Metal-based nano composite powder material, preparation method and application thereof

A metal powder and nano-composite technology, applied in metal processing equipment, additive processing, transportation and packaging, etc., to achieve the effects of good fluidity, high sphericity, and high bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0051] In a first exemplary embodiment of the present disclosure, a method for preparing a metal matrix nanocomposite powder material is provided.

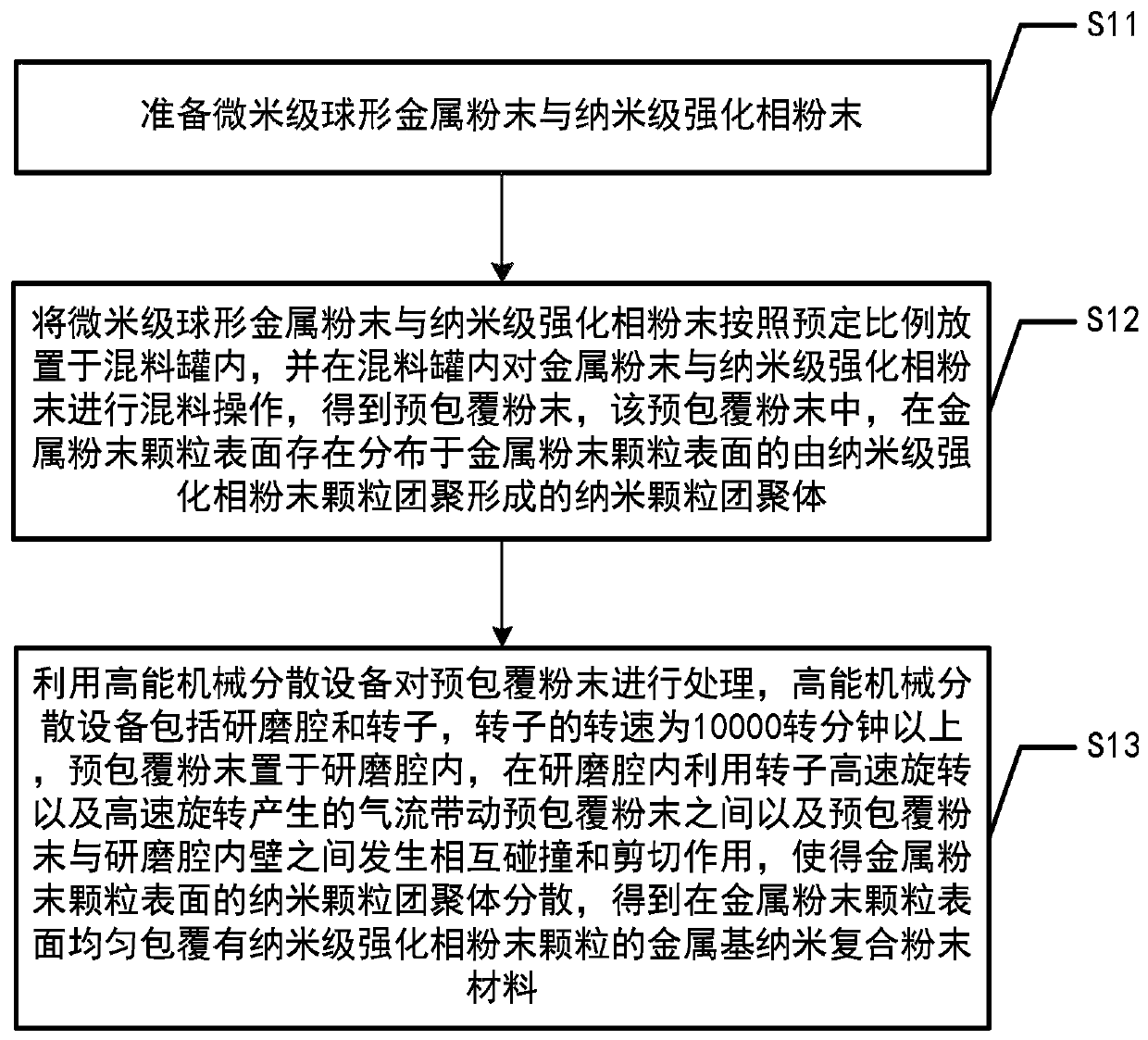

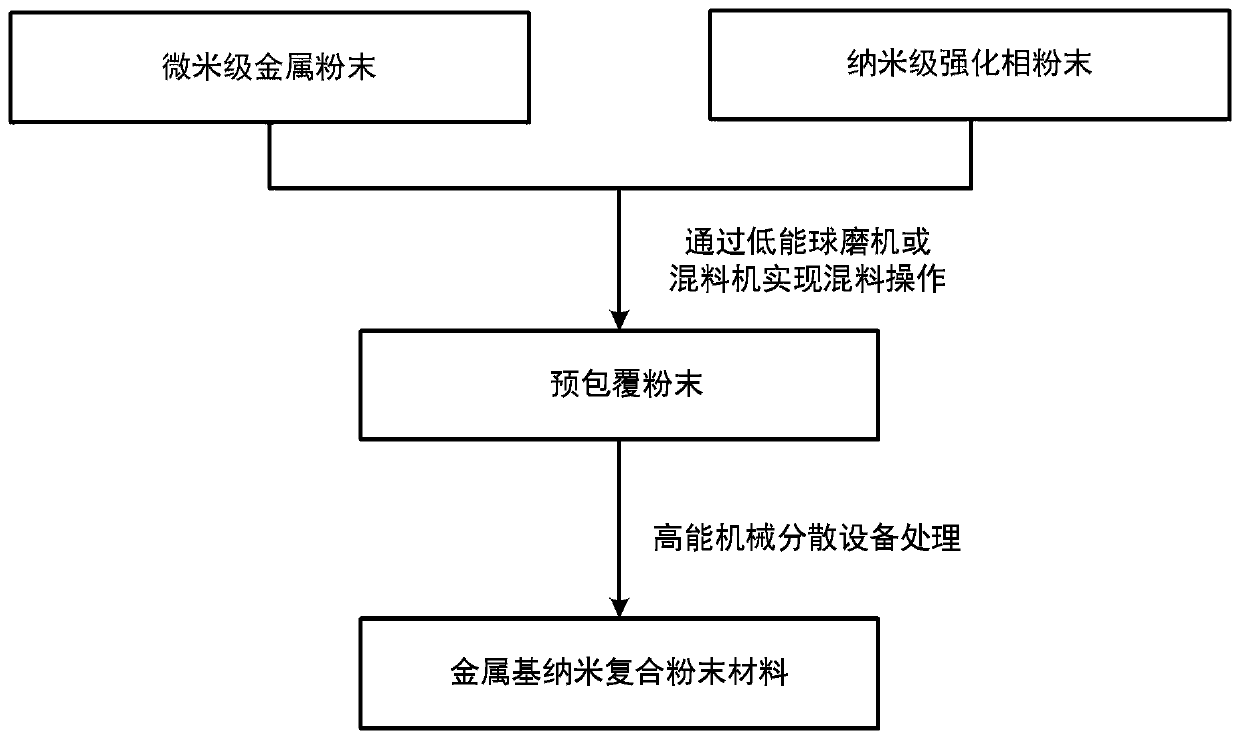

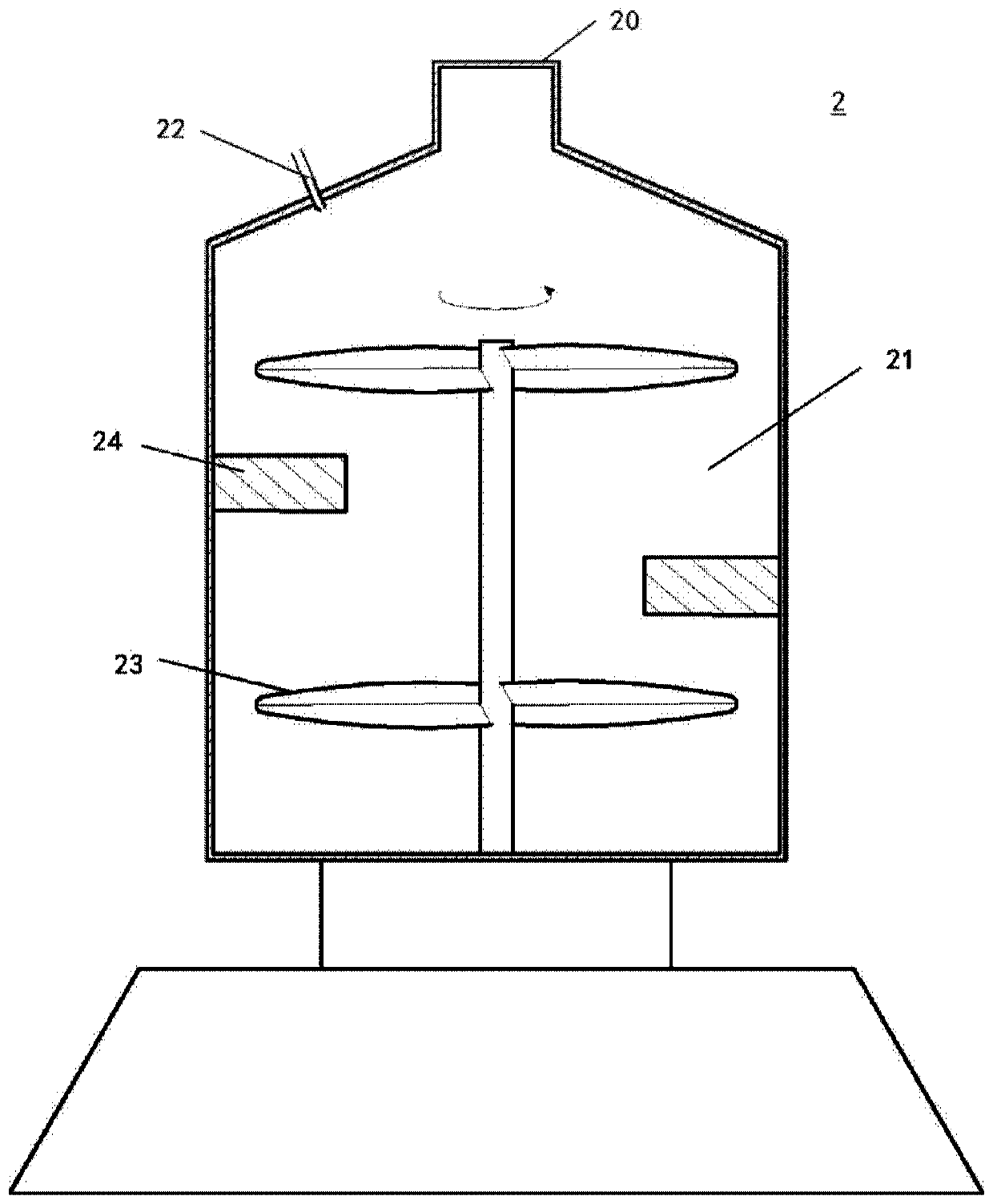

[0052] figure 1 It is a flowchart of a method for preparing a metal-based nanocomposite powder material according to an embodiment of the present disclosure. figure 2 For such figure 1 Schematic diagram of the implementation of the preparation method of the metal-based nanocomposite powder material shown.

[0053] refer to figure 1 and figure 2 As shown, the preparation method of the metal-based nanocomposite powder material in this embodiment includes: step S11, step S12 and step S13.

[0054] In step S11, micron-scale spherical metal powder and nano-scale reinforcing phase powder are prepared.

