Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Guaranteed curing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing lumber-core board

InactiveCN1796069AQuality improvementGuaranteed curing qualityWood treatment detailsCoating impregnationTrappingPulp and paper industry

The present invention relates to a production process of veneered strip-glued board. Said process includes the following steps: sawing raw material to obtain squared timber, drying, defining thickness and processing double faces, making strips by using multiblade saw, making board, coating adhesive, matching board, forced cooling, first sanding, sticking transverse single board, prepressing, hot-pressing, forced cooling, secondary sanding, sticking surface board, secondary prepressing, secondary hot-pressing, cutting edge, third sanding, sorting finished products and putting the finished products into storage. The urea-formaldehyde adhesive formula used in the adhesive-coating process is formed from (by weight portion) 100 portions of low-formaldehyde urea-formaldehyde resin, 20-35 portions of filling agent, 5-10 portions of formaldehyde trapping agent and 0.4-1.0 portion of solidifying agent.

Owner:CHANGLIN WOOD IND

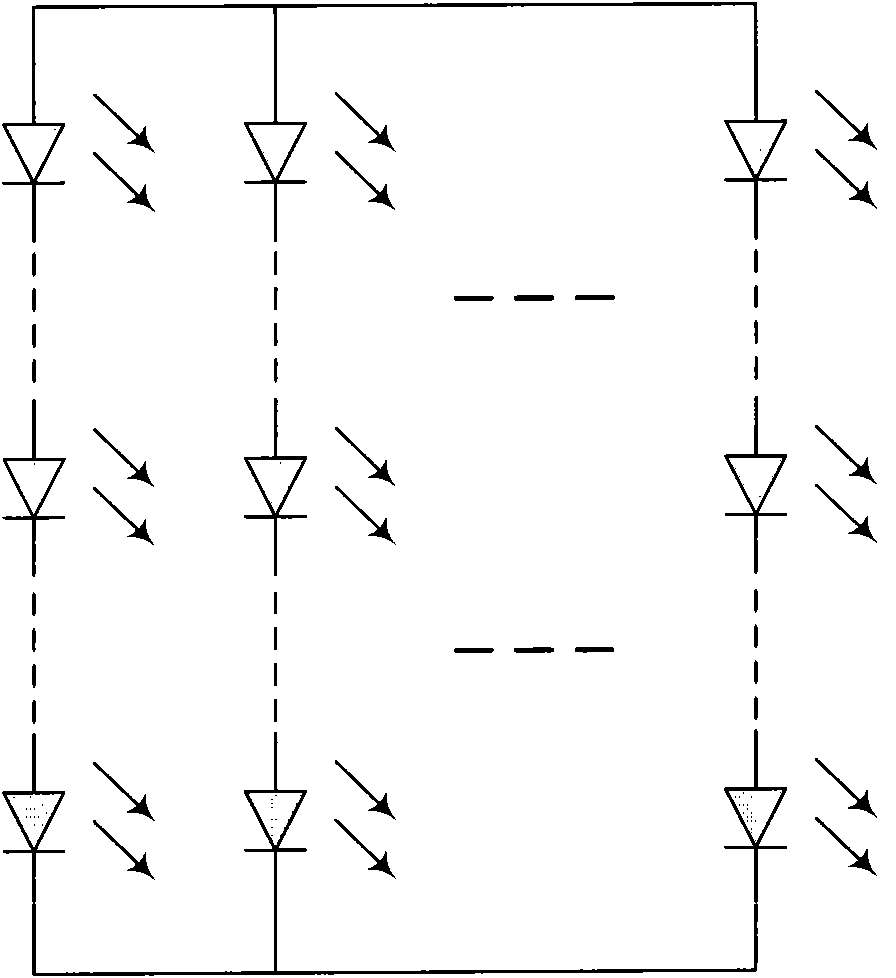

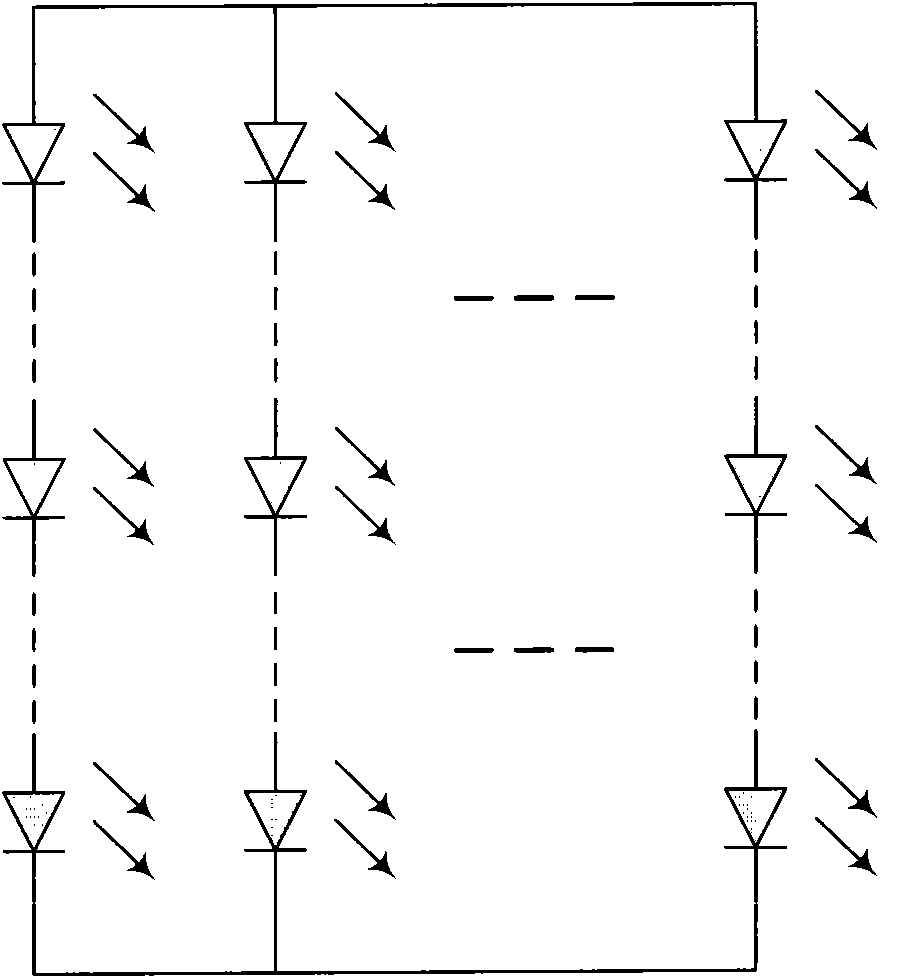

Device and method for monitoring abnormal state of light-emitting diode

InactiveCN102118913AAccurate real-time monitoringRealize real-time monitoringElectric light circuit arrangementEngineeringLight-emitting diode

The invention relates to a device and method for monitoring the abnormal state of a light-emitting diode. The device is connected to both ends of the light-emitting diode and can be used for monitoring the abnormal state of the light-emitting diode by detecting the change of the working voltage of the light-emitting diode. The device and the method can be used for monitoring the working voltage VF of each light-emitting diode in a light-emitting diode matrix in real time, judging whether the working voltage VF is higher than a determined high threshold voltage VH or not and whether the working voltage VF is lower than a determined low threshold voltage VL or not, and accordingly judging whether a current light-emitting diode abnormally works or not, or short circuit or open circuit faults are already generated or not; and in addition, the positions of the light-emitting diodes which abnormally work and go wrong can be positioned quickly under the working state of the light-emitting diode matrix so as to facilitate maintenance and replacement.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

