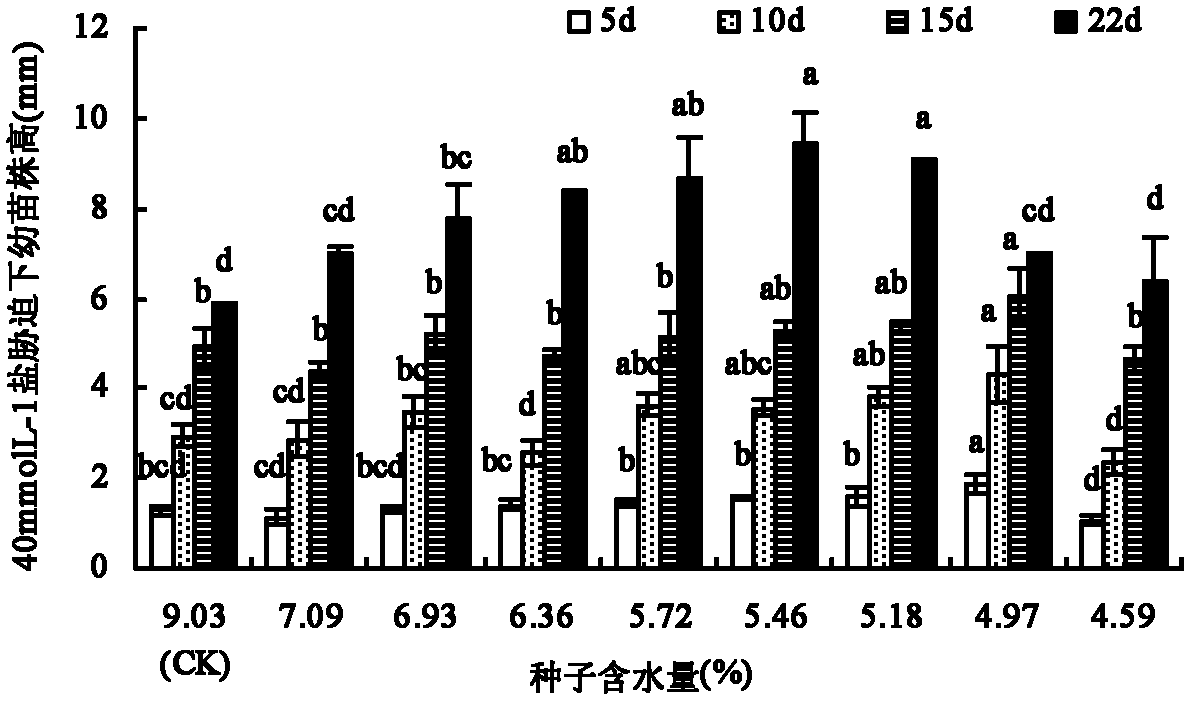

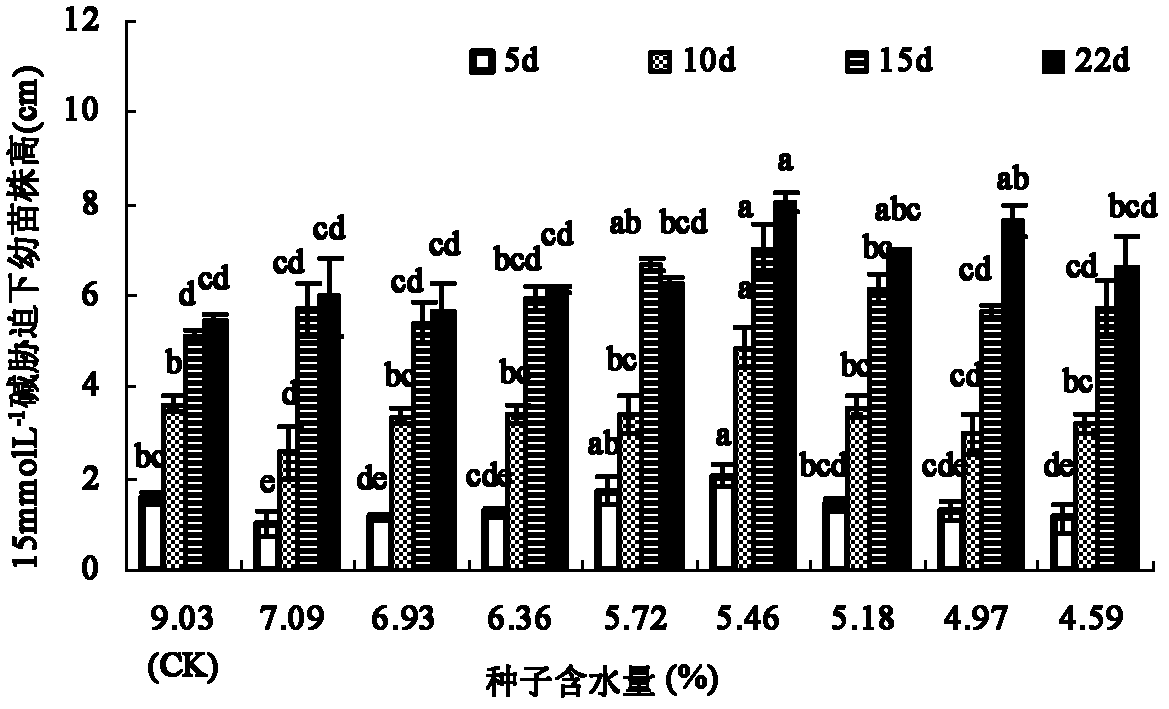

The invention discloses an alfalfa seed pretreatment method for improving vigor of seedlings and saline-alkali resistance. The alfalfa seed pretreatment method comprises the steps of: firstly putting seeds in an air-permeable mesh bag, placing in a dry container filled with silica gel and sealing with aluminized paper, drying the seeds with the silica gel at the room temperature to reduce the water content of the seeds to be 4.59 to 7.09 percent, sealing the dried seeds with the aluminized paper, placing in a dry container filled with drying silica gel, and storing the seeds at the room temperature. Before seeding, the highly dried and stored seeds are sequentially placed in closed environments the relative humidity of which is increased in sequence, and the water content of seeds is improved gradually. The seeds are highly dried so that the vigor of seeds and the stress resistance of seedlings can be improved, thus the method is a simple, energy-saving and effective seed pretreatment method which can prolong the storage life of seeds. Simultaneously, the osmotic stress resistance of seeds in the germination period is enhanced, and the osmotic stress resisting function of seedlings in a saline environment is improved. The water saving effect and the drought tolerance are achieved in alfalfa cultivation by adopting a method of improving the seedling regularity and germinating speed.

Owner:GANSU AGRI UNIV

Preparation method for iron-coated ceramic composite powder of core-shell structure

ActiveCN108705077ASimple processReduce manufacturing costTransportation and packagingMetal-working apparatusCeramic compositeHydrogen

The invention discloses a preparation method for iron-coated ceramic composite powder of a core-shell structure. The preparing method comprises the following steps that (1) ceramic particles are selected to be placed into a fluidized bed, mixed fluidization gas of hydrogen and argon passes through a fluidized bed, and the ceramic particles are in the fluidized state; (2) the ceramic particles in the fluidized state are heated; (3) an iron precursor is heated, and the argon is used as carrier gas to carry iron precursor steam to enter a fluidized bed reaction section zone; (4) a chemical vapordeposition reaction is carried out in the fluidized bed reaction section zone; and (5) after the reaction is finished, argon shield cooling is carried out and the product temperature reaches to the room temperature, and the iron-coated ceramic composite powder of the core-shell structure is obtained. The composite powder has the advantages that the product is pure, impurities and pollution are avoided, the bonding force between an iron-coated layer and a ceramic base is high, iron is evenly distributed to the surface of the powder, and the content can be controlled. The preparation method foriron-coated ceramic composite powder has the advantages that the technological process is simple, the reaction condition is gentle, and large-scale and continuous production is facilitated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

