Preparation method of critical material for absorbing layer of thin film solar cell

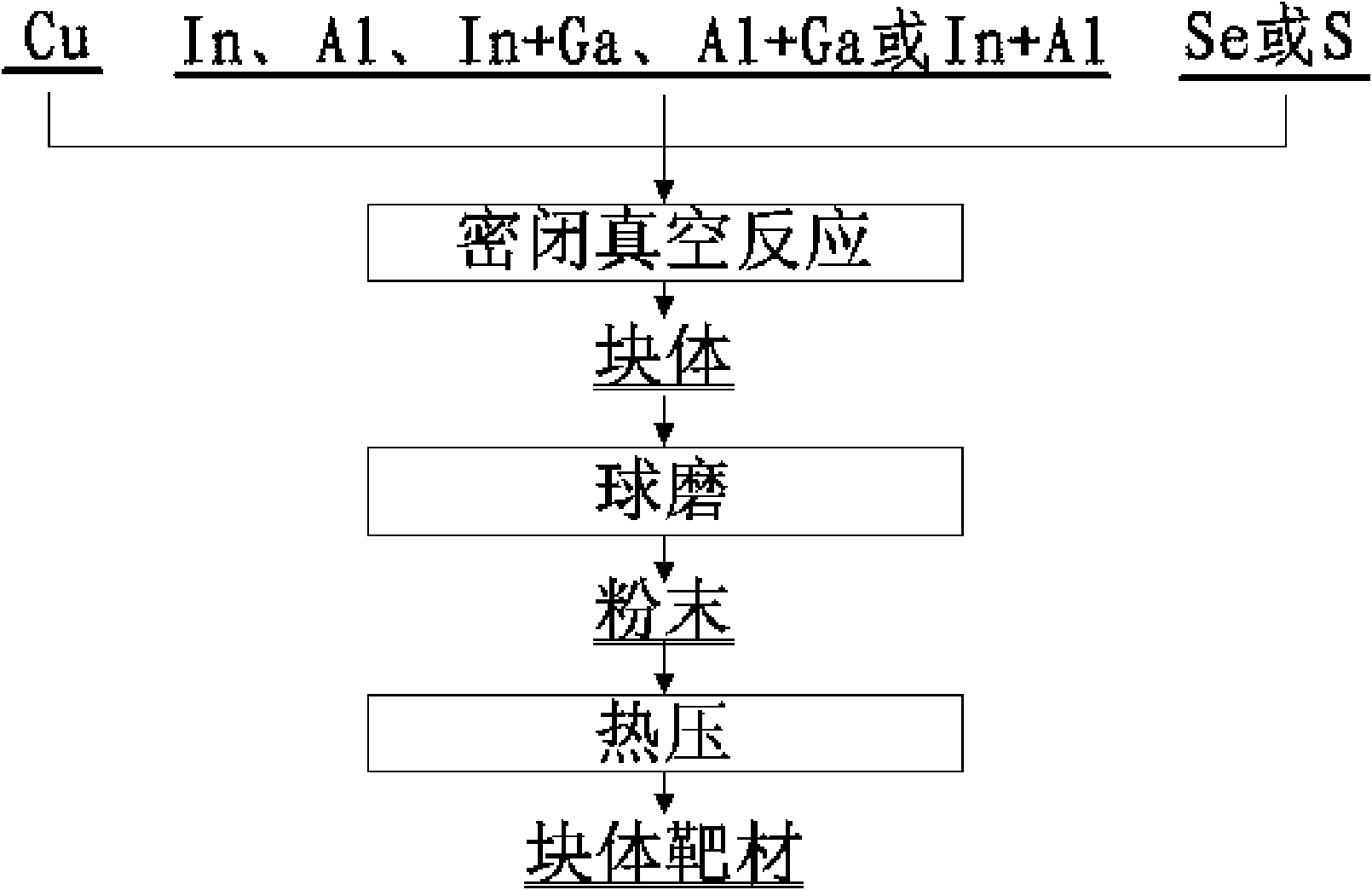

A technology for solar cells and key materials is applied in the field of preparation of key materials for absorption layers of thin-film solar cells, and can solve the problems of inability to meet the requirements for preparation of absorption layers of thin-film solar cells, uneven distribution of element concentrations, and large differences in composition, and the like. The effect of easy control of element ratio, uniform composition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Put Cu powder, In block, and Se block with a purity of 99.98% in a molar ratio of Cu:In:Se=1:1:2, and put them into an autoclave lined with alumina ceramics. -3 Close the autoclave under Pa vacuum condition.

[0022]The temperature of the autoclave was adjusted to 1050° C. for 2 hours, and then slowly cooled to room temperature within 8 hours. The prepared block was taken out from the autoclave and then ball-milled, and the powder was sieved into 400-mesh grade to obtain CuInSe 2 Powder, powder purity greater than 99.9%.

[0023] Put the prepared powder into a mold with a diameter of 76mm and press it in a hot-press sintering furnace at 850°C and 150MPa, and then process it into a target with a diameter of 70mm. The target density can reach 99.1%.

Embodiment 2

[0025] Put Cu powder with a purity of 99.995%, In block and S block in a ratio of 400g according to the molar ratio of Cu:In:S=1:1:2, and then put them into a reaction tank lined with zirconia ceramics. -3 Close the reaction tank under Pa vacuum condition.

[0026] The reaction tank sealed under vacuum was adjusted to a temperature of 1010° C. for 8 hours, and then slowly cooled to room temperature within 8 hours. The prepared block was taken out from the reaction tank and ball milled, and the powder was sieved into -200 mesh grade to obtain CuInS 2 Powder, powder purity greater than 99.99%.

[0027] Put the prepared powder into a mold with a diameter of 70mm and press it in a hot-press sintering furnace under the conditions of 860°C and 110MPa, and then process it into a target with a diameter of 60mm. The density of the target can reach 99.2%.

Embodiment 3

[0029] Put Cu powder, Al powder, and Se blocks with a purity of 99.98% in a molar ratio of Cu:Al:Se=1:1:2 to 700g, put them into a reaction kettle lined with alumina ceramics, and fill the The autoclave was sealed with pressured argon.

[0030] The reaction kettle filled with argon was adjusted to a temperature of 1100° C. for 2.5 hours, and then slowly cooled to room temperature within 8 hours. The prepared block was taken out from the reactor and then ball-milled, and the powder was sieved into -300 mesh grade to obtain CuAlSe 2 Powder, powder purity greater than 99.9%.

[0031] Put the prepared powder into a mold with a diameter of 320mm and press it in a hot-press sintering furnace under the conditions of 870°C and 70MPa to process it into a target with a diameter of 300mm, and the target density can reach 98.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com