Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

313results about How to "Low free formaldehyde content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental protection urea-formaldehyde resin and preparation method thereof

InactiveCN101265314ALow free formaldehyde contentExtended shelf lifeAldehyde/ketone condensation polymer adhesivesThermal waterWeak base

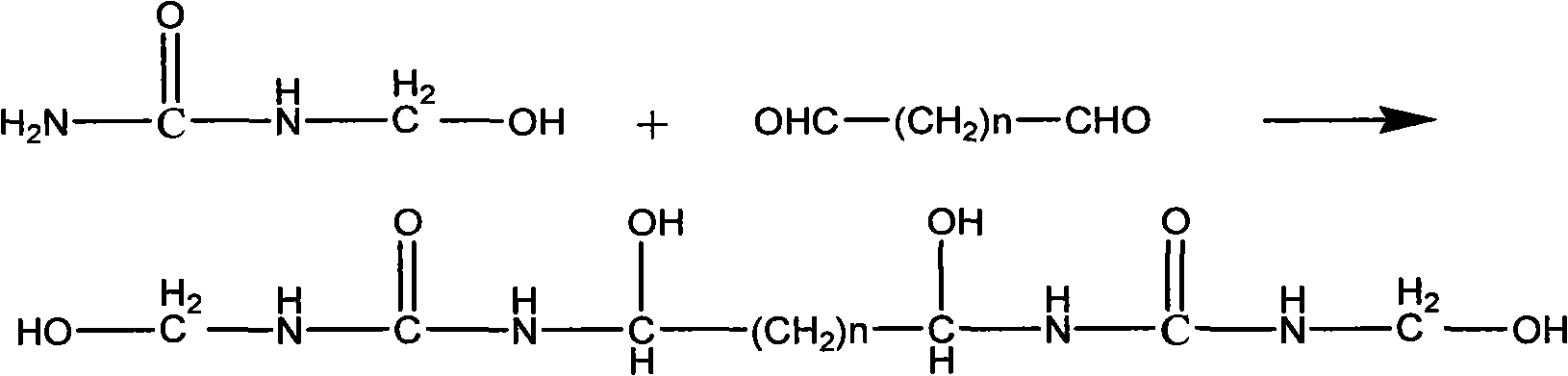

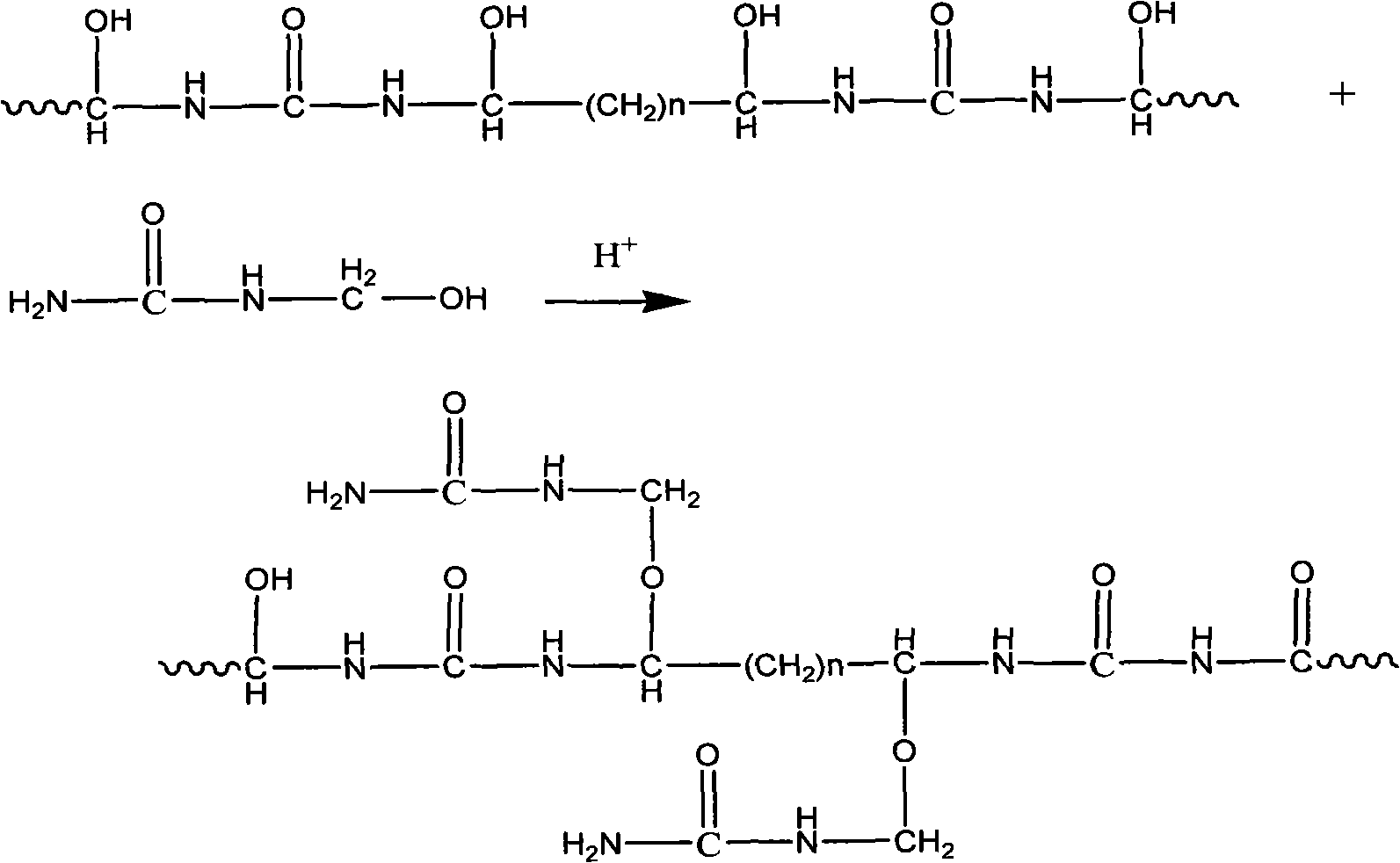

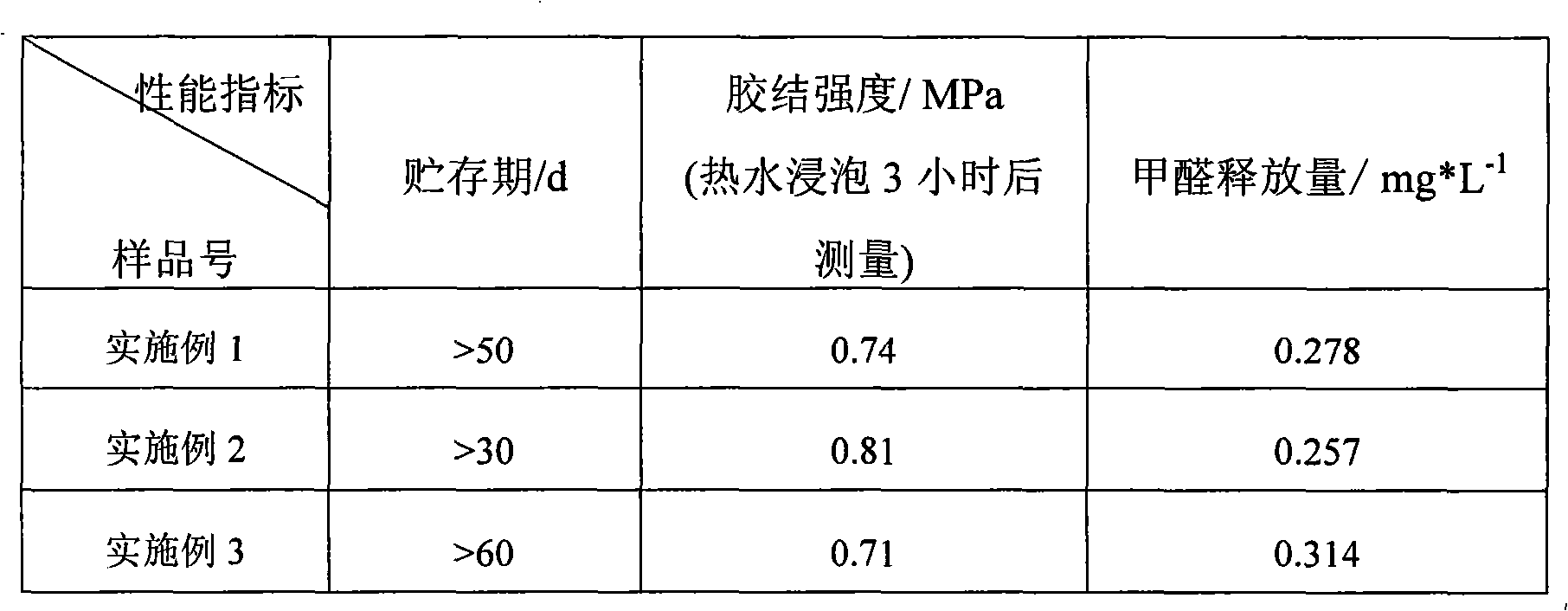

A novel environmental protective urea-formaldehyde resin and a preparation method belong to the field of wood processing adhesives. The urea-formaldehyde resin is formed by the reaction of urea, formaldehyde, aldehyde, one or more stabilizers and modifier according to the route of weak base-weak acid-weak base. The method firstly controls the F / U feed ratio, the pH value and the temperature during the reaction process to reduce the content of free formaldehyde in the resin; then the aldehyde is introduced to allow the resin to generate the stable alkyl ether (-(CH2)n-O-(CH2)n-) structure, thus reducing the content of methylene-ether bond (-CH2-O-CH2-) in the resin structure, simultaneously reducing the using amount of the formaldehyde and further greatly reducing the release amount of the formaldehyde during the using process of a plate from the two aspects; in addition, the introduction of a long chain and polyaldehyde can ensure the resin to have great bonding strength and water resistance. The urea-formaldehyde resin which is prepared by the invention has the advantages of low content of free formaldehyde, simple process, low cost, etc., the release amount of the formaldehyde of the plate which is prepared by using the adhesive achieves the E0 level standard, and the high bonding strength can be maintained after being boiled in hot water.

Owner:BEIJING UNIV OF CHEM TECH

Composite modification method for phenolic resin adhesive

ActiveCN102108275ASimple processEasy to controlAldehyde/ketone condensation polymer adhesivesPolymer scienceResin adhesive

