Alfalfa seed pretreatment method for improving vigor of seedlings and saline-alkali resistance

A pretreatment and seed technology, applied in the direction of seed and rhizome treatment, application, agriculture, etc., can solve the problems of easy introduction of pathogenic bacteria, damage to seed vigor, increase the emergence rate, etc. Osmotic stress, the effect of improving the speed of emergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

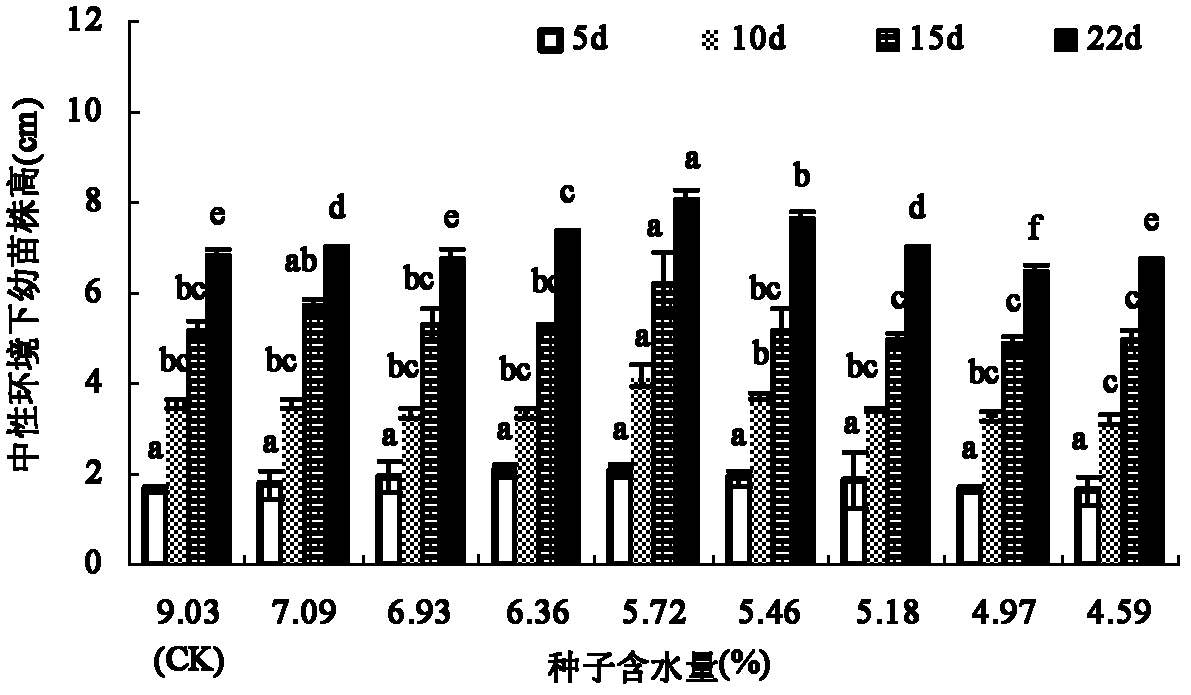

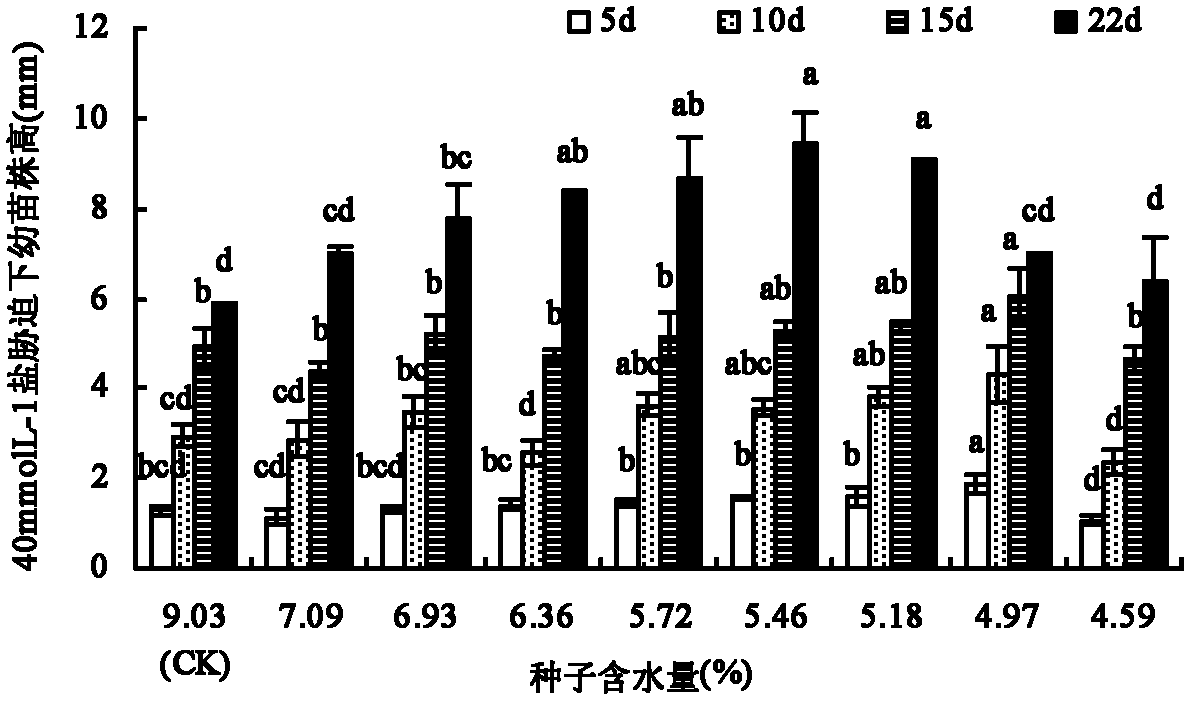

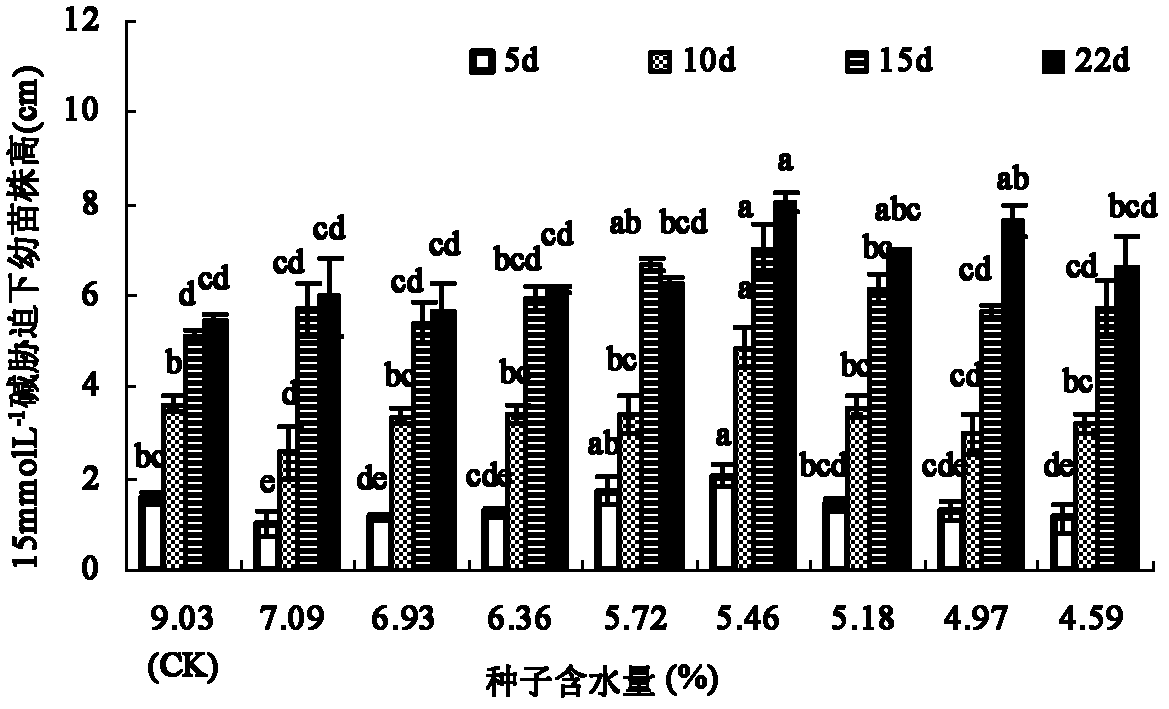

Embodiment 1

[0031] Put 5.0 g of Longdong alfalfa seeds into a nylon mesh bag with good air permeability, and place them evenly in a drying dish filled with silica gel. The ratio of seeds to silica gel is 1:10 (mass ratio), and then replace the silica gel every 23 hours. The silica gel was dried at a high temperature of 120°C to constant weight and cooled; the seeds were dried with silica gel in a sealed container at room temperature for 12 hours, and the water content of the seeds was 7.09% (mass fraction), and the dried seeds were sealed with double-layer aluminum foil paper and placed in Store at room temperature for 6 days in a desiccant filled with dried silica gel.

[0032] Before sowing, the super-dry treated and stored seeds were placed in a closed environment with increasing relative humidity in order to gradually increase the water content of the seeds. The environment of the rehydration treatment used in this embodiment is as follows: CaCl 2 A closed environment with a relative...

Embodiment 2