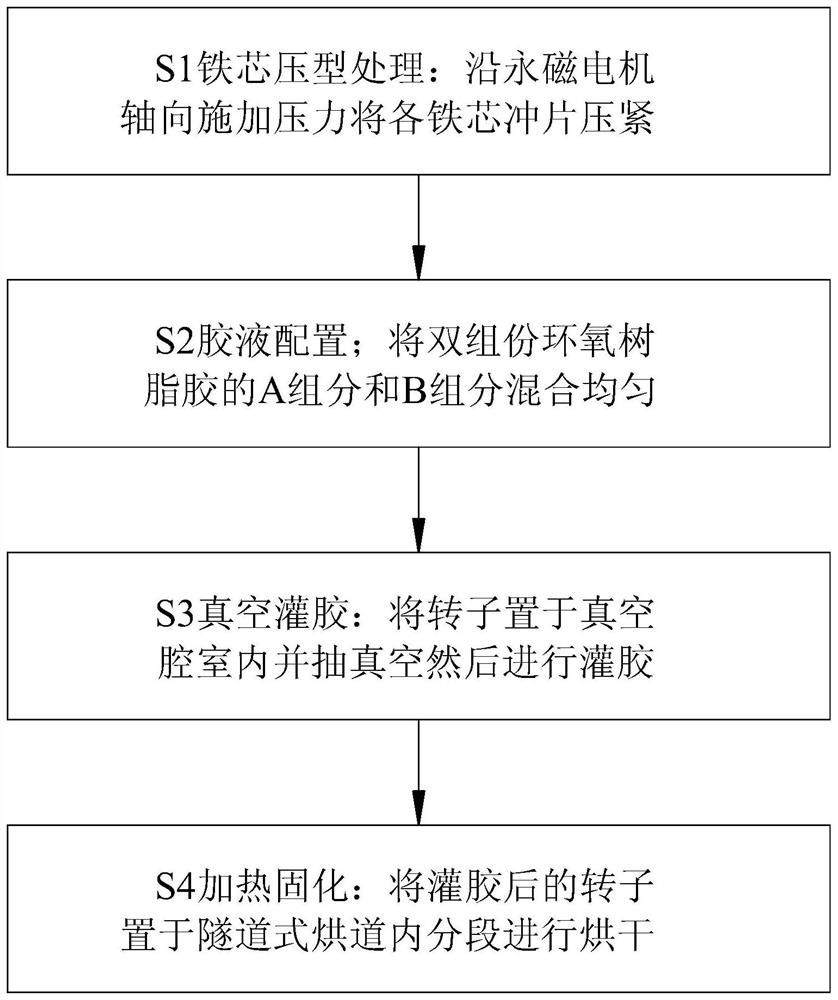

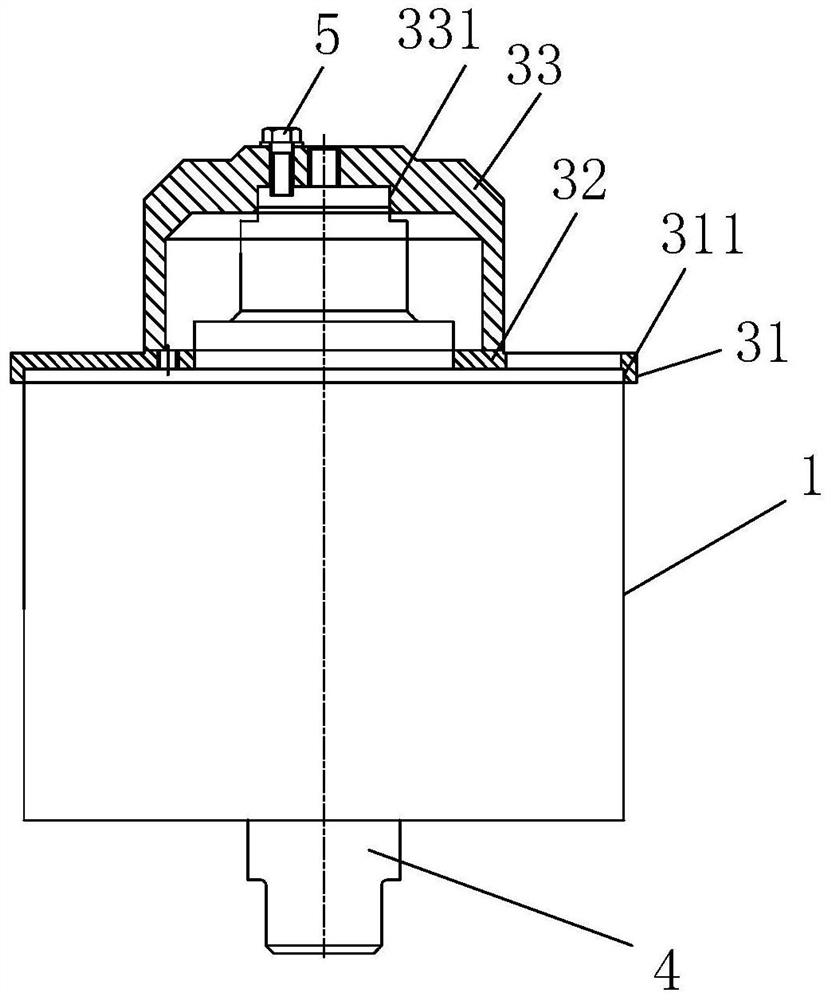

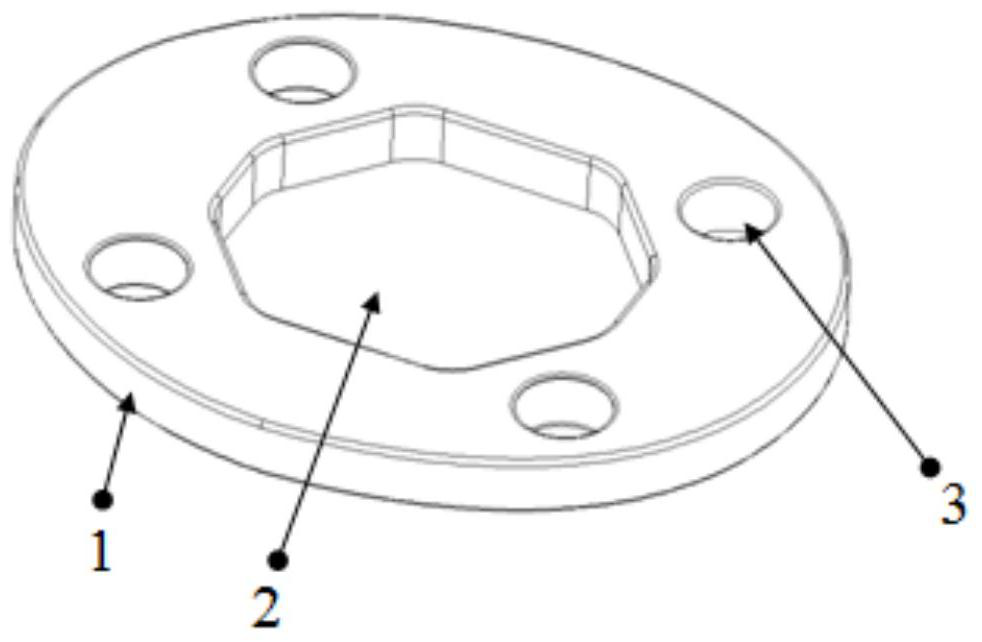

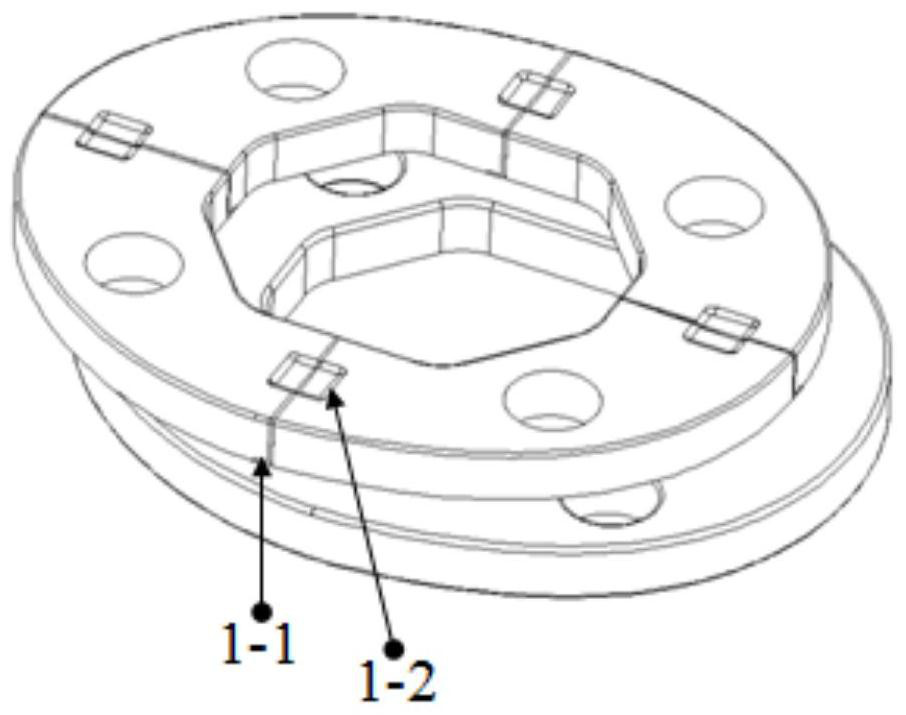

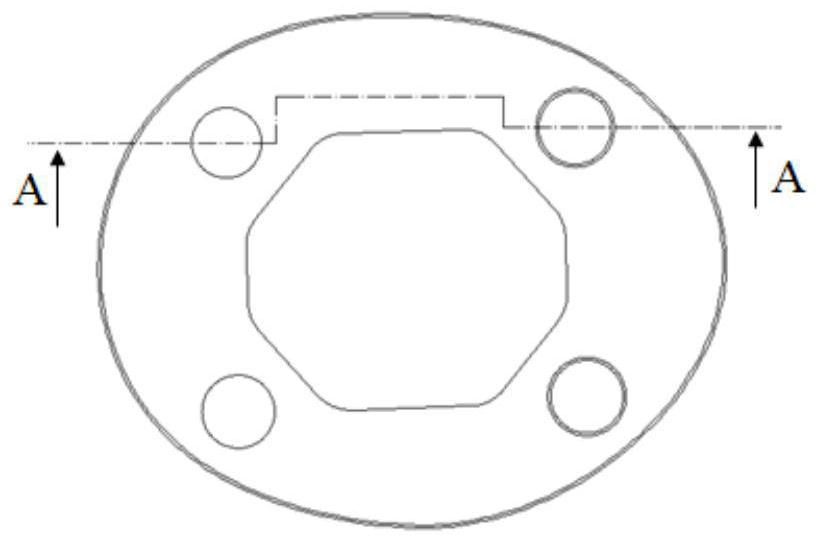

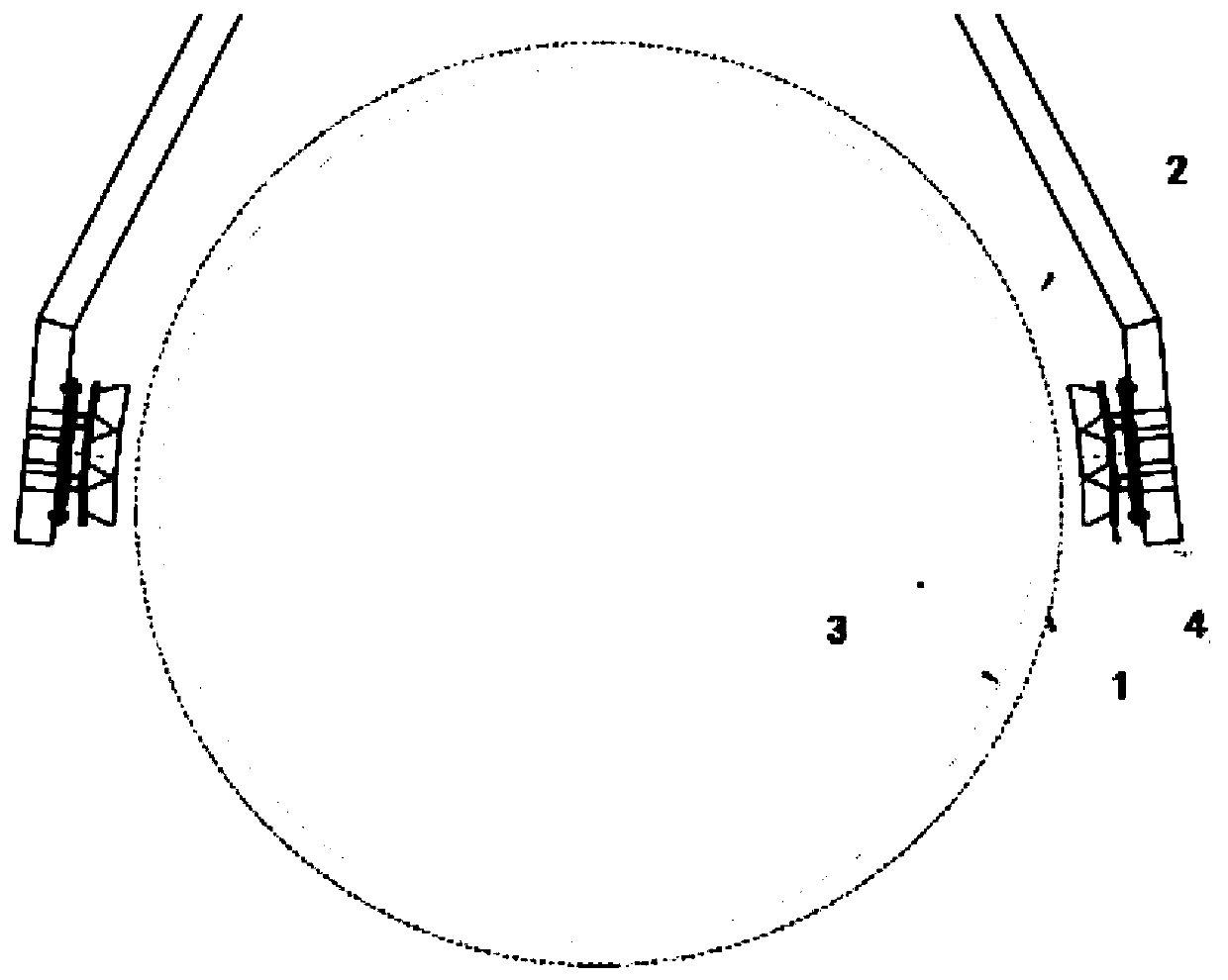

Vacuum glue pouring method for permanent magnetism motor rotors

ActiveCN109698590AReduce gapAvoid churnPretreated surfacesManufacturing stator/rotor bodiesEpoxyVacuum pumping

The invention discloses a vacuum glue pouring method for permanent magnetism motor rotors. The method includes the following steps: S1, a step of iron core profiling processing, namely the step of applying pressure to compress iron core punching sheets in an axial direction of a permanent magnetism motor; S2, a step of glue solution configuration, namely the step of uniformly mixing an A componentand B component of a two-component epoxy resin adhesive; S3, a step of vacuum glue pouring, namely the step of placing a rotor into a vacuum cavity to perform vacuum pumping, and then performing gluepouring; and S4, a step of heating and curing, namely the step of placing the rotor after glue pouring into a tunnel type baking channel to perform segment drying. The method has high glue pouring efficiency, tooth tension and glue loss phenomenon is not easy to occur, and the quality of products can meet the filling technical requirements of the permanent magnetism motor rotor.

Owner:湖南中车商用车动力科技有限公司

Solidification method of UV lacquer for coating object and its equipment

InactiveCN1718291AOvercome temperatureOvercoming the defect of dust ingressPretreated surfacesCoatingsCoated surfaceLacquer

A method for solidifying the UV paint coated on an object features that an ultraviolet lamp tube used as light source and with the output power more than 30w / cm is arranged above said object at a distance of 50-250 mm and is able to move relatively to said object at 2-100m / min. Its apparatus is composed of a sealed casing, longitudinal and transverse tracks, irradiation unit and drive unit. It features high quality and no dust pollution.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN

Two-day curing process for positive plate of storage battery

InactiveCN105895863AShorten the timeGuaranteed curing qualityLead-acid accumulator electrodesEngineeringHumidity

The invention aims to provide a two-day curing process for a positive plate of a storage battery. The two-day curing process comprises eleven steps, wherein curing is carried out from step 1 to step 5, the curing temperature, time and humidity of each step are adjusted to be optimal, drying is carried out from step 6 to step 11, the drying temperature and time of each step are also adjusted to be optimal, and the total time does not exceed two days. By the two-day curing process, the time is shortened, the curing quality is ensured, and the energy efficiency and the production efficiency are improved.

