Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

167 results about "Antimony compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antimony forms chemical compounds in three oxidation states: -3, +3, and +5. -3 compounds are called antimonides. They are made by reacting antimony with other metals. They react with acids to make the toxic and unstable gas stibine.

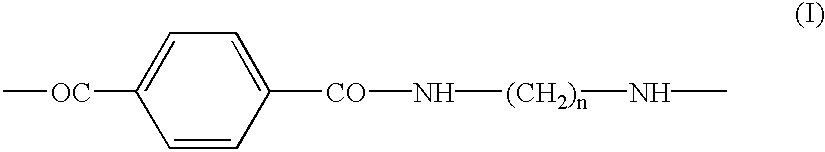

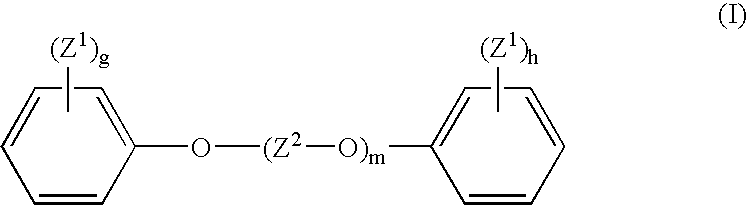

Polyester polymerization catalyst, polyester produced by using the same, and process for producing polyester

ActiveUS7144614B2Improve thermal stabilityPrevent thermal degradationWrappers shrinkageAnimal housingPolyesterFiber

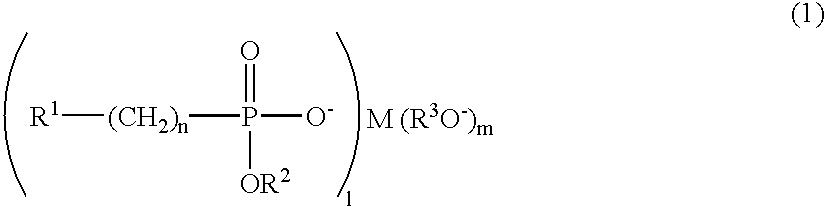

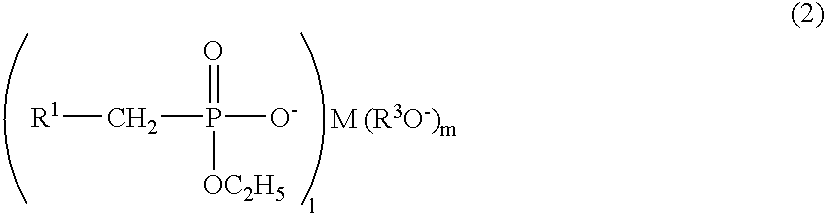

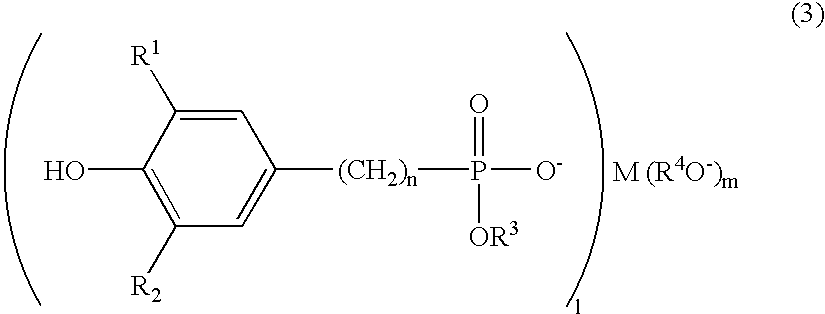

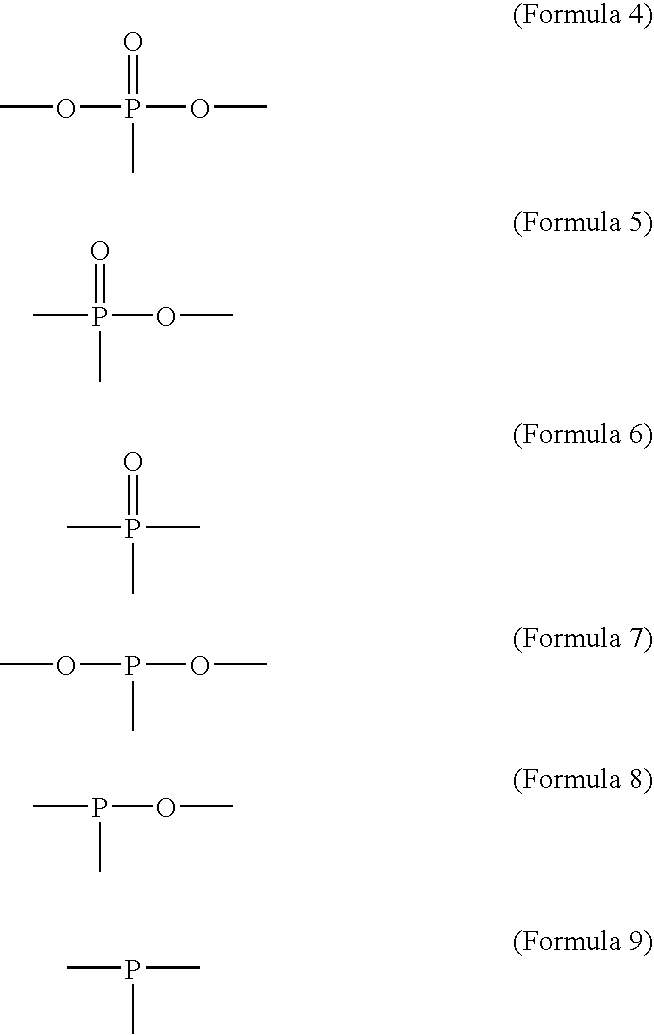

This invention provides a novel polymerization catalyst other than antimony compounds, polyester produced by using the same and a process for producing polyester. The polycondensation catalyst of this invention is a polyester polymerization catalyst comprising an aluminum compound and a phosphorus compound having a specific structure. Further, this invention relates to polyester produced by using this polyester polymerization catalyst and a process for producing polyester. Further, this invention relates to fibers, films and hollow molded articles comprising the polyester.

Owner:TOYO TOYOBO CO LTD

Arsenic and antimony free, titanium oxide containing borosilicate glass and methods for the production thereof

ActiveUS20130207058A1Well formedGood chemical resistanceGlass drawing apparatusGlass forming apparatusAntimony compoundsSelenium Compound

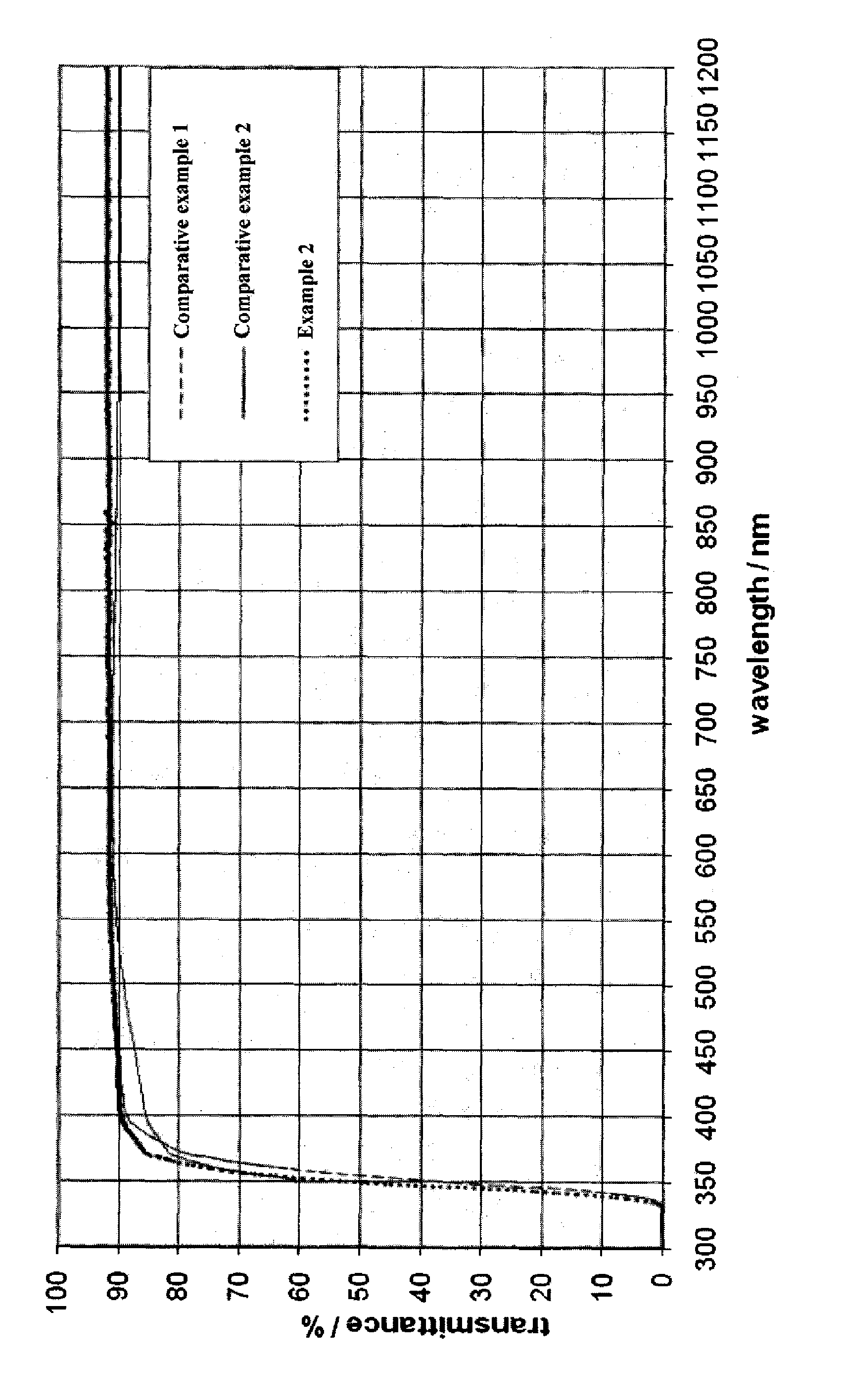

Titanium oxide containing borosilicate glasses, which have been produced without the use of arsenic and antimony compounds, are provided. An environmentally friendly refining method for providing titanium oxide containing borosilicate glass is also provided. The method includes using oxygen containing selenium compounds as refining agents to provide glasses with good transmittance values in the infrared range and show no disturbing discolorations. The glasses of the present disclosure are particularly suitable for the production of IR light conductors, cover glasses for photo sensors, and UV filters.

