Phenolic-resin-modified urea formaldehyde resin and preparation method thereof

A technology of phenolic resin and urea-formaldehyde resin, applied in the field of phenolic resin modified urea-formaldehyde resin and its preparation, can solve the problems of free formaldehyde release and poor water resistance, free phenol polluting the environment, small reaction equilibrium constant, etc. Easy-to-obtain and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

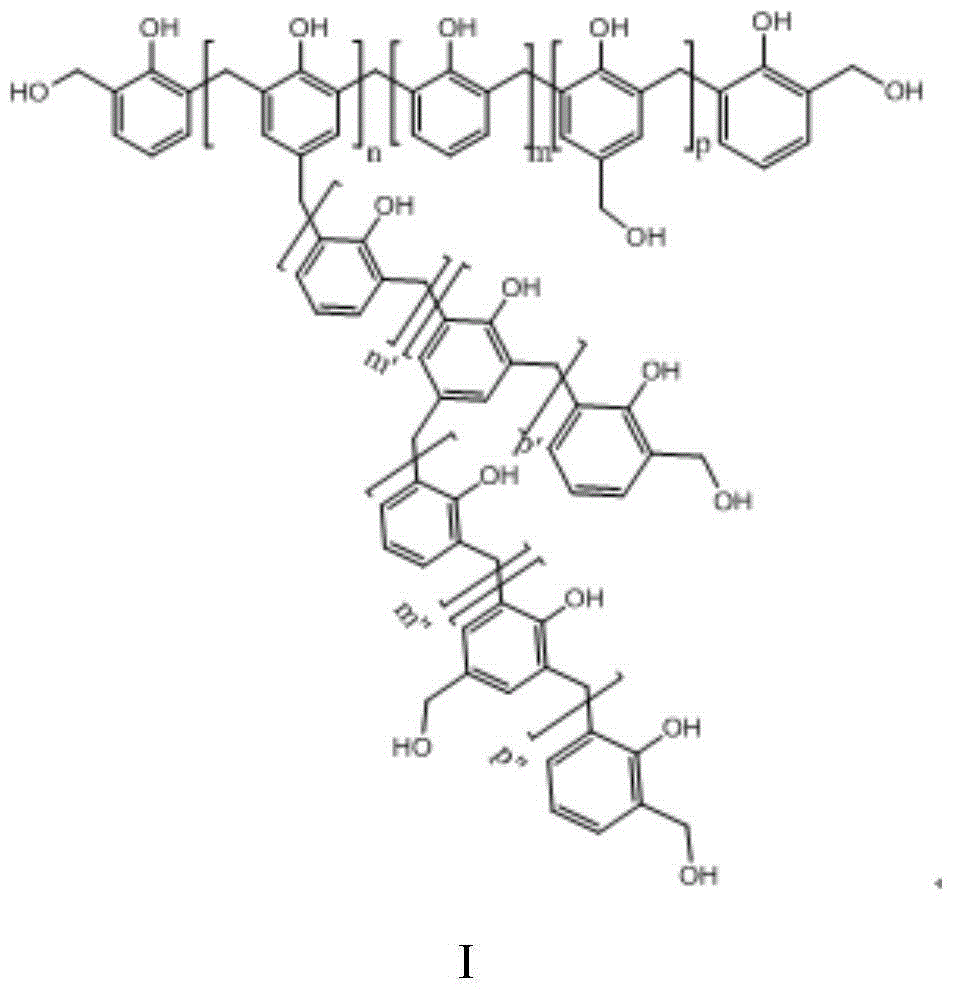

Image

Examples

Embodiment 1

[0030] A kind of phenolic resin modified urea formaldehyde resin, its preparation method comprises the following steps:

[0031] 1) Feed phenol and formaldehyde into the reactor at a molar ratio of 1:1.5, and stir evenly; add sodium hydroxide to the reactor, and the molar ratio of sodium hydroxide to phenol is 0.05:1; heat up to 45°C, Stirring and reacting for 4 hours; the obtained product was dehydrated to a solid content of 55% at 45°C to obtain the phenolic resin;

[0032] 2) Add 100 parts by weight of formaldehyde aqueous solution (concentration is 37wt%), 5 parts by weight of phenolic resin and 30 parts by weight of urea in the reaction vessel successively and mix uniformly, adjust the pH value to 7.5 with aqueous sodium carbonate solution, at 65 ℃ After keeping warm for 15 minutes, continue to heat up to 85°C and keep warm for 30 minutes to obtain reaction system I;

[0033] 3) Regulate step 2) the pH value of gained reaction system I with formic acid aqueous solution t...

Embodiment 2

[0036] A kind of phenolic resin modified urea formaldehyde resin, its preparation method comprises the following steps:

[0037] 1) Feed phenol and formaldehyde into the reactor at a molar ratio of 1:2, and stir evenly; add sodium hydroxide to the reactor, and the molar ratio of sodium hydroxide to phenol is 0.1:1; heat up to 60°C, Stirring and reacting for 8 hours; the obtained product was dehydrated to a solid content of 60% at 60°C to obtain the phenolic resin;

[0038] 2) In the reaction vessel, add successively 100 parts by weight of formaldehyde solution (concentration is 38wt%), phenolic resin of 15 parts by weight and the urea of 33 parts by weight and mix uniformly, adjust system pH value with sodium carbonate solution to be 8.0, at 70 After keeping the temperature for 30 minutes at ℃, continue to heat up to 88 ℃ and keep the temperature for 45 minutes to obtain the reaction system I;

[0039] 3) Regulate the pH value of step 2) gained reaction system I with formic...

Embodiment 3

[0042] A kind of phenolic resin modified urea formaldehyde resin, its preparation method comprises the following steps:

[0043] 1) Feed phenol and formaldehyde into the reactor at a molar ratio of 1:2.2, and stir evenly; add sodium hydroxide to the reactor, and the molar ratio of sodium hydroxide to phenol is 1:1; heat up to 75°C, Stirring and reacting for 24 hours; the obtained product was dehydrated to a solid content of 65% at 75°C to obtain the phenolic resin;

[0044] 2) In the reaction vessel, add successively the urea of 100 parts by weight of formaldehyde solution (concentration is 40wt%), the phenolic resin of 30 parts by weight and 37 parts by weight of urea and mix uniformly, adjust system pH value with sodium carbonate solution to be 9.0, at 75 After 45 minutes of heat preservation at ℃, continue to heat up to 92 ℃ and keep heat for 60 minutes to obtain reaction system I;

[0045] 3) Adjust the pH value of the reaction system I obtained in step 2) with formic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com