The invention provides a composite modification method for a phenolic resin adhesive. A mixture of organic silicon and (or) a polyhydric compound serves as a modifier in a synthetic process of phenolic resin. The composite modification method is technically characterized in that: the modifier is added in a prepolymerization reaction process or after the prepolymerization reaction; formaldehyde is added at one time under an alkaline condition; dehydration is not performed in the later period of the reaction; the whole process flow is simple and is easy to operate; the product has stable performance and does not pollute environment; and the content of free formaldehyde is low.

Owner:江苏泰尔新材料股份有限公司 +1

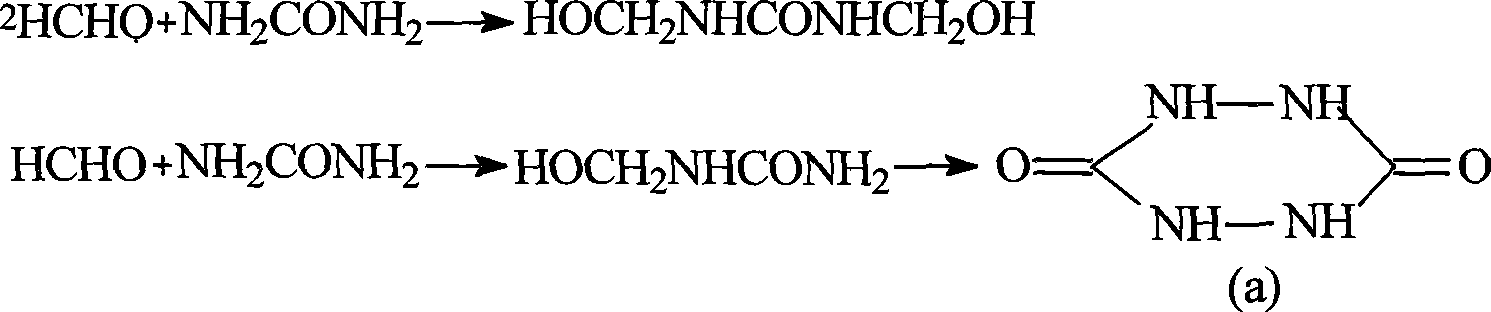

Industrial production method and device of urea-formaldehyde slow-release compound fertilizer

ActiveCN103011982ALow free formaldehyde contentMeet needsAgriculture gas emission reductionFertilizer mixturesPotassiumNitrogen

The invention relates to an industrial production method and device of a urea-formaldehyde slow-release compound fertilizer and a device thereof. The industrial production method comprises the steps of adding water and oxidized starch to a reaction still and then pasting, adding urea of which the nitrogen content is 46wt% and formalin, stirring, dissolving and then adjusting the pH value to 8.5-8.8 by an alkaline matter, reacting at constant temperature of 60 DEG C to obtain reaction liquid; adjusting the pH value to 5.4-5.1 by the reaction liquid; reacting for 45 minutes at the constant temperature of 65-68 DEG C, then adjusting the pH value to 6.8-7.2, and terminating reaction to obtain the urea formaldehyde condensation product solution; mixing the urea formaldehyde condensation product solution with nitrogen, phosphorus and potassium materials, pelletizing, drying and cooling to below 35 DEG C, and screening to obtain the urea-formaldehyde slow-release compound fertilizer. The industrial production device of the urea-formaldehyde slow-release compound fertilizer is also provided by the invention. Urea formaldehyde is taken as a skeleton; rapid disintegration phenomenon of fertilizer particles caused by water absorption expansion is effectively prevented; the urea-formaldehyde slow-release compound fertilizer has good nutrient slow-release performance, and is high in pelletizing rate in the production process and strong in granule hardness, and the total nutrient content is improved.