[0034] Put 5.0 g of Longdong alfalfa seeds into a nylon mesh bag with good air permeability, and place them evenly in a drying dish filled with silica gel. The ratio of seeds to silica gel is 1:10 (mass ratio), and then replace the silica gel every 24 hours. The silica gel was dried at a high temperature of 120°C to constant weight and cooled; the seeds were dried with silica gel in a sealed container at room temperature for 24 hours, and the water content of the seeds was 6.93% (mass fraction), and the dried seeds were sealed with double-layer aluminum foil paper, and placed in Store at room temperature for 30 days in a desiccant filled with dried silica gel.

[0035] Before sowing, the super-dry treated and stored seeds were placed in a closed environment with increasing relative humidity in order to gradually increase the water content of the seeds. The environment of the rehydration treatment used in this embodiment is as follows: CaCl 2 A closed environment with a relati...

Embodiment 3

[0037] Put 5.0 g of alfalfa seeds in Longdong alfalfa into a nylon mesh bag with good air permeability, and place them evenly in a drying dish filled with silica gel. The ratio of seeds to silica gel is 1:10 (mass ratio), and then replace the silica gel every 25 hours. The silica gel was dried at a high temperature of 120°C to constant weight and then cooled; the seeds were dried with silica gel in a sealed container at room temperature for 48 hours, and the water content of the seeds was 6.36% (mass fraction), and the dried seeds were sealed with double-layer aluminum foil paper and placed in Store at room temperature for 60 days in a desiccant filled with dried silica gel.

[0038] Before sowing, the super-dry treated and stored seeds were placed in a closed environment with increasing relative humidity in order to gradually increase the water content of the seeds. The environment of the rehydration treatment used in this embodiment is as follows: CaCl 2 A closed environmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com