Owner:TIANNENG BATTERY WUHU

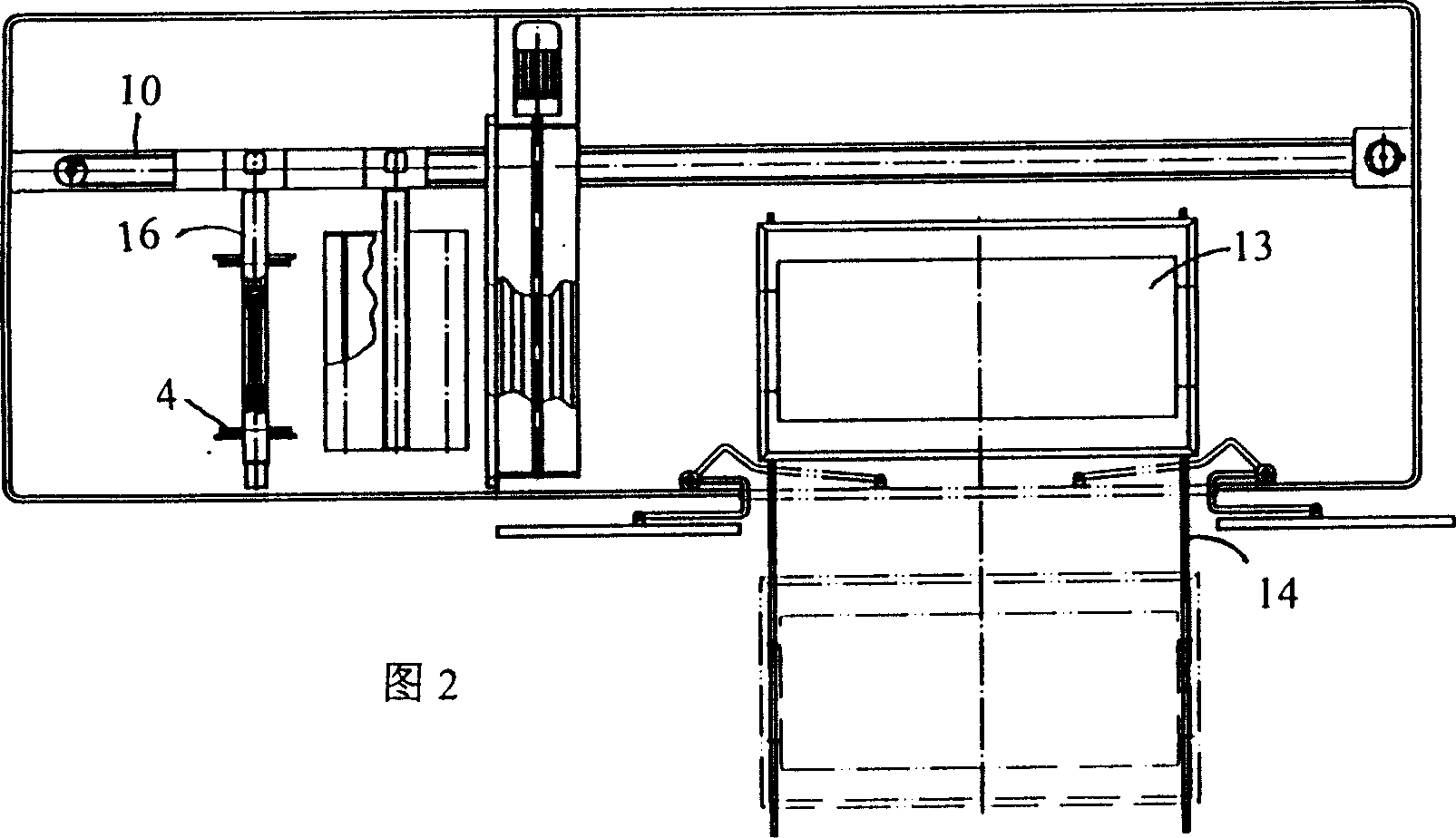

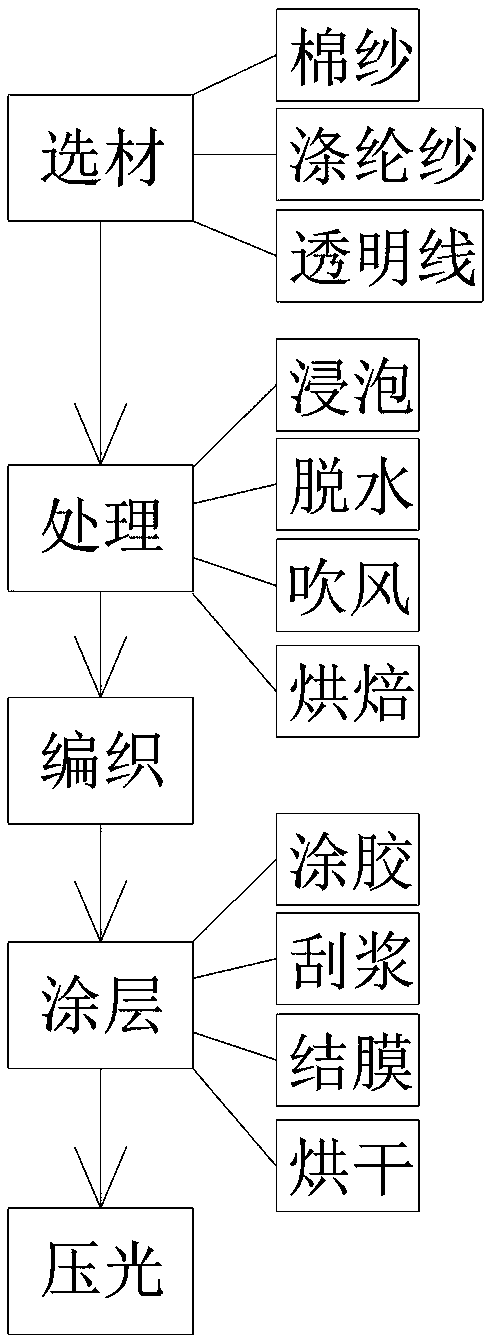

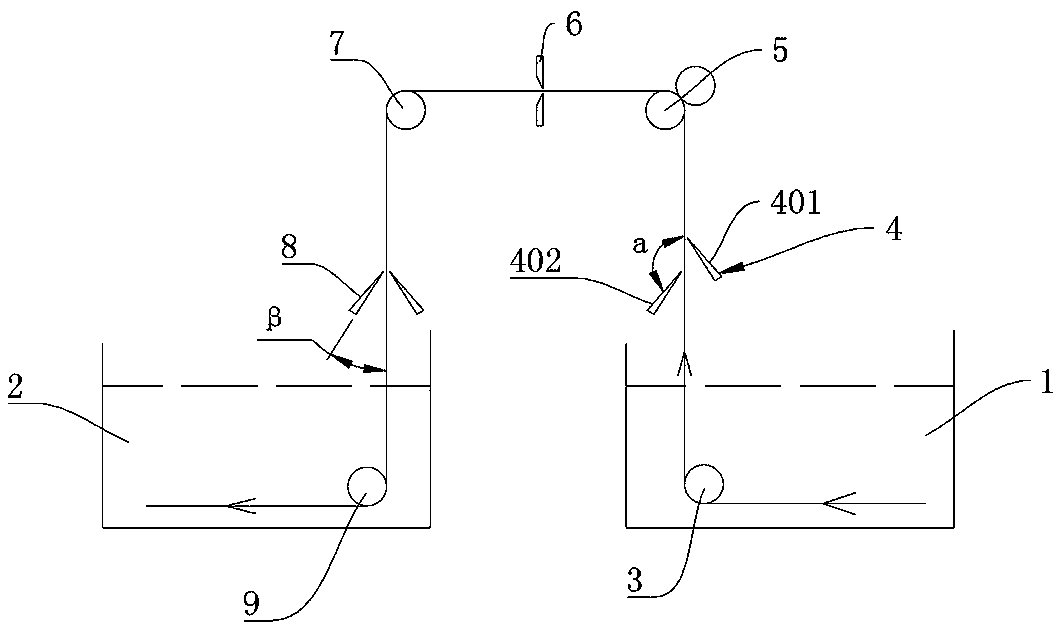

Manufacture method of anti-counterfeiting brand woven tape

InactiveCN107829194AGood anti-counterfeiting effectImprove anti-counterfeiting effectWoven fabricsLiquid/gas/vapor yarns/filaments treatmentPolyesterTrademark

The invention relates to a manufacture method of an anti-counterfeiting brand woven tape. The method comprises the following steps: material selecting, which relates to at least selecting cotton yarnand polyester yarn as warp yarn, and selecting transparent thread as weft yarn; treating, which relates to dewatering and drying the cotton yarn subjected to anti-counterfeiting solution dipping treatment; weaving, which relates to weaving the warp yarn and the weft yarn into brand gray fabric according to an anti-counterfeiting mark as required; coating, which relates to gelatinizing formed brandgray fabric by adopting a wet-type coating method, introducing the brand gray fabric to enter a water bath tank, enabling the brand gray fabric to form a membrane in water bath, and then drying to obtain brand cloth; and press polishing, which relates to adopting a hot-pressing roller to perform press polishing treatment. The manufacture method adopted by the invention can be used for effectivelycombining an anti-counterfeiting material with the surface of a cotton thread, so that the anti-counterfeiting material is difficult to fall off in the subsequent weaving process, and the manufactured fabric has a good anti-counterfeiting effect.

