System and method for aerating and plugging alkali metal steam chamber of mini type CPT atomic clock

An alkali metal, steam cavity technology, applied in metal material coating technology, microstructure technology, gaseous chemical plating and other directions, can solve the problems of frequency drift, high environmental requirements, difficult to batch production, etc. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

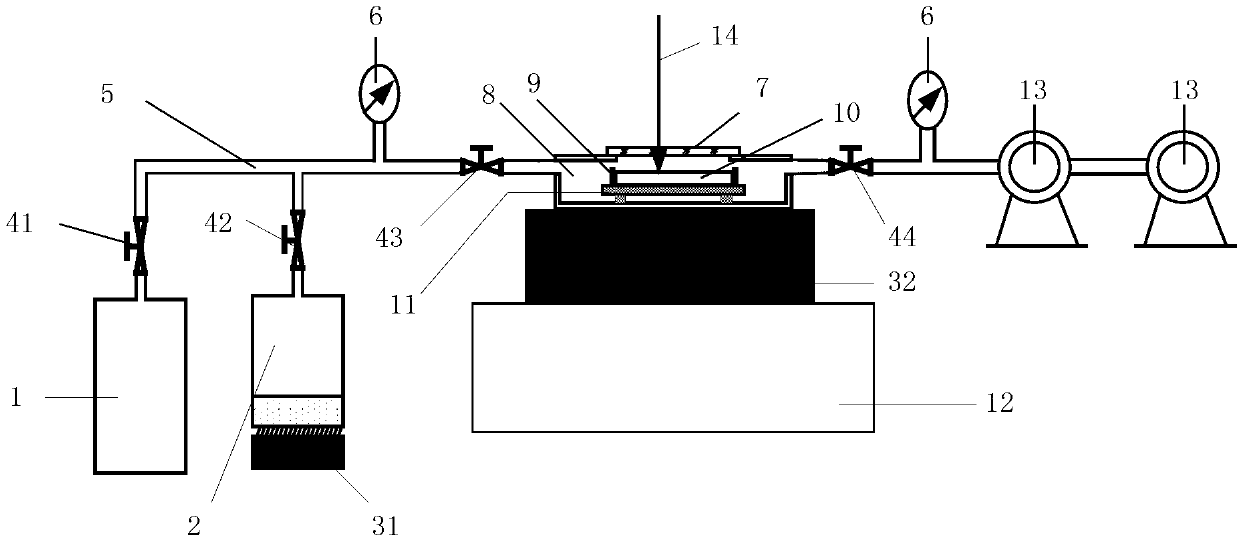

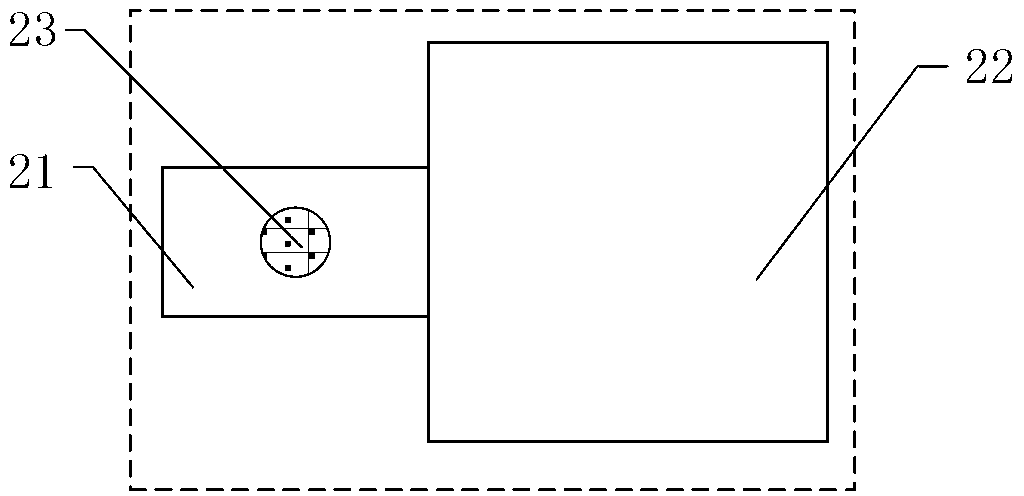

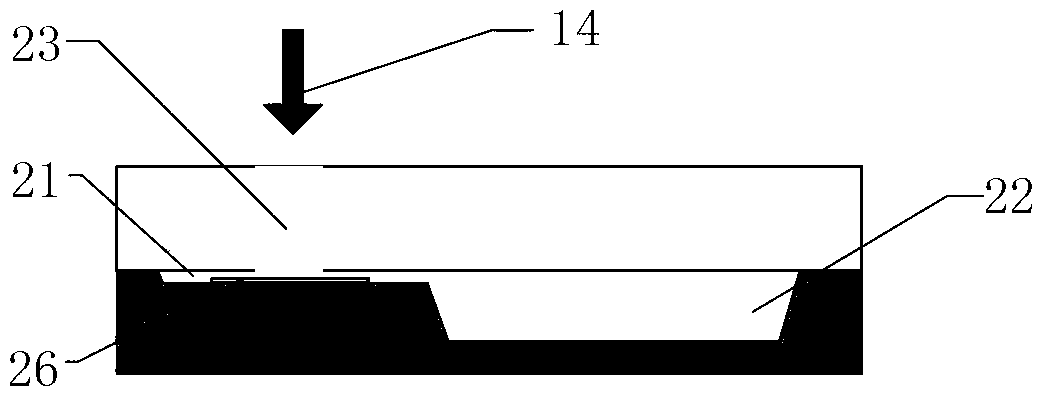

[0052] as attached Figure 2a-2b Shown, wherein 2a is a top view of 2b. The atomic clock alkali metal vapor chamber adopts Si-Glass two-layer anode bonding structure. The lower layer is a silicon wafer, which uses ordinary N-type double-sided precision polished silicon wafers. The upper layer is a glass wafer, which uses Pyrex7740 glass. Inflatable holes 23 on the glass. First, use wet etching on the semiconductor silicon material to make the upper silicon ventilation groove 21 and the upper silicon alkali metal vapor chamber 22, and then use mechanical drilling or laser drilling on the glass material to make gas on the glass with alkali metal vapor Hole 23, make a thin layer of SiO on the corresponding silicon vent groove directly below the gas filling hole 2 Layer 26, and finally carry out Si-Glass anode bonding to make the alkali metal vapor cavity of the miniature CPT atomic clock to be inflated and sealed.

[0053] Then put the disc of the miniature CPT atomic clock a...

Embodiment 2