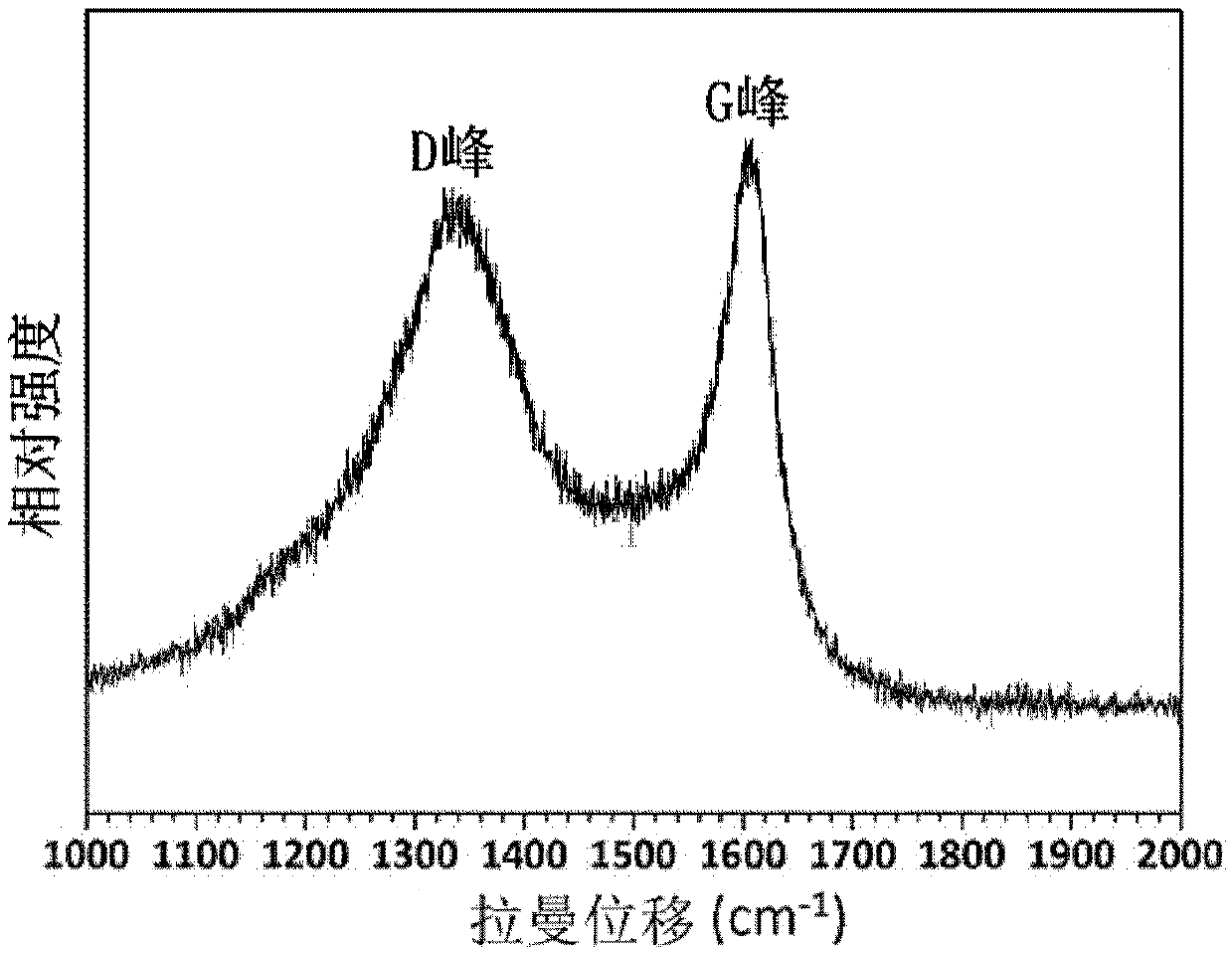

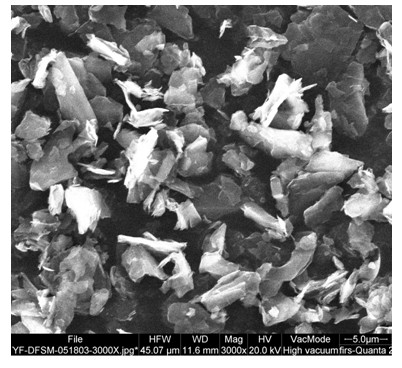

Preparation method and application of high-purity high-fineness graphite powder

ActiveCN102689895AEasy to introduceSimple preparation processCarbon compoundsNanotechnologyFiberElectrical battery

The invention discloses a method for preparing high-purity high-fineness graphite powder, comprising the following steps of: a), irradiating graphite raw materials by rays under a room temperature; and b) grinding and pulverizing the graphite raw materials which are obtained after the treatment of step a) to obtain high-purity graphite powder. The graphite powder can be applied to preparation of coatings, plastics, rubbers, fibers, heat preservation cottons, power supplies and batteries. Because the preparation process is simple, the times for grinding can be greatly reduced, impurities are difficult to enter, and the high-purity graphite powder, of which the grain diameter is less than 1mm, can be prepared. The preparation method and the application can be widely applied to the field of graphite processing.

Owner:王宏晓

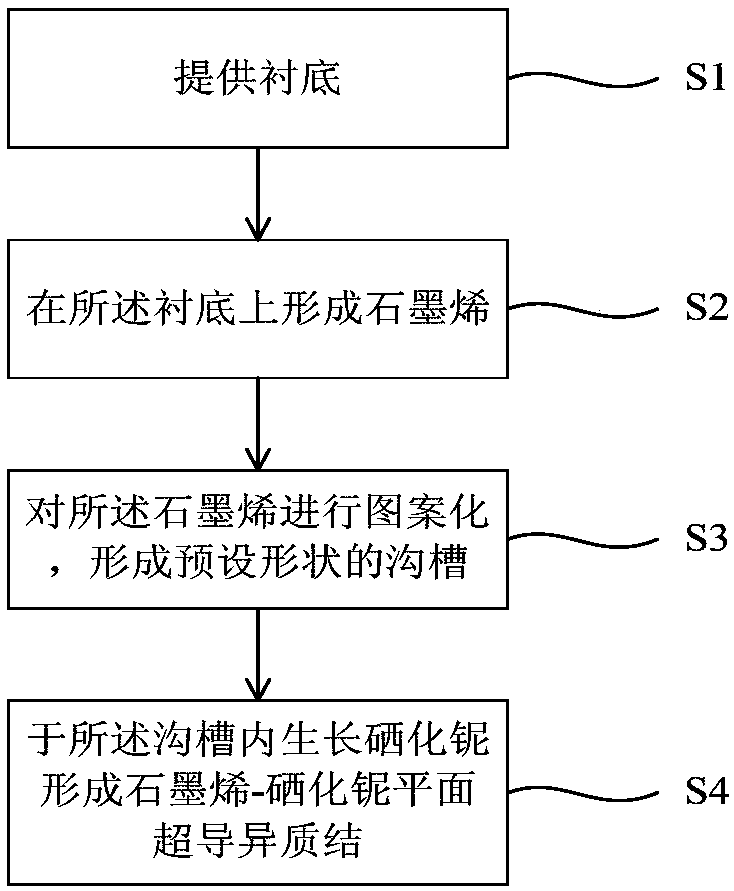

Graphene-niobium selenide superconducting heterojunction device and preparation method thereof

ActiveCN107634089AEasy to introduceControllable sizeSemiconductor/solid-state device manufacturingSuperconductor devicesHeterojunctionNiobium

The invention provides a graphene-niobium selenide superconducting heterojunction device and a preparation method thereof. The method includes: providing a substrate; forming graphene on the substrate; performing patterning on the graphene to form grooves with preset shapes; and growing niobium selenide in the grooves to form a graphene-niobium selenide planar superconducting heterojunction, wherein the niobium selenide is grown along the boundary epitaxy of the graphene. According to the graphene-niobium selenide superconducting heterojunction device and the preparation method thereof, the graphene-niobium selenide planar heterojunction is grown in an epitaxial manner through a chemical vapor deposition method, the introduction of impurities is avoided, the process is simple, the dimension of an obtained product is easy to control, the yield is high, the cost is low, and the requirements of industrial and batch production can be satisfied.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