Owner:河南豫邮金大地科技服务有限公司

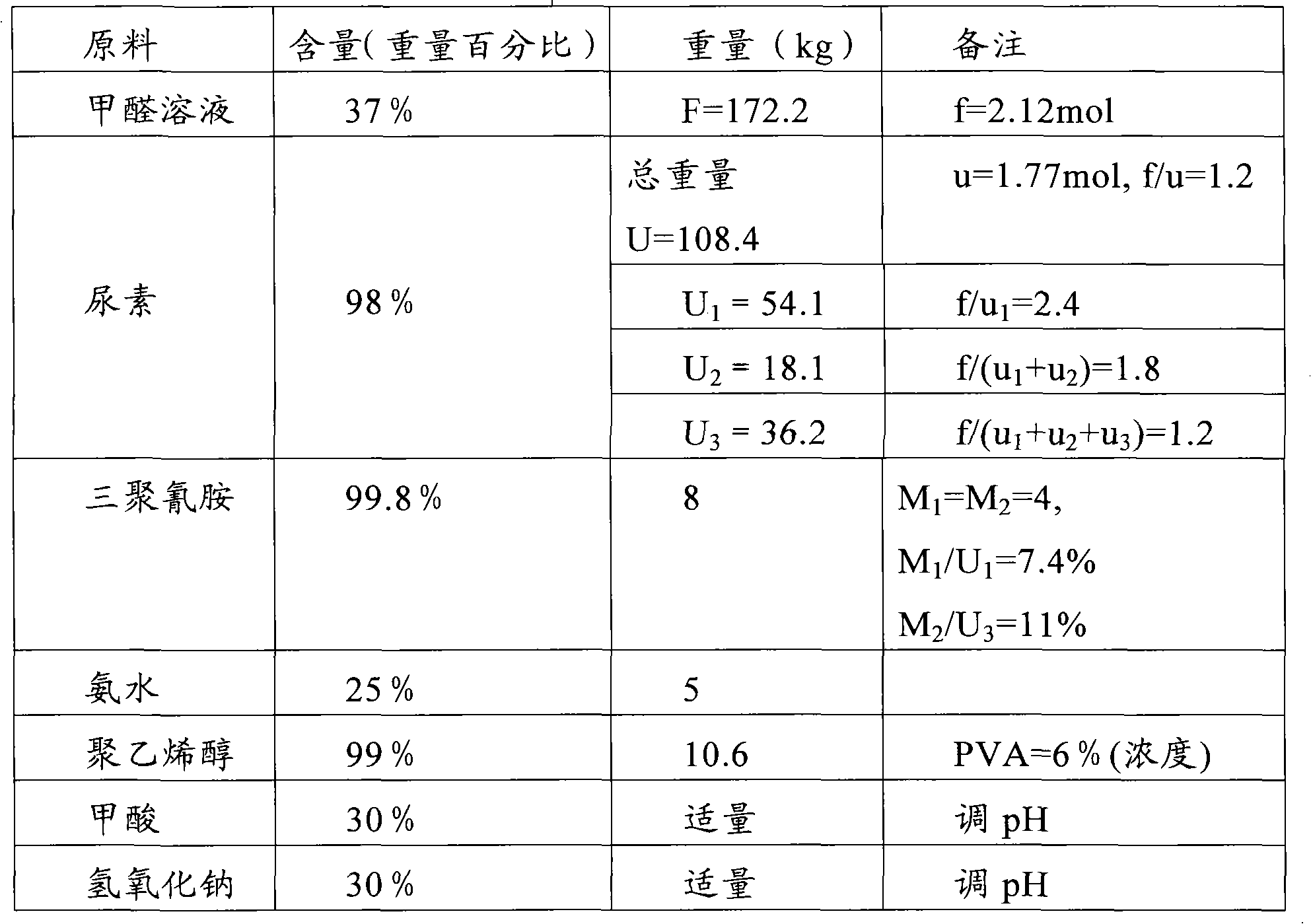

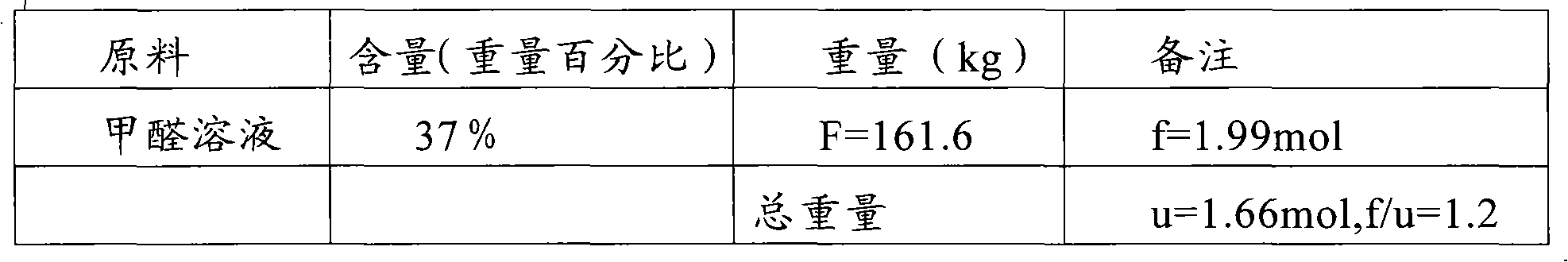

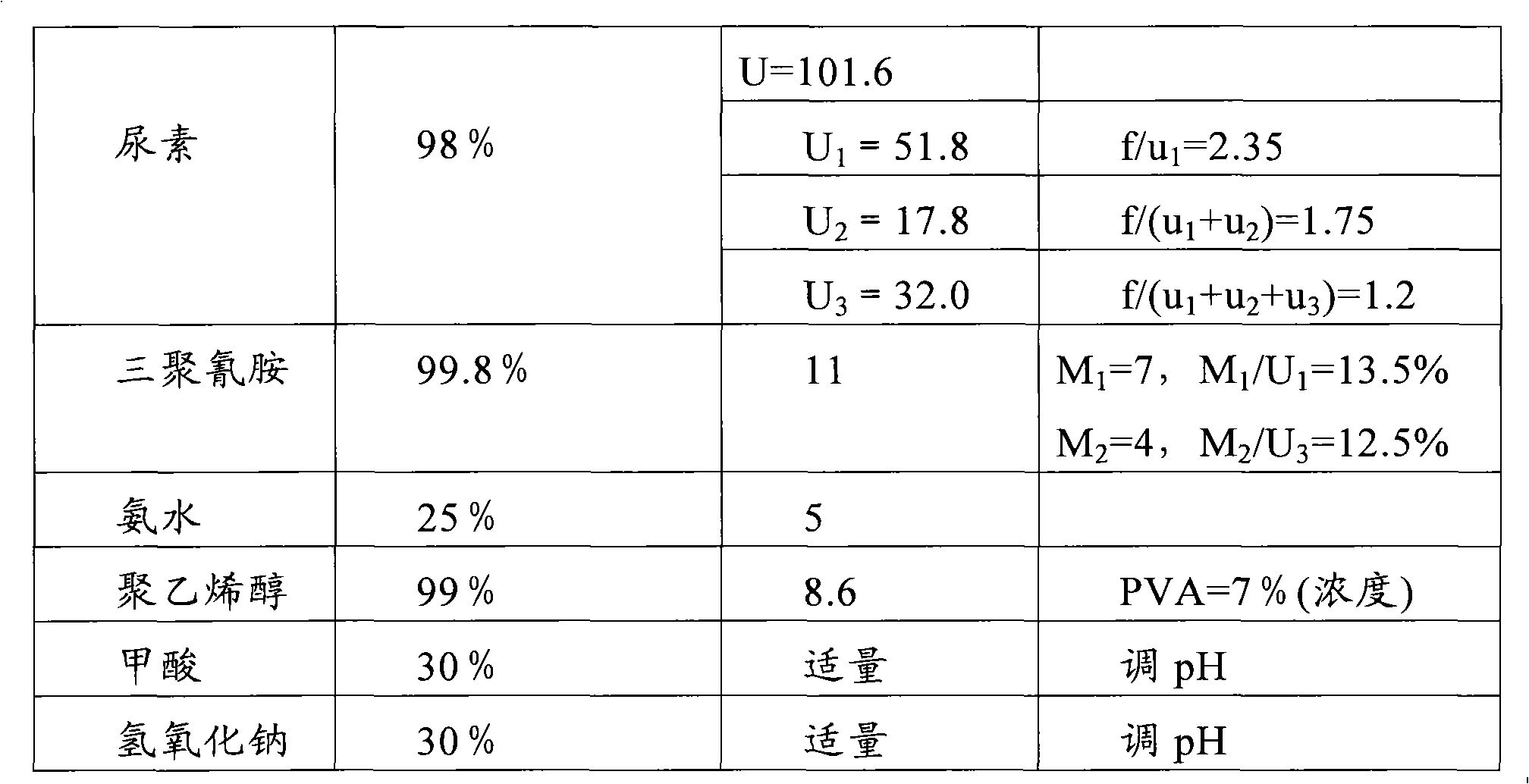

Environment-friendly urea resin for laminating plywoods from high water-content veneers and preparation and application thereof

ActiveCN102086257AThe polycondensation reaction is sufficientGood water solubilityAldehyde/ketone condensation polymer adhesivesHigh water contentUltimate tensile strength

The invention relates to a preparation method and application of environment-friendly urea resin for laminating plywoods from high water-content veneers. The method for synthesizing the resin is simple, and low in cost; the laminated plywoods can meet the national E1 grade and even E0 grade environmental protection requirements; and the problems of low prepressing performance and water resistance when the high water-content veneers are laminated into the plywoods are mainly solved. In the synthesis of the urea resin, an acid-base-acid-base process is adopted, formaldehyde and polyvinyl alcohol are added at one time, urea is added by three batches, melamine is added by two times, and after ammonia water is added, the ammonia water, the urea, the formaldehyde and urea-form condensate are reacted to generate a series of triazine ring compounds, and the microstructure of the resin is improved. When the resin is cured, the crosslinking density is improved, wet shear strength of the plywoods is obviously improved and the formaldehyde emission is obviously reduced.

