Core-shell structure carbon-coated titanium and titanium alloy composite powder and preparation method thereof

A composite powder, core-shell structure technology, used in metal processing equipment, transportation and packaging, gaseous chemical plating, etc., can solve problems such as damage to the second phase strengthening effect of titanium matrix, brittle fracture of materials, and fragile two-phase interface. , to achieve the effect of good industrialization prospect, low production cost and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] As another aspect of the present invention, a method for preparing a core-shell structure carbon-coated titanium and titanium alloy composite powder is provided, comprising the following steps:

[0035] (1) Add the oxygen scavenger to the fluidized bed in the oxygen removal system, add the powder raw material to the fluidized bed of the chemical vapor deposition system, check the airtightness of the reaction device, and then pass high-purity inert gas to exhaust the air in the device;

[0036] (2) The fluidized bed in the oxygen removal system and the fluidized bed in the chemical vapor deposition system are placed in their respective heating equipment that reaches the preset reaction temperature. After stabilization, the flow rate of the inert gas is reduced, and at the same time, high-purity Acetylene and high-purity hydrogen for chemical vapor deposition reaction;

[0037] (3) After the chemical vapor deposition reaction, stop the flow of high-purity hydrogen and hi...

Embodiment 1

[0048] (1) Raise the muffle furnace in the oxygen removal system and the muffle furnace in the fluidized bed chemical vapor deposition system to 450°C and 650°C respectively;

[0049] (2) Use a cylindrical quartz fluidized bed with an inner diameter and a distribution plate diameter of 20mm as the oxygen removal reactor, and use a nested quartz fluidized bed as the chemical vapor deposition reactor, and the outer tube is a cylindrical quartz tube with a diameter of 40mm , the inner tube is a conical fluidized bed, the cone angle is 15°, and the diameter of the distribution plate is 20mm. The aperture diameter of the distribution plate of the above two fluidized beds is 200 μm, and the diameter of the inlet and outlet holes of the fluidized bed is 6 mm;

