Nanophase doped bismuth telluride-based thermoelectric material and preparation method thereof

A bismuth telluride-based, thermoelectric material technology, applied in chemical instruments and methods, polycrystalline material growth, self-regional melting method, etc., can solve problems such as inability to disperse, achieve improved ZT value, improved thermoelectric properties, and improved mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

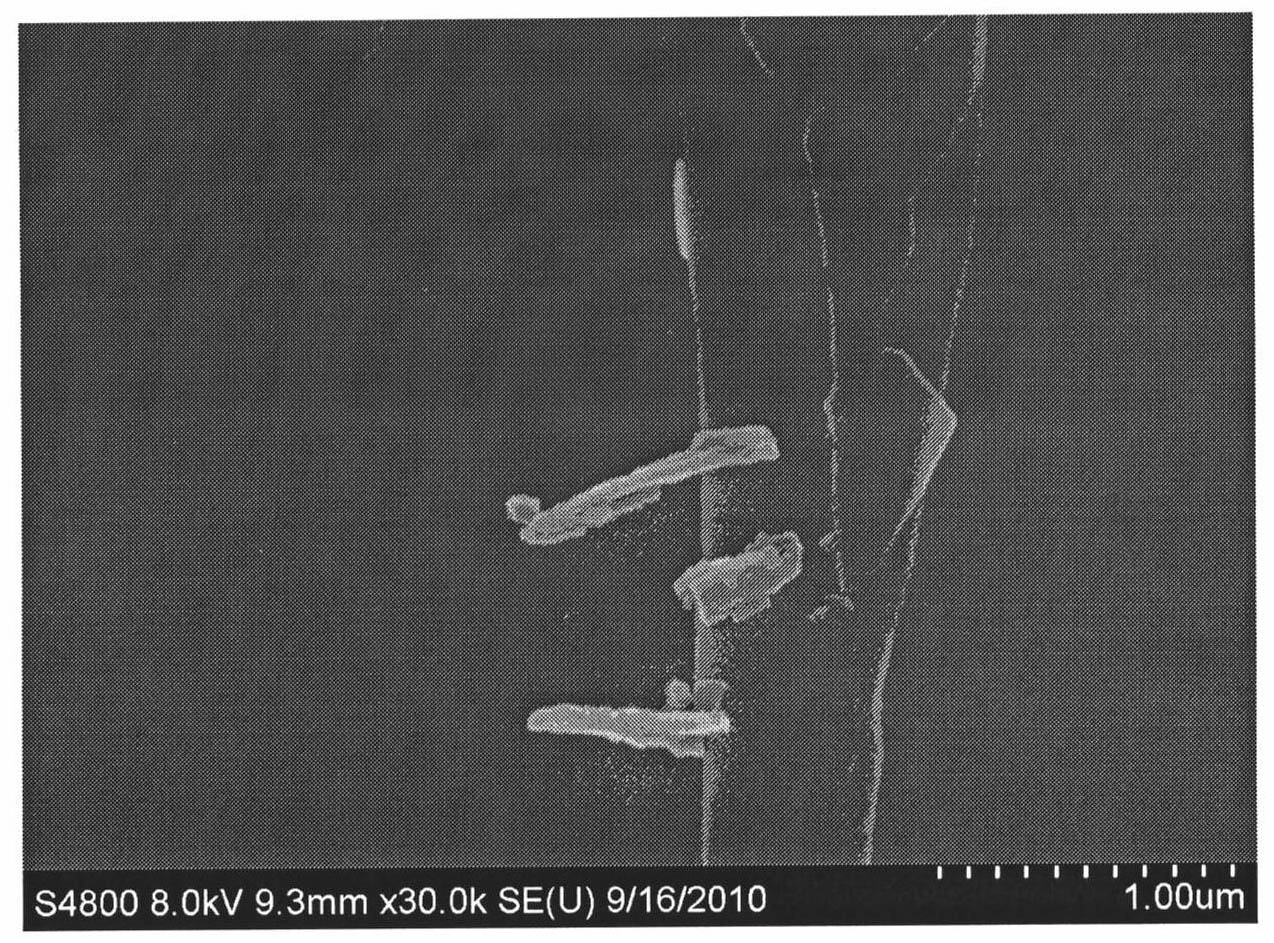

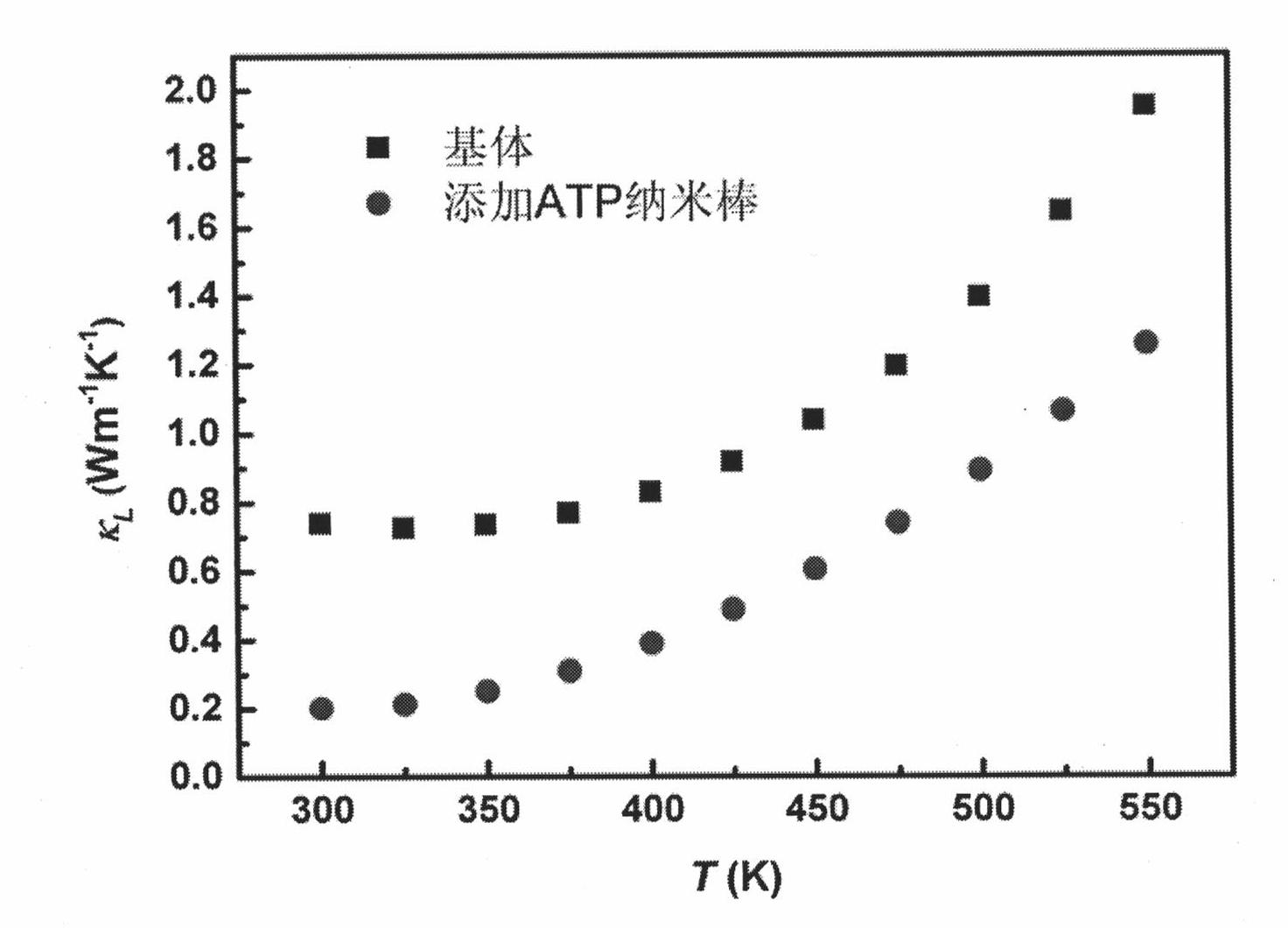

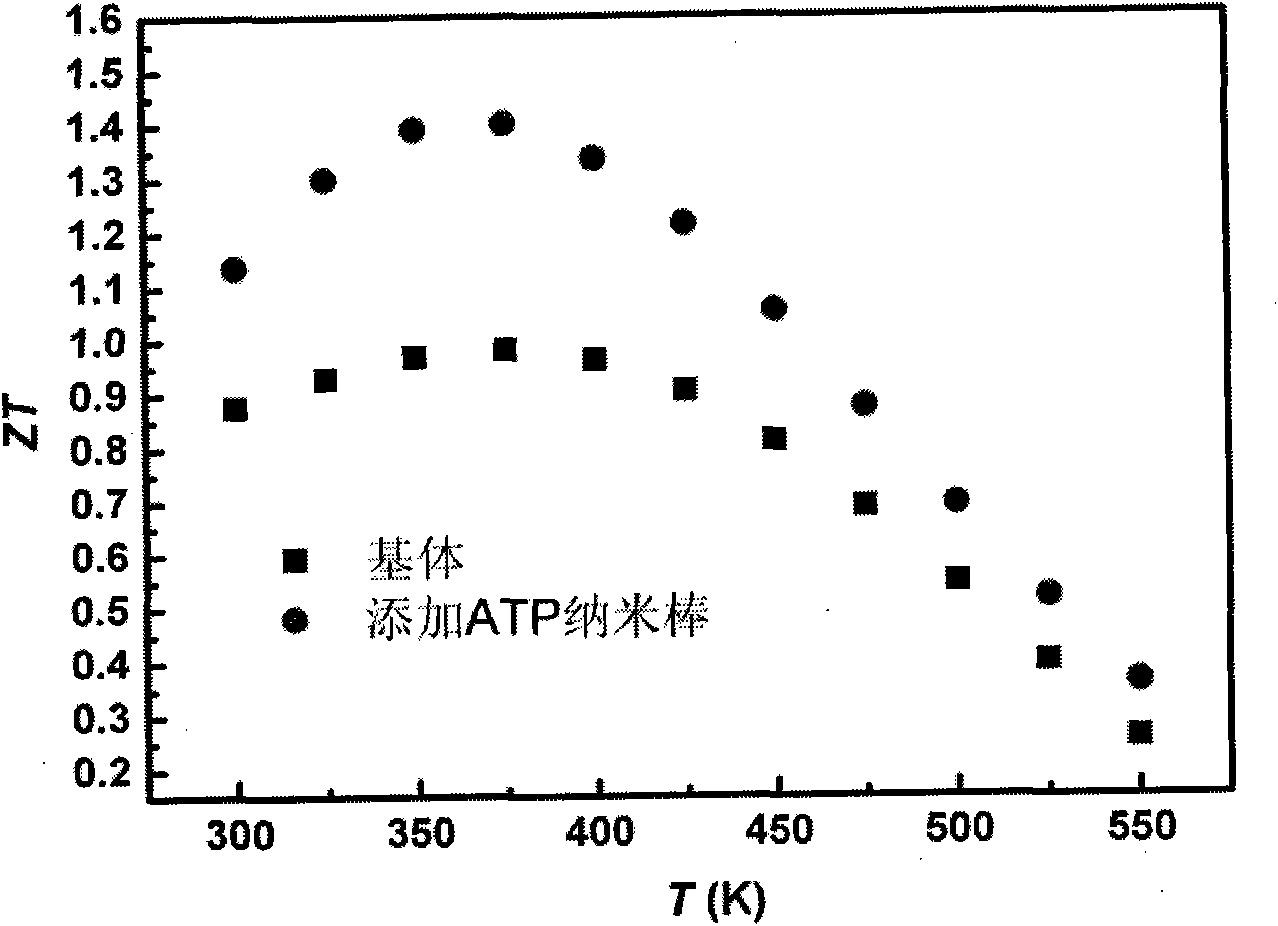

[0028] The bismuth telluride-based thermoelectric material doped with nanophase is based on the bismuth telluride-based thermoelectric material composed of tellurium element, bismuth element and antimony element. The chemical molecular formula of the matrix is (Bi 0.22 Sb 0.78 ) 2 Te 3 , the one-dimensional nano-phase attapulgite is doped in the matrix, and the attapulgite is referred to as ATP, and the mass of the one-dimensional nano-phase attapulgite accounts for 0.5% of the mass of the matrix.

[0029] The preparation method of the bismuth telluride-based thermoelectric material doped with the nanometer phase is as follows:

[0030] Step 1: According to (Bi 0.22 Sb 0.78 ) 2 Te 3 In the stoichiometric ratio, take high-purity matrix raw materials tellurium, bismuth and antimony blocks, and weigh attapulgite powder according to the mass of one-dimensional nano-phase attapulgite accounting for 0.5% of the mass of the matrix;

[0031] Step 2: Put the one-dimensional na...

Embodiment 2

[0038] The bismuth telluride-based thermoelectric material doped with nanophase is based on the bismuth telluride-based thermoelectric material composed of tellurium element, bismuth element and antimony element. The chemical molecular formula of the matrix is (Bi 0.22 Sb 0.78 ) 2 Te 3 , the one-dimensional nano-phase attapulgite is doped in the matrix, and the mass of the one-dimensional nano-phase attapulgite accounts for 0.05% of the mass of the matrix.

[0039] The preparation method of the bismuth telluride-based thermoelectric material doped with the nanometer phase is as follows:

[0040] Step 1: According to (Bi 0.22 Sb 0.78 ) 2 Te 3 In the stoichiometric ratio, take high-purity matrix raw materials tellurium, bismuth and antimony blocks, and weigh attapulgite powder according to the mass of one-dimensional nano-phase attapulgite accounting for 0.05% of the mass of the matrix;

[0041] Step 2: Put the one-dimensional nano-phase attapulgite powder that has been...

Embodiment 3

[0047] The bismuth telluride-based thermoelectric material doped with nanophase is based on the bismuth telluride-based thermoelectric material composed of tellurium, bismuth, antimony and iodine as the matrix. The chemical formula of the matrix is (Bi 0.92 Se 0.08 ) 2 Te 3 / 0.15wt.%TeI 4 , namely TeI 4 Accounting for 0.15% of the mass of the matrix, the matrix is doped with single-arm carbon nanotubes (SCNT), and the mass of the single-arm carbon nanotubes accounts for 0.5% of the mass of the matrix.

[0048] The preparation method of the bismuth telluride-based thermoelectric material doped with the nanometer phase is as follows:

[0049] Step 1: According to (Bi 0.92 Se 0.08 ) 2 Te 3 / 0.15wt.%TeI 4 In the stoichiometric ratio, take high-purity matrix raw material tellurium, bismuth and antimony blocks, weigh the single-arm carbon nanotube powder according to the mass of the single-arm carbon nanotube accounts for 0.5% of the mass of the matrix;

[0050] Step 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com