Owner:广西鑫恒晶木业股份有限公司

Method for preparing silicate nano-clay/urea resin composite adhesive

ActiveCN101818036AGood dispersionHigh reactivityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesiveDeep processing

The invention provides a method for preparing a silicate nano-clay / urea resin composite adhesive, and belongs to the field of deep processing of non-metallic mine and high polymer materials. The technical scheme of the method comprises the following steps of: first, performing surface activating treatment on the silicate clay; then, inorganically and organically modifying the nano-clay by using soluble silicate solution and a silane coupling agent respectively; and finally, adding the modified nano-clay in a process of synthesizing the urea resin so as to prepare the silicate nano-clay / urea resin composite adhesive. The raw materials of the composite adhesive have rich sources and low price; and the method has a simple process, can effectively reduce the free formaldehyde content of the urea resin, and simultaneously improve the mechanical performance of the urea resin.

Owner:溧阳常大技术转移中心有限公司

Synthetic resin adhesive for E0/E1 level shaving board

InactiveCN101348699AHigh bonding strengthReduce releaseAldehyde/ketone condensation polymer adhesivesHigh concentrationPolyvinyl alcohol

The invention discloses a synthetic resin adhesive for an E0 / E1 grade flakeboard, which is melamine modified urea-formaldehyde resin; formaldehyde with the concentration of 48 percent in mass percentage is adopted as a raw material; the adhesive comprises the following reaction materials in percentage by mass: 4.0 to 5.0 percent of melamine, 43.0 to 45.0 percent of urea, 48.0 to 51.0 percent of formaldehyde, 1.00 to 1.10 percent of addition agent, 0.20 to 0.22 percent of polyvinyl alcohol and proper acid and alkali; the total molar ratio is between 1.08 and 1.11; and the materials are reacted and synthesized, thereby preparing the adhesive. The high-concentration formaldehyde is adopted as the raw material; the adhesive has excellent bonding strength, proper curing time, good storage stability and the free formaldehyde content of between 0.06 and 0.08 percent; with the adhesive, the E1 and E0 flakeboard with excellent quality can be stably produced; and the adhesive has the advantages of low adhesive application amount, strong process adaptability, rapid curing, etc.

Owner:DARE TECH

Preparation method of highly methyl etherified amino resin

The invention discloses a preparation method of highly methyl etherified amino resin, and relates to a synthetic preparation method of a liquid coating cross-linking agent-amino resin. The method comprises the following steps of: putting methanol and hexamethylolmelamine in a reaction kettle, wherein the weight ratio of the methanol and hexamethylolmelamine is 1:1-10, adding acid to adjust pH value to acidity, raising temperature to 20-50 DEG C for the first time, maintaining the temperature for 15min to 2h, raising temperature to 50-80 DEG C for the second time, then maintaining the temperature for 15min to 2h, then adding alkali to neutralize, adjusting the pH value to 7-10, raising the temperature by steam, dealcoholizing at constant pressure, then depressurizing, further removing the low-boiling-point substances at a pressure lower than -0.09MPa to obtain the highly methyl etherified amino resin product. The invention solves the problem of complex manufacturing processes, combines the two steps into one step, is simple and convenient to operate and control with period of time shortened from original 18h / kettle to about 9h / kettle and enhances the yield obviously, lowers the cost, reduces the energy consumption by 2 / 3, reduces the content of free formaldehyde and improves the environmental performance.

Owner:奥仕集团有限公司

Method for preparing modified urea-formaldehyde resin

InactiveCN100572445CLow free formaldehyde contentReduce formaldehyde emissionPolymer scienceNational standard

A method for preparing a modified urea-formaldehyde resin, the method comprises mixing and contacting the product of the contact reaction between formaldehyde and urea and a urea-formaldehyde resin modifier, wherein the urea-formaldehyde resin modifier is added at least twice. The free formaldehyde content of the urea-formaldehyde resin prepared by the preparation method of the modified urea-formaldehyde resin provided by the invention is very low, so that the formaldehyde release amount of wood-based panel products can be greatly reduced when used in the wood manufacturing process. For example, the free formaldehyde content of the modified urea-formaldehyde resin prepared by the method provided by the invention can be reduced to no more than 0.20%, so that the plywood prepared by using the modified urea-formaldehyde resin can reach the E1 (≤1.5 mg / liter) regulation in the national standard . In addition, the modified urea-formaldehyde resin prepared by the method provided by the invention can not only be in liquid form, but also in powder form, and can be used under wet and outdoor conditions.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Phenol-formaldehyde resin having low concentration of tetradimer

InactiveUS20080064284A1Improve stabilityLimited shelf lifeSynthetic resin layered productsAldehyde/ketone condensation polymer adhesivesGlass fiberFiber

A phenol-formaldehyde resin, having a low concentration of tetradimer, making the resin suitable for preparing a binder composition for making non-woven fiber products, such as fiberglass insulation, prepared by reacting phenol and formaldehyde in the presence of a sulfite source.

Owner:GEORGIA PACIFIC CHEM LLC

Method for preparing adhesive for grade-E0 medium density fiberboards

InactiveCN102134468ALow free formaldehyde contentModerate curing timeAldehyde/ketone condensation polymer adhesivesAdhesivePolyvinyl alcohol

The invention provides an adhesive for grade-E0 medium density fiberboards. The raw materials of the adhesive include formaldehyde, polyvinyl alcohol, urea and tripolycyanamide. The production process of the adhesive comprises: firstly, adding all formaldehyde into a reaction kettle, regulating the pH value of formaldehyde solution to 7.5 to 8.5 by using sodium hydroxide solution, adding the 40 to 50 percent of polyvinyl alcohol and urea and adding 80 to 90 percent of tripolycyanamide and adding the 10 to 20 percent of urea; secondly, adjusting the pH value to 5 to 6 by using formic acid, reacting for 20 to 30 minutes till a cloud point, regulating the pH value to 705 to 8.5 with caustic soda solution, and adding the 10 to 20 percent of tripolycyanamide and 20 to 30 percent of urea; and finally, adding 10 to 20 percent of urea, regulating the pH value of the adhesive to 6.6 to 7.5, and discharging. The adhesive has the advantages that: the free formaldehyde content is very low, and the manufactured medium density board is of grade E0; the curing time is proper, the storage stability is high, and the normal-temperature storage period is about 1 month; and the manufactured medium density board has high internal combining strength and high waterproof and dampproof performance.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

Preparation of urea-formaldehyde resin for environment-friendly artificial board

InactiveCN101475676AIncrease the lengthLow free formaldehyde contentAldehyde/ketone condensation polymer adhesivesEtherHydroxymethyl

The invention relates to a preparation method for a urea formaldehyde resin used for an environmentally friendly man-made panel. The preparation method comprises the following steps: taking a reaction route of weak base-weak acid-weak base, firstly carrying out the polyaddition of formaldehyde and urea to generate dimethylolurea through a plurality of condensation polymerizations based on the traditional one filling reaction, then carrying out the gradual condensation in an acid medium to generate a linear urea formaldehyde resin, finally gradually adding urea molecules as connection means to improve the length of a linear molecule, reducing the content of free formaldehyde in the urea formaldehyde resin glue, directly synthesizing the green low formaldehyde urea formaldehyde resin glue product, improving the condensation degree and reducing the content of hydroxymethyl, methylene ether and hemiformal through step control, promoting the formation of body type organic micromolecules via microscope, adding a tiny amount of formaldehyde capture agent at the solidification phase to remove residual free formaldehyde, and setting the content of the free formaldehyde in the product to be less than or equal to 0.1 percent, and finally making the product performance technical indicators reach the domestic leading level.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