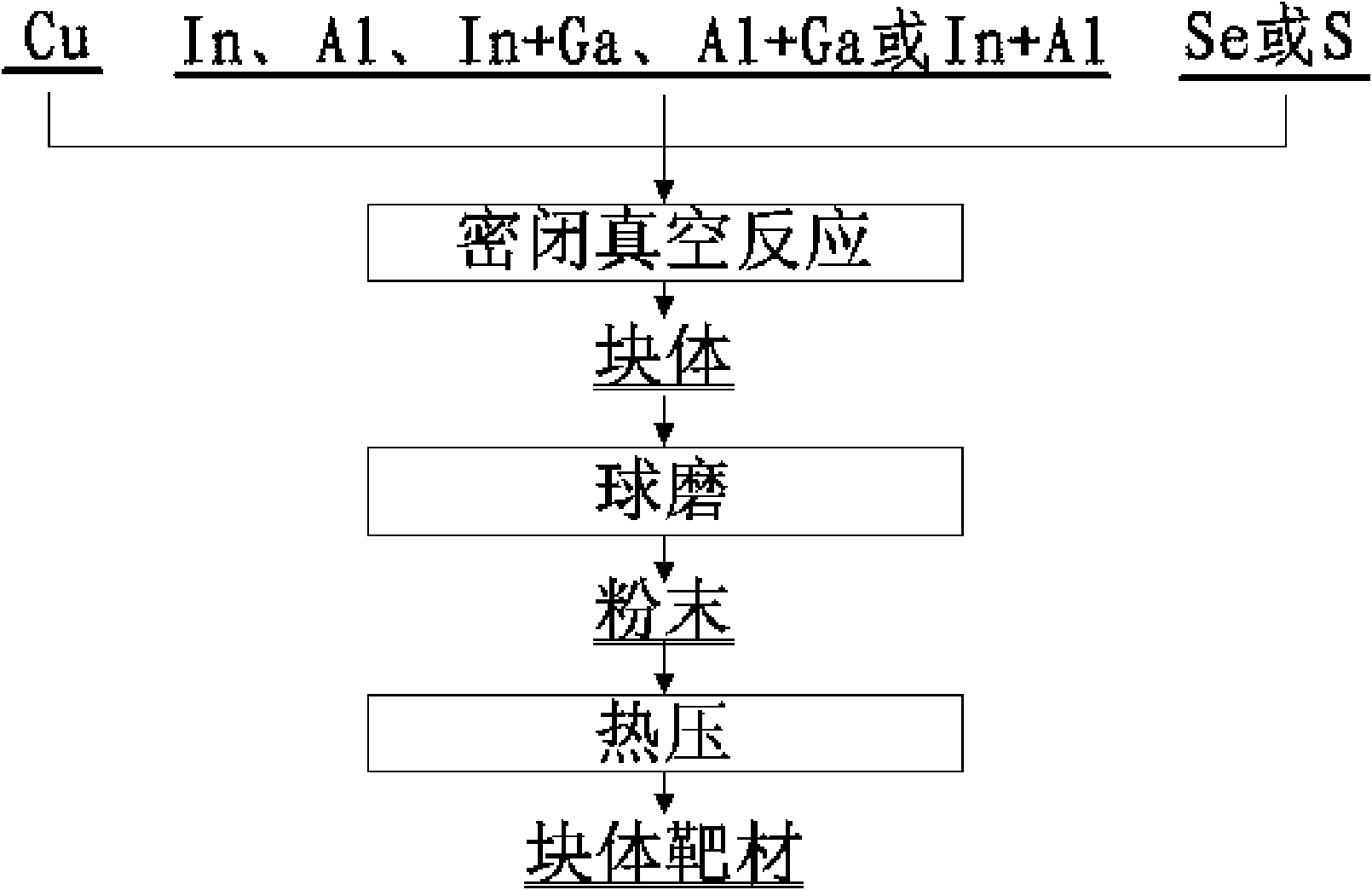

Preparation method of critical material for absorbing layer of thin film solar cell

InactiveCN101667610AUniform compositionPrecise ratioFinal product manufactureSemiconductor devicesNitrogen gasHot press

The invention relates to a preparation method of critical material for an absorbing layer of a thin film solar cell. The critical material is CuM(1-2x)R2(1+x), wherein M is selected from one of Al andIn, or selected from two of Al, In and Ga, R is selected from S or Se, and the value of x is -0.2 to 0.1; the state of material is powder or block target material. The preparation method of the materials is as follows: synthesizing the blocks of the materials in a vacuum closed container or in a closed container charged with argon, nitrogen or helium gas having the pressure lower than atmospherepressure; crushing the blocks to obtain the required powder; and finally synthesizing the required block target material in a hot-pressing furnace. The method is a pure element method liquid phase synthesis technique, has wide applicability, accurate proportioning, low cost, high quality of prepared target materials, compactness of powder material reaching more than 99.9%, and compactness of blocktarget material reaching more than 98.9%.

Owner:LIUZHOU BAIRENTE ADVANCED MATERIALS +1

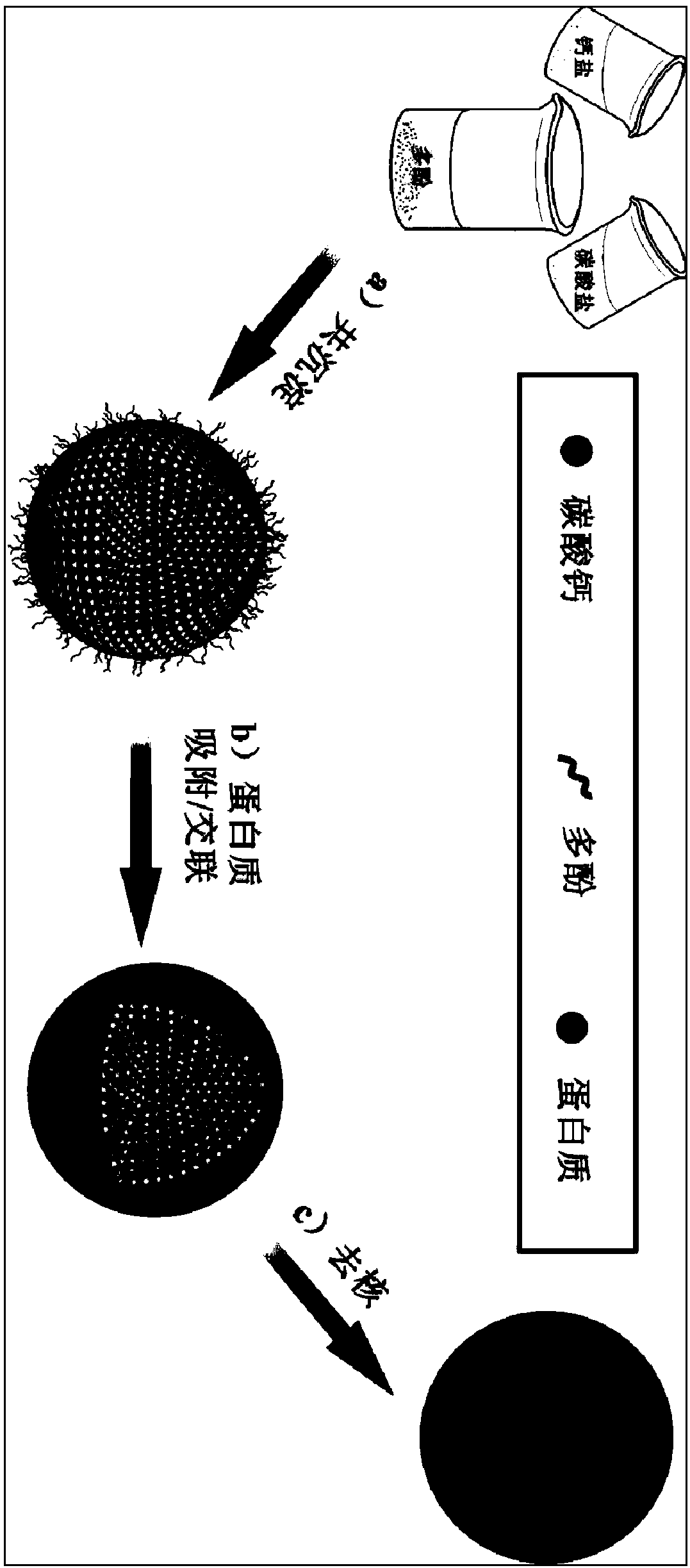

Preparation method for microcapsules with magnetic nanoparticles-containing capsule walls

InactiveCN103735531AAvoid reunionEnables controllable targeted deliveryInorganic non-active ingredientsMacromolecular non-active ingredientsCross-linkMagnetite Nanoparticles

The invention relates to a preparation method for microcapsules with magnetic nanoparticles-containing capsule walls. The microcapsules are medicine-carried microcapsules which take cross-linked films of sulfydryl-containing amino acid or peptide-modified magnetic nanoparticles as capsule walls and take an oil phase loaded with hydrophobic medicines as a core material. According to the preparation method, the magnetic nanoparticles are directly loaded on the capsule walls of the microcapsules, so that the agglomeration of the magnetic nanoparticles is avoided; the magnetic nanoparticles are uniformly distributed on the capsule walls of the microcapsules, so that the contact between the magnetic nanoparticles and the medicines loaded in capsule cores is reduced to the maximum; therefore, the influence on the medicine effect and the targeting caused by the magnetic nanoparticles is reduced; the controllable targeting transmission of the medicines is realized by utilizing the magnetic targeting of the magnetic nanoparticles; the controllable targeting release of the medicines is realized by utilizing the reduction responsiveness of disulfide bonds; the preparation method is easy to operate, efficient and quick, and moreover, impurities are not easily introduced.

