Method and device for reducing volatile matters of o-cresol-formaldehyde epoxy resin

A novolac epoxy resin and volatile content technology, which is applied in the direction of separation methods, chemical instruments and methods, evaporation, etc., can solve the problems of reducing the volatile content of epoxy resin products, methods or devices, and has not been seen, so as to increase resin film formation Surface area, improvement effect, effect of reducing volatile matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

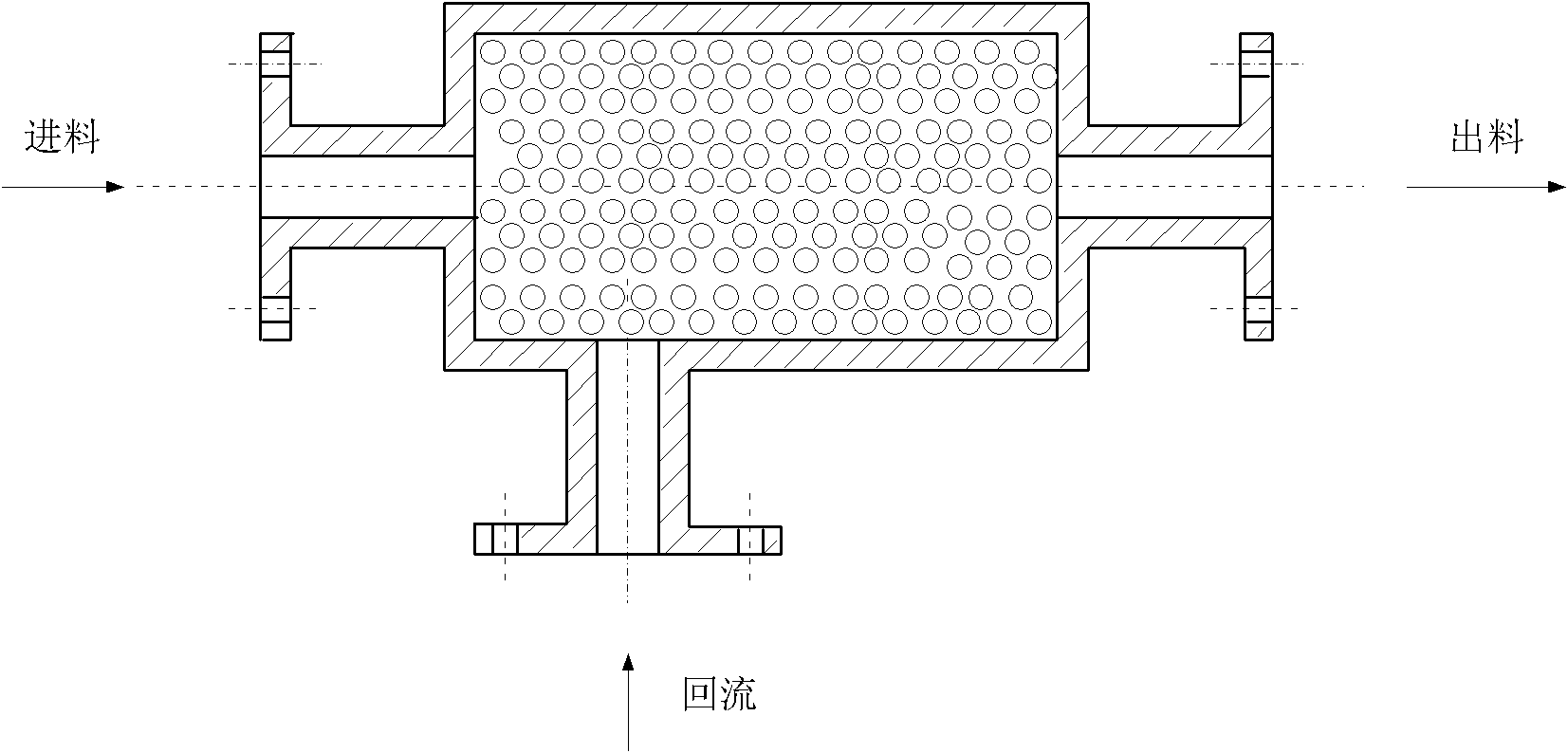

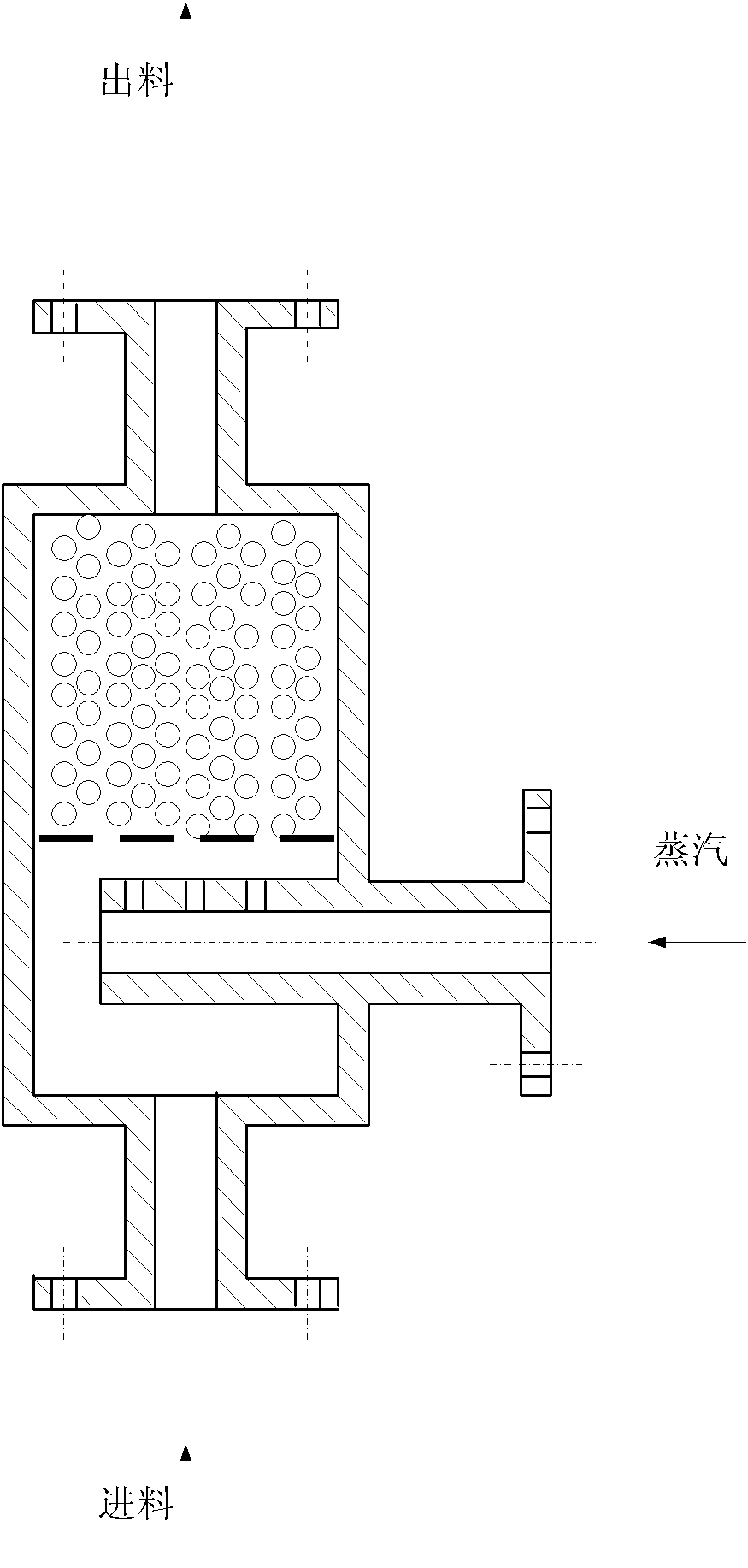

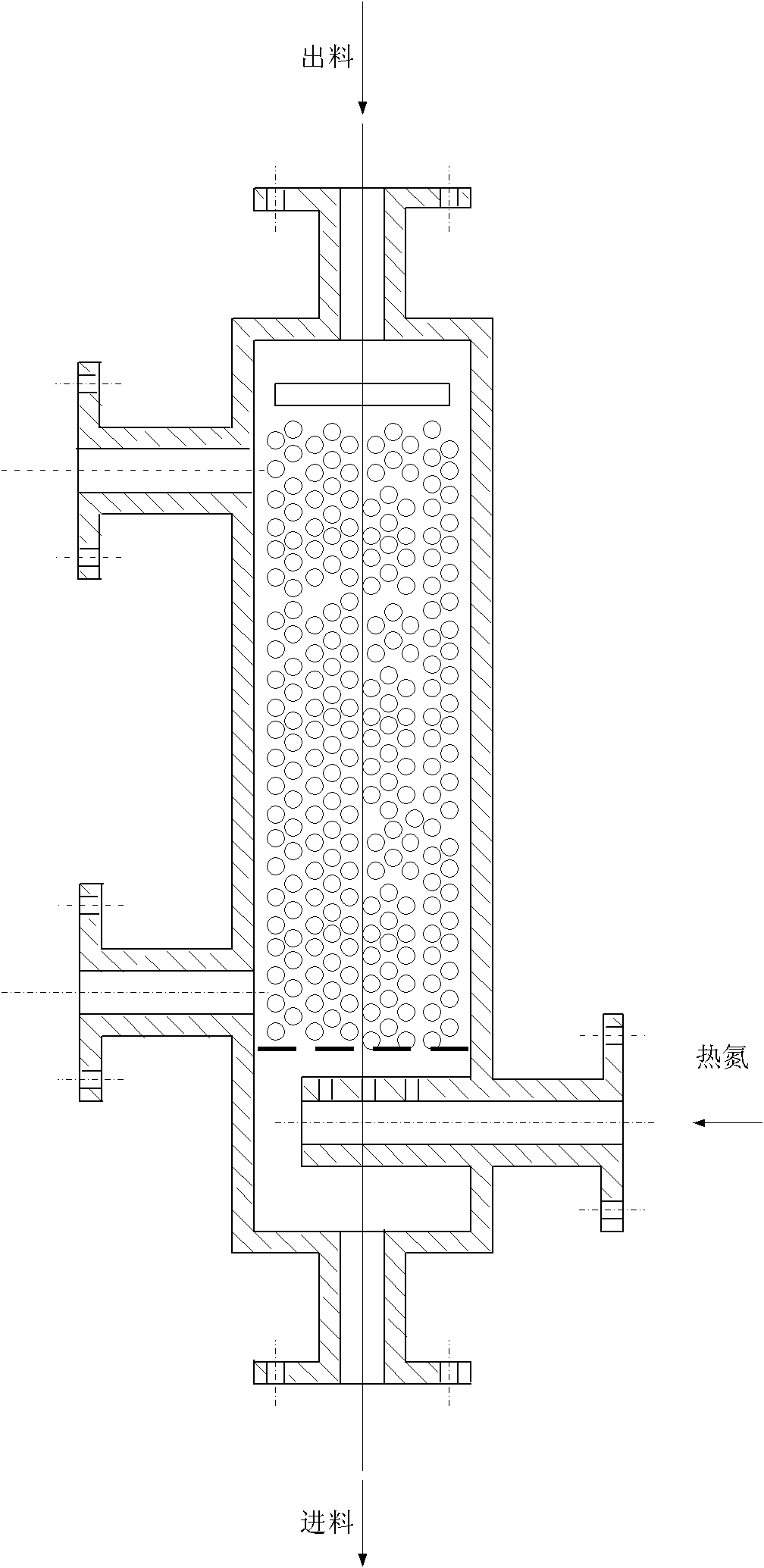

[0036] The structure of horizontal pipe mixer, vertical pipe mixer and packed tower are as follows: Figure 1-3 shown.

[0037] The filler in the horizontal pipeline mixer can make the refluxed liquid phase and the resin solution two kinds of materials with different viscosities evenly mixed, so that the material entering the falling film evaporator can form a uniform film, improve the effect of reflux and reprocessing, and at the same time improve the feed rate. The role of temperature.

[0038] The vertical pipeline mixer makes the water vapor and the resin flow in the same direction, and is condensed and discharged together with the volatile matter in the condenser through the wiped film evaporator.

[0039] The packed tower makes the heated nitrogen and resin flow in reverse, and is discharged from the exhaust port of the vacuum pump through the wiped film evaporator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com