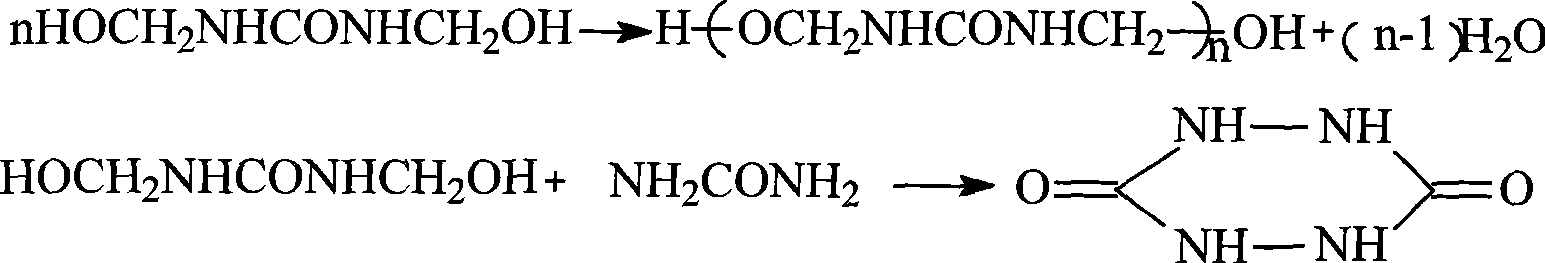

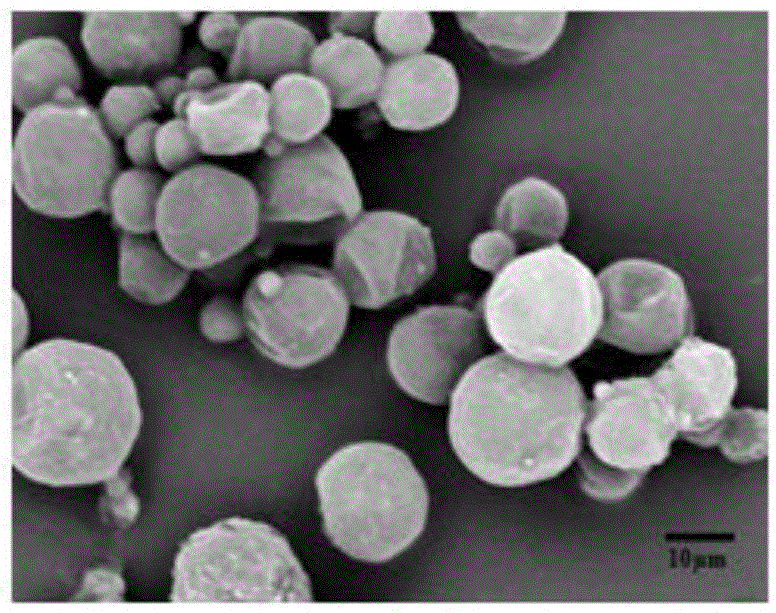

Preparation method of phase change microcapsule

InactiveCN104861935AImprove performanceReduce breakage rateHeat-exchange elementsMicroballoon preparationPolymerChemistry

The invention discloses a preparation method of a phase change microcapsule. The preparation method comprises the following steps: using a solid-liquid phase change material as a core material and a polymer as a wall material, and preparing a white powdered phase change microcapsule by adopting synthesis of a prepolymer, emulsification of the phase change material and step-by-step dropwise addition of the prepolymer, wherein when the prepolymer is dropwise added each time, the pH value of the emulsion is controlled to enable the prepolymer to be sufficiently reacted. The prepared phase change microcapsule is excellent in properties, low in breakage rate, and low in residual free formaldehyde content; the preparation method of the phase change microcapsule is suitable for preparing the microcapsule by using melamine-formaldehyde, urea formaldehyde resin, phenolic resin, urea-melamine-formaldehyde resin and the like as the shell materials; the preparation method is simple, lower in cost, cheap and accessible in the used raw materials; the preparation method of the phase change microcapsule, disclosed by the invention can be used for effectively reducing the residual formaldehyde content in the phase change microcapsule and expanding the range of application of the phase change microcapsule.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for preparing oxidization starch modified urea-formaldehyde resin

The invention relates to a preparation technology of the modified urea-formaldehyde resin; with the strong agitation and the presence of the catalyst, the urea, formaldehyde, water and oxidized starch are added at a time according to the stoichiometric ratio; or first the urea and formaldehyde are used to make the urea-formaldehyde resin with the presence of the catalyst, and then the oxidized starch is used to do the cross-linking step-by-step polymerization; after mixing well, the temperature is raised to be 45 to 110 Celsius system; the acid of a certain amount in the return process is added; the reaction is kept for 40 minutes to 3 hours at a constant temperature; the pH value of the solution is maintained between 3.0 and 6.5. Then the alkaline substance is used to adjust the pH value to be between 7.2 and 9.8; the method is to continue to stir for 15 minutes and stop heating; after the reaction, the modified urea-formaldehyde resin product can be made with a certain solid content. The invention has the advantages of the reduction of the cost and at the same time, the increase of the cross-linking reaction, which further lowers the free-formaldehyde content in the resin, lengthens the time for storage, and reduces the environmental pollution. The product produced in the invention has the advantages of a good stability, a high solid content, the saving of energy and so on.

Owner:JIANGSU UNIV

Furan resin for cast steel and synthesis method thereof

The invention relates to a furan resin for cast steel and a synthesis method thereof. The furan resin is characterized by comprising the following raw materials in percentage by mass: 70-80% of furfuryl alcohol, 9-15% of solid formaldehyde, 10-15% of phenol, 0.5-5.0% of urea, 0.2-0.5% of coupling agent and 2-5% of water. The solid formaldehyde is used instead of liquid formaldehyde in the synthesis process of the furan resin for cast steel, thereby reducing the sewage generated in the production process of the furan resin for cast steel; and the furan resin for cast steel has the characteristics of high strength, low viscosity, favorable molding-sand property and the like.

Owner:YULIN LANKE CASTING MATERIAL

Method for processing lumber-core board

InactiveCN1796069AQuality improvementGuaranteed curing qualityWood treatment detailsCoating impregnationTrappingPulp and paper industry

The present invention relates to a production process of veneered strip-glued board. Said process includes the following steps: sawing raw material to obtain squared timber, drying, defining thickness and processing double faces, making strips by using multiblade saw, making board, coating adhesive, matching board, forced cooling, first sanding, sticking transverse single board, prepressing, hot-pressing, forced cooling, secondary sanding, sticking surface board, secondary prepressing, secondary hot-pressing, cutting edge, third sanding, sorting finished products and putting the finished products into storage. The urea-formaldehyde adhesive formula used in the adhesive-coating process is formed from (by weight portion) 100 portions of low-formaldehyde urea-formaldehyde resin, 20-35 portions of filling agent, 5-10 portions of formaldehyde trapping agent and 0.4-1.0 portion of solidifying agent.

Owner:CHANGLIN WOOD IND

Modified urea-formaldehyde powder adhesive

InactiveCN1542074AReduce sizing costsHigh bonding strengthAldehyde/ketone condensation polymer adhesivesStrong acidsToughening

The modified urea-formaldehyde powder adhesive for adhering wood product mainly is prepared by using spray dried pure urea-formaldehyde powder or melamine-urea-formaldehyde powder as base material; composite curing agent comprising amine salt of strong acid, organic acid and maleic anhydride; fine water soluble vinyl resin powder, tanning extract and coconut shell powder as toughening, antiageing and free aldehyde absorbing additive; and certain amount of corn powder, gypsum powder and flour as stuffing, and through mixing. The modified urea-formaldehyde powder adhesive has the advantages of high strength, high toughness, ageing resistance, water resistance, chemical corrosion resistance and environment friendship.

Owner:SHANGHAI UNIV

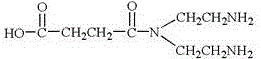

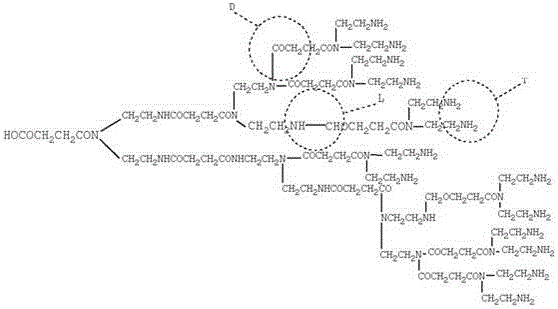

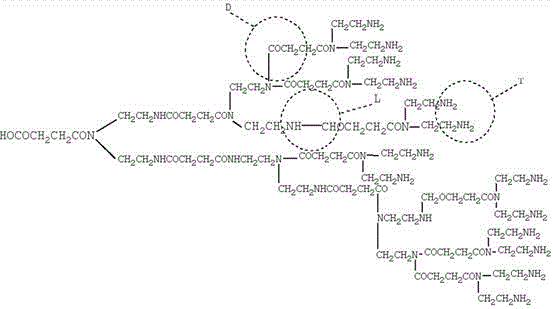

Application of hyperbranched polyamide in removing formaldehyde in urea-formaldehyde resin adhesive

InactiveCN106366308ASolving activitySolve some problems caused byMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolyamideHuman health

The invention relates to the technical field of removal of formaldehyde in urea-formaldehyde resin adhesives for artificial boards, particularly preparation and application of hyperbranched polyamide. The hyperbranched polyamide is synthesized by the following steps: carrying out reaction on butanedioic anhydride and diethylenetriamine used as raw materials to generate two AB2 monomers, and carrying out reaction on the two AB2 monomers under certain reaction conditions to obtain the hyperbranched polyamide. The hyperbranched polymer has multiple branches and multiple terminal amino groups, and thus, has multiple reaction active sites and can sufficiently react with formaldehyde. The hyperbranched polymer has low viscosity, has the three-dimensional structure, does not have intermolecular entanglement, and thus, can implement high utilization value after being added into the urea-formaldehyde resin adhesive. The hyperbranched polyamide is an environment-friendly formaldehyde catcher, thereby reducing the hazards to the human health and satisfying the requirements for national green material production.