Owner:JILIN UNIV

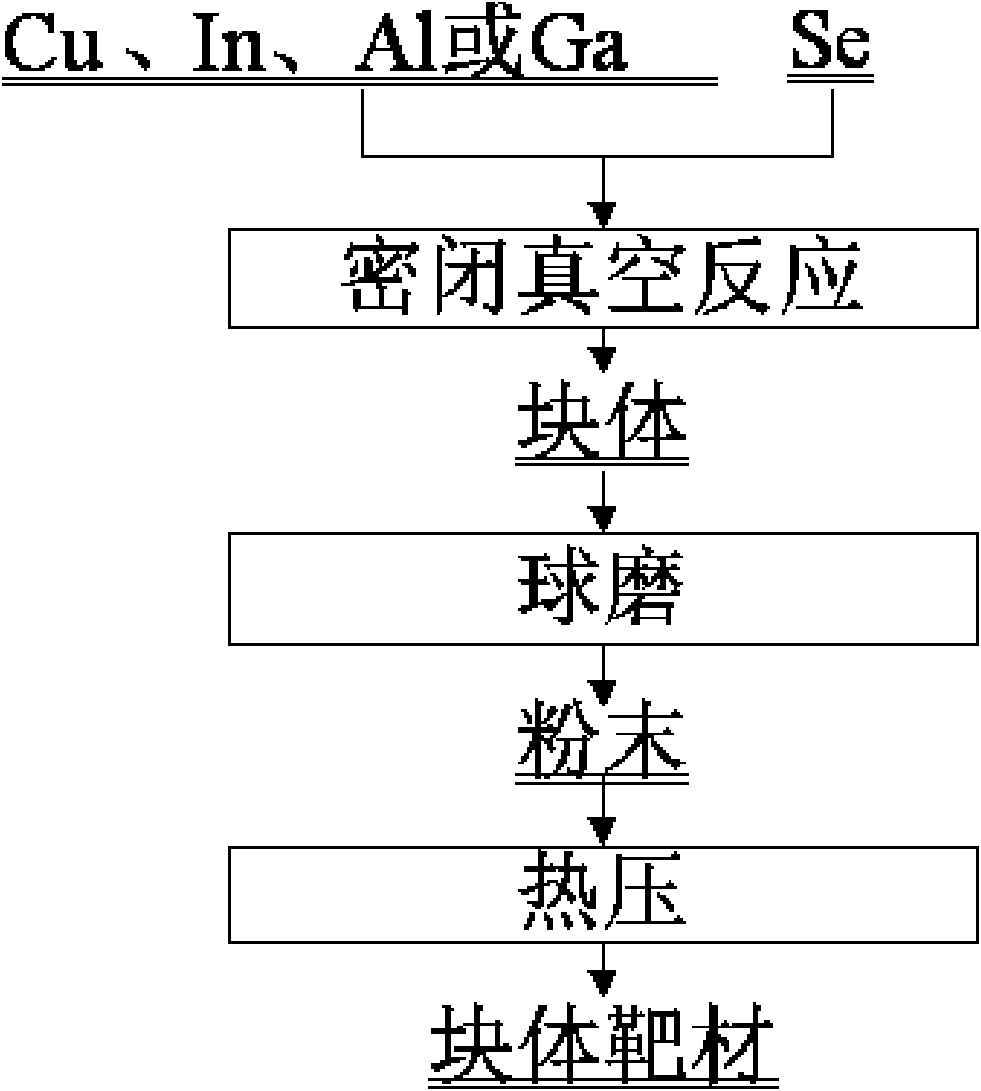

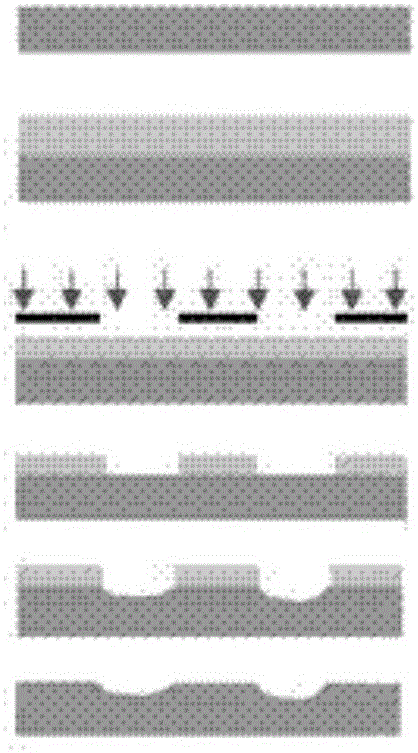

Preparation method of selenide material for absorbing layer of thin film solar cell

ActiveCN101645473AWide applicabilityStable performanceFinal product manufactureSemiconductor devicesSelenideSelenium

The invention relates to a preparation method of selenide material for the absorbing layer of a thin film solar cell and the selenide material is Cu2Sex and M2Sey, wherein M is one element of Al, In and Ga, x is 0.95-1.05, y is 2.8-3.2 and selenide material is powdered or block target material. The preparation method comprises the following steps: placing a sealed vacuum container or a container filled with argon or nitrogen with the pressure of less than normal pressure in a furnace to perform gradient temperature-elevating and temperature-keeping in a defined heating rate, performing liquidphase cooling to synthesize bulk material after stage temperature-keeping, crushing the bulk material to obtain the desired powder and finally synthesizing the desired bulk target in a hot pressing furnace. The method is a pure element method liquid-phase synthesis technology and has the advantage of wide applicability, accurate proportioning and low cost; the prepared target has high quality andthe consistencies of the powdery material and the bulk target material are separately more than 99.7% and 99.0%.

Owner:有研科技集团有限公司 +1

Folic acid modified chitosan micro-capsule with reducing responsiveness and preparation method thereof

ActiveCN105326810AAchieve controlled releaseEasy to introduceAmide active ingredientsOil/fats/waxes non-active ingredientsUltrasonic radiationOil phase

The invention relates to a folic acid modified chitosan micro-capsule with reducing responsiveness and a preparation method thereof. The capsule wall is modified by folic acid and provided with a disulfide bond structure with reducing responsiveness, a chitosan crosslinking film modified by folic acid and compounds with sulfydryl or biomolecules is adopted as the capsule wall, and the oil phase loaded with hydrophobic drugs is adopted as a core material. Firstly, chitosan is modified by folic acid and the compounds with sulfydryl or the biomolecules, ultrasonic radiation is conducted on the oil phase loaded with the hydrophobic drugs and a chitosan water solution modified by the compounds with sulfydryl or the biomolecules, and the chitosan drug-loaded micro-capsule with the capsule wall provided with folic acid and the disulfide bond structure is obtained. The preparation method is rapid, easy and convenient, efficient, environmentally friendly and wide in material source, the product is pure and free of toxins, the drug loading capacity is large, the micro-capsule can be widely applied to covering the hydrophobic drugs, targeted conveyance of drugs is achieved through the targeting of folic acid, controllable release of the drugs is achieved through the reducing responsiveness of disulfide bonds, and good application prospects are achieved.