Owner:SCHOTT AG

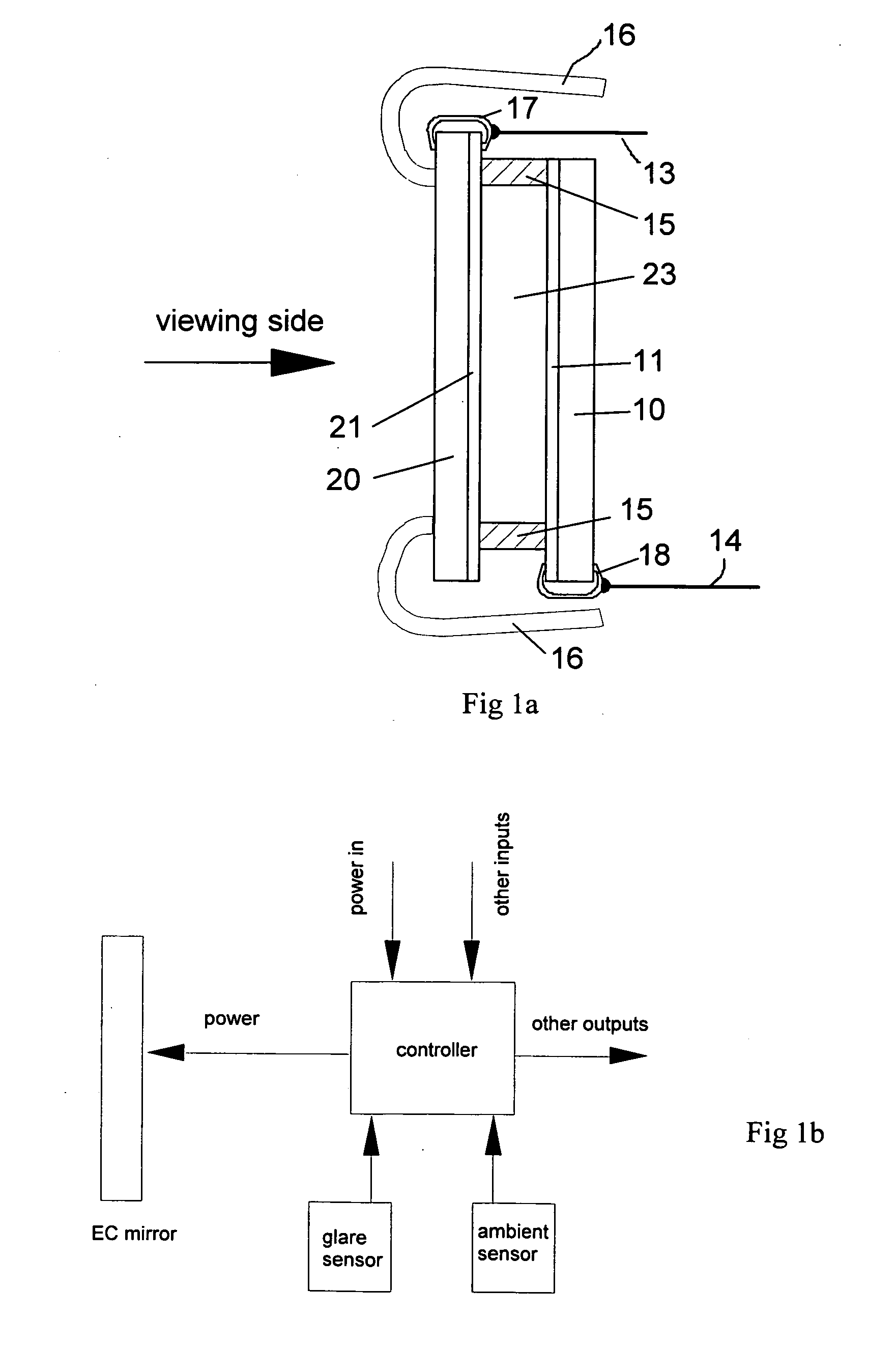

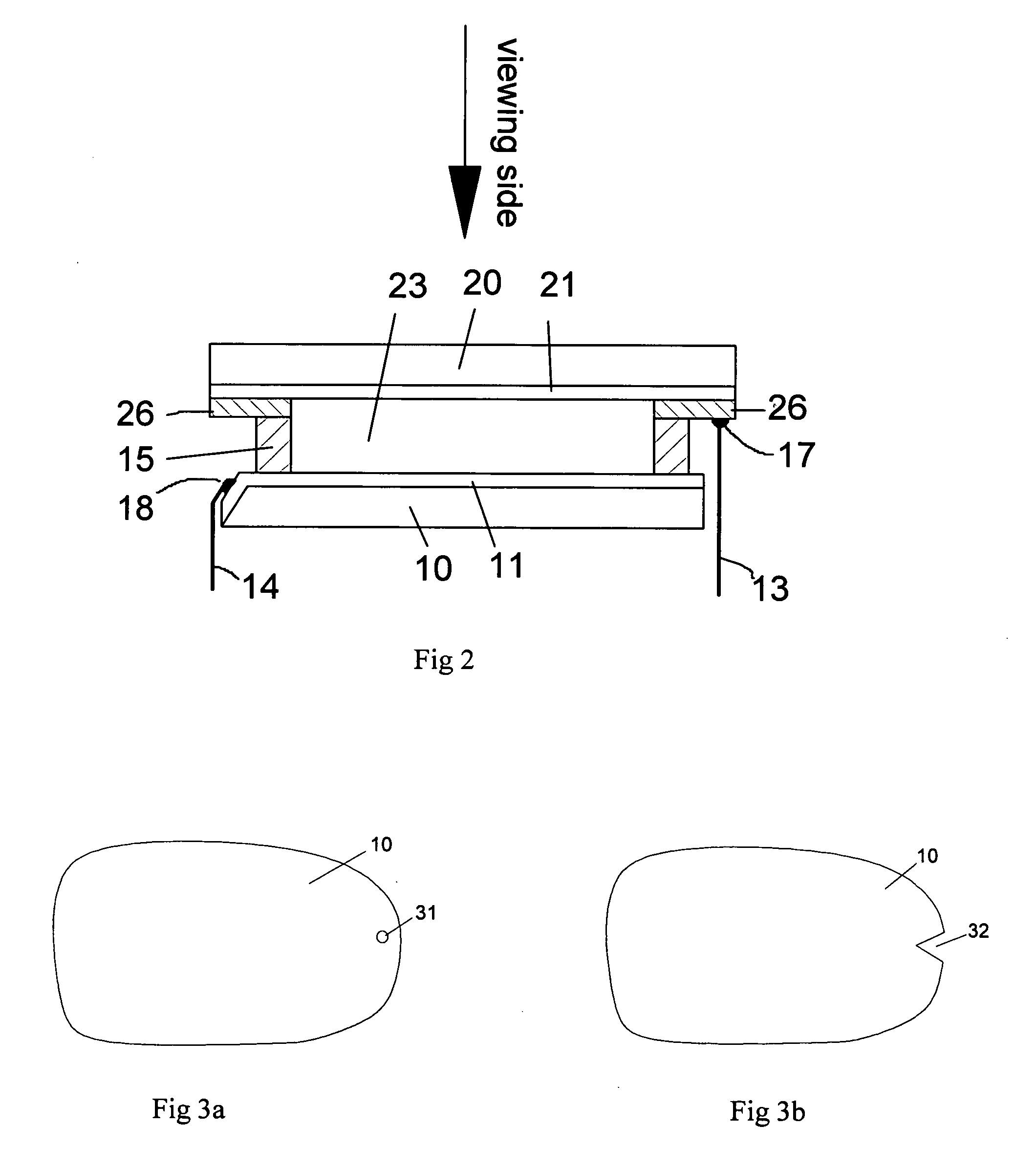

Environmentally safe electrochromic mirrors

This invention recognizes the hazards of beryllium and beryllium oxide in automotive applications and offers alternative material solutions. In particular, commercial electrochromic mirrors use beryllium comprising alloys for busbars and may also use beryllium oxide for the electronics used to power and control these mirrors. Further, this can be combined by reducing other known hazards such as mercury, cadmium, lead and antimony compounds.

Owner:AJJER

Flame-retardant, antistatic polyester resin composition

PCT No. PCT / JP97 / 03541 Sec. 371 Date Jun. 5, 1998 Sec. 102(e) Date Jun. 5, 1998 PCT Filed Oct. 2, 1997 PCT Pub. No. WO98 / 15596 PCT Pub. Date Apr. 16, 1998A polyester-type resin composition which has sufficient anti-static property and flame-retardant property, in addition to maintaining mechanical strength and thermal resistance and which is useful for, in particular, electrical and electronic mechanical parts field. The flame-retardant anti-static polyester-type resin composition of the present invention comprises 100 parts by weight of a thermoplastic polyester (A), from 1 to 35 parts by weight of a bromine-type flame-retardant (B), from 0.1 to 5 parts by weight of an antimony compound (C) and from 3 to 12 parts by weight of conductive carbon black (D), wherein the Br / Sb weight ratio in said polyester-type resin composition is in a range from 5.5 / 1 to 35.0 / 1. Moreover, a reinforcing filler (E), a crystallizing accelerator (F) and a multifunctional compound (G) can be added in further to the said polyester-type resin composition.

Owner:KANEKA CORP

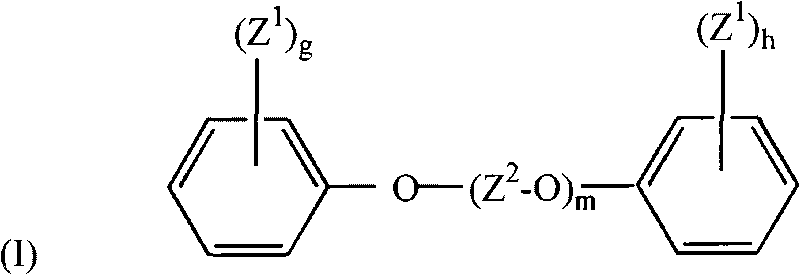

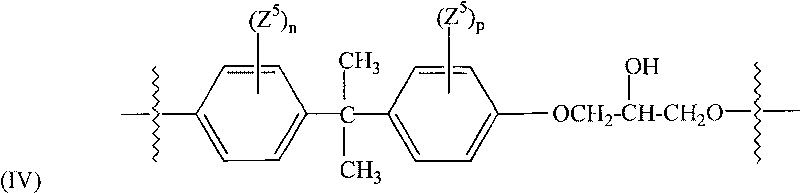

Flame retardant epoxy resin compositions

InactiveUS6143423AImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEpoxyCarbon number