Owner:UNIV OF JINAN

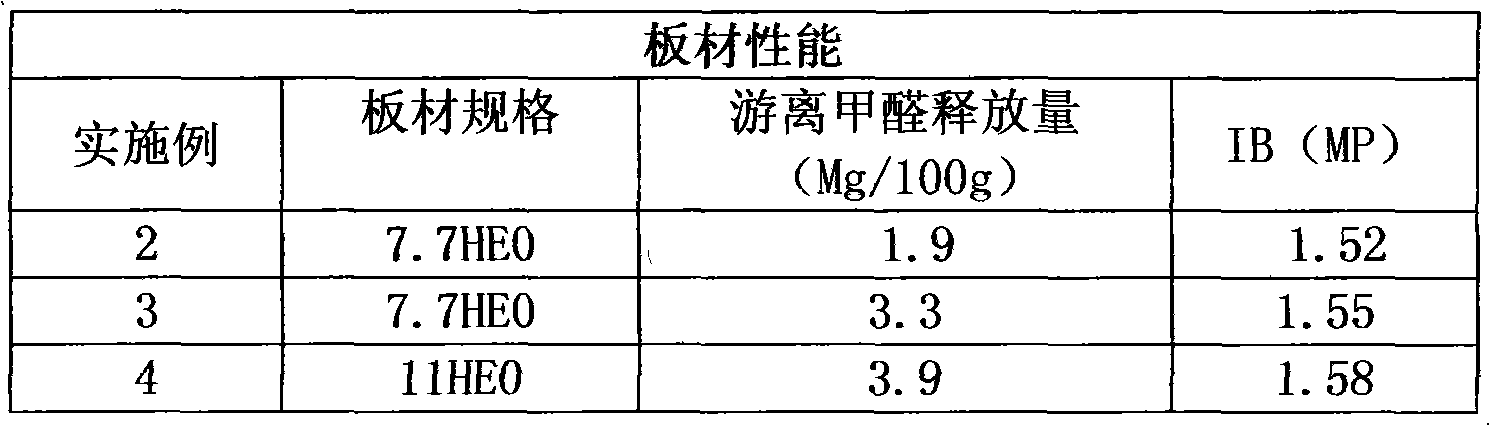

Preparation method of E0-grade melamine modified urea formaldehyde resin

ActiveCN105348465ALow free formaldehyde contentReduce manufacturing costPolyvinyl alcoholUltimate tensile strength

The invention provides a preparation method of E0-grade melamine modified urea formaldehyde resin. According to the preparation method, formaldehyde, urea, polyvinyl alcohol and melamine are selected as main raw materials; urea is added in three batches, so that the molar ratios of the first, second and third batches of urea to formaldehyde are 1:2.24, 1:1.54 and 1:0.95 respectively; polyvinyl alcohol and melamine are respectively added into a reaction kettle before and during an addition reaction, so that the raw materials can be subjected to reactions in four media of which the pH values are 7.5-8.0, 5.1-5.0, 6.2-6.5 and 8.0-8.5 respectively; finally, E0-grade melamine modified urea formaldehyde resin is prepared. The preparation method has the advantages that addition of a formaldehyde catching agent is not needed; the preparation process is simple; the bonding strength, the waterproof property and the pre-pressing effect of the product, namely E0-grade melamine modified urea formaldehyde resin, are improved; the E0-grade requirement for free formaldehyde can be met; the market application range is broad.