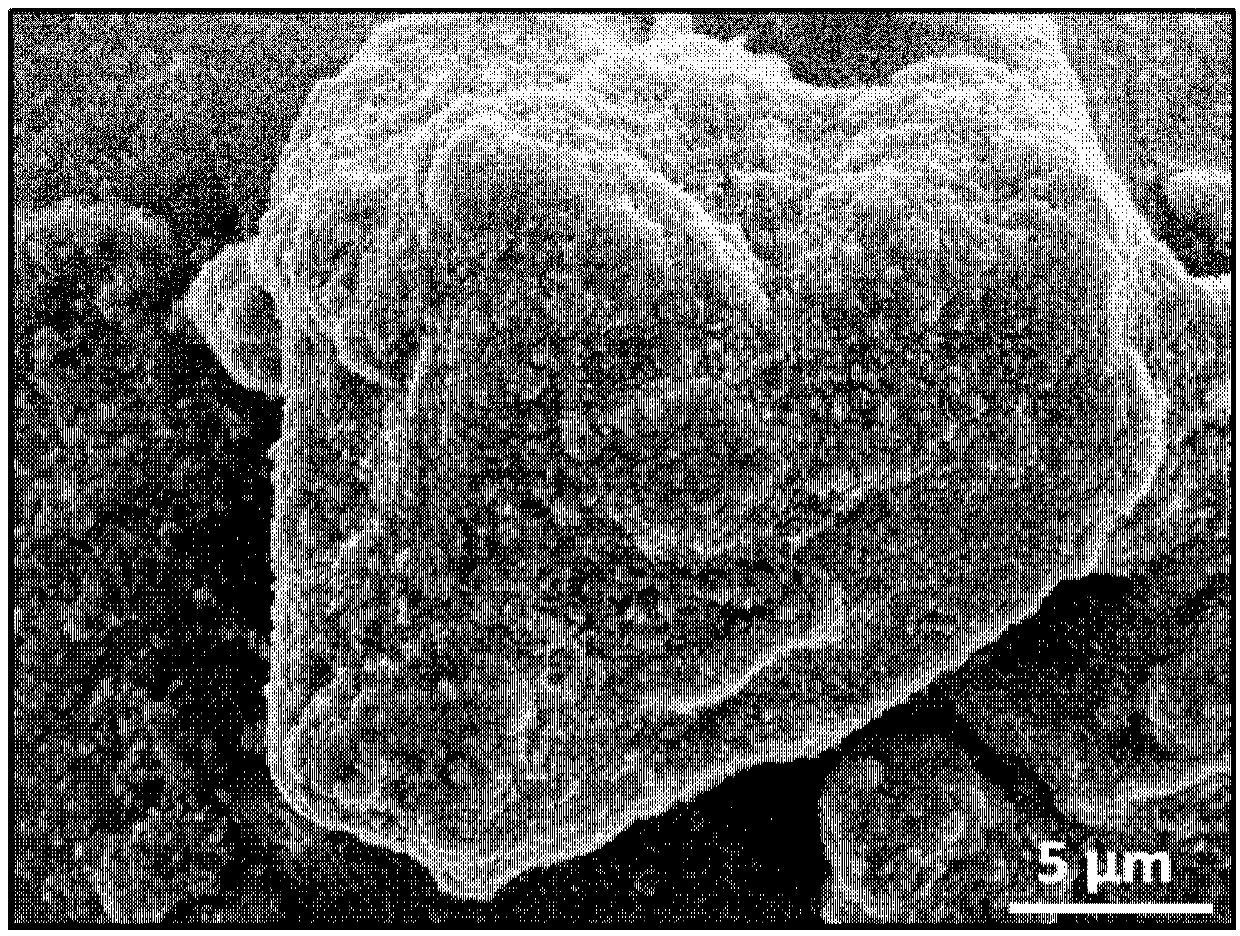

[0050] (3) Hydrodehydrogenation non-spherical titanium powder with a particle size of 48 μm is used as an oxygen scavenger, the purity is higher than 98.5% (mass fraction), and the weight is 8 g; the hydrogenated dehydrogenati...

Embodiment 2

[0057] Concrete experimental procedure is with embodiment 1, and difference is only in:

[0058] (1) Hydrodehydrogenated TC4 titanium alloy powder with a particle size of 74 μm is used as the chemical vapor deposition coating substrate, with a weight of 12 g;

[0059] (2) the proportioning of mixed gas is changed from argon: acetylene: hydrogen=400sccm: 80sccm: 80sccm to argon: acetylene: hydrogen=250sccm: 125sccm: 125sccm, and the reaction time is changed from 60min to 30min;