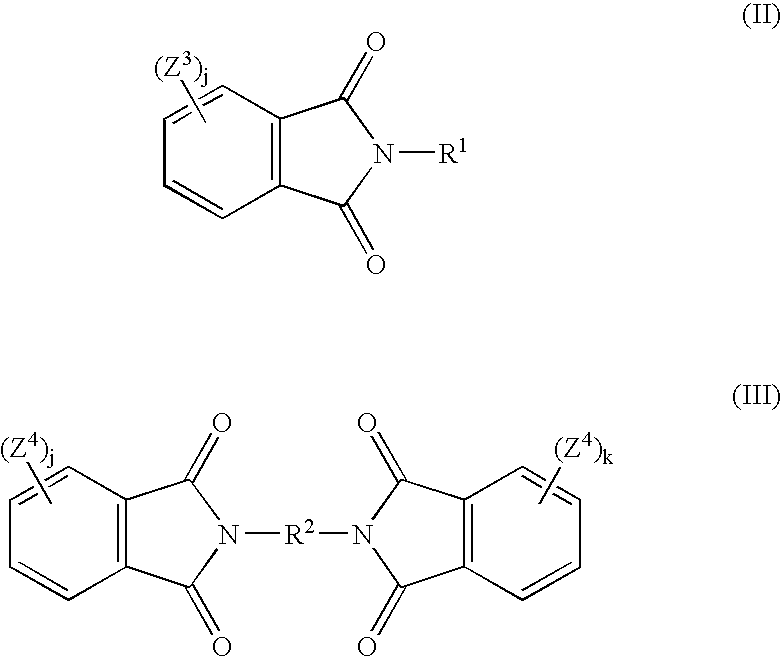

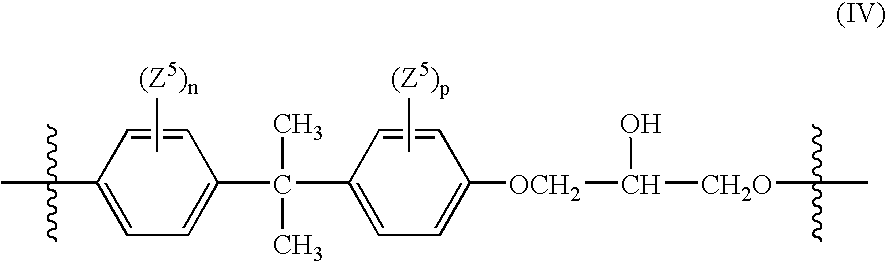

An epoxy resin composition contains (A) an epoxy resin having an epoxy equivalent of at least 185 and possessing a skeleton having a structure in which two benzene rings are conjugable to each other directly or via an aliphatic unsaturated double bond, carbon atoms having an atomic orbital of SP2 type accounting for at least 50% of the carbon number, (B) a phenolic resin having a hydroxyl equivalent of at least 160, carbon atoms having an atomic orbital of Sp2 type accounting for at least 85% of the carbon number, (C) a polyimide resin in an amount of 1-20 parts by weight per 100 parts by weight of components (A) and (B) combined, and (D) 70-85% by volume of the entire composition of an inorganic filler. The composition cures into products having flame retardancy and high-temperature reliability even though it is free of bromine compounds and antimony compounds.

Owner:SHIN ETSU CHEM IND CO LTD

Antistatic fireproof composite polyethylene pipe and its production process

InactiveCN1487014AGood synergistic effect of antistatic and flame retardantGood physical and mechanical propertiesTubular articlesBromineCarbon black

The antistatic fireproof composite polyethylene pipe is made of the material comprising bromated fire retardant 5-15 wt%, antimonial compound 3-10 wt%, conducting carbon black 5-8 wt%, polyethylene wax 1-3 wt% and antioxidant 0.5-3 wt% except polyethylene. The conducting carbon black is preferably conducting carbon black modified through heating at 100-300 deg.c at vacuum degree of 1000 Pa for over 10 min. The polyethylene is preferably the mixture of low density polyethylene 15-30% of the total pipe material weight and high density polyethylene 30-70% of the total pipe material weight. The pipe has excellent and lasting antistatic performance, good fireproof performance and excellent physical and chemical performance, and its may be used in coal mine resulting in high safety.

Owner:ZIBO JIUHE PLASTIC PROD

Fire retardant polyamide composition and use thereof

InactiveUS20020086928A1Retardant propertiesRetardant resistanceSolid ballsPolymer scienceZinc compounds

A fire retardant polyamide composition comprising: 20 to 85% by weight of a polyamide (A) of 280° C. or higher melting point, comprising repeating units constituted of: dicarboxylic acid component units (i) consisting of 30 to 100 mol % of terephthalic acid component units, 0 to 70 mol % of component units of an aromatic dicarboxylic acid other than terephthalic acid and 0 to 70 mol % of component units of an aliphatic dicarboxylic acid having 4 to 20 carbon atoms, provided that the sum of these dicarboxylic acid component units is 100 mol %, and diamine component units (ii) composed of aliphatic diamine component units and / or alicyclic diamine component units; 5 to 50% by weight of an inorganic reinforcement (B); 5 to 40% by weight of a brominated fire retardant additive (C) obtained by copolymerizing brominated polystyrene with an olefin having an epoxy group; and 0.1 to 10% by weight of an antimony compound and / or a zinc compound oxide (D), provided that the sum of components (A), (B), (C) and (D) is 100% by weight. This fire retardant polyamide composition is excellent in fire retardant properties, flowability, toughness and reflow heat resistance.

Owner:MITSUI CHEM INC

Biaxially oriented polyester film to be laminated on a metal plate and molded

InactiveUS6617006B1Improve impact resistanceReduce heat resistance requirementsFibre treatmentSynthetic resin layered productsPolyesterTitanium

A biaxially oriented polyester film to be laminated on a metal plate and molded, which comprises an aromatic polyester composition comprising:(A) an aromatic polyester which comprises ethylene terephthalate as the main recurring unit and a titanium compound and a phosphorus compound both of which satisfy at least one of the following expressions (1) and (2):wherein Ti is the amount (mmol %) of elemental titanium of the titanium compound contained in this aromatic polyester and P is the amount (mmol %) of elemental phosphorus of the phosphorus compound contained in the aromatic polyester, and the following expression (3):wherein Ti is as defined hereinabove, and which contains alkali metal compounds, germanium compound and antimony compound in a total amount of not more than 3 ppm in terms of the total of elemental alkali metals, elemental germanium and elemental antimony; and(B) 0.05 to 5.0 wt % based on the aromatic polyester composition of inert fine particles having an average particle diameter of 2.5 mum or less.

Owner:TEIJIN LTD

Flame-retardant metal-coated cloth

InactiveUS20050159061A1Improve flame retardant performanceSoft touchChemical protectionHeat protectionPhosphoric Acid EstersMetal coating

A flame-retardant metal-coated cloth having a high degree of flame retardancy and a soft feeling without the use of any halogen compound or antimony compound is provided. In the flame-retardant metal-coated cloth, a flame-retardant film comprising a mixture (E) of a phosphorus compound (A), a metal hydroxide (B), a phosphoric ester (C), and a thermoplastic resin (D), is formed on at least one surface of a metal-coated cloth, and the ratio of (A):(B):(C):(D) is 20 to 200:100 to 950:10 to 250:100 in terms of a weight ratio.

Owner:DAIKYO CHEM +1

High flame resistant union fabric

InactiveCN1653220AImprove fire performanceFlame-proof filament manufactureMonocomponent synthetic polymer artificial filamentYarnCompound a

A fabric is provided that has high degree of flame resistance in the case of a union fabric consisting of a halogen-containing flame resistant fiber including antimony compounds (A), and a cellulosic fiber, and the fabric is classified into class M1 of NF P 92-503 combustion test in France. A flame resistant union fabric obtained by co-weaving: a compound yarn (A) 30% to 70% by weight obtained by compounding a halogen-containing flame resistant fiber (a-1) including an antimony compound 25 to 50 parts by weight in an acrylic based copolymer 100 parts by weight obtained by polymerizing a monomer mixture including acrylonitrile 30 to 70% by weight, a halogen containing vinyl based monomer 30 to 70% by weight, and a vinyl based monomer copolymerizable therewith 0 to 10% by weight, and an other fiber (a-2), the compound yarn (A) having an elongation percentage less than 5% under a condition of a load of 300 mg / metric count of No. 17, and of a temperature range of 100 degrees C. to 500 degrees C.; a cellulosic fiber yarn (B) 70 to 30% by weight.

Owner:KANEKA CORP

Flame retardant thermoplastic resinous composition

Disclosed are compositions comprising: a flame retardant composition comprising (i) an acrylonitrile-styrene-acrylate graft copolymer (ASA) or acrylate- modified ASA, (ii) at least one rigid thermoplastic polymer comprising structural units derived from styrene and acrylonitrile; alpha-methylstyrene and acrylonitrile; alpha-methylstyrene, styrene, and acrylonitrile; styrene, acrylonitrile, and methyl methacrylate; alpha-methyl styrene, acrylonitrile, and methyl methacrylate; or alpha- methylstyrene, styrene, acrylonitrile, and methyl methacrylate, or mixtures thereof, (iii) at least one halogenated flame retardant, (iv) at least one antidrip additive, (v) optionally at least one additive which comprises an inorganic or organic antimony compound, and (vi) optionally at least one acid scavenger. Articles made from said compositions are also disclosed.