Owner:湖州倍亨纺织有限公司

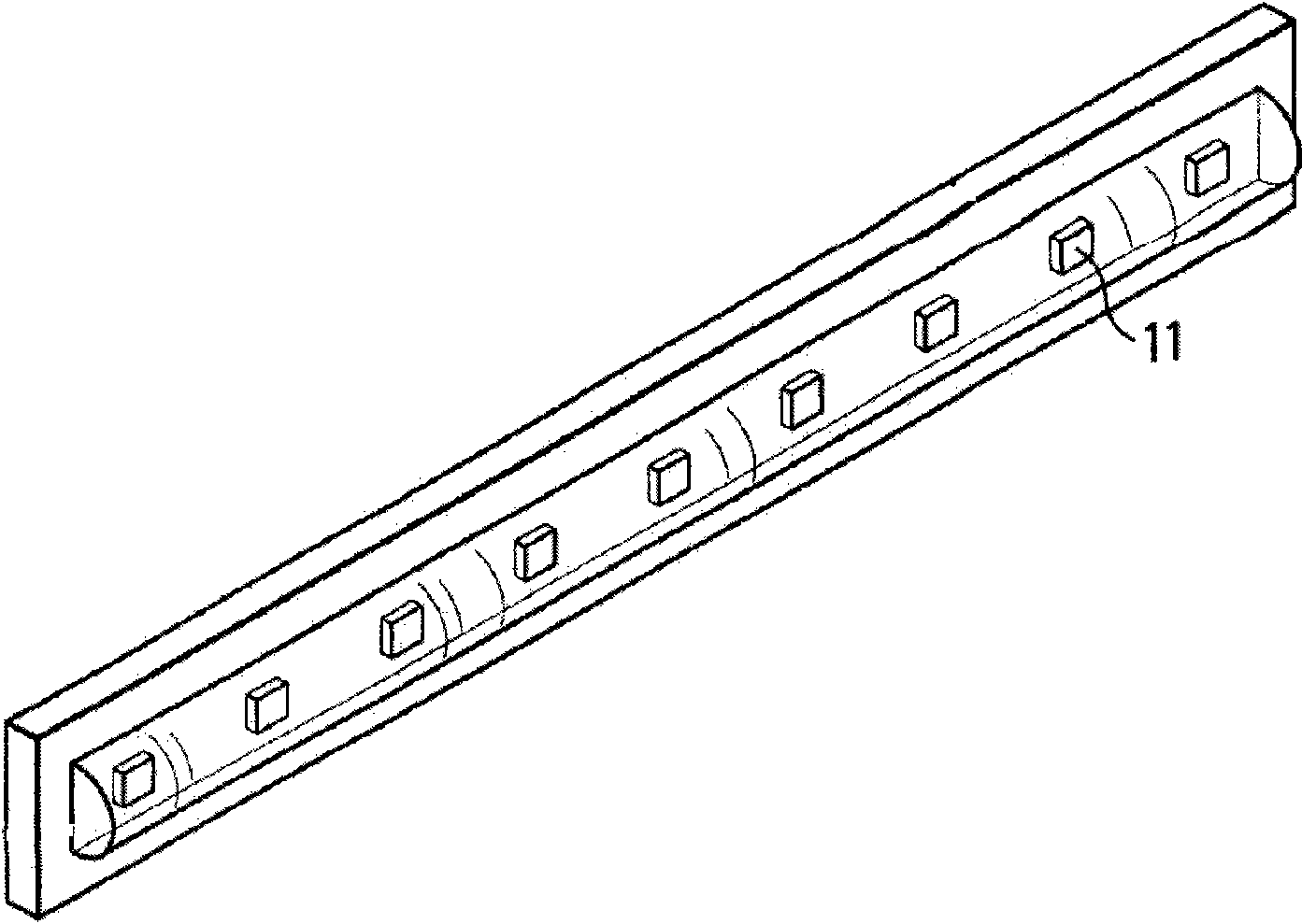

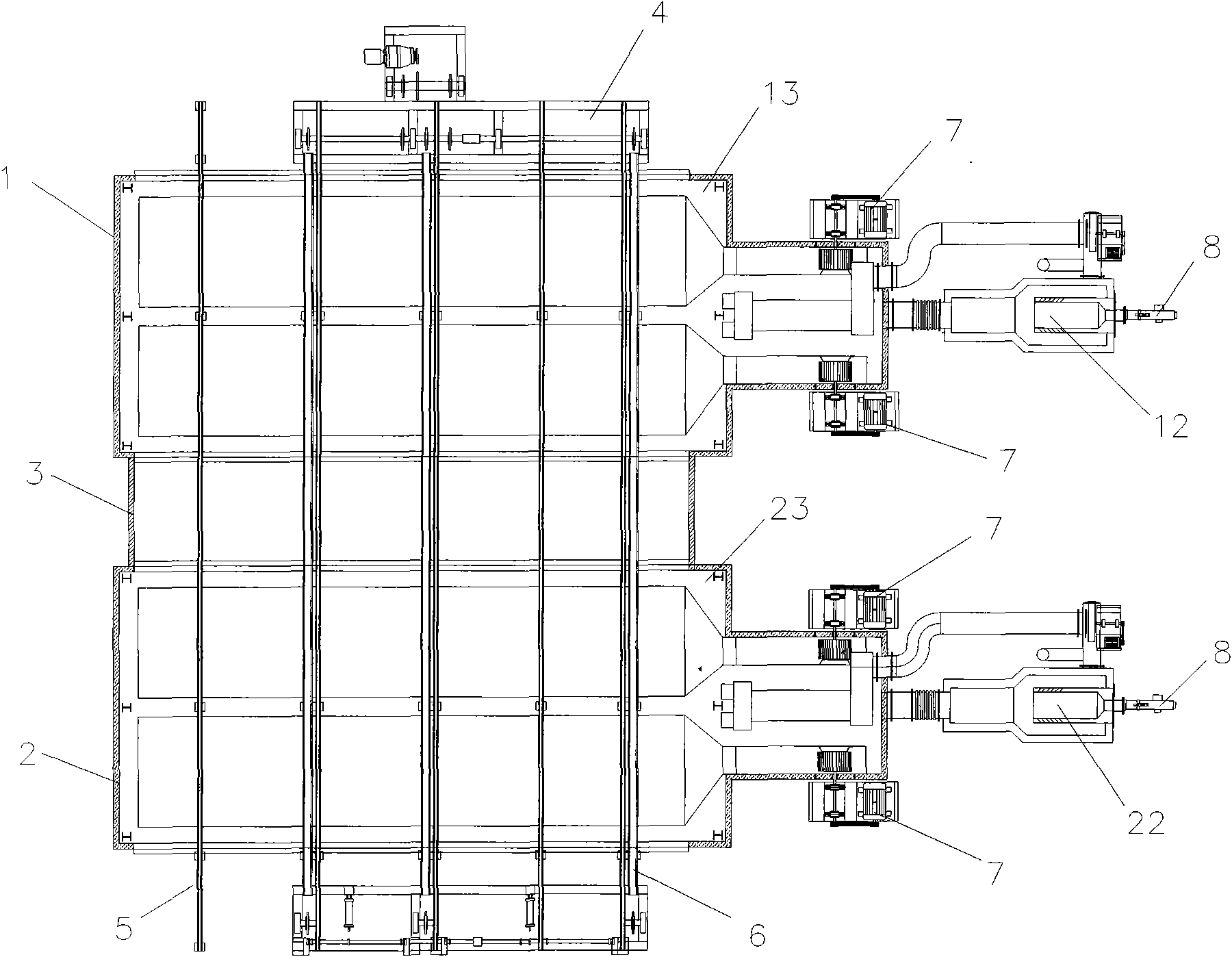

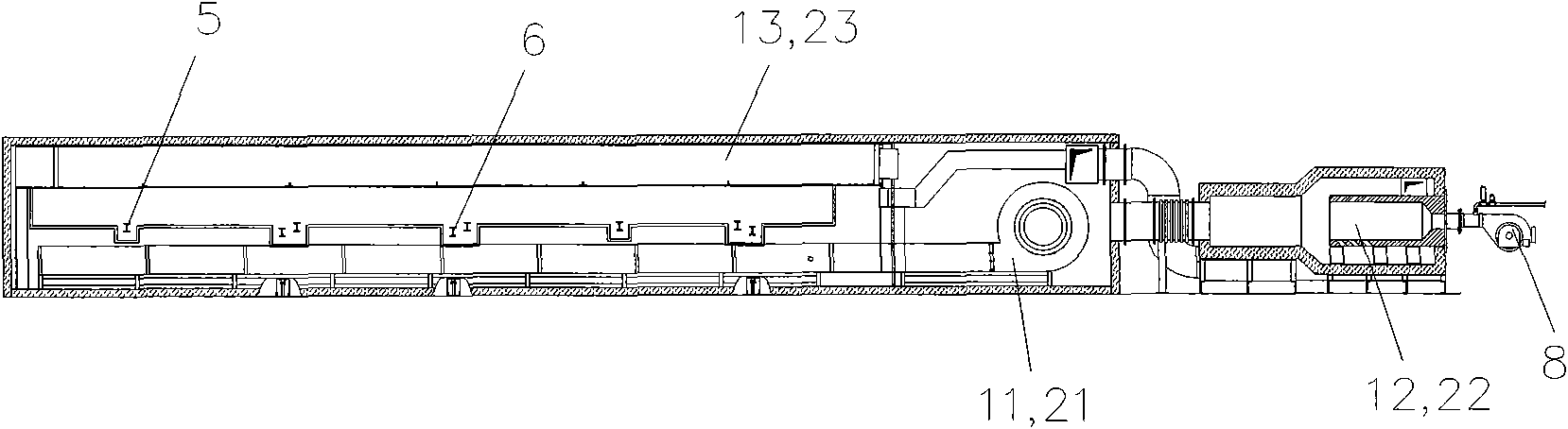

Device for baking and curing inner anti-corrosion layer of pipe

InactiveCN101992182AAvoid coolingEfficient ConcentrationPretreated surfacesCoatingsEngineeringHeat balance

The invention provides a device for baking and curing an inner anti-corrosion layer of a pipe, which comprises a baking oven, a curing oven, a heat insulation chamber and a chain conveying mechanism, wherein the heat insulation chamber is arranged between the baking oven and the curing oven and is mutually communicated with the baking oven and the curing oven, and the chain conveying mechanism sequentially passes through the baking oven, the heat insulation chamber and the curing oven to form a circulation loop. The pipe is directly conveyed from the baking oven to the curing oven by the device through the chain conveying mechanism, the cooling of the pipe baked by the baking oven can be effectively prevented through the heat insulation chamber, therefore, the energy can be saved, and the consumption can be reduced; the heat energy can be effectively collected through a worm case arranged in the oven, the stability and the uniformity of the circulated air supply can be ensured, the heat balance in a hearth can be ensured, meanwhile, the heat energy is prevented from being spread out, and the energy consumption can be saved.

