Associative acrylate thickening agent as well as preparation method and application thereof

A technology of acrylate and thickener, which is applied in the field of associative acrylate thickener and its preparation, and can solve problems such as inconvenient use, reduced thickening efficiency, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

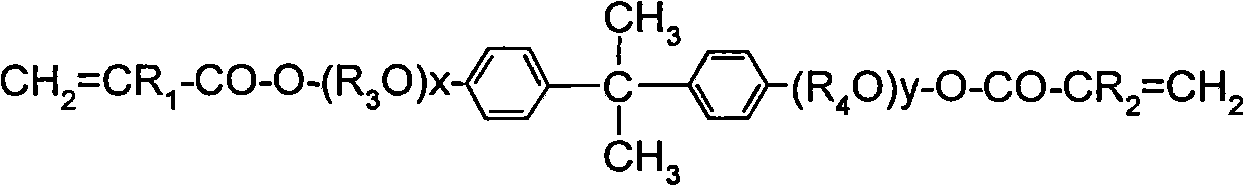

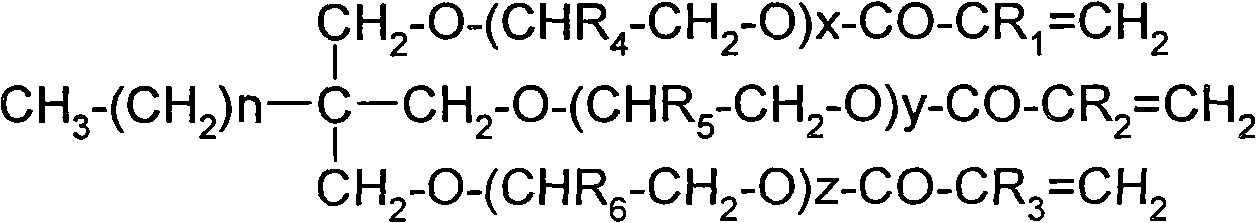

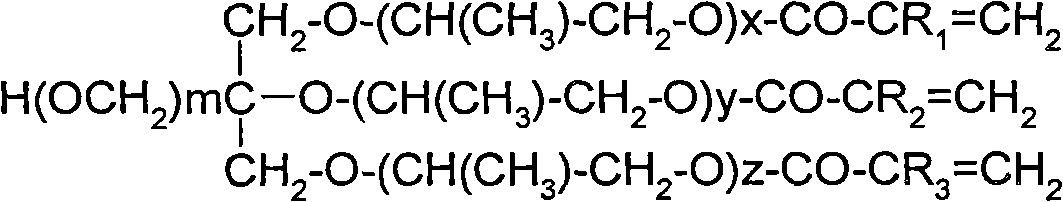

Image

Examples

Embodiment 1

[0119] (1) Preparation of reactive surfactant:

[0120] 0.105mol of maleic anhydride, 0.1mol of fatty alcohol polyoxyethylene ether (Pingpingjia O-15, Jiangsu Haian Chemical Factory, and CH 3 Add COONa into a four-neck flask equipped with a stirring, reflux condenser and a thermometer, stir within 10 minutes and raise the temperature to 70°C to melt the reactants. After raising the temperature to 110°C, keep it warm for 3 hours to obtain 115g of light yellow wax, which is a fatty alcohol polysaccharide. Oxyethylene ether maleate half ester has the following structural formula, and its acid value is 61.24 mg / g KOH.

[0121] C 18 h 37 O(CH 2 CH 2 O) 15 COCH=CHCOOH

[0122] (2) Preparation of monomer emulsion:

[0123] Add 100mL of deionized water into the flask, add 6g of reactive surfactant prepared according to step (1), 21g of acrylic acid, 70g of ethyl acrylate and 2g of ethoxylated trimethylolpropane trimethacrylate (SR368 , American Sartomer Corporation). Stirring...

Embodiment 2

[0129] (1) Preparation of reactive surfactant:

[0130] With embodiment 1.

[0131] (2) Preparation of monomer emulsion:

[0132] 100mL of deionized water was added to the flask, and 3g of the reactive surfactant prepared in Example 1, 23g of methacrylic acid, 71.2g of ethyl methacrylate and 2g of propoxylated glycerol trimethacrylate ( SR492, Sartomer, USA). Stirring was kept at room temperature for 1 h to obtain 199.2 g of monomer emulsion.

[0133] (3) Preparation of associative acrylate thickener:

[0134] A, 0.8g ammonium persulfate is dissolved with deionized water, is settled to 8ml, obtains 10% ammonium persulfate solution;

[0135] B. Add 1 / 5 mass of monomer emulsion prepared in step (2) and 1 / 4 volume of ammonium persulfate solution prepared in step A to 100 mL of deionized water, heat up to 86°C and stir for 0.5 h under nitrogen protection , to obtain seed emulsion;

[0136] C. Then dropwise add 1 / 2 mass of the ammonium persulfate solution prepared in step A a...

Embodiment 3

[0138] (1) Preparation of reactive surfactant:

[0139] 0.01mol of acrylic acid, 0.1mol of fatty alcohol polyoxyethylene ether Ethylan 1008 (AkzoNobel) and 0.5% of CH 3 COONa was added to a four-necked flask equipped with a stirring, reflux condenser and a thermometer, stirred and heated to 70°C within 15 minutes to melt the reactants, then heated to 105°C, and kept for 3.5h to obtain 82g of fatty alcohol polyoxyethylene ether acrylate. Its acid value is 97.6mg / g KOH, and its structural formula is as follows:

[0140] C 10 h 21 O(CH 2 CH 2 O) 8 COCH=CH 2 .

[0141] (2) Preparation of monomer emulsion:

[0142] 80 mL of deionized water was added to the flask, and 7.8 g of the reactive surfactant prepared according to Example 1, 10 g of acrylic acid, 21 g of methacrylic acid, 60 g of ethyl acrylate and 0.2 g of pentaerythritol triacrylate were added dropwise in sequence. Stirring was kept at room temperature for 1 h to obtain 179 g of monomer emulsion.

[0143] (3) Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com