Method for preparing graphite crucible with recycled graphite

A technology for regenerating graphite and graphite crucibles, which is applied in the field of waste graphite recycling, can solve problems such as restricting product specifications, and achieve the effects of product quality improvement, energy reuse, and strong corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

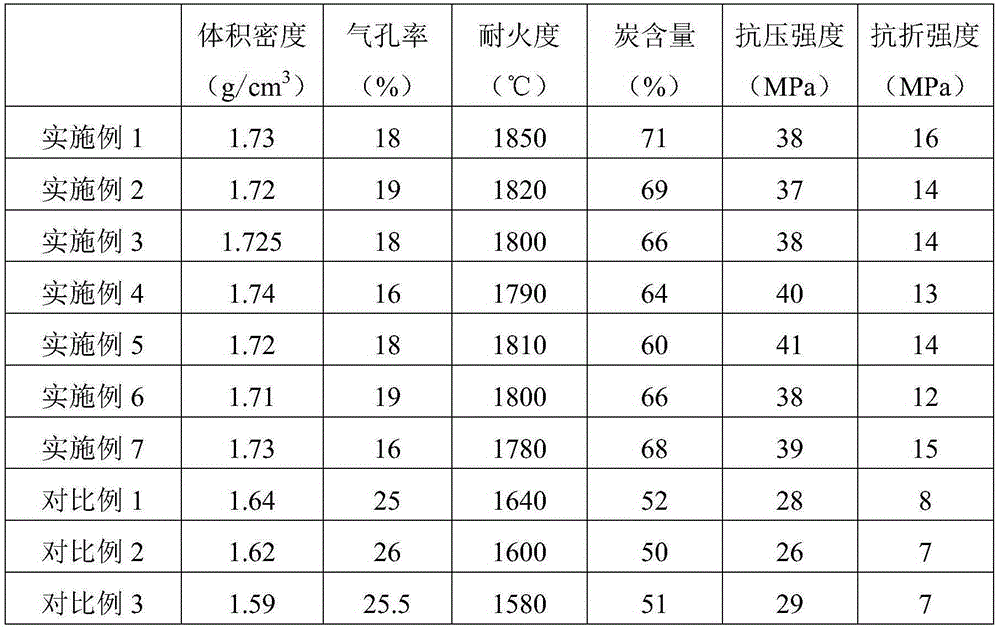

Examples

Embodiment 1

[0046] 1) Preparation of medium-temperature modified asphalt: place the asphalt in an asphalt melting tank at a temperature of 160°C for dehydration and precipitation for 72 hours to obtain medium-temperature modified asphalt;

[0047] 2) Crushing: crush and sieve the regenerated graphite and calcined coke respectively to obtain regenerated graphite powder and calcined coke powder, the particle size of the regenerated graphite powder is 0.5mm, and the particle size of calcined coke powder is 0.075mm, and set aside;

[0048] 3) Ingredients: Take 60kg of the above-mentioned spare regenerated graphite powder and 13kg of calcined coke powder, and mix them evenly to obtain a mixed dry material;

[0049] 4) Kneading: Put the mixed dry material obtained in step 3) into a kneading pot, dry mix for 35 minutes, make the temperature of the mixed dry material reach 128°C, then add 27 kg of prepared medium-temperature modified asphalt, and wet mix for 35 minutes;

[0050] 5) Dry the materi...

Embodiment 2

[0066] 1) Preparation of medium-temperature modified asphalt: place the asphalt in an asphalt melting tank at a temperature of 180°C for dehydration and precipitation for 68 hours to obtain medium-temperature modified asphalt;

[0067] 2) Crushing: crush and sieve the regenerated graphite and calcined coke respectively to obtain regenerated graphite powder and calcined coke powder, the particle size of the regenerated graphite powder is 0.335mm, and the particle size of calcined coke powder is 0.005mm, and set aside;

[0068] 3) Ingredients: Take 60kg of the above-mentioned spare regenerated graphite powder and 15kg of calcined coke powder, and mix them evenly to obtain a mixed dry material;

[0069] 4) Kneading: Put the mixed dry material obtained in step 3) into a kneading pot, dry mix for 45 minutes, make the temperature of the mixed dry material reach 132°C, then add 25 kg of prepared medium-temperature modified asphalt, and wet mix for 45 minutes;

[0070] 5) Dry the mate...

Embodiment 3

[0085] 1) Preparation of medium-temperature modified asphalt: place the asphalt in an asphalt melting tank at a temperature of 160°C for dehydration and precipitation for 75 hours to obtain medium-temperature modified asphalt;

[0086] 2) Crushing: crush and sieve the regenerated graphite and calcined coke respectively to obtain regenerated graphite powder and calcined coke powder, the particle size of the regenerated graphite powder is 0.4mm, and the particle size of calcined coke powder is 0.055mm, and set aside;

[0087] 3) Ingredients: Take 60kg of the above-mentioned spare regenerated graphite and 14kg of calcined coke, and mix them evenly to obtain a mixed dry material;

[0088] 4) Kneading: Put the mixed dry material obtained in step 3) into a kneading pot, dry mix for 38 minutes, make the temperature of the mixed dry material reach 135°C, then add 26 kg of prepared medium-temperature modified asphalt, and wet mix for 38 minutes;

[0089] 5) Dry the material: the kneade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com