Owner:JILIN UNIV

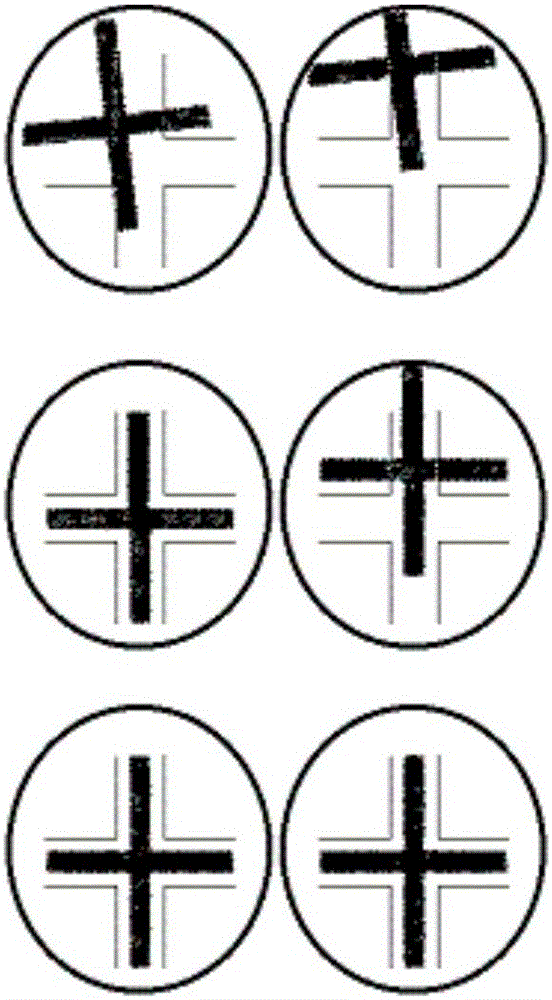

Alignment mark for silicon carbide device and preparation method thereof

InactiveCN105047547AReduce misuseReduce rework rateSemiconductor/solid-state device detailsSolid-state devicesBrightness perceptionIon implantation

The present invention discloses an alignment mark for a silicon carbide device and a preparation method thereof. The preparation method comprises the steps of carrying out ion implantation on the position where an alignment mark is to be marked at the surface of a silicon substrate to form an ion implantation area, making a difference of the brightness of an ion-implantation area and a non-ion-implantation area to form the alignment mark, wherein an ion implantation area which is aligned with the alignment mark is formed at the surface of the silicon substrate, and the brightness of the ion-implantation area and the non-ion-implantation area is different. According to the preparation method, by using the alignment mark formed on a wafer by using the ion implantation, the difference of the alignment mark and a background is large enough, the identification positioning can be realized through eyes and an image recognition device, thus wrong operations can be reduced, the rework rate is reduced, doped atoms are nearly not diffused in a silicon carbide material, and the possibility of pollution is little.

Owner:GLOBAL POWER TECH CO LTD

One-step adsorption method used for preparing protein microcapsules

ActiveCN108451924AEasy to introduceSimple preparation processMacromolecular non-active ingredientsMicroballoon preparationMicrometerBiocompatibility Testing

The invention relates to a one-step adsorption method used for preparing protein microcapsules, and belongs to the field of biomaterial. The one-step adsorption method is characterized in that: a polyphenol is adopted for doping of calcium carbonate micrometer particles, adsorption of protein is realized under mild conditions, crosslinking of the proteins adsorbed by the surfaces of the particlesis carried out, and at last calcium carbonate is removed so as to obtain the protein microcapsules. The advantages are that: the proteins used for preparing the protein microcapsules possess high universality; a plurality of times of assembling is not needed in preparation of the microcapsules; the one-step adsorption method is simple; preparation efficiency is high; conditions are mild; no impurity is introduced; the protein microcapsules possesses excellent biocompatibility and biodegradability, and is promising in medicine research and application prospect.

