Ultrathin high porosity film and preparation method thereof

A highly breathable and breathable film technology, applied in the field of new materials, can solve the problems of the quality of the finished product of the breathable film, the difficulty of opening the market, and halogenation, etc., to achieve the accuracy of measurement and the uniformity of mixing. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The raw material batch number is YH-Y-03:

[0040] Wherein the ratio of raw materials is as follows:

[0041] YH-Y-03

[0042] Raw material model ratio

[0043] LLDPE 25.5%

[0044] LDPE 15%

[0046]Modification additive 4.5%

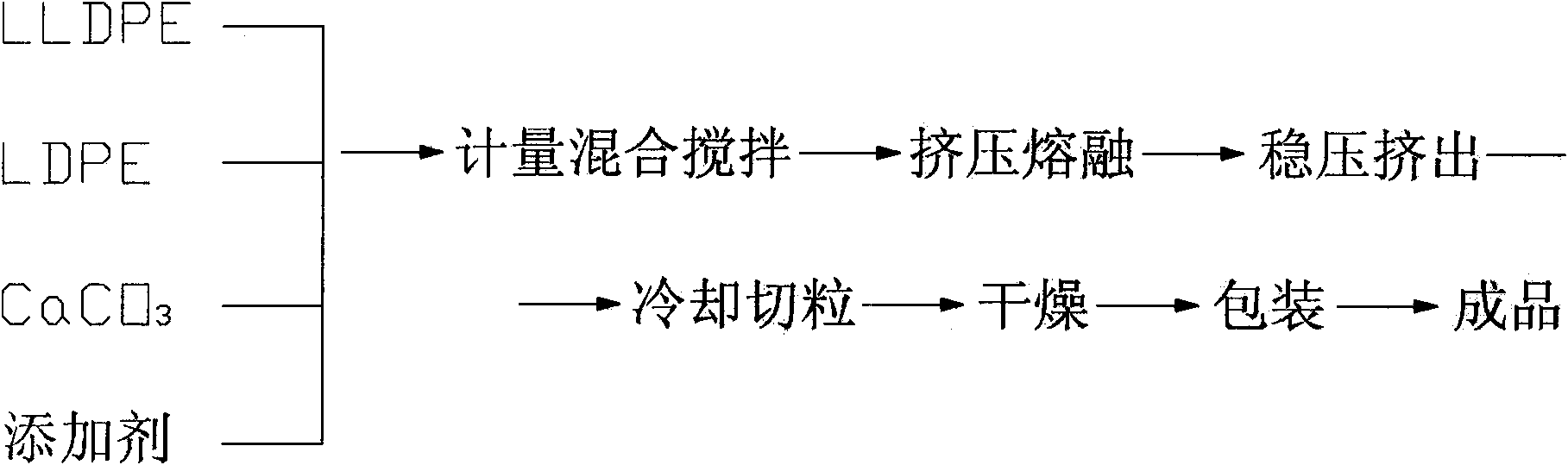

[0047] Granulation process:

[0048] (1) Granulation process temperature

[0049] Warm zone

a district

Second District

Third District

Four districts

five districts

District six

District Seven

eight districts

District 9

Die

temperature / ℃

140

160

180

200

200

190

190

180

180

170

[0050] (2) Film-forming production process temperature

[0051] Warm zone

a district

Second District

Third District

Four districts

five districts

District six

District Seven

eight districts

Die

temperature / ℃

180

185

225

230

2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com