Owner:SABIC INNOVATIVE PLASTICS IP BV

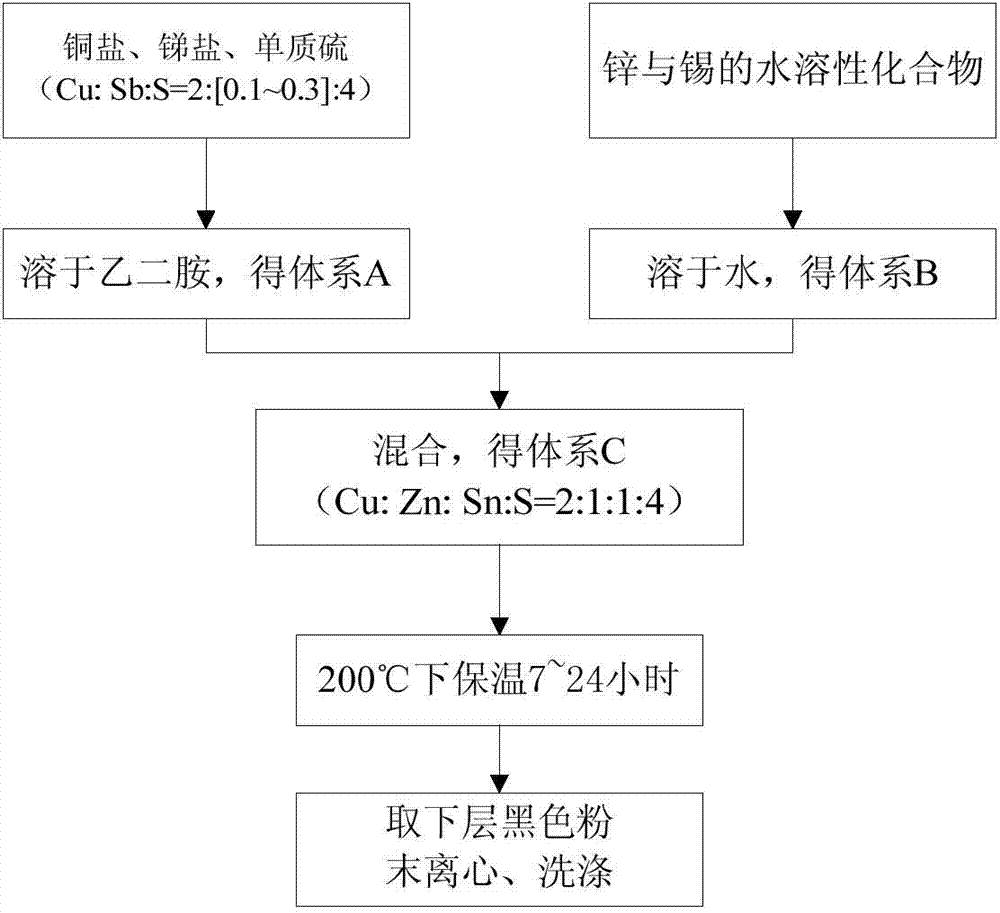

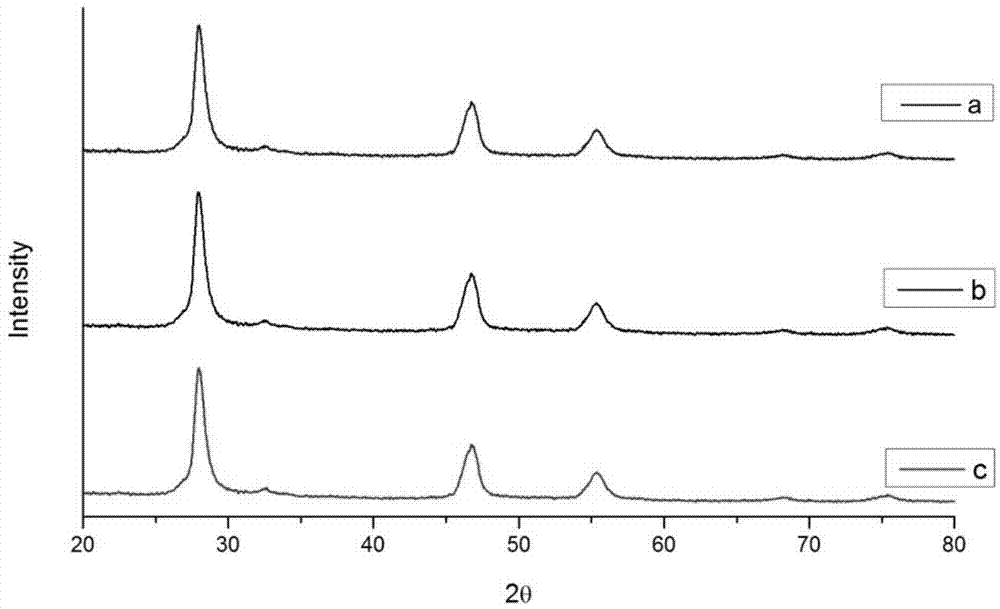

Preparation method for CZTS nano-particle material

InactiveCN103482687AHigh crystallinityUniform particle size distributionMaterial nanotechnologyTin compoundsEthylenediamineCrystallinity

A preparation method for a CZTS nano-particle material belongs to the technical field of materials. The method comprises the following steps: first, respectively preparing a reaction system A (dissolving copper salt, antimonic salt and elemental sulfur in ethylene diamine in an ultrasonic manner) and a reaction system B (a water solution of zinc salt and tin salt); then, mixing the system A and the system B in an ultrasonic manner, sealing and heating to 200 DEG C; keeping the the temperature for 7-24 hours for reaction; finally, taking black powder at the lower layer, and obtaining a target product through centrifugation and washing. According to the invention, a moderate amount of an antimony compound is added to allow copper ions and Sb ions to react with the sulfur so as to generate a mobile-phase copper-antimony-sulfur compound and to promote the growth of Cu2ZnSnS4; meanwhile, the crystal grain dimensions of the Cu2ZnSnS4 nano particles are more uniform. The prepared CZTS nano-particle is good in crystallinity, has no other impurity phase, and is more uniform in dimension distribution; the reaction time is greatly shortened under the action of the mobile phase; only sealing and heating equipment is required during the preparation process, so that the preparation steps are simple, and mass production is achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Flame-retarding synergist and flame-retarding alkyl benzene sulphonate (ABS) prepared by flame-retarding synergist

The invention discloses a flame-retarding synergist and flame-retarding alkyl benzene sulphonate (ABS) prepared by the flame-retarding synergist. The formula of the novel flame-retarding synergist includes 20-50 parts of talcum powder, 0.5-10 parts of inorganic silicate, 10-30 parts of organosilicon substance, 20-50 parts of antimony compound and 0.2-5 parts of dispersing agent. The novel flame-retarding synergist can completely and equivalently replace antimonous oxide in a bromine-antimony compound flame-retarding system and prepare the low-cost flame-retarding ABS. Compared with the flame-retarding ABS prepared by an existing antimonous oxide brominated flame-retarding synergist, the flame-retarding ABS is lower in cost, better in flame-retarding stability and reduction of combustion smoke density and simpler and more convenient to produce and use, and other mechanical properties are remained the same or have better technical effect.

Owner:TIANJIN KINGFA NEW MATERIAL +3

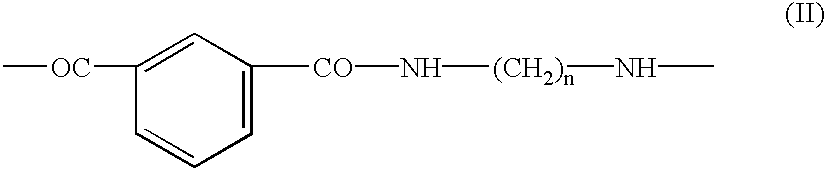

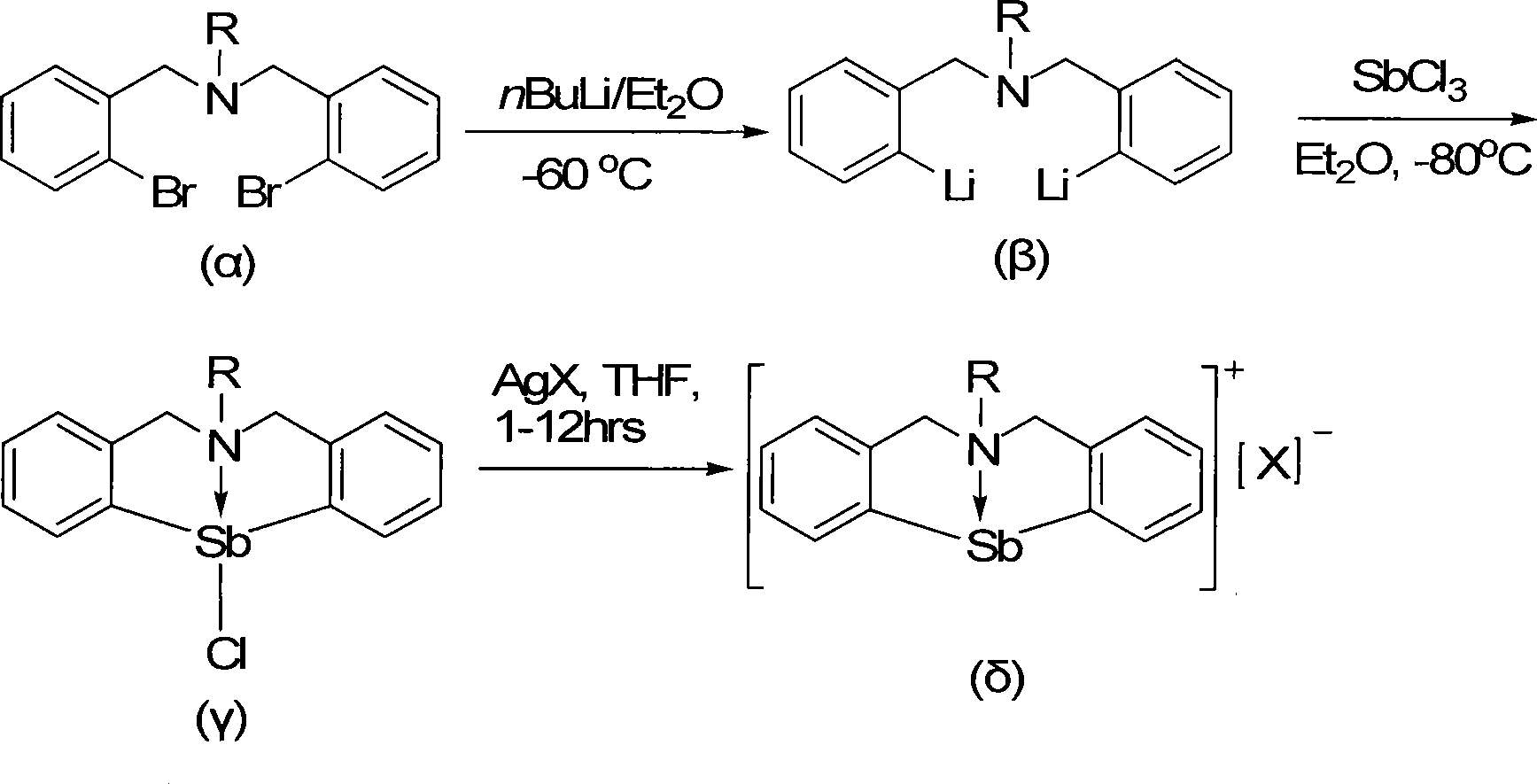

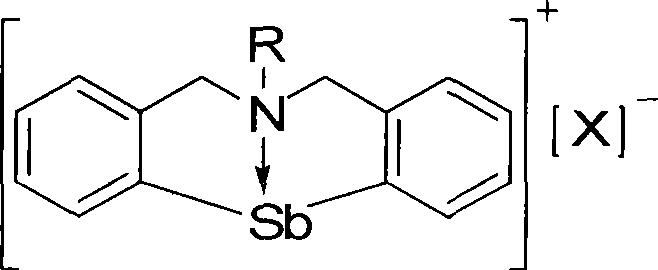

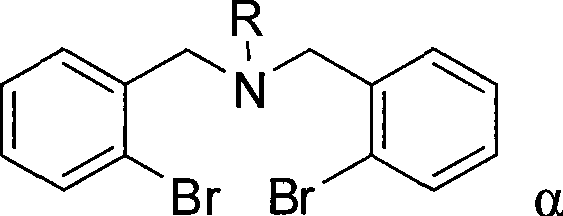

Organic antimony compound bearing a nitrogen-bridged ligand and its preparation and application

InactiveCN101544672ANovel structureEasy to makeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOrganic synthesisNitrogen

The present invention discloses a new type of organic antimony compound bearing a nitrogen-bridged ligand. The structural formula of the ligand is [PhCH2]N[R][CH2Ph], wherein R is a substituent on nitrogen atom; group X that directly links antimony is an anion with strong charge pulling ability; and in this antimony compound, Sb<3+> not only forms bonds with the two carbon atoms of the ligand but also forms a coordinate bond with the nitrogen atom of the ligand and an ionic bond with the corresponding anion. The present invention also provides the preparation method of this organic antimony compound, as well as its application in organic synthesis as a catalyst.