Owner:WENZHOU INST OF BIOMATERIALS & ENG

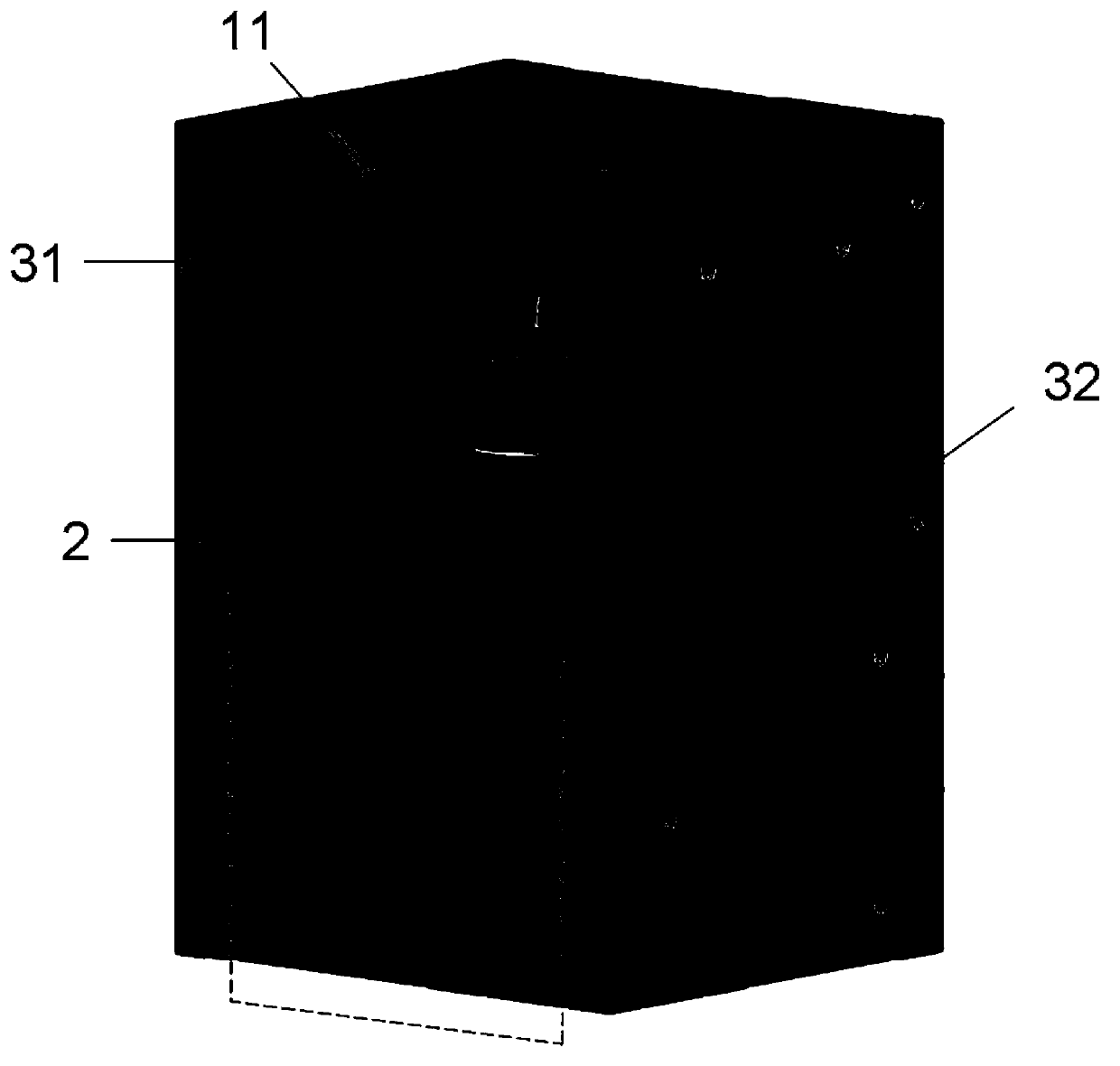

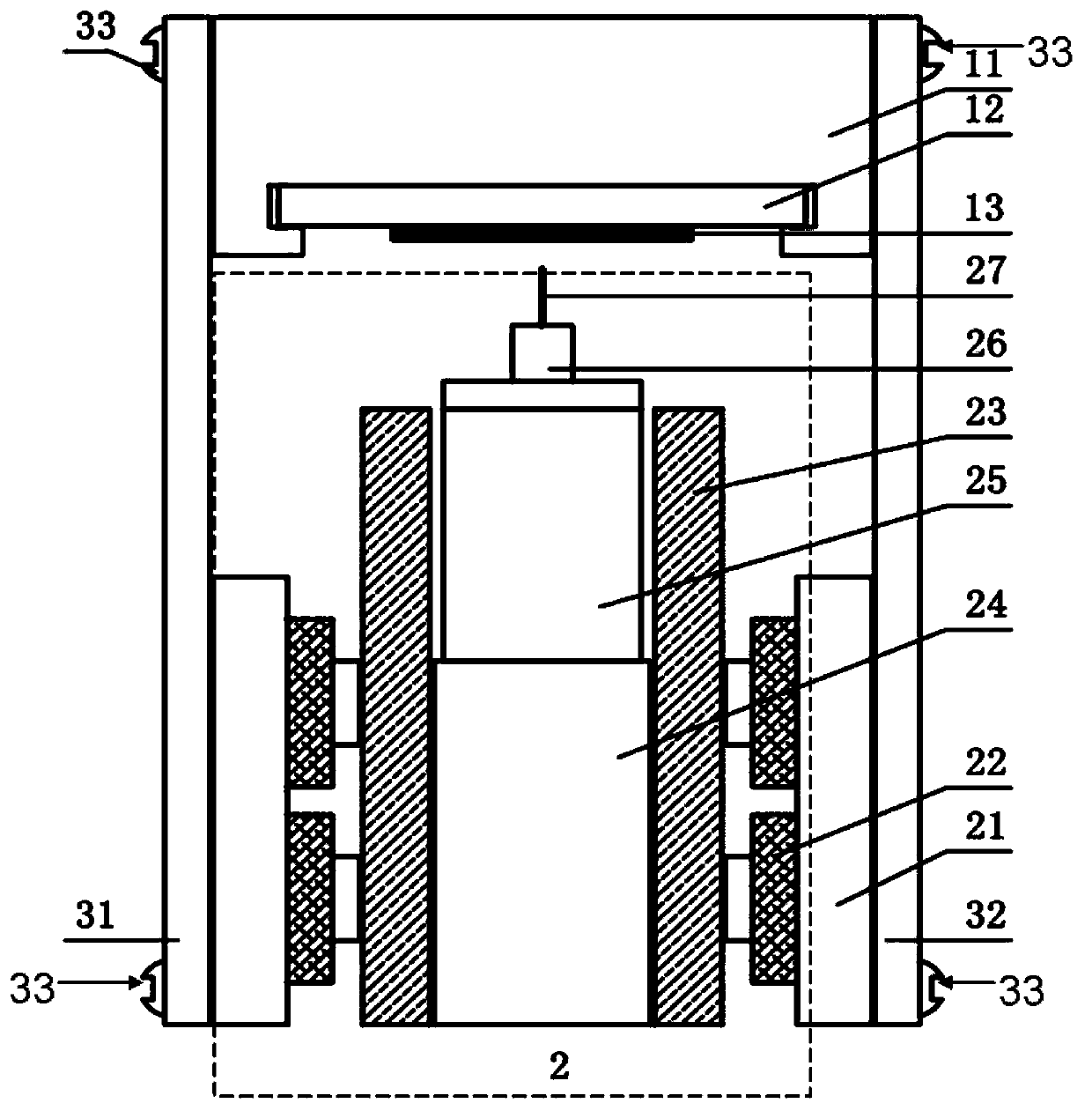

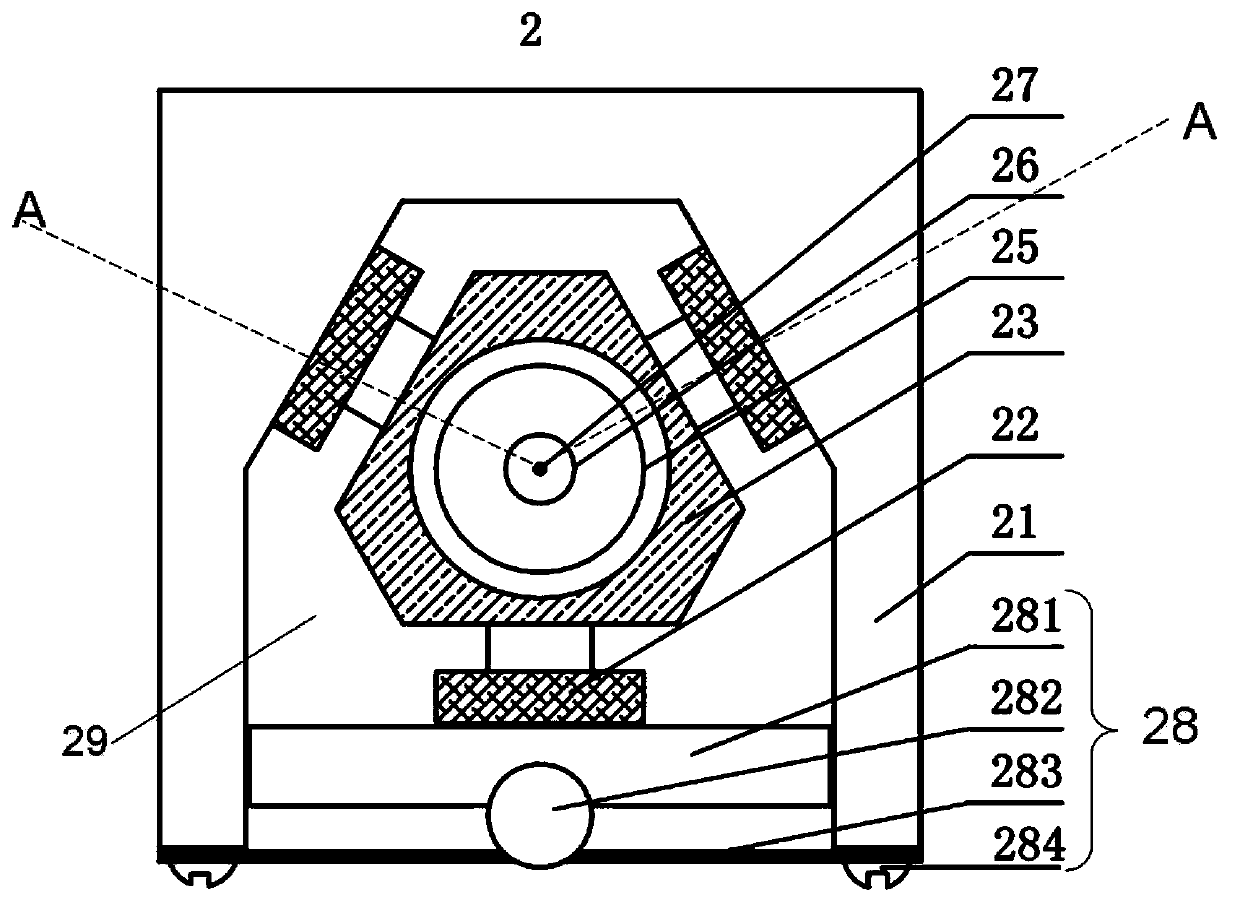

Scanning tunneling microscope scanning probe head

InactiveCN104181335AImprove stabilityImprove rigidityScanning probe microscopyScanning tunneling microscopeMicroscope

The invention provides a scanning tunneling microscope scanning probe head comprising a sample base which is used for bearing a sample; a scanning pedestal which is used for controlling a scanning probe; and a side plate which is used for rigidly connecting the sample base and the scanning pedestal.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Preparation method of nickel coated ceramic composite powder

ActiveCN108689726ASimple preparation processReduce manufacturing costCeramic compositeReaction temperature

The invention discloses a preparation method of nickel coated ceramic composite powder. The preparation method comprises the following steps that a fluidized bed reactor is heated to reaction temperature; ceramic powder is added into a fluidized bed; fluidized gas is mixed gas of argon gas and hydrogen gas; a nickel precursor is used as a nickel source; heating is performed to obtain nickel precursor steam; the nickel precursor steam is carried into the fluidized bed by using argon gas as carrier gas and takes chemical vapor deposition reaction with hydrogen gas in the fluidized bed; the nickel coated ceramic composite powder is obtained. The preparation technology process of the nickel coated ceramic composite powder provided by the invention is simple; the production cost is low; the amplification production and the continuous operation can be easily realized. The synthesized nickel coated particle powder has core-shell structure features; the interface combining capacity of metal nickel and particle powder is high; the abrasion resistant performance of a metal ceramic composite material is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