Owner:SHANGHAI TUBE COTE PETROLEUM PIPE COATING

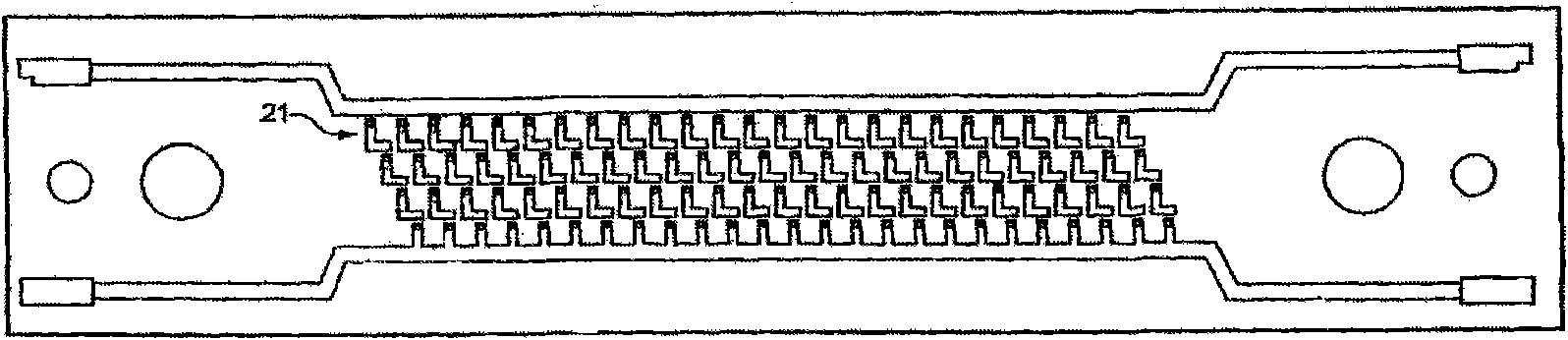

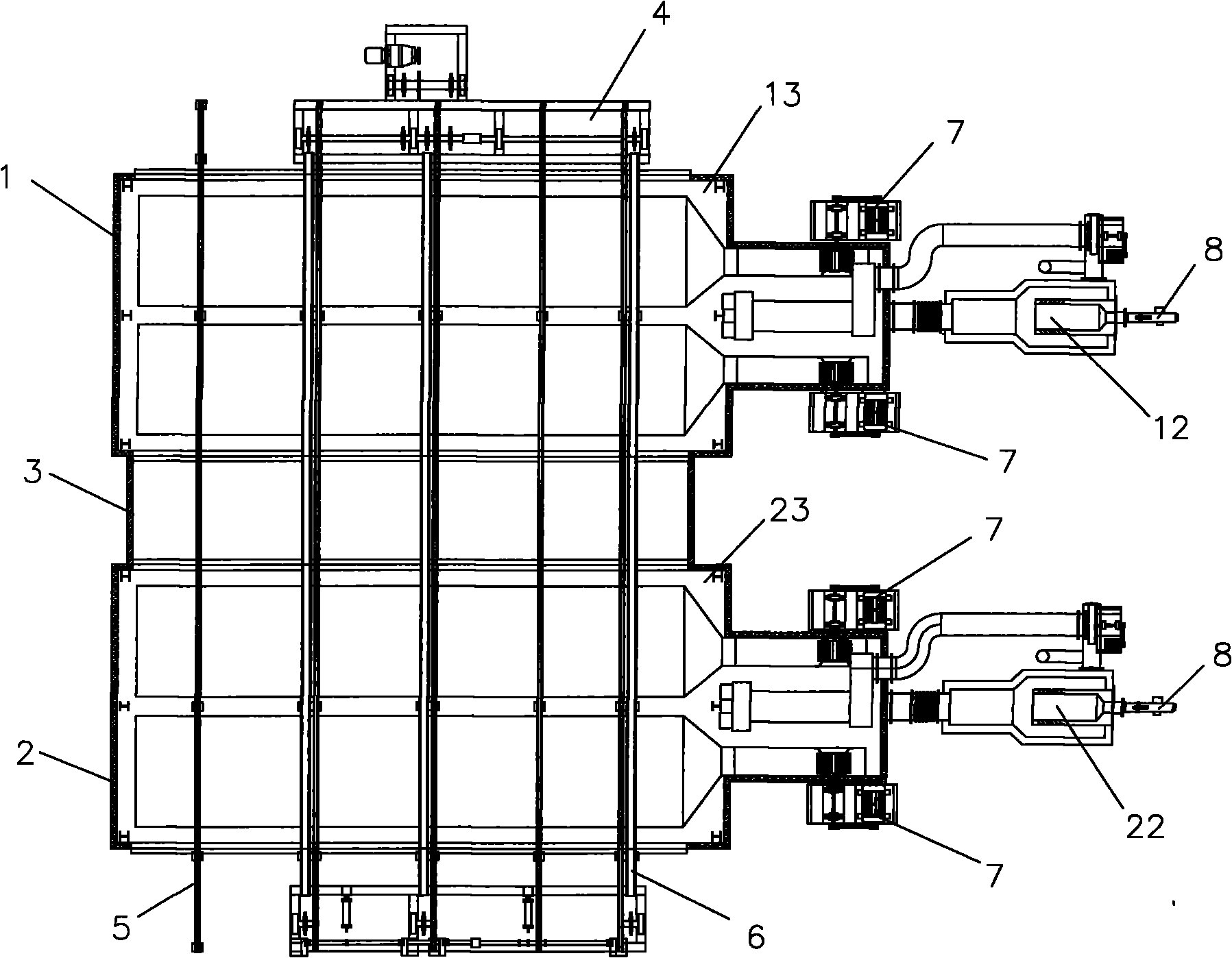

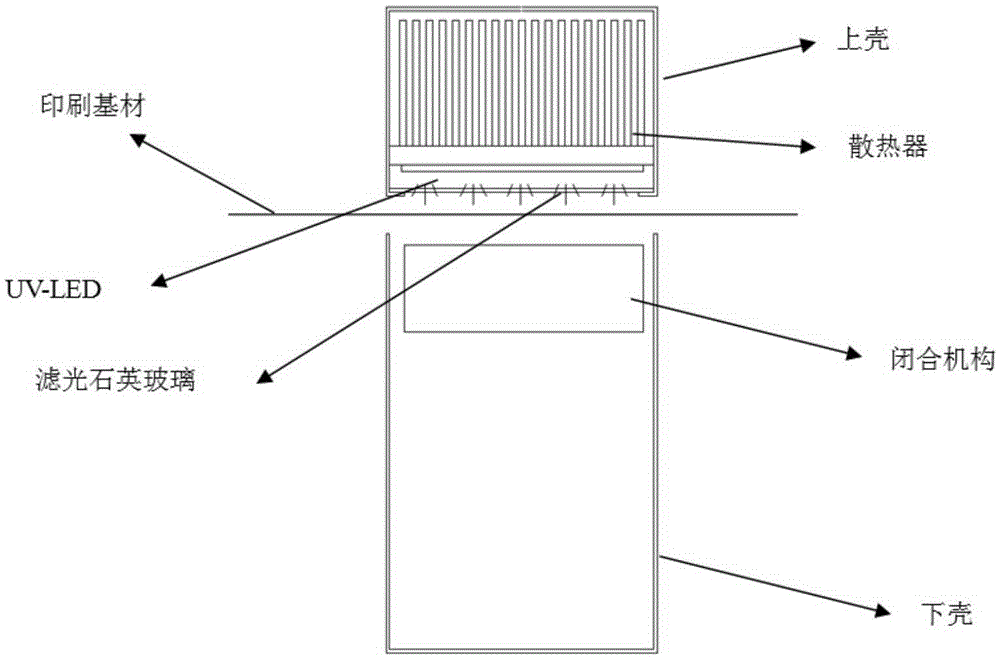

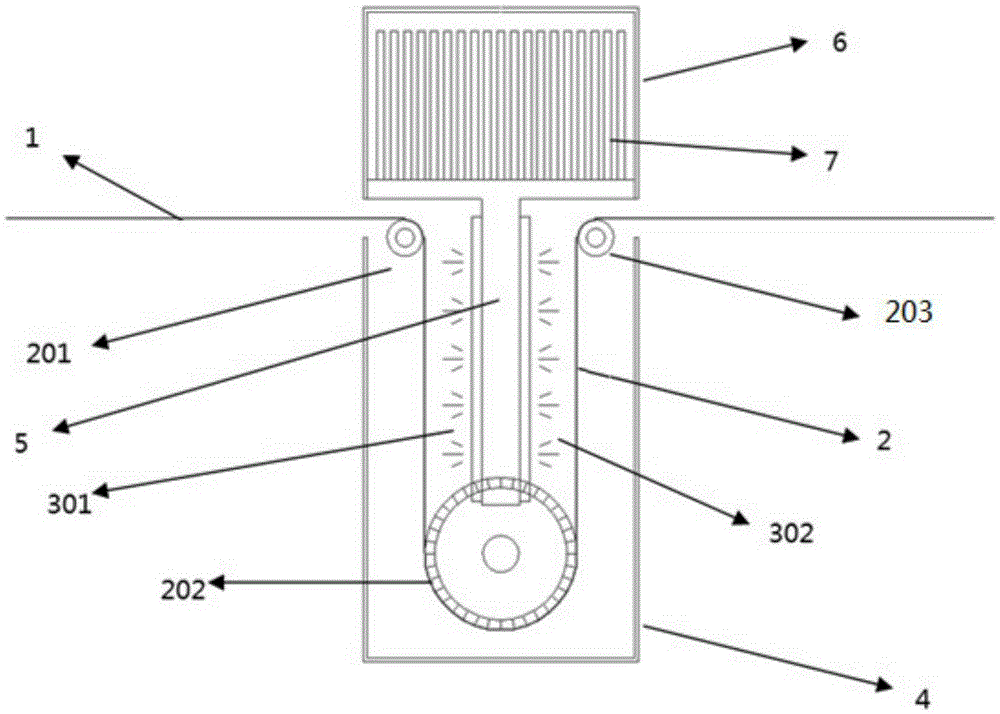

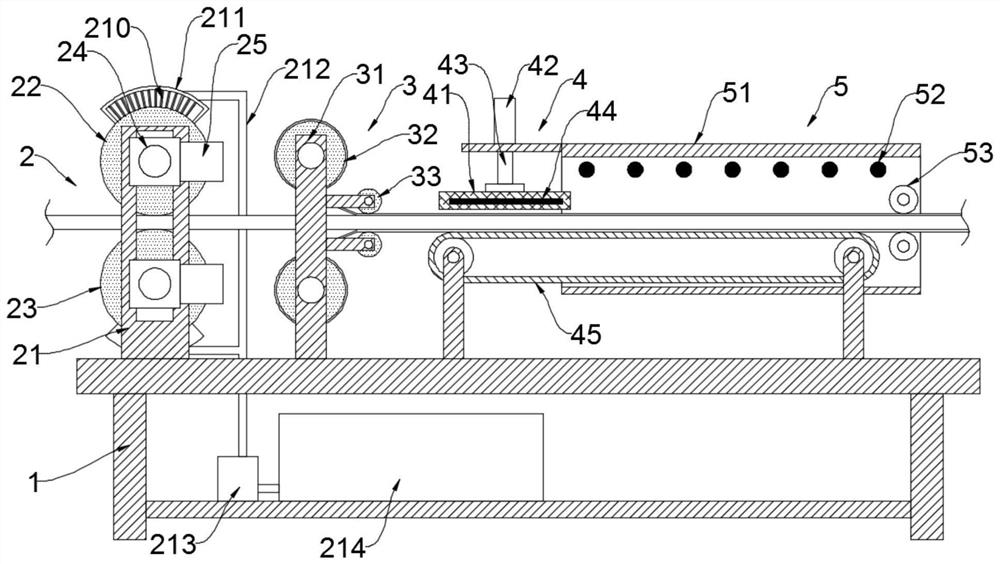

Printing ink curing device

ActiveCN105291576AGuarantee ink curing qualityImprove ink curing effectPrinting press partsPrinting inkLinear operation

The invention discloses a printing ink curing device. The printing ink curing device comprises a conveying component and curing components, wherein the conveying component is used for controlling a printing substrate to move according to a set operation line; the curing components are arranged on the two sides or any one side of the set operation line in a sectional mode. According to the printing ink curing device, under the circumstance that the size of an original device is kept unchanged, an original linear operation line of the printing substrate is designed into a curve surface operation form, the irradiated area of printing ink on the substrate is effectively increased, namely the curing time of the printing ink is prolonged, and thus the curing quality of the printing ink is guaranteed; besides, through the UV-LED printing ink curing light sources arranged on the two sides in the sectional mode, the curing effect of the printing ink is further improved, and the printing speed is remarkably increased on the premise that the printing quality is ensured.