Owner:HUNAN UNIV

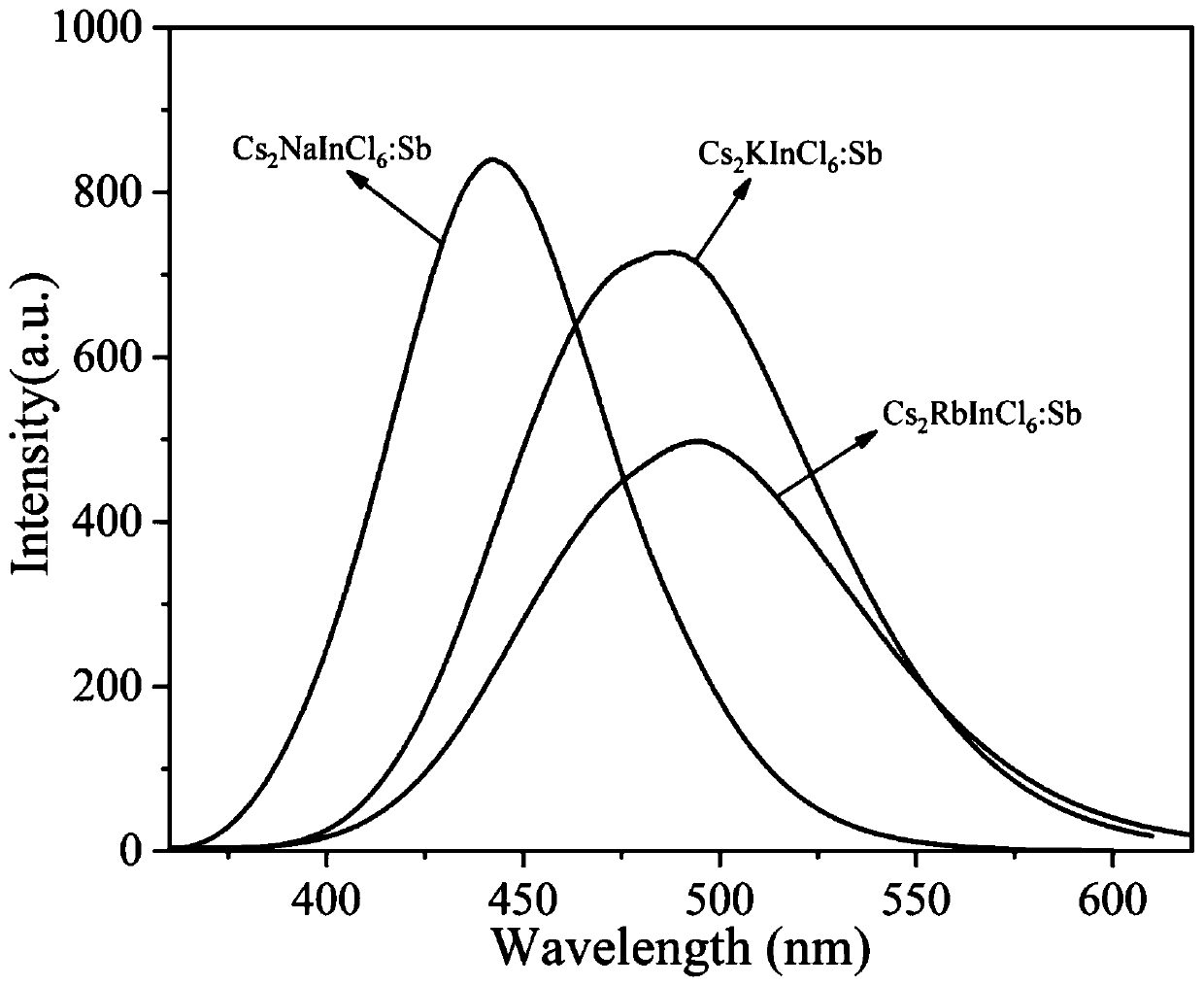

Sb-doped Cs2AInCl6 double-perovskite material as well as preparation method and application thereof

The invention discloses a preparation method and an application of an Sb-doped Cs2AInCl6 double perovskite material. In the Sb-doped Cs2AInCl6 double perovskite material, A is Na, K and Rb, a cesium-containing compound, an A-containing compound, an antimony-containing compound and an indium-containing compound are used as reaction reagents, concentrated HCl is used as a solvent, the Sb-doped Cs2AInCl6 double-perovskite material is prepared, and the influence of the reaction temperature on the luminous efficiency of the Cs2AInCl6 double-perovskite material is explored. The Sb-doped Cs2AInCl6 double-perovskite material prepared by adopting a solvothermal method is good in crystallinity, high in quality, and capable of being rapidly synthesized in quantity and simple in process; and doping ofdifferent concentrations can be effectively realized by adjusting the feeding ratio of Sb. The material provided by the invention has good stability and high quantum efficiency (PLQY), is suitable for industrial production, and has a wide application prospect in the fields of illumination, backlight batteries, display screens, solar cells and the like.

Owner:GUANGXI UNIV

Substrates coated with flame retardant compositions based on organic polymers and zeolites

Substrates, which may be either flexible or rigid, are coated with a flame retardant composition containing an organic polymer, a filler and a zeolite. Good flame retardant properties are obtained even where the composition contains low levels of conventional flame retardant additives such as antimony compounds, brominated compounds and zinc compounds. The flame retardant composition may also be used to adhere different substrates together.

Owner:POLYMER PROD

Flame-retardant PBT/PET (polybutylece terephthalate/polyethylene terephthalate) alloy, preparation method and application thereof

The invention belongs to the technical field of polymer modification, and provides a flame-retardant PBT / PET (polybutylece terephthalate / polyethylene terephthalate) alloy, a preparation method and application thereof. The flame-retardant PBT / PET alloy is prepared from the following components in parts by weight: 30 to 50% of PBT resin, 5 to 15% of PET resin, 15 to 20% of brominated flame retardant, 0.5 to 2% of antimony compound, 4 to 10% of kaolin, and 20 to 40% of reinforcing material, wherein the synergistic agent is a compound synergistic agent; the compound synergistic agent consists of the antinomy compound and the kaolin; the sum of the percentages of the components by weight is 100%. Compared with the traditional art, the preparation method of the flame-retardant PBT / PET alloy hasthe advantages that the V-0 flame-retardant grade of UL-94 and the IEC 60335 safety standard can be simultaneously reached, the loss of mechanical property is very small, the adding amount of the antinomy compound is very low, and the material cost is lower.

Owner:BENSONG ENG PLASTICS HANGZHOU

Lithium secondary battery with enhanced heat-resistance

ActiveUS9017878B2Cell seperators/membranes/diaphragms/spacersFinal product manufactureElectrochemistryThermal safety

Disclosed is an electrode whose surface includes an organic / inorganic composite porous coating layer comprising heat-absorbing inorganic particles and a binder polymer, wherein the heat-absorbing inorganic particle is at least one particle selected from the group consisting of antimony-containing compounds, metal hydroxides, guanidine-based compounds, boron-containing compounds and zinc tartrate compounds. A separator using the heat-absorbing inorganic particles as a component for forming or coating the separator, and an electrochemical device including the electrode and / or the separator are also disclosed. The separator using the heat-absorbing inorganic particles as a component for forming or coating the separator can ensure excellent thermal safety and minimizes degradation of the quality of a battery.

Owner:LG ENERGY SOLUTION LTD

Environmentally safe electrochromic mirrors

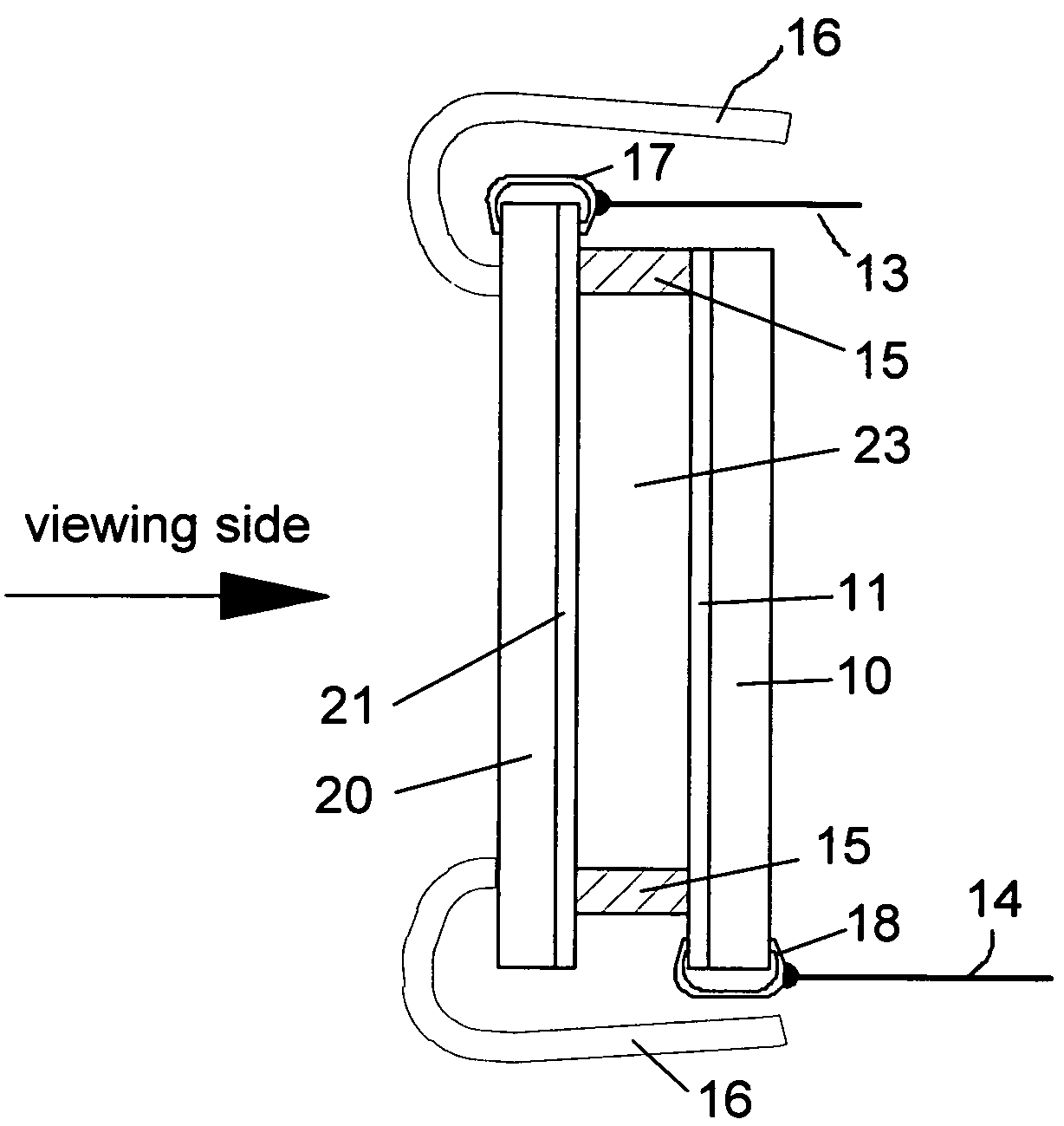

InactiveUS7733555B2Increase surface areaGood lookingNon-linear opticsOptical viewingElectricityAntimony compounds

This invention recognizes the hazards of beryllium and beryllium oxide in automotive applications and offers alternative material solutions. In particular, commercial electrochromic mirrors use beryllium comprising alloys for busbars and may also use beryllium oxide for the electronics used to power and control these mirrors. Further, this can be combined by reducing other known hazards such as mercury, cadmium, lead and antimony compounds.

