Method for preparing ultra-fine tungsten-copper composite powder

A composite powder, tungsten-copper technology, applied in the field of preparation of ultra-fine tungsten-copper composite powder, can solve problems such as difficult microstructure, unfavorable thermal conductivity, influence, etc., to achieve high physical and mechanical properties of materials, accurate and controllable material composition , The effect of low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] 1. Preparation of W-Cu composite powder

[0024] Now take ammonium tungstate and copper sulfate as the example of free radical-induced cross-linking homopolymerization as raw materials, and the non-limiting examples are described as follows:

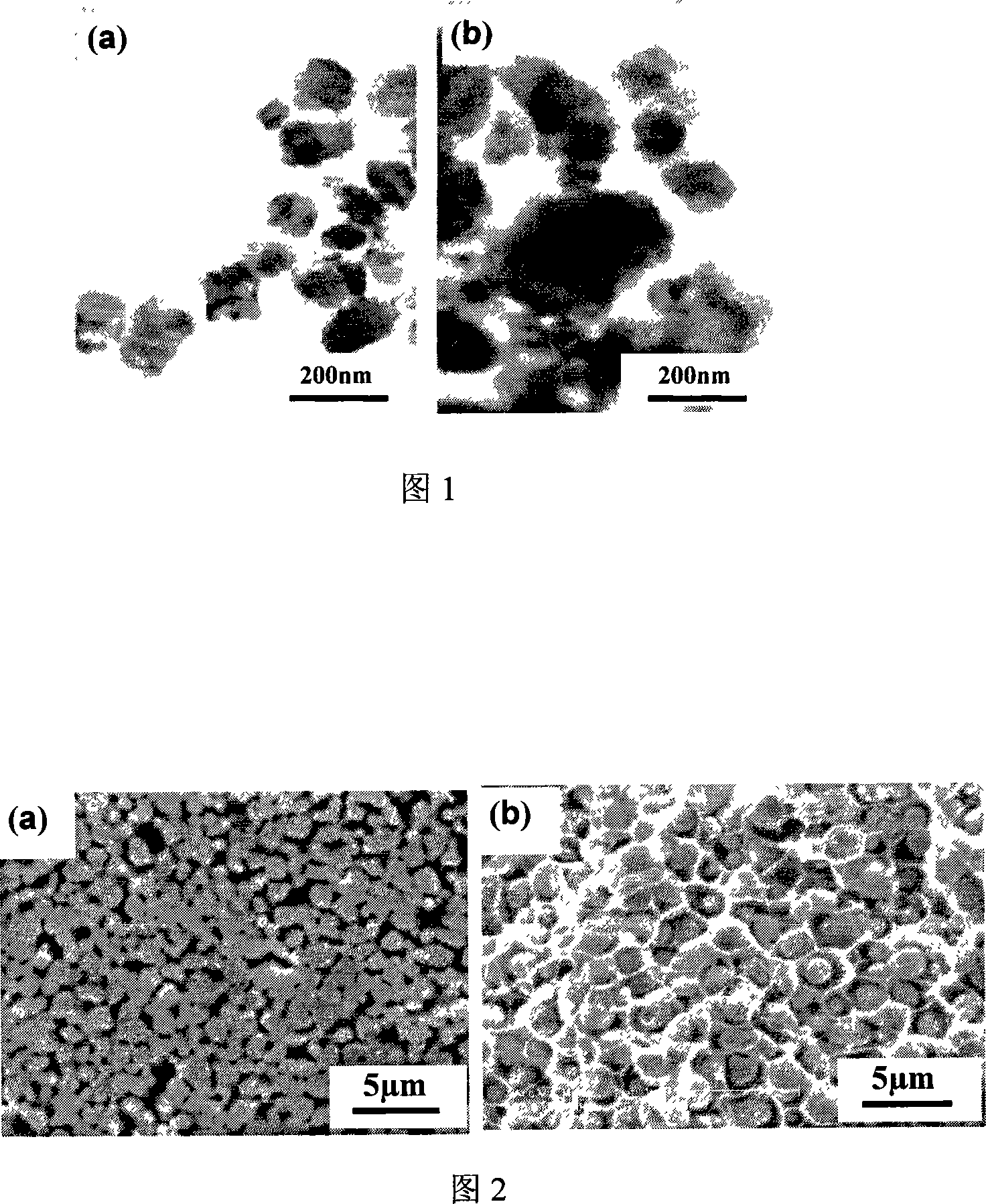

[0025] Add chemically pure ammonium tungstate and copper sulfate powder to acrylamide (AM) monomer and N,N-methylenebisacrylamide (MBAM) at a concentration of 20 wt.% at a mass ratio of W to Cu of 8:2 In the mixed aqueous solution (AM:MBAM=20:1) composed of crosslinking agent, after 16 hours of ball milling and mixing, add an appropriate amount of ammonium persulfate initiator and tetramethylethylenediamine catalyst to the resulting suspension, and heat to about At 60°C, the organic monomer is cross-linked and solidified to form a wet gel. The wet gel was heated to 110-120°C to dry and dehydrate to obtain a dry gel, and then calcined at 700°C, and the calcined product was reduced at 800°C for 2 hours in a hydrogen atmosphere, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com