Owner:TIANJIN JINYA ELECTRONICS

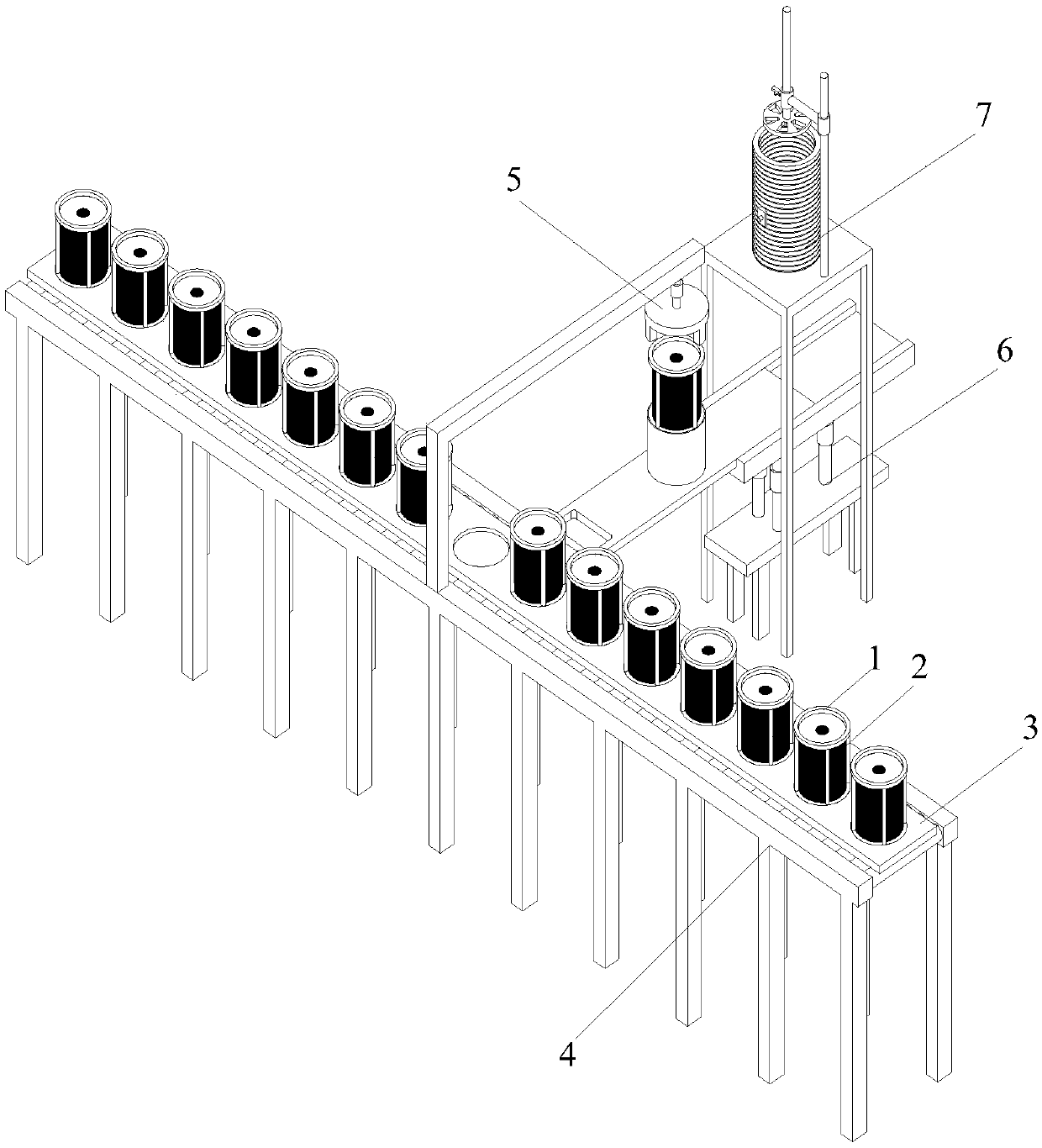

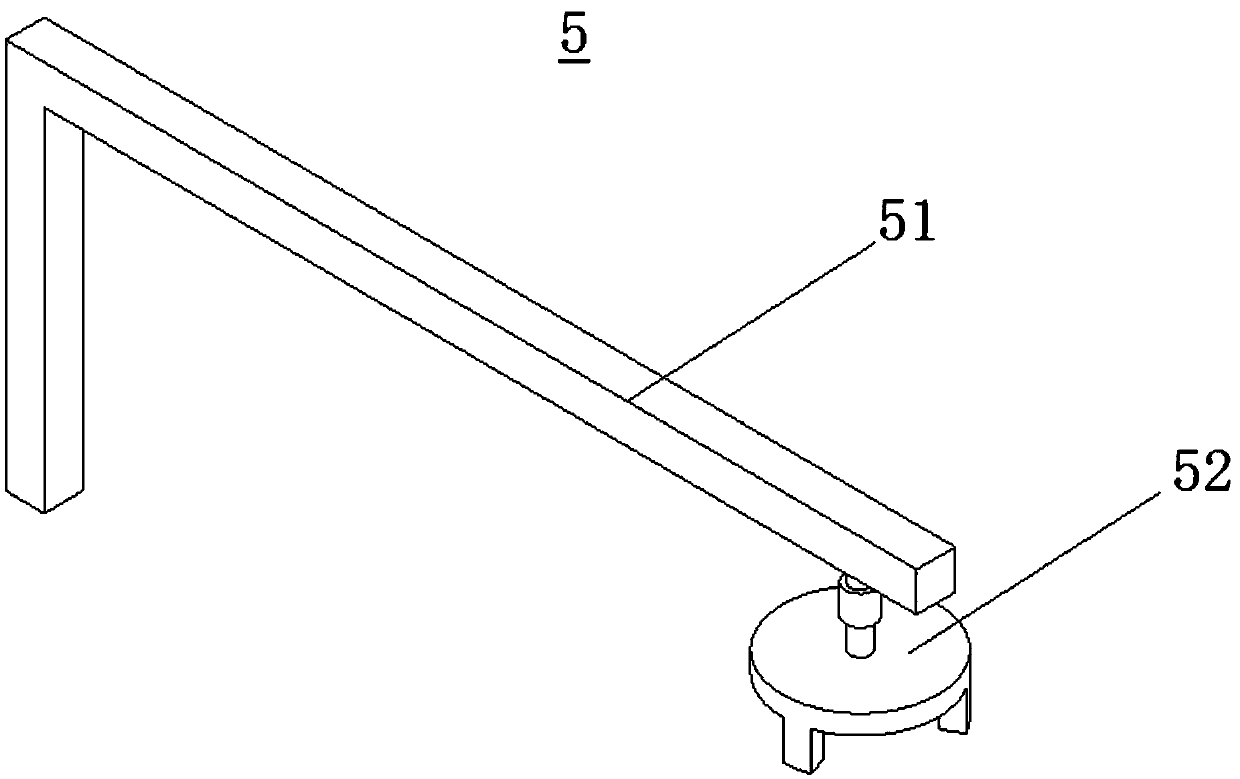

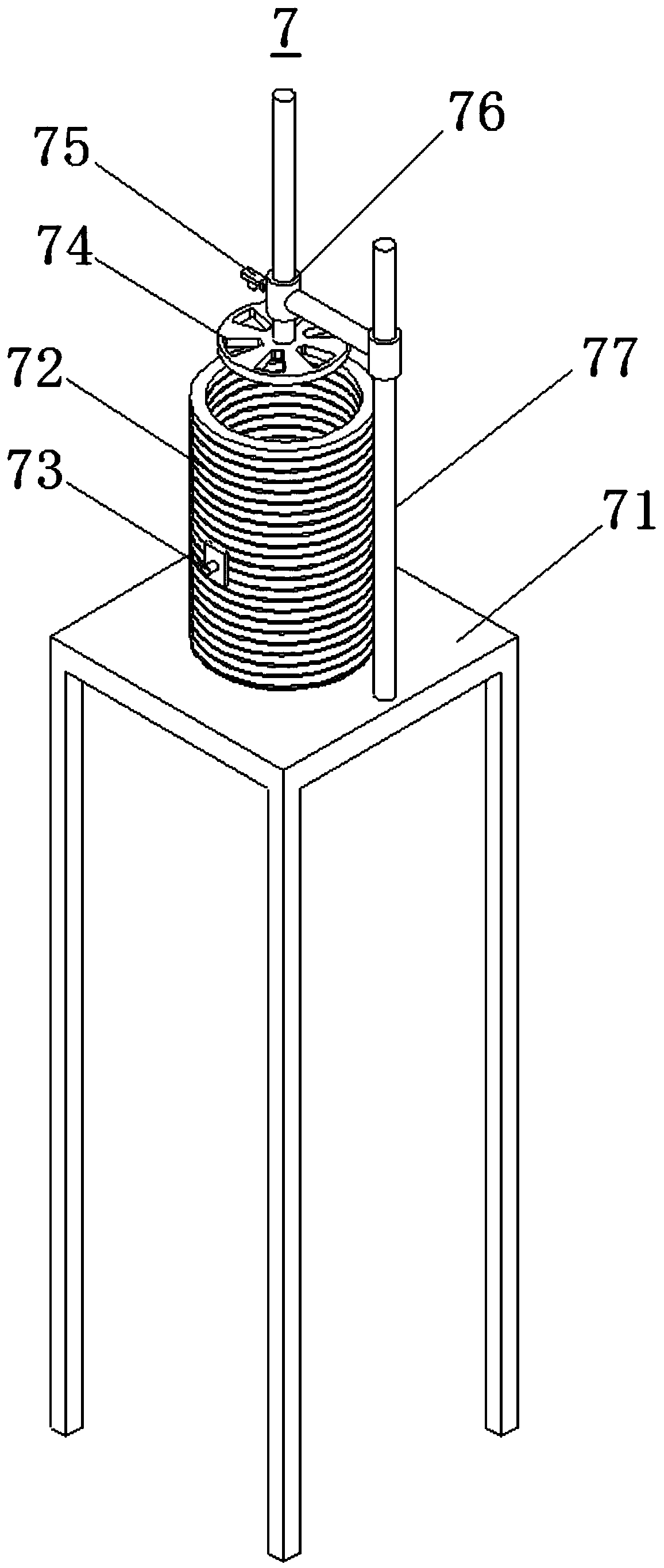