Owner:AJJER

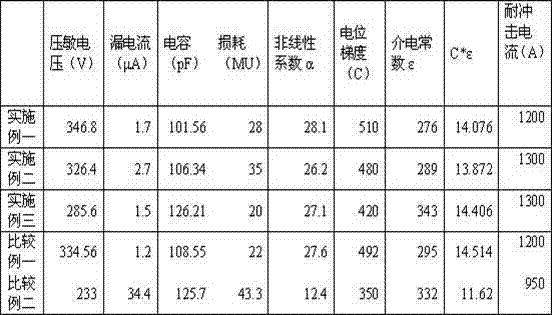

Zinc oxide pressure-sensitive resistor raw material

InactiveCN102584206AStrengthen semiconductorAdd nonlinearityVaristor coresOvervoltage protection resistorsAntimony compoundsManganese

The invention discloses a zinc oxide pressure-sensitive resistor raw material. The zinc oxide pressure-sensitive resistor raw material contains the following components in percentage by mole: 91-97% of ZnO, 0.1-3% of Bi2O3, 0.1-2% of Cr2O3, 0.1-1.5% of manganese-containing compound, 0.1-1.5% of cobalt-containing oxide and 0.1-1.5% of Nb2O5. According to the zinc oxide pressure-sensitive resistor raw material, a zinc oxide powder material is adopted as a main material, a stibium-containing compound as one of the traditional additive components is removed, and a variety of metal oxide components are added as additives; and the pressure-sensitive resistor manufactured by the raw material can make up various performance defects caused by the removal of the stibium-containing compound, the properties such as electrical property, mechanical property and reliability and the like are greatly improved, the pressure-sensitive voltage can be controlled in a wider range at the same time, and good comprehensive performance is gained.

Owner:SHENZHEN SUNLORD ELECTRONICS

Method of manufacturing a glazing panel

InactiveUS7037555B2Improve the level ofHigh selectivityGlass/slag layered productsSpecial surfacesAntimony compoundsGas phase

A method of manufacturing a glazing panel having a solar factor (FS) of less than 70% and being composed of a vitreous substrate and a tin / antimony oxide coating layer provided on the vitreous substrate and having a Sb / Sn molar ratio ranging from 0.01 to 0.5, preferable 0.03 to 0.5, the method including the steps of providing reactants in gaseous phase which comprise tin and antimony compounds, which are present in an amount effective to form the tin / antimony oxide coating layer; and forming the tin / antimony oxide coating layer pyrolytically on the vitreous substrate from the reactants in gaseous phase to provide the glazing panel having a solar factor (FS) of less than 70%.

Owner:GLAVERBEL SA

Catalyst system and process for preparing of polyester resins, fibre, filaments and yarn using said catalyst system

InactiveUS20130184414A1Reduce polymerization timeReduce generationMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsYarnPolyester resin

The present invention relates to a process for preparation of polyester resin in the presence of a novel catalyst system comprising an antimony compound and inorganic tin compound. The present invention also relates to a catalyst system for the preparation of polyester comprising an antimony compound and inorganic tin compound which reduces the polymerization time at all stages of polyester synthesis and reduces the generation of degradation product. This invention further relates to polyester resin with improved L color having significant importance in end-use applications.

Owner:RELIANCE INDUSTRIES LIMITED

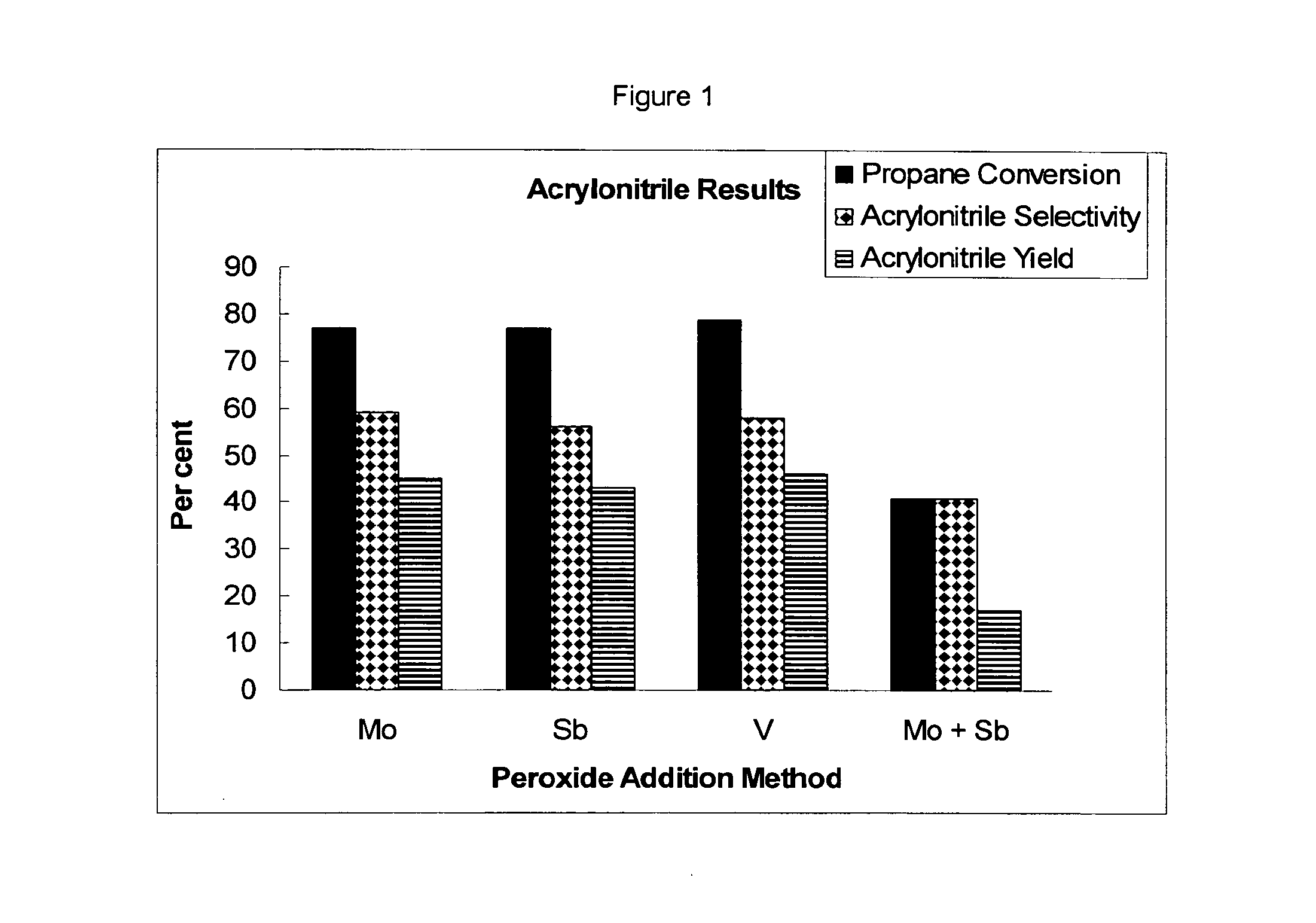

Method of making mixed metal oxide catalysts for ammoxidation and/or oxidation of lower alkane hydrocarbons

InactiveUS20110218352A1Organic compound preparationHeterogenous catalyst chemical elementsMethacrylonitrileAntimony

The present invention comprises a method for preparing a mixed oxide catalyst for use in producing acrylonitrile or methacrylonitrile from propane or isobutane by ammoxidation in a gaseous phase via methods of contacting any one of the antimony compound, the molybdenum compound, and the vanadium compound with hydrogen peroxide prior to combining with source compounds for the remaining elements in the catalyst.

Owner:INEOS USA LLC

Flame retardant thermoplastic resinous compostion

Disclosed are compositions comprising: a flame retardant composition comprising (i) an acrylonitrile-styrene-acrylate graft copolymer (ASA) or acrylate-modified ASA, (ii) at least one rigid thermoplastic polymer comprising structural units derived from styrene and acrylonitrile; alpha-methylstyrene and acrylonitrile; alpha-methylstyrene, styrene, and acrylonitrile; styrene, acrylonitrile, and methyl methacrylate; alpha-methyl styrene, acrylonitrile, and methyl methacrylate; or alpha-methylstyrene, styrene, acrylonitrile, and methyl methacrylate, or mixtures thereof, (iii) at least one halogenated flame retardant, (iv) at least one antidrip additive, (v) optionally at least one additive which comprises an inorganic or organic antimony compound, and (vi) optionally at least one acid scavenger. Articles made from said compositions are also disclosed.

Owner:SABIC INNOVATIVE PLASTICS IP BV

A water-soluble catalytic cracking multifunctional deactivator and a preparing method thereof

InactiveCN104162455AImprove passivation effectHigh yieldCatalytic crackingCatalyst protectionAntimony compoundsAqueous solubility

A water-soluble catalytic cracking multifunctional deactivator is disclosed. The deactivator comprises following components by weight: 6-30% of an antimony compound and 2-10% of a ligand, with the balance being water. In addition, a preparing method of the deactivator is disclosed. The deactivator has characteristics of capability of deactivating a plurality of metals simultaneously, good dispersity, high activity, low toxicity, miscibility with water, high deposition efficiency of effective components, and significant deactivating effects.