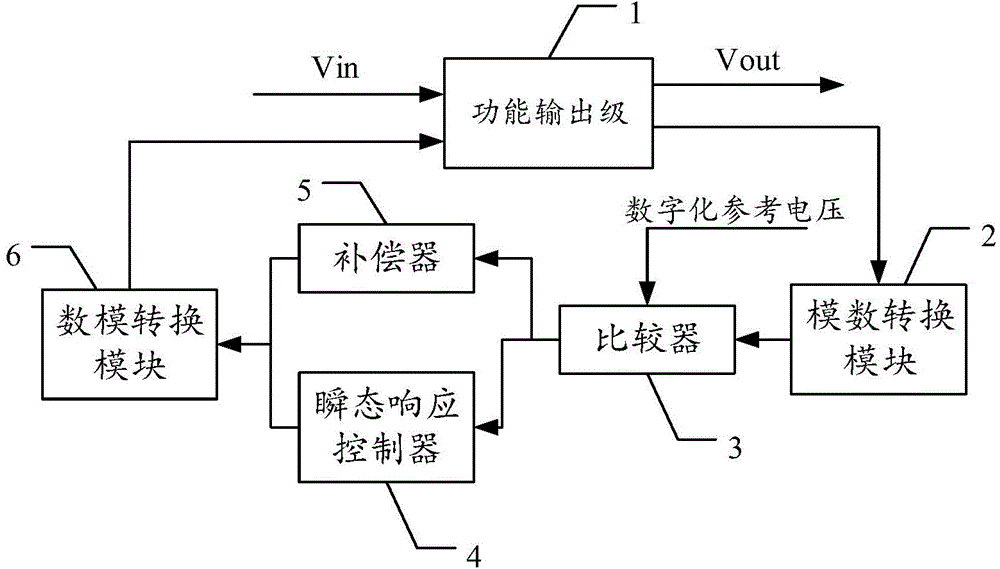

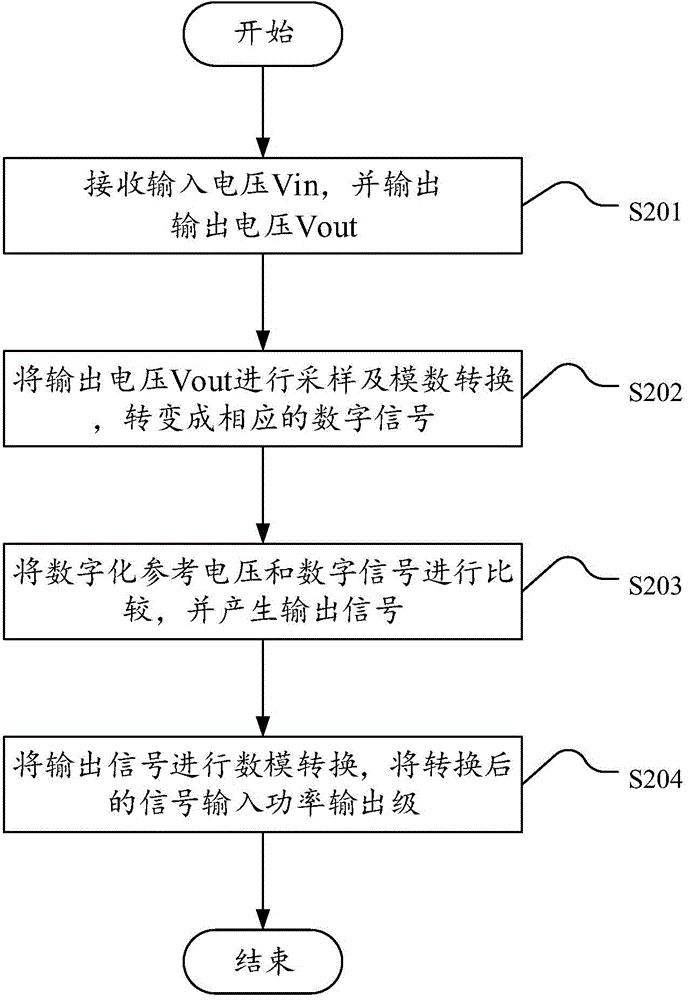

Numerically-controlled linear voltage regulator power supply circuit and method

ActiveCN104793681AImprove transient responseEasy to introduceElectric variable regulationDigitizationComparator

The embodiment of the invention discloses a numerically-controlled linear voltage regulator power supply circuit and method. The power supply circuit comprises a power output stage, an analog-to-digital conversion module, a comparator and a digital-to-analog conversion module. The power output stage is used for receiving input voltage and sending output voltage to the analog-to-digital conversion module. The analog-to-digital conversion module is used for receiving the output voltage sent by the power output stage, conducting sampling and analog-to-digital conversion on the output voltage, converting the output voltage into a corresponding digital signal and sending the digital signal to the comparator. The comparator is used for receiving digitization reference voltage and the digital signal sent by the analog-to-digital conversion module, comparing the digitization reference voltage with the digital signal, generating an output signal and sending the output signal to a compensator and a transient response controller. The digital-to-analog conversion module is used for conducting digital-to-analog conversion on the output signal and inputting the converted signal into the power output stage. By means of the numerically-controlled linear voltage regulator power supply circuit and method, multi-voltage power supply can be achieved in a chip, output of the power output stage can be controlled precisely, and transient response of a numerically-controlled linear voltage regulator is improved.