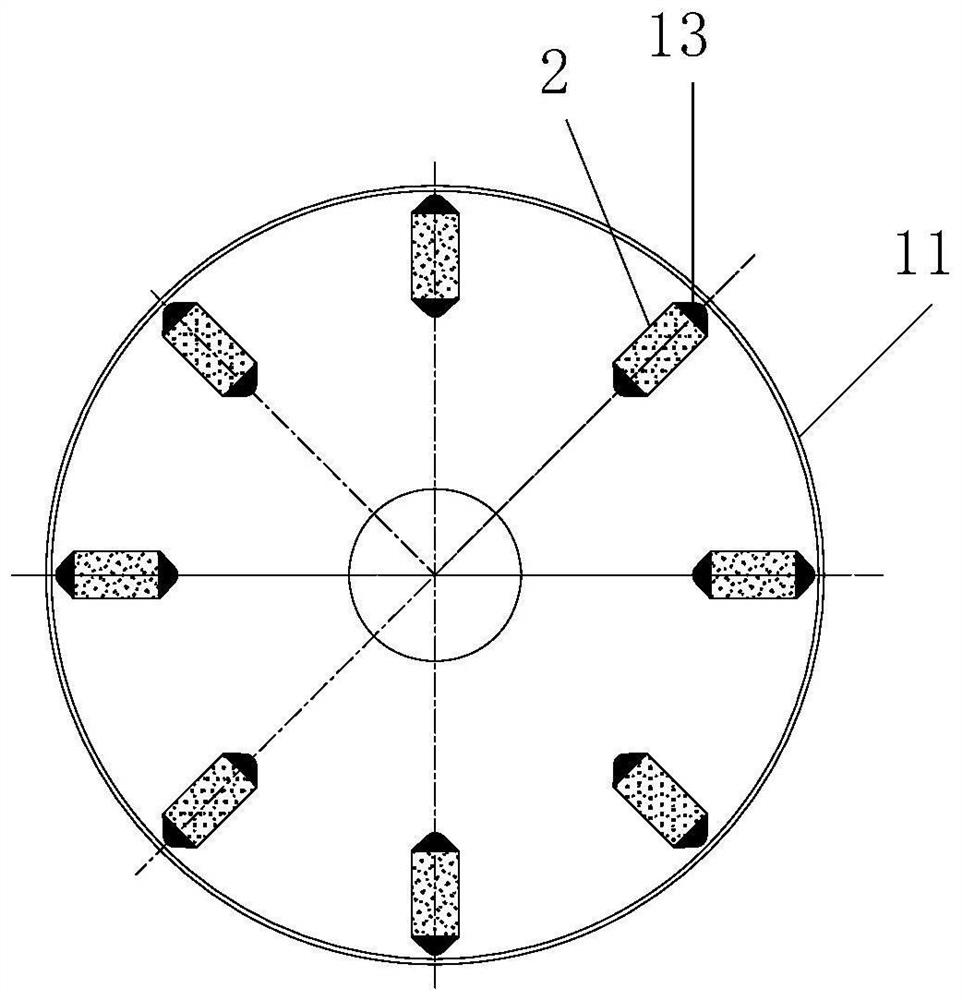

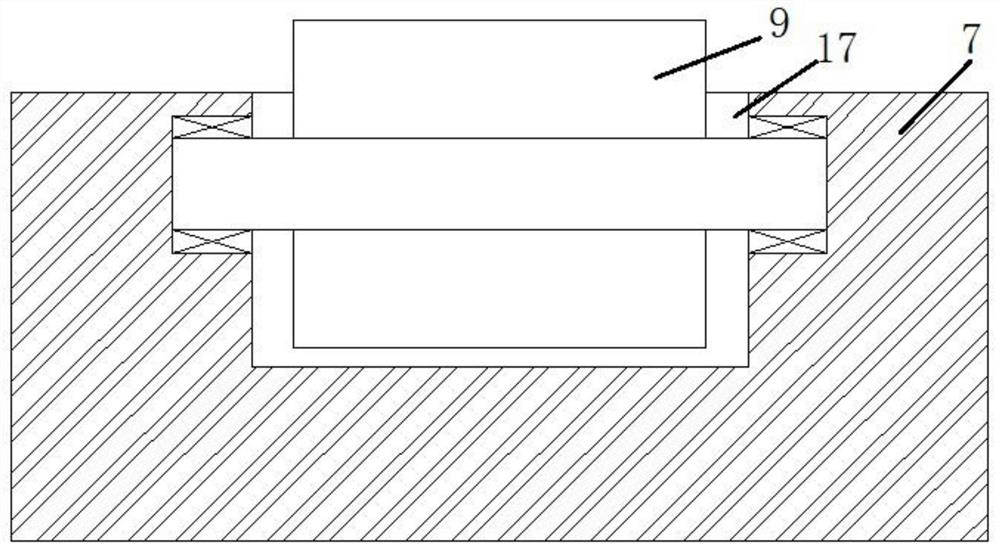

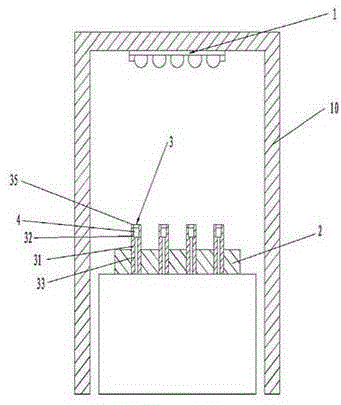