Owner:宜兴汉光高新石化有限公司

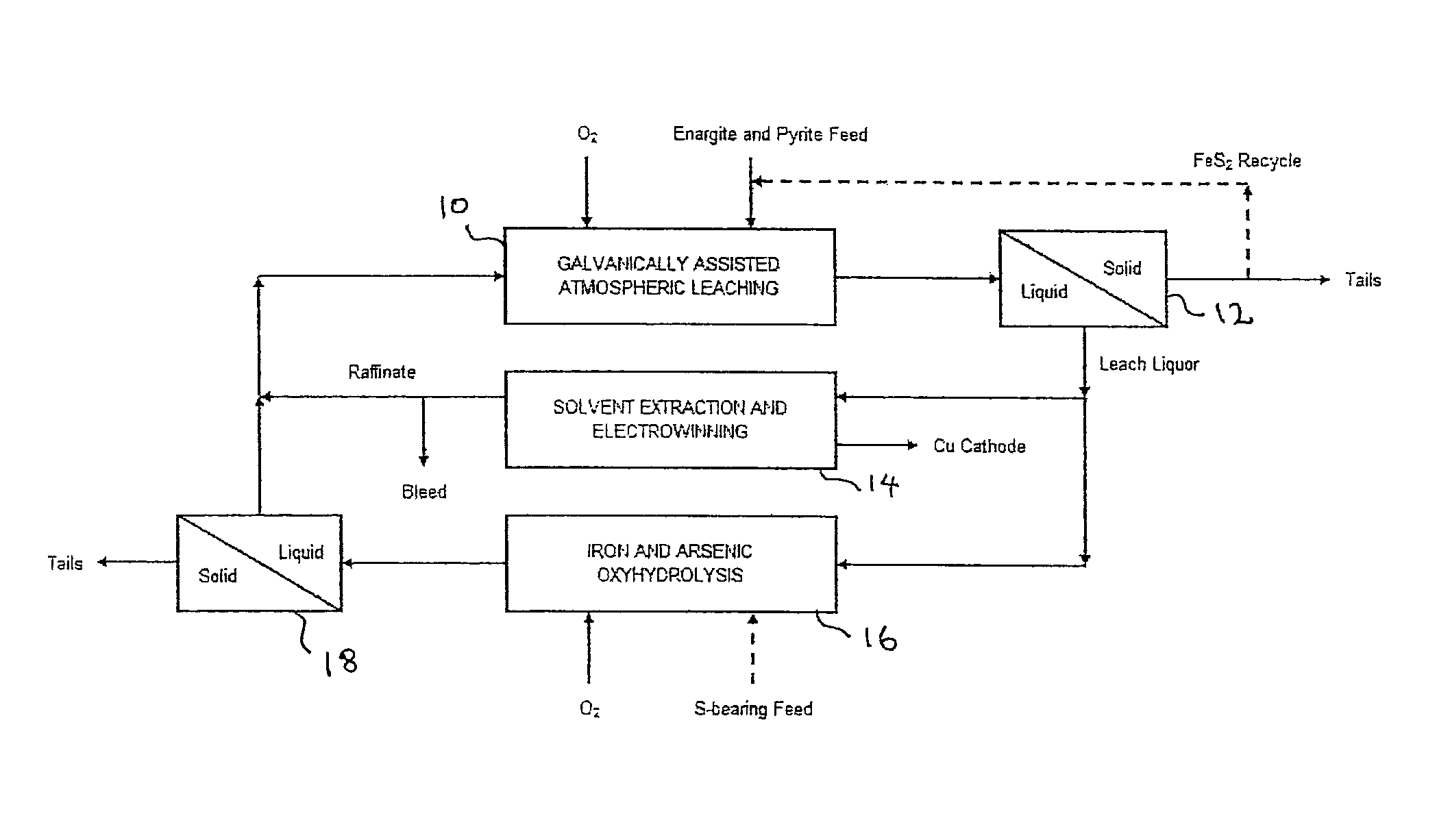

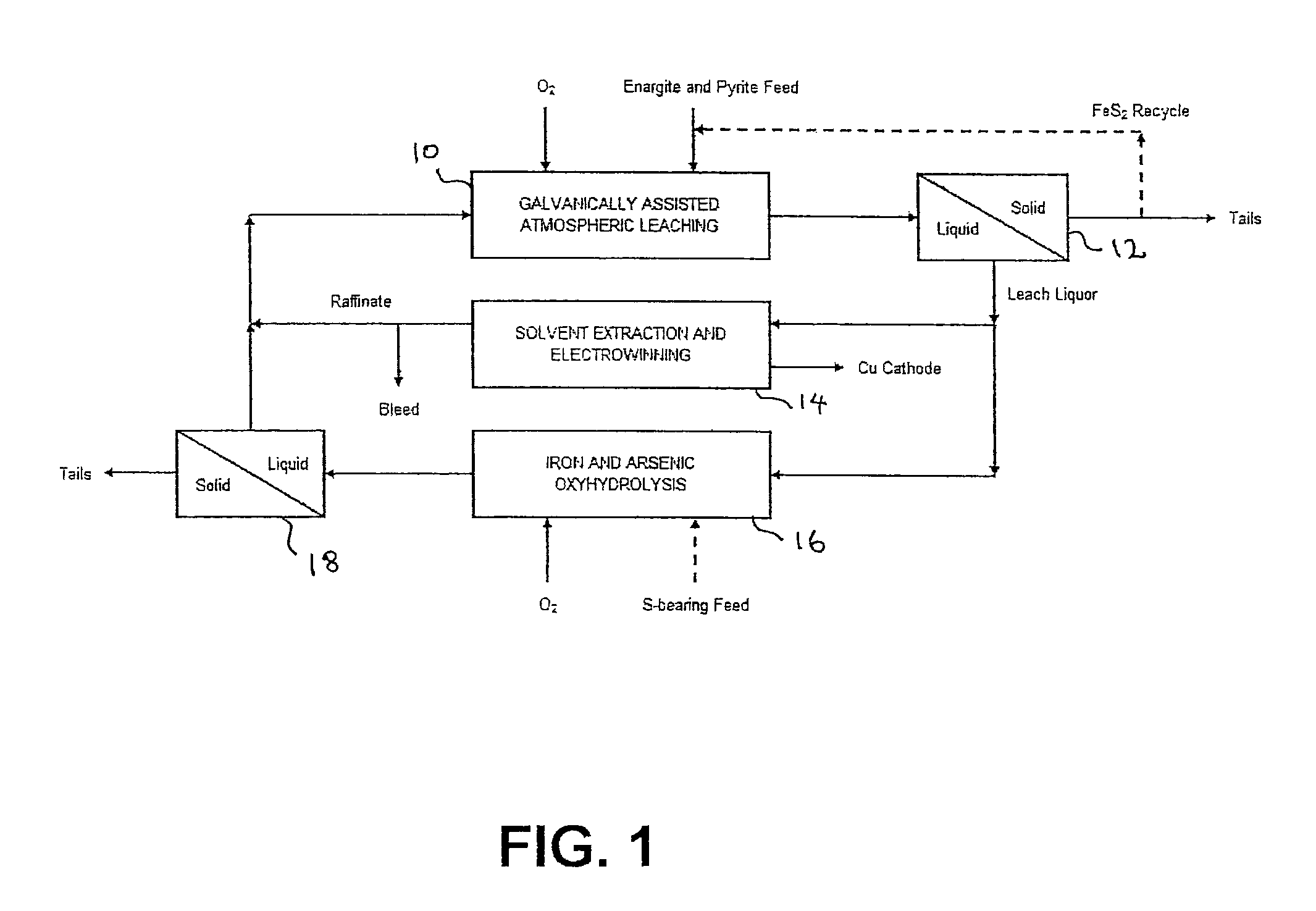

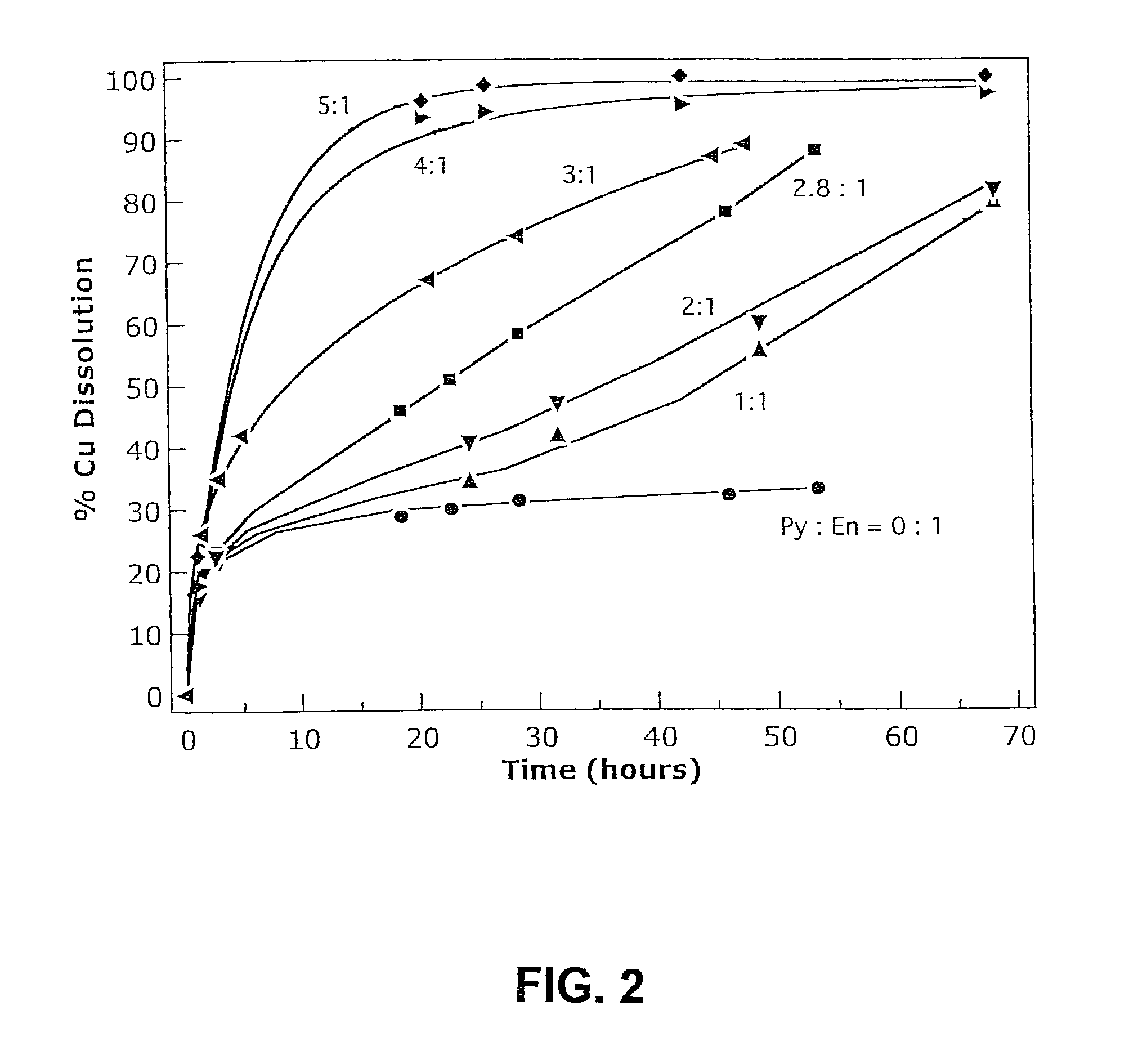

Leaching process for copper concentrates containing arsenic and antimony compounds

A method of recovering copper from a copper sulfide concentrate comprising a copper arsenic sulfosalt or a copper antimony sulfosalt, using pyrite as a catalyst. The concentrate and pyrite are added to an acidic sulfate leach solution. The copper is leached from the concentrate, in the presence of an oxygen-containing gas, under conditions whereby the pyrite is substantially unoxidized. The pyrite:copper sulfide ratio of the pyrite being added to the copper sulfide present in the concentrate being added is at least 1:3. The pyrite may be maintained at a concentration in the leach solution of at least 9 grams per liter. The leached copper is recovered from the solution by conventional methods.