Owner:广西沃森木业科技有限公司

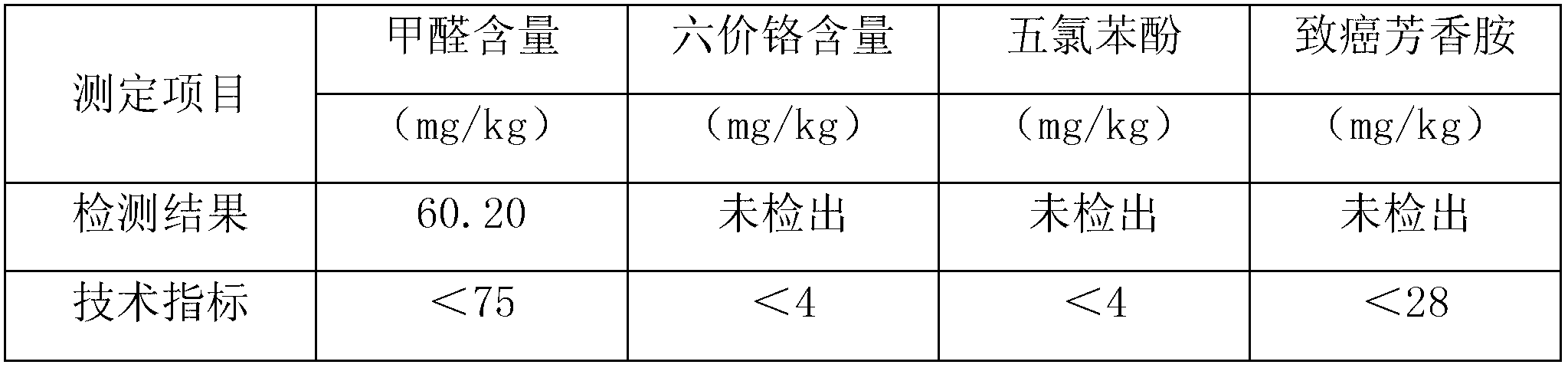

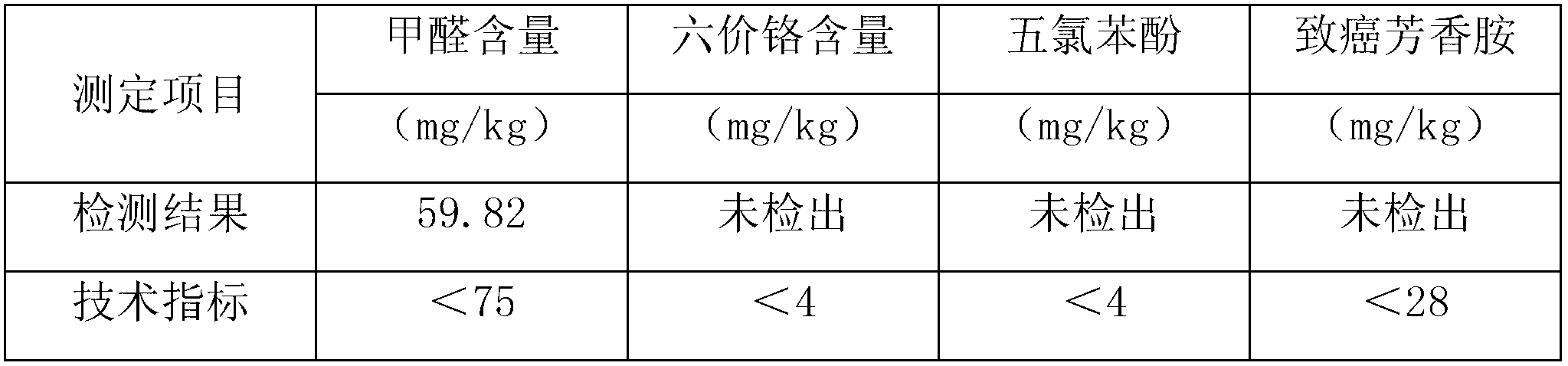

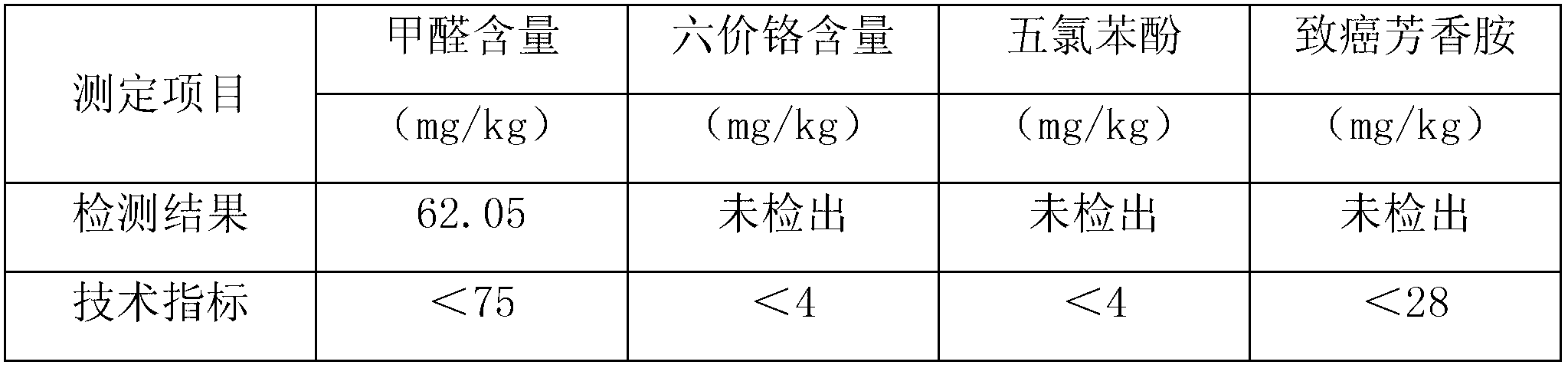

Chromium-free tanning production process of low-formaldehyde beach woolskin

ActiveCN102703620AReduce governance costsPure white coatTanning treatmentPre-tanning chemical treatmentChemistryWool

The invention relates to a chromium-free tanning production process of a low-formaldehyde beach woolskin. The chromium-free tanning production process comprises the following process procedures of: water soakage, fleshing, degreasing, softening, WT tanning, alkali extraction after the tanning, wet grinding, water scrubbing, drying in the air, conditioning, retanning, alkali extraction after the retanning, fat addition, drying in the air, skin shoveling, dry grinding and dust brushing to obtain a finished product. The chromium-free tanning production process is characterized in that the tanning and the retanning are respectively completed in a tanning solution and a retanning solution which do not contain chromium. By using the chromium-free tanning production process, the processing of the beach woolskin is carried out by adopting a chromium-free tanning agent; not only can the waste chromium zero emission of a tanning working procedure and a retanning working procedure be realized and the sewage treatment cost of an enterprise be decreased, but also the produced beach woolskin is natural in color and is curly and attractive; a leather body is full and soft in hand feel and is lower than 75 mg / kg; a shrinkage temperature is higher than above 80 DEG C; and physical properties and mechanical prosperities can reach those of a fur acquired by an ordinary chromium tanning method.

Owner:宁夏西部皮草有限公司 +1

Melamine tableware and preparation method thereof

The invention discloses melamine tableware and a preparation method of nano crystalline cellulose modified melamino-formaldehyde resin. The melamine tableware is prepared from the nano crystalline cellulose modified melamino-formaldehyde resin, alpha-wood pulp fiber, microcrystalline cellulose, food coloring, a curing agent, nano-titania, zinc stearate and mica powder according to different weight parts. The toughness of the melamine tableware can be improved through matched use of the nano crystalline cellulose modified melamino-formaldehyde resin, alpha-wood pulp fiber and the microcrystalline cellulose. The invention further discloses a preparation method of the melamine tableware. The melamine tableware is prepared by material mixing, preforming, decalcomania, gold plating, trimming and polishing. In the material mixing process, the raw materials except the curing agent are mixed uniformly firstly, and the curing agent is added finally.

Owner:美尔耐密胺制品宜兴有限公司

Production technology of furan resin used for casting steel

ActiveCN102775572ASave resourcesUnique process methodFoundry mouldsFoundry coresFurfuryl alcoholProduction cycle

The invention relates to a production technology of furan resin, in particular to a production technology of furan resin used for casting steel. The technology comprises the following steps of: closing an outlet valve at the bottom of the reactor, opening a feed valve, starting a mixer, adding certain content of paraformaldehyde, urea and furfuryl alcohol, adding certain content of basic catalyst to adjust the PH value of the seasoning liquid; heating up to 80-100 DEG C, insulating for 60-80 minutes; stopping the insulation, opening cooling water and cooling down to 60-90 DEG C, adding 50% of the total amount of furfuryl alcohol; adding certain amount of acid catalyst to adjust the PH value of the seasoning liquid to 3-5 when the temperature drops to 60 DEG C; heating up to 85-100 DEG C, insulating for 50-70 minutes; adding the 25% of the total amount of furfuryl alcohol, adding certain amount of silane coupling agent ammonia and methanol; and continuing to stir for 30 minutes after discharging and submitting for censorship. The invention provides a method of using imported paraformaldehyde and urea to produce urea-formaldehyde glue on the basis of traditional resin technology instead of using aqueous solution of formaldehyde. The production technology provided by the invention has the advantages of needlessness of dehydration in the post-synthetic phase, production cycle reducing, cost saving and environmental protection.

Owner:GANSU KOCEL CHEM

High performance environment friendly urea-formaldehyde resin adhesive and its preparing method and use

InactiveCN1944564ANo pollution in the processUnique ideaAldehyde/ketone condensation polymer adhesivesWood layered productsOrganic acidChemistry

Owner:时君友

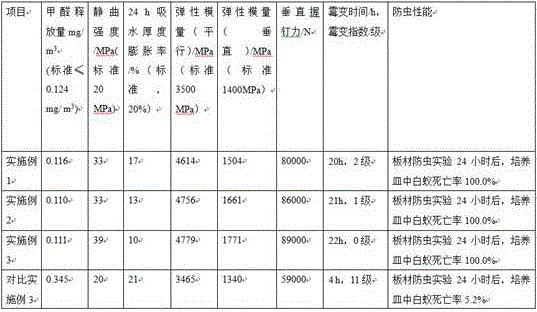

Method for manufacturing anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials

InactiveCN106346589AWhite colorGood film formingFlat articlesDomestic articlesOptoelectronicsImpurity

The invention discloses a method for manufacturing an anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials. The manufacturing method comprises the following steps of: preparing materials, drying, peeling and removing impurities, sorting and storing, respectively gluing on a surface core layer, hierarchically paving, in advance hot press molding, and sanding wood finishes; an isocyanate sawdust powder hybrid adhesive is coated on the surface, and an anti-insect and anti-mold composite urea-formaldehyde resin adhesive is coated on the core layer; wood shavings on the core layer are divided into three-layer structures, comprising intermediate layer of core layer, upper surface layer of core layer and lower surface layer of core layer; the intermediate layer of the core layer is paved longitudinally, and the upper surface layer of the core layer and the lower surface layer and surface layer of the core layer are paved horizontally. For the oriented strand board prepared by the method, the static bending intensity in a parallel direction is in a scope of 33-39 MPA, the parallel elasticity modulus is in the scope of 4614-4779 MPA, the vertical elasticity modulus is in the scope of 1504-1771 MPA, the thickness swelling rate of water absorption in 24 h is in the scope of 10%-17%, and the vertical nail-holding power reaches up to 89000N. In the manufacturing method, a problem that the board is easy to suffer from erosion of white ants and moths is thoroughly solved by adding an anti-insect and anti-mold additive, and the service life of the board is prolonged.

