Preparation method of high-safety and high-performance lithium battery negative electrode

A negative electrode, high-performance technology, applied in the direction of battery electrodes, electrode manufacturing, secondary batteries, etc., can solve the problems of not being able to effectively alleviate volume expansion, occupy a large area, and reduce safety, and achieve good apparent quality and safety High performance, the effect of mentioning safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention comprises the following steps:

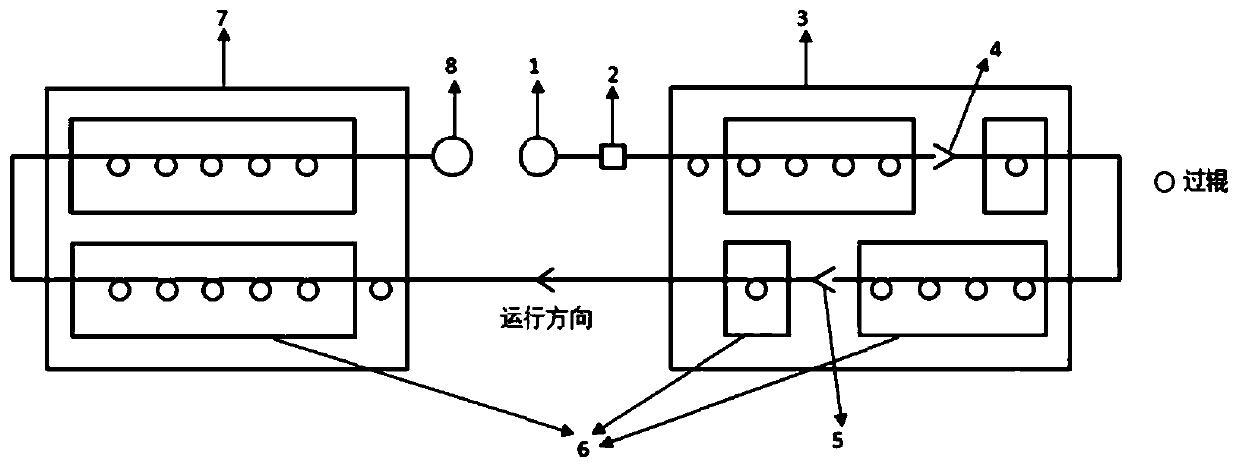

[0030] (1) Lead the copper foil (thickness 6-20um, coated with 1-4um thick conductive agent) through the unwinding unit 1, control the tension and speed of the roller, so that the copper foil runs stably without large jitter;

[0031] (2) Pass the copper foil through the corona surface treatment unit 2, utilize the generated plasma area to enhance the surface activity of the material, increase the surface roughness of the copper foil, improve the surface tension of the copper foil, and improve the coating effect;

[0032] (3) The silicon-carbon negative electrode slurry (silicon mass fraction is 6%) is coated on the copper foil through the double-sided extrusion coating mechanism 3 to obtain a uniform coating. During the single-side baking process of the pole piece, when the remaining solvent content is 10% and the surface is in a gel state, the laser mechanism 4 (laser power 100W) is used to punch micropores on the...

Embodiment 2

[0036] The present invention comprises the following steps:

[0037] (1) Lead the copper foil (thickness 6-20um, coated with 1-4um thick conductive agent) through the unwinding unit 1, control the tension and speed of the roller, so that the copper foil runs stably without large jitter;

[0038] (2) Pass the copper foil through the corona surface treatment unit 2, utilize the generated plasma area to enhance the surface activity of the material, increase the surface roughness of the copper foil, improve the surface tension of the copper foil, and improve the coating effect;

[0039] (3) Coating the silicon-carbon negative electrode slurry (the mass fraction of silicon is 8%) on the copper foil through the double-sided extrusion coating mechanism 3 to obtain a uniform coating. During the single-side baking process of the pole piece, when the remaining solvent content is 20% and the surface is in a gel state, the laser mechanism 4 (laser power 500W) is used to punch micropores on ...

Embodiment 3

[0043] The present invention comprises the following steps:

[0044] (1) Lead the copper foil (thickness 6-20um, coated with 1-4um thick conductive agent) through the unwinding unit 1, control the tension and speed of the roller, so that the copper foil runs stably without large jitter;

[0045] (2) Pass the copper foil through the corona surface treatment unit 2, utilize the generated plasma area to enhance the surface activity of the material, increase the surface roughness of the copper foil, improve the surface tension of the copper foil, and improve the coating effect;

[0046] (3) The silicon-carbon negative electrode slurry (silicon mass fraction is 10%) is coated on the copper foil through the double-sided extrusion coating mechanism 3 to obtain a uniform coating. During the single-side baking process of the pole piece, when the remaining solvent content is 30% and the surface is in a gel state, the laser mechanism 4 (laser power 1000W) is used to punch micropores on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Laser power | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com