Owner:THE UNIV OF BRITISH COLUMBIA

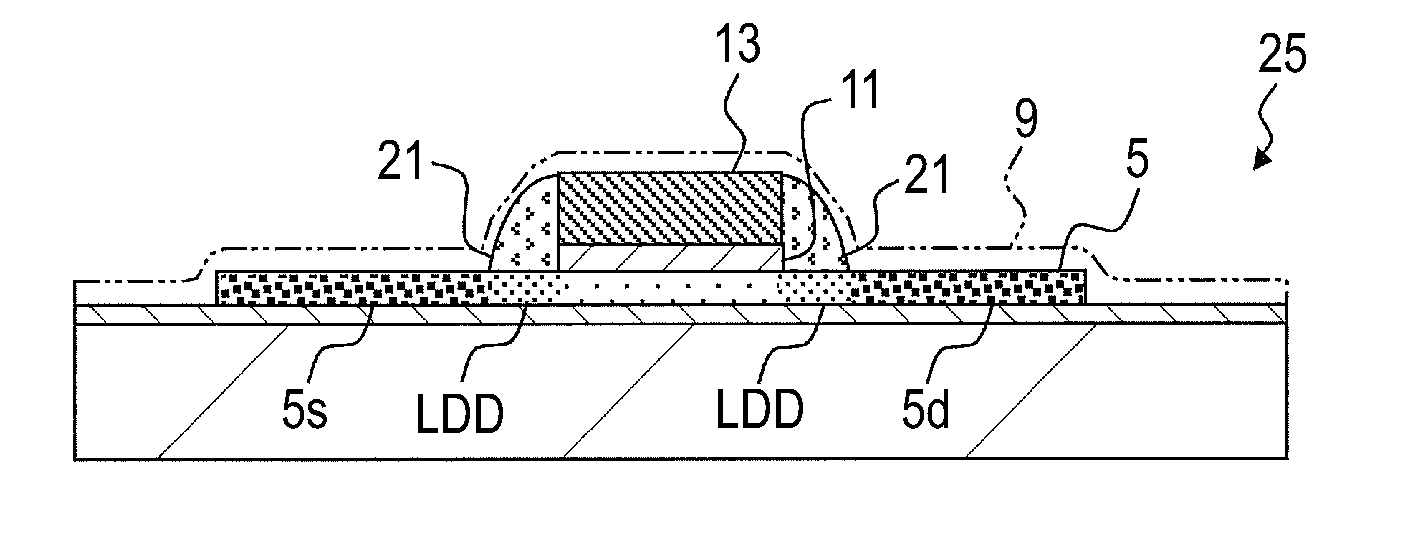

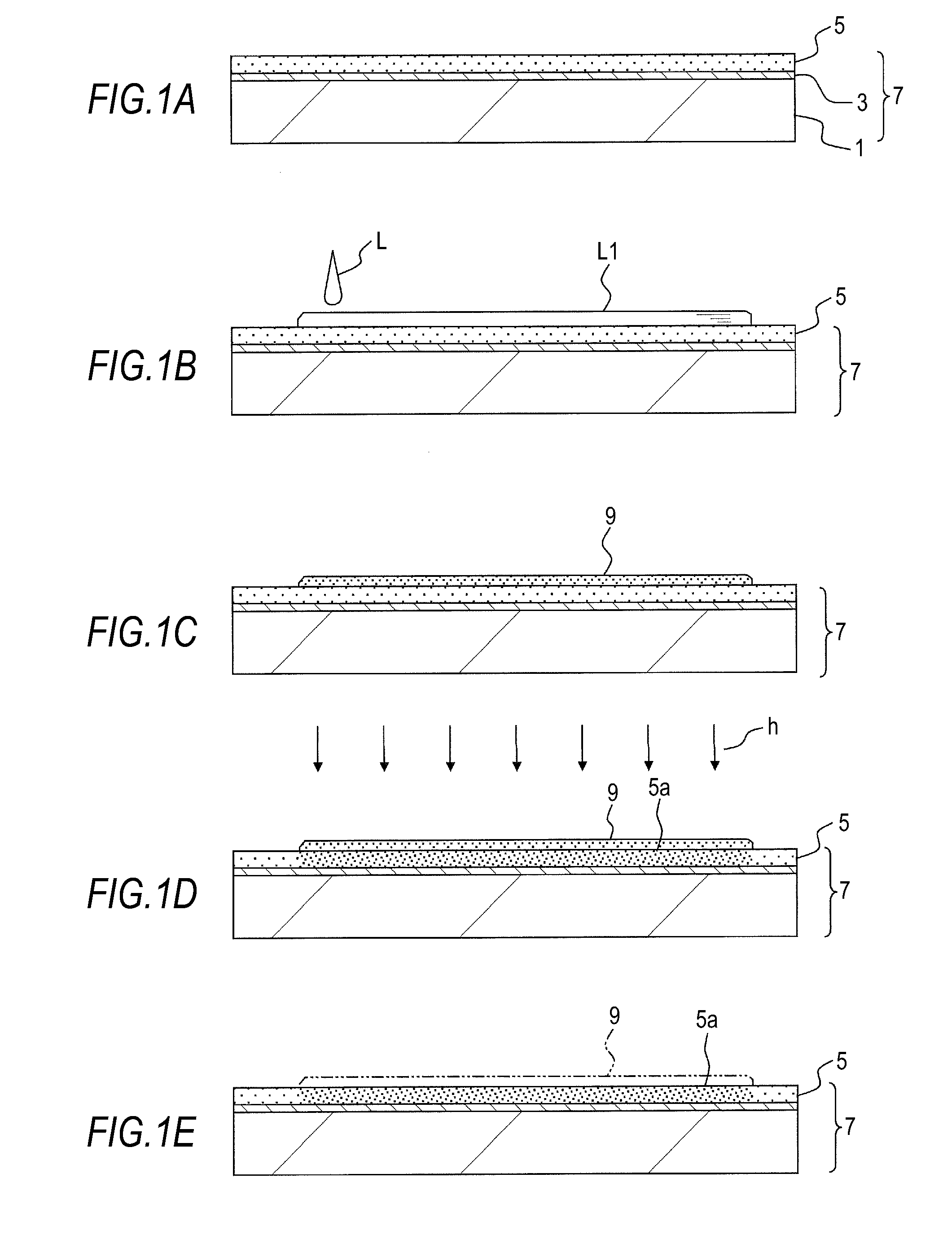

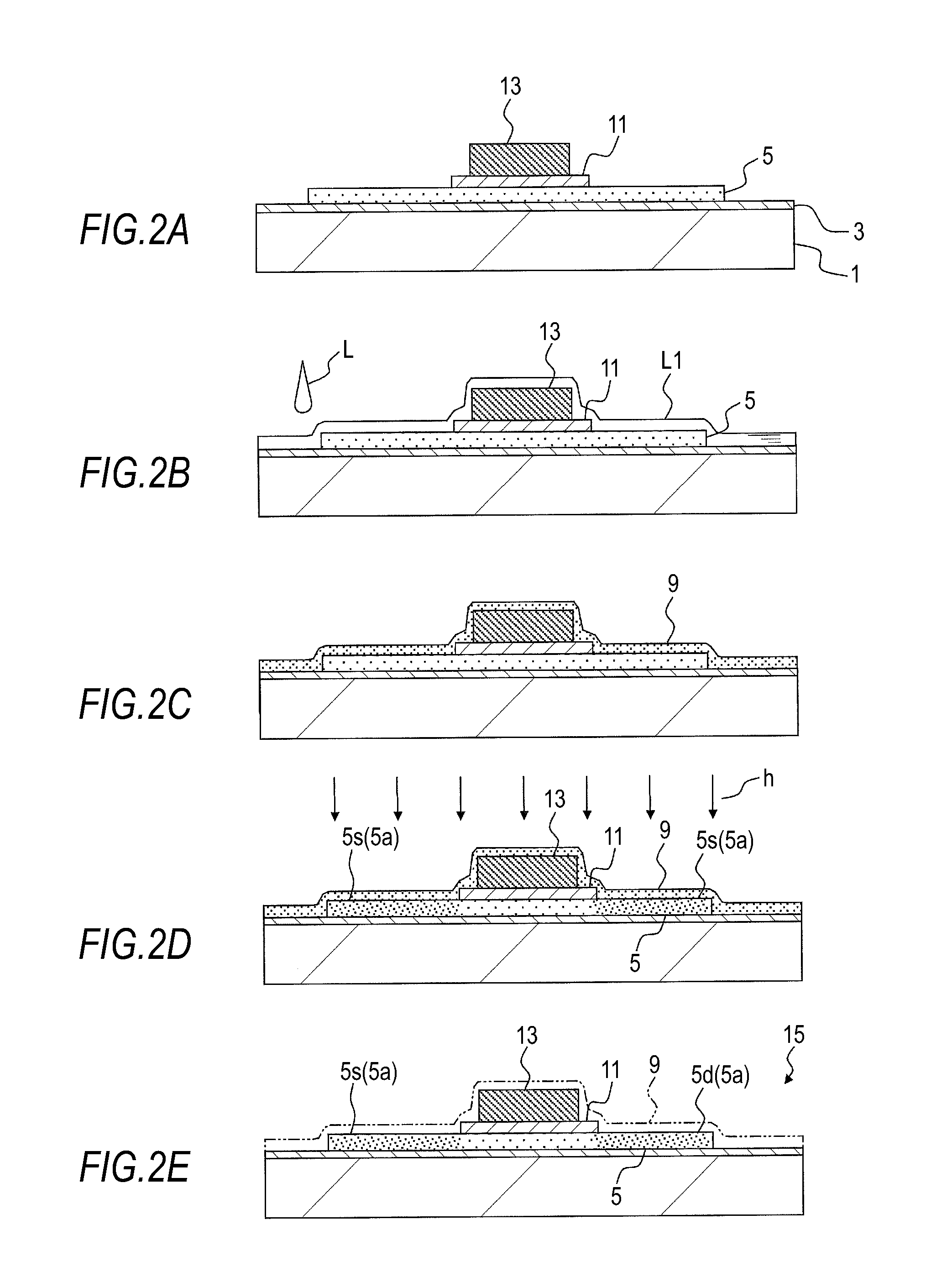

Doping method, and method for producing semiconductor device

InactiveUS20110033999A1High accuracy without losing the semiconductor propertiesWell controlled property accuracySemiconductor/solid-state device manufacturingSemiconductor devicesHydrogenAntimony compounds

A doping method includes: a first step of depositing a material solution containing an antimony compound containing elements selected from the group consisting essentially of hydrogen, nitrogen, oxygen, and carbon together with antimony to a surface of a substrate; a second step of drying the material solution to form an antimony compound layer on the substrate; and a third step of performing heat treatment so that antimony in the antimony compound layer is diffused into the substrate.

Owner:SONY CORP

Process for removing Ni from waste etching FeCl3 solution containing Ni

InactiveCN1386906AEfficient separationEfficient recyclingWater/sewage treatmentAntimony compoundsIron powder

A process for removing Ni from the used etching Ni-containing FeCl3 solution includes adding iron powder or fraky iron scales, reduction reaction, heating to 55-95 deg.C, adding iron powder and sulfur powder, precipitating 2-valence Ni, adding iron powder and sulfur or As compound or Sb compound for further precipitation, and filtering. Its advantages are high effect on recovering Ni and regenerating FeCl3 solution and low cost.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

Polymerization catalyst for polyesters, polyester produced with the same, and process for production of polyester

InactiveUS7208565B1Solve the lack of activityQuality improvementOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterFiber

This invention provides a novel polycondensation catalyst using no antimony compound, polyester produced by using the same, and a process for producing polyester. A novel catalyst comprising an aluminum compound and a phosphorus compound is used as the polycondensation catalyst in producing polyester. The polyester of this invention can be applied to fibers for clothes, fibers for industrial materials, various films, sheets and molded articles such as bottles and engineering plastics, as well as coatings and adhesives.

Owner:TOYO TOYOBO CO LTD

Polymerization catalyst for polyester production, polyester and process for producing polyester

A polymerization catalyst for polyester production which consists mainly of ingredients other than antimony compounds and germanium compounds, has excellent catalytic activity, and gives a polyester which, even without undergoing catalyst deactivation or removal, is effectively inhibited from thermally deteriorating during melt processing and has excellent thermal stability; a polyester obtained by using the catalyst; and a process for producing a polyester with the catalyst. The catalyst contains neither antimony nor germanium, has an activity parameter (AP) satisfying AP (min) < 2T (min), gives polyethylene terephthalate having an index of thermal stability (TD, %) satisfying TD<25, and comprises a metallic ingredient and an organic compound ingredient containing an Ar-O- and / or Ar-N< unit. The polyester is usable as, e.g., various molded articles such as a fiber, film, sheet, and hollow molding.

Owner:TOYOBO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com