Thermosetting resin and preparation method thereof

A thermosetting and resin technology, applied in the field of chemical materials, can solve the problems of low temperature resistance and achieve the effects of low volatile matter, strong adhesion, and excellent mechanical properties of the cured product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

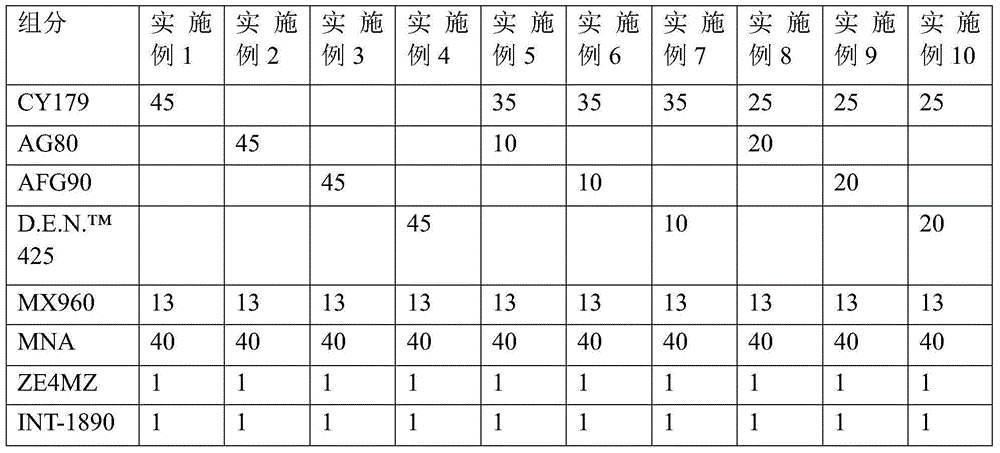

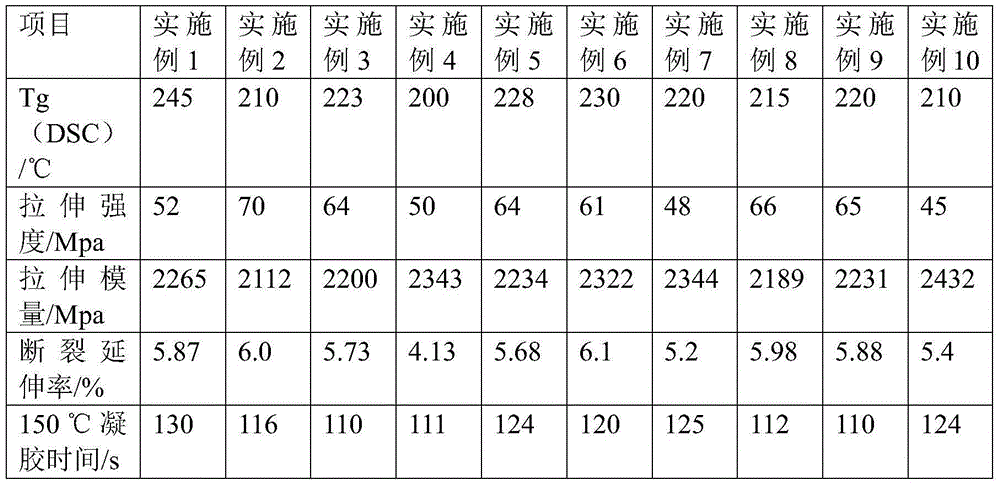

[0018] In an embodiment, as shown in Table 1, first select CY179, AG80, AFG-90 and D.E.N. TM 425 At least one of these different epoxy resins is used as an epoxy resin mixture, and the epoxy resin mixture and the toughening agent MX960 are uniformly dispersed with a high-speed dispersant at 60°C as component A, and the curing agent MNA, Accelerator 2E4MZ and internal release agent INT-1890 are stirred at high speed at room temperature and dispersed evenly as component B. Mix components A and B evenly at room temperature. / T 2567-1995 Preparation of resin casting body to test its performance.

[0019] CY179 is a cycloaliphatic epoxy resin available as a gift from Huntsman Chemical Company, AG80 is a tetrafunctional epoxy resin obtained from Shanghai Huayi Resin Co., Ltd., and AFG-90 is a trifunctional epoxy resin obtained from Shanghai Huayi Company Epoxy, D.E.N. TM 425 is a liquid novolac epoxy resin obtained from Dow Chemical Company, MNA is a modified methyl nadic anhydrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com