Owner:广西横县新威林板业有限公司

Environment friendly coating

InactiveCN101397431ALow free formaldehyde contentHigh contrast ratioCoatingsAlkylphenolResidual monomer

The invention relates to interior wall paint, in particular to an environment-friendly paint which can be widely applied to the decoration of indoor walls, ceilings, plasterboards and the like, does not contain APEO (alkylphenol polyethenoxy ether), is scentless and has low free formaldehyde. The paint is prepared by mainly adopting the technology as follows: first, a dispersant, a wetting agent, a foam suppressor, a thickening agent and a mildew-proof algaecide are added into water sequentially under low speed; titanium pigment, a pH regulator, coarse whiting, calcined kaolin or washed kaolin, french chalk and a mildew-proof agent are added sequentially under medium speed; high-speed dispersion or sanding are carried out until the fineness of less than 50 Mum; and finally, a polystyrene-acrylic copolymer, a polyacrylic copolymer or a vinyl acetate copolymer-acrylic copolymer, a film-forming accessory agent, an antifreezing agent, a preservative, the foam suppressor, a rheology agent and H2O are added sequentially under low speed. The paint dose not contain APEO, thus having no effect on the reproductive system of human and animal; the paint has low odor, and no odor basically, reduces the harm of the residual monomer to human body, and has extremely good physical performances, thus being capable of meeting the requirements on indoor decoration.

Owner:SKSHU PAINT

Resin glue adhesive for E0 grade fibre board

InactiveCN101307215ALow water resistanceLow aging resistanceAldehyde/ketone condensation polymer adhesivesDomestic articlesFirming agentUltimate tensile strength

The invention discloses a synthetic resin cementing compound used for an EO-stage fiberboard. The synthetic resin cementing compound consists of melamine modified urea resin and a firming agent and is characterized in that the compositions of reaction material of the urea resin by weight percentage are: 4.0 to 6.0 percent of the melamine, 40.0 to 42.0 percent of urea, 52.0 to 56.0 percent of formaldehyde, and 0.4 to 0.6 percent of an accelerating agent; acid and alkali are appropriate and the total mol ratio is between 0.90 and 0.93; and the cementing compound is obtained by the systemization and reaction of the materials. The cementing compound has good cementation strength, appropriate curing time, and the content of 0.06 to 0.08 percent of free formaldehyde, etc. E1 and the E0-stage fiberboard with good quality can be produced stably and have the advantages of low glue feeding amount, strong adaptability to the hot press molding technology and high curing speed in the hot press molding process, etc., thereby meeting the need of the market on products of high environmental performance fiberboards.

Owner:DARE TECH

Production technology of furan resin for casting

ActiveCN102516482AEmission reductionAvoid pollutionFoundry mouldsFoundry coresFuranUltimate tensile strength

The invention relates to a production technology of furan resin, particularly to a production technology of the furan resin for casting, comprising the following steps: charging, heating up, dehydrating, opening a steam valve, heating up to 80-108 DEG C in 20-30 min, preserving heat for 60-90 min, discharging, packaging, and warehousing. According to the invention, a product with low free formaldehyde and high strength can be provided by the technology, and the production process has no generation of three wastes and is green.

Owner:共享新材料(山东)有限公司

Preparation method of nano-silica rosin modified phenolic resin

ActiveCN104693679APromote polycondensation reactionIncrease stickinessHigh volume manufacturingHeat resistance

The invention belongs to the technical field of preparation of phenolic resin, and in particular relates to a preparation method of nano-silica rosin modified phenolic resin. The method is that xylenol, tert-butylphenol, dodecyl-phenol, hydrogenated bisphenol A and formaldehyde are used as the raw materials; the weak-base and weak-acid process is carried out to prepare phenolic resin; rosin and nano-silica are utilized for modifying, so as to prepare the nano-silica rosin modified phenolic resin. The preparation method is simple in process; the prepared phenolic resin is high in viscosity, high in softening point, small in free formaldehyde content, high in heat resistance and corrosion resistance, suitable for industrial mass production, and applicable to preparation of coating and ink, and can be also used as adhesive and rubber components.

Owner:桂林兴松林化有限责任公司

Eastern larch bark rapid pyrolysis oil modified phenolic resin adhesive

InactiveCN101328396ALow molar ratioUniform molecular weight growthAldehyde/ketone condensation polymer adhesivesEnvironmentally friendlyPhenols

The invention relates to a preparation method for a low-cost environmentally friendly (low formaldehyde release) larch bark pyrolyzed oil modified phenol-formaldehyde resin adhesive for manufacturing wood composite material. According to the invention, larch bark quickly pyrolyzed oil is used to replace 40 percent of the dosage of phenol, and the pyrolyzed oil modified phenol-formaldehyde resin adhesive is prepared by the means of adding pyrolyzed oil at the middle period to control a mild reaction temperature, and adding formaldehyde and sodium oxide batch by batch. Testing results show that: compared with pure phenol-formaldehyde resin, the modified phenol-formaldehyde resin with a pyrolyzed oil substitution rate of 40 percent can reduce the raw material cost by 33 percent and meet the production requirements of plywood and particle boards; the larch bark pyrolyzed oil modified phenol-formaldehyde resin adhesive reaches GB requirements and makes the formaldehyde release reach the environmental protection requirements of E1 grade and even reach the environmental protection standards of E0 if required; and if the particle boards adopt the pyrolyzed oil modified phenol-formaldehyde resin for glue application layer by layer, the thickness of a surface procuring layer can be effectively reduced.

Owner:BEIJING FORESTRY UNIVERSITY

Urea-formaldehyde adhesive with low free formaldehyde and expanding characteristic and its preparation method

InactiveCN1640906AGood storage performanceImprove efficiencyAldehyde/ketone condensation polymer adhesivesChemistryWeather resistance

The urea formaldehyde resin prepared through one sectioned process with formaldehyde and urea as main material and in the presence of Lewis acid or alkali has free formaldehyde content of about 0.1 % and less than 0.5 %. During the preparation, organic amine assistant is added, and this makes the adhesive possess obvious expansion performance during formation and be suitable for use in producing various kinds of board. The products with the adhesive have low formaldehyde release amount, excellent mechanism performance, excellent weather resistance, etc. The liquid resin may be spray dried to prepare urea formaldehyde adhesive powder capable of maintaining reaction activity for long time. The adhesive of the present invention has no need of adding formaldehyde trapping agent.

Owner:倪卓

Glycidyl ether modified urea formaldehyde resin and preparation method thereof

ActiveCN102585131AHigh bonding strengthImprove water resistanceAldehyde/ketone condensation polymer adhesivesAdhesive cementPolymer science

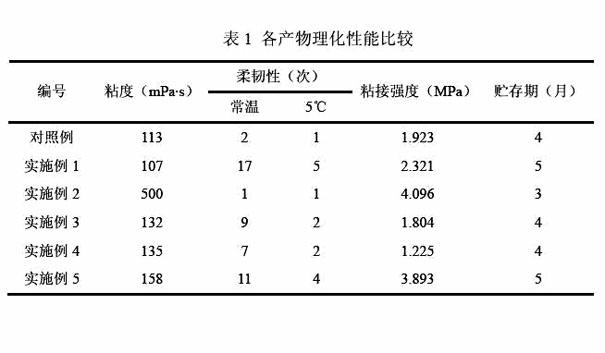

The invention discloses a glycidyl ether modified urea formaldehyde resin and a preparation method thereof. The glycidyl ether modified urea formaldehyde resin is prepared from formaldehyde, urea, long-chain multifunctional glycidyl ether and a modifying agent according to the technological line of weak alkali-weak acid-weak alkali. According to the method, the long-chain multifunctional glycidylether is introduced as a crosslinking agent of the urea formaldehyde resin; a plurality of epoxy groups on the end group of glycidyl ether are used for enhancing the curing crosslinking degree of urea formaldehyde resin with a low aldehyde to urea (F / U) molar ratio; and meanwhile, a long chain is used for enhancing the flexibility of the resin and reducing internal stress generated in the curing process of the resin so as to enhance the cementing strength and the water resistance of the resin. The urea formaldehyde resin prepared by the method has the advantages of low content of free formaldehyde, simple technology and excellent cementing strength; meanwhile, the use period of the resin is prolonged greatly; the construction performance of an adhesive is improved; and the average value of the release amount of platy formaldehyde prepared by the adhesive is smaller than or equal to 0.3mg / L.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com