Owner:NEXWISE INTELLIGENCE CHINA LTD

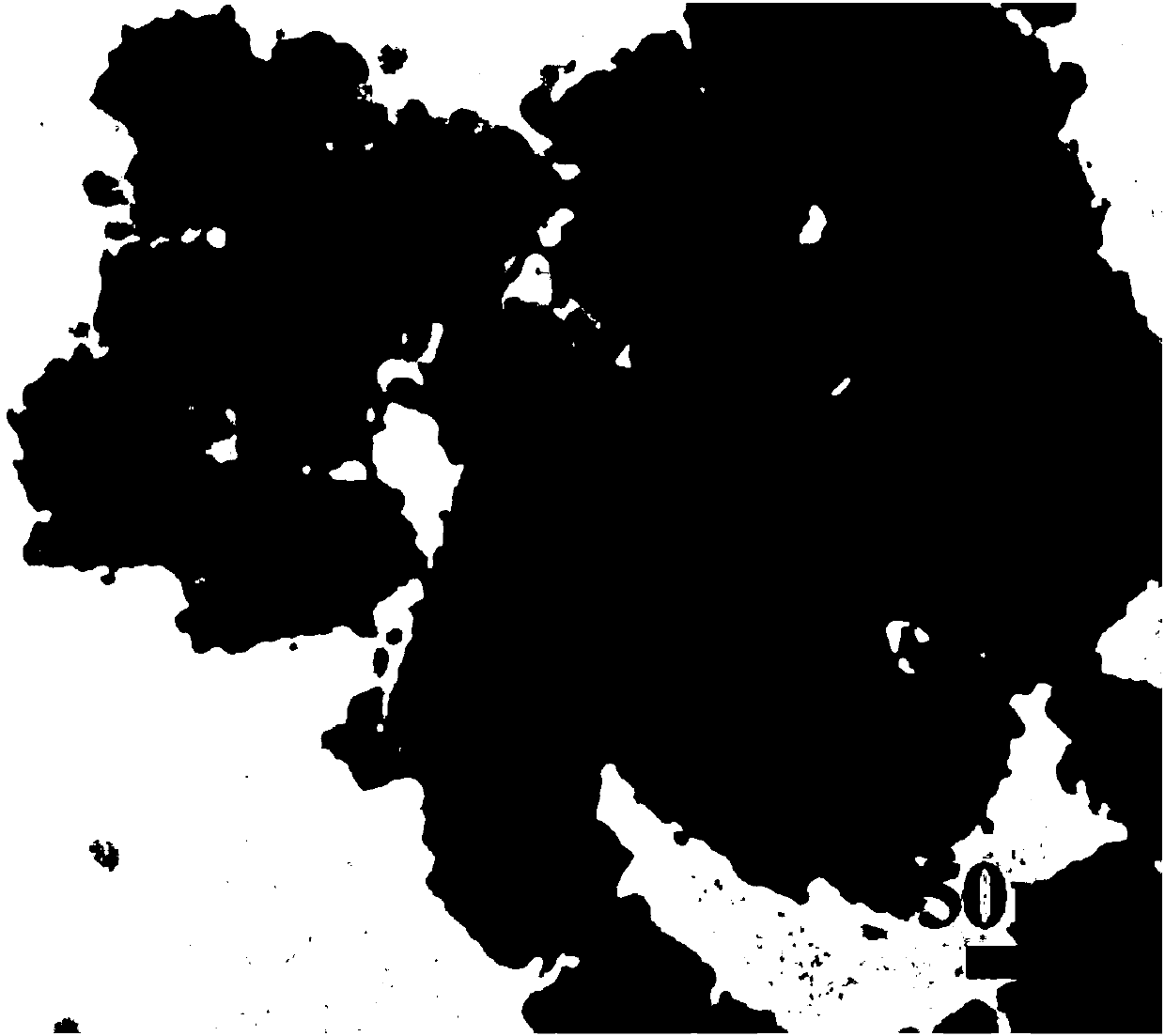

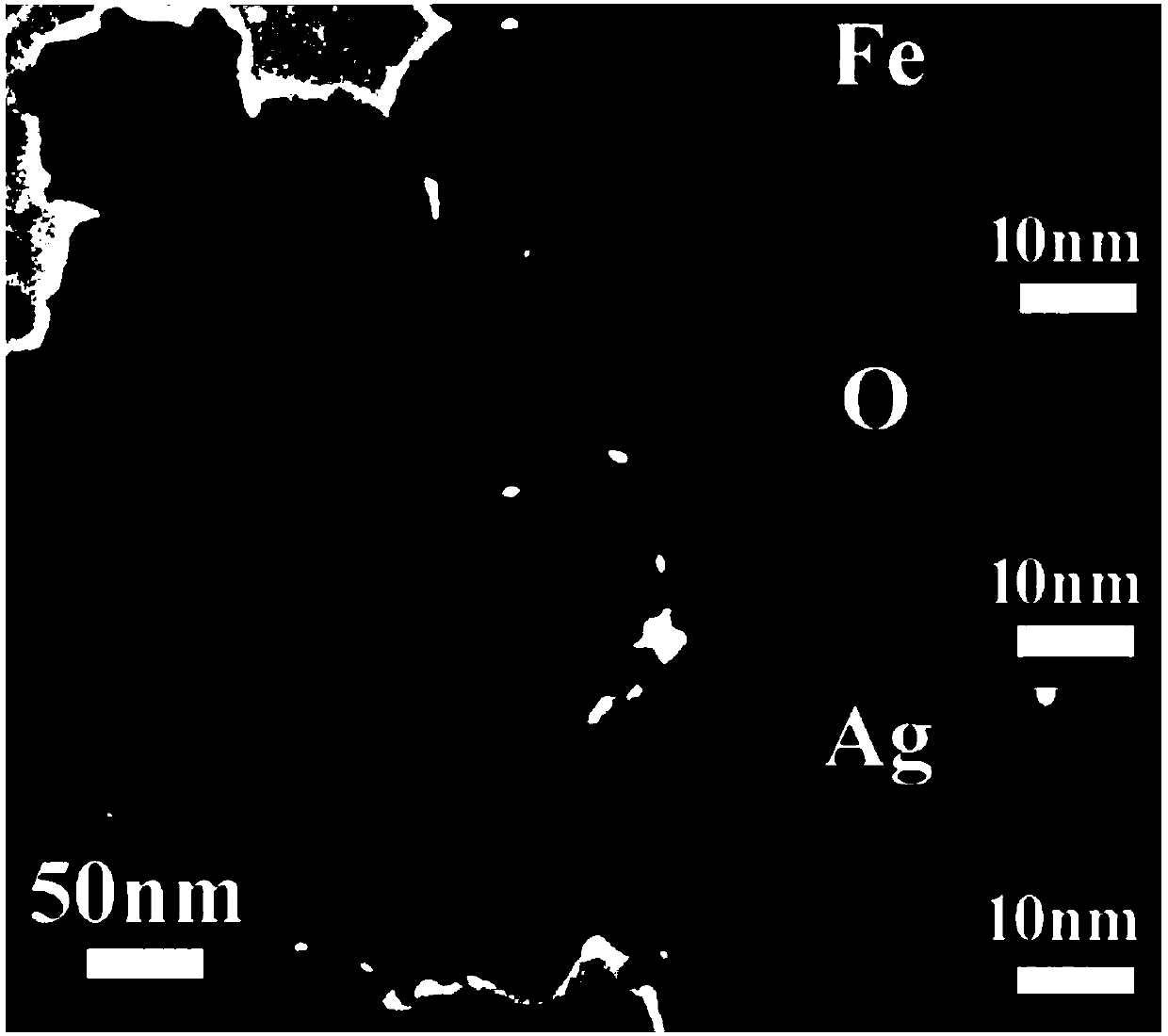

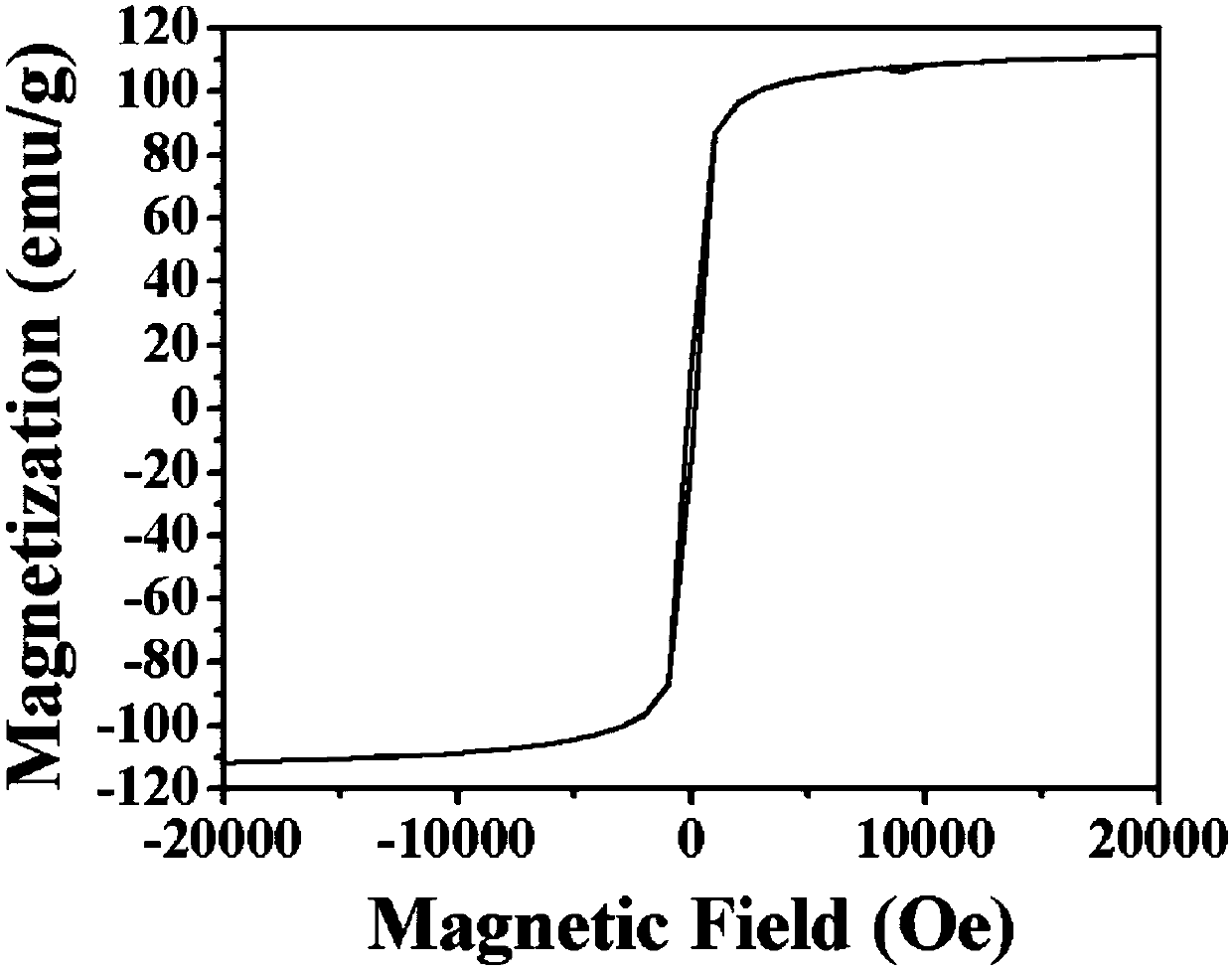

High-saturation-magnetization Fe3O4-Ag composite material and preparation method thereof

ActiveCN107617738AEasy to operateImprove controllabilityMaterial nanotechnologyInorganic material magnetismNanoparticleMagnetization

The invention discloses a high-saturation-magnetization Fe3O4-Ag composite material and a preparation method thereof, and belongs to the technical field of magnetic functional materials. In order to solve the problem that saturation magnetization of the Fe3O4-Ag composite material prepared by the preparation method is greatly reduced in comparison with that of Fe3O4, the high-saturation-magnetization Fe3O4-Ag composite material takes PEI-DTC as a bonding layer to modify Fe3O4 nano-particles, and a method for regulating the pH value of a solution is utilized for preparing Ag nano-particles withdimensions smaller than 10 nm. A seed growth method is utilized to prepare the Fe3O4-Ag composite material, so that operation is simple, controllability is strong and repeatability is good; and the prepared Fe3O4-Ag composite material is uniform in grain size and is good in dispersion; and silver particles are uniformly deposited on the Fe3O4 nano-particles, so that saturation magnetization of the Fe3O4-Ag nano-particles is 70-72 emu / g.

Owner:JILIN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com