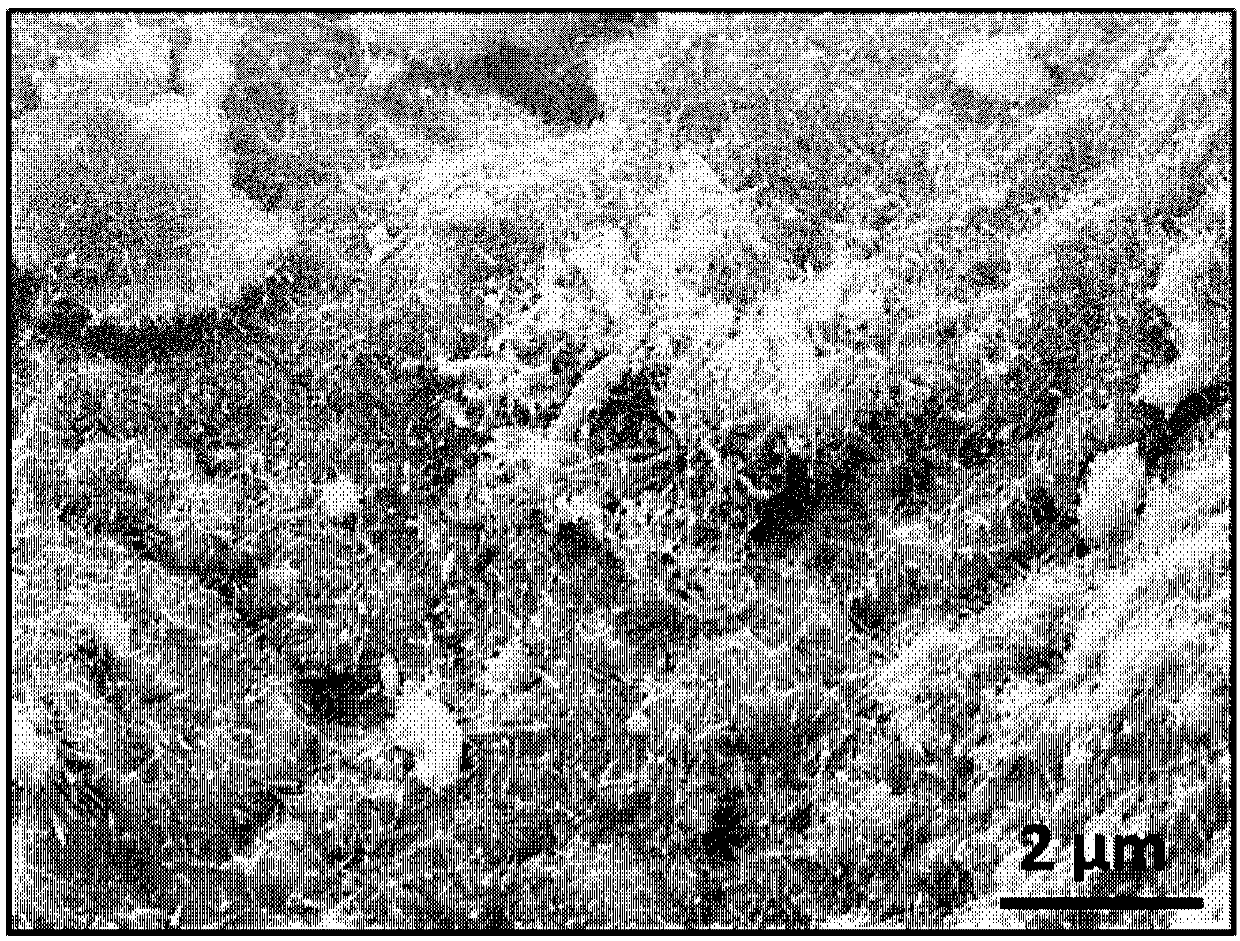

[0060] image 3 It is the scanning electron microscope picture of the carbon-coated TC4 titanium alloy composite powder in Example 2. It can be seen from the figure that a large number of carbon nanotubes or carbon nanorods grow on the surface of the TC4 titanium alloy powder, and the length of the carbon nanotubes and carbon nanorods is more than 2 μm, evenly distributed.

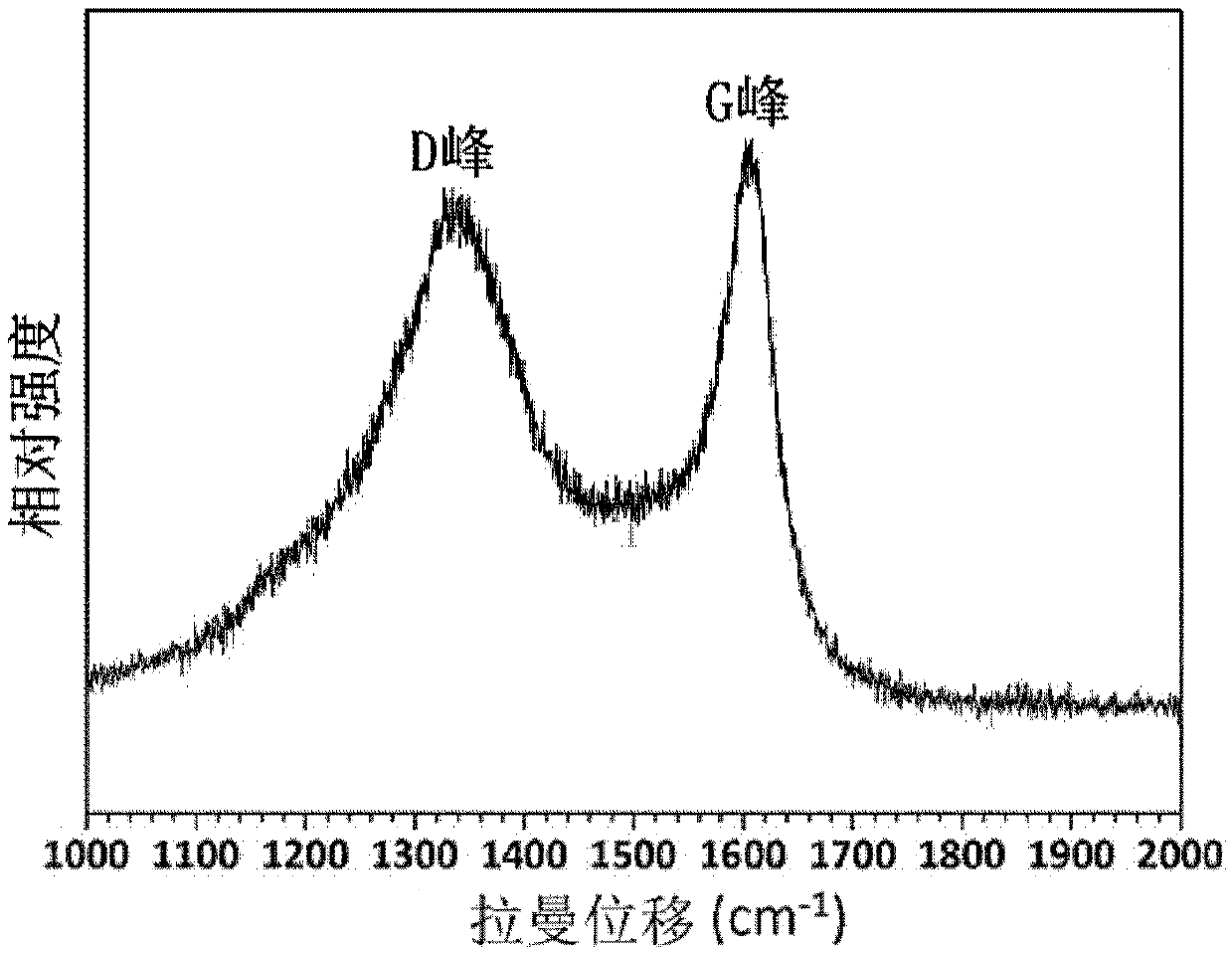

[0061] Figure 4 It is the X-ray diffraction analysis diagram of the carbon-coated TC4 titanium alloy composite powder in Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com