Alignment mark for silicon carbide device and preparation method thereof

An alignment mark, silicon carbide technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as increased cost, increased difficulty, contamination of wafers or equipment, and reduced misoperations , The effect of reducing the rework rate and not easy to contaminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

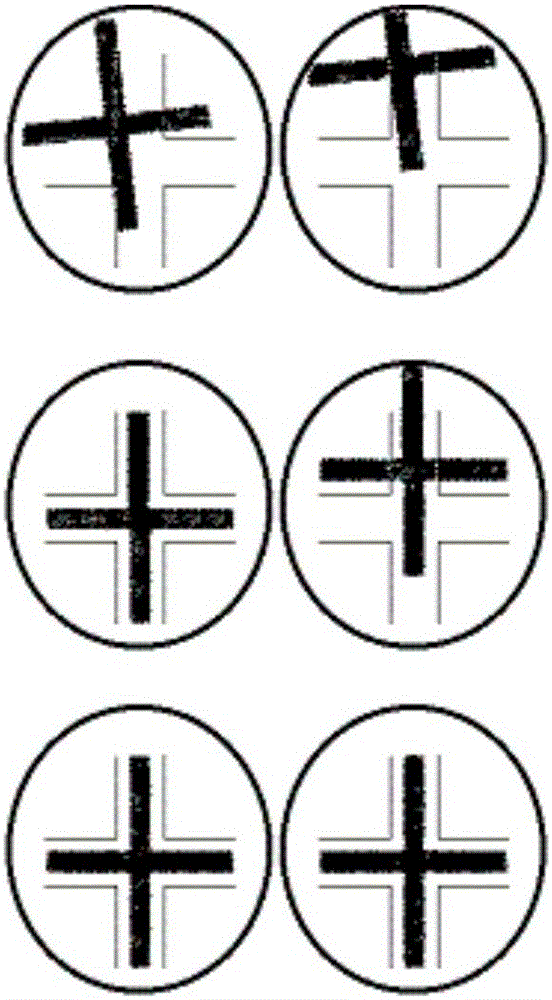

[0037] Such as image 3 As shown, the method for preparing an alignment mark for a silicon carbide device provided in this embodiment includes the following steps:

[0038] Ion implantation is performed on the surface of the silicon carbide substrate 1 at the position where the alignment mark is to be formed to form an ion implantation region 2 .

[0039] The above-mentioned elements for ion implantation include aluminum, boron, nitrogen, phosphorus or argon.

Embodiment 2

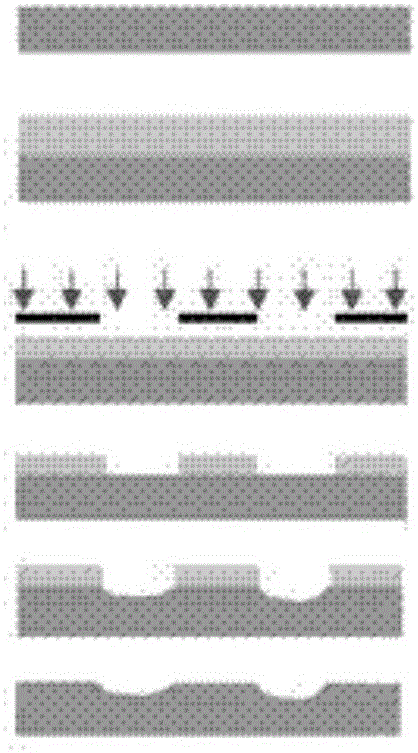

[0041] Such as Figure 4 As shown, the method for preparing an alignment mark for a silicon carbide device provided in this embodiment includes the following steps:

[0042] S1: forming a patterned mask 3 with openings on the surface of the silicon carbide substrate 1;

[0043] S2: performing ion implantation through the above-mentioned opening to form an ion-implantation region 2 , the brightness of the ion-implantation region 2 and the non-ion-implantation region form a contrast and thus constitute an alignment mark.

[0044] In a preferred implementation manner of this embodiment, after the ion implantation, the above preparation method further includes: removing the patterned mask 3 .

[0045] The above-mentioned elements for ion implantation include aluminum, boron, nitrogen, phosphorus or argon.

Embodiment 3

[0047] Such as Figure 5 As shown, the method for preparing an alignment mark for a silicon carbide device provided in this embodiment includes the following steps:

[0048] S1: forming a patterned mask 3 with openings on the surface of the silicon carbide substrate 1;

[0049] S2: With the help of the above-mentioned patterned mask 3, forming a recess 4 on the surface of the above-mentioned silicon carbide substrate 1 where the alignment mark is to be formed;

[0050] S3: Perform ion implantation on the above-mentioned recessed part 4 to form an ion-implanted area 2. The brightness of the above-mentioned ion-implanted area 2 and the non-ion-implanted area form a contrast to form an alignment mark. extending into the aforementioned silicon carbide substrate 1 .

[0051] The patterned mask 3 is a dielectric mask or a positive photoresist, and the exposed surface of the silicon carbide substrate 1 is etched by means of the patterned mask 3 to form the recessed portion 4 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com