[0056] The disc of the miniature CPT atomic alkali metal vapor chamber is put into the inflation and sealing system, which is the same as in Example 1. The difference is that in this embodiment, the atomic alkali metal vapor chamber adopts a Si-Glass two-layer anode bonding structure, and the lower layer It is a silicon wafer, using ordinary N-type double-sided precision polished silicon wafer, the upper layer is a glass sheet, using Pyrex 7740 glass, and the air-filling and sealing channel is the micro-inflation channel 24 on the glass, as attached Figure 3a-3b Shown, wherein 3a is a top view of 3b. Firstly, on the semiconductor silicon material, wet etching is used to fabricate the upper-silicon vent groove 21 and the upper-silicon alkali metal vapor chamber 22, and then on the glass material, mechanically or laser-drilled holes are used to make corresponding holes directly above the silicon vent groove. The air-filled hole 23 on the glass that produces the alkali metal va...

Embodiment 3

[0058] The disc of the miniature CPT atomic alkali metal vapor chamber is put into the inflation and sealing system is the same as that of Example 1, the difference is that in this embodiment, the atomic alkali metal vapor chamber adopts a Glass-Si-Glass three-layer anode bonding structure , the middle layer is a silicon wafer, using N-type double-sided precision polished silicon wafers, the upper and lower layers are glass wafers, using Pyrex 7740 glass, and the air-filling and sealing channel is the air-filling hole 23 on the glass, as attached Figure 4a-4b Shown, wherein 4a is a top view of 4b. First, use wet etching on the semiconductor silicon material to make the silicon vent groove 21 and the silicon alkali metal vapor chamber 22 that is etched through, and then carry out anodic bonding of the glass and the back of the silicon wafer, and then use mechanical etching on the glass material. Holes or laser drilling and other methods are used to make air-filled holes 23 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com