[0055] In the step S11 , it includes: sieving the micron-sized spherical metal powder to obtain the micron-sized spherical metal powder with a particle size of 20 μm˜60 μm.

[0056] In an embodiment of the present disclosure, the...

no. 2 example

[0088] In a second exemplary embodiment of the present disclosure, a metal matrix nanocomposite powder material is provided, the metal matrix nanocomposite powder is prepared by the above preparation method.

[0089] The metal-based nanocomposite powder material is a composite material of micron-scale spherical metal powder and nano-scale strengthening phase powder, wherein the micron-scale spherical metal powder includes several spherical metal powder particles; the surface of the metal powder particles is evenly coated with non-agglomerated nano-scale strengthening phase powder particles.

[0090] In one embodiment, the tungsten-based composite powder prepared by the above preparation method is taken as an example.

[0091] In this embodiment, spherical tungsten powder with a particle size of 20 μm to 30 μm and La with a particle size of 40 nm 2 o 3 The powder is used as raw material, with 99% by mass of spherical tungsten powder, 1% of La 2 o 3The powder is the material...

no. 3 example

[0099] In the third exemplary embodiment of the present disclosure, a raw material for metal additive manufacturing, powder injection molding and other powder metallurgy is provided, which is prepared by any of the above-mentioned preparation methods or includes any of the above-mentioned metal-based Nanocomposite powder materials. Due to the good fluidity and high bulk density of the metal-based nanocomposite powder materials prepared by the above preparation method, they can be used as raw materials for metal additive manufacturing, powder injection molding or other powder metallurgy processes, and can solve the problem of high-energy ball milling in the preparation of composite powders. The technical problems of poor fluidity, easy introduction of impurities, and the difficulty of preparing composite powders uniformly coated with reinforcing phase particles without agglomeration by conventional coating technology.

[0100] To sum up, the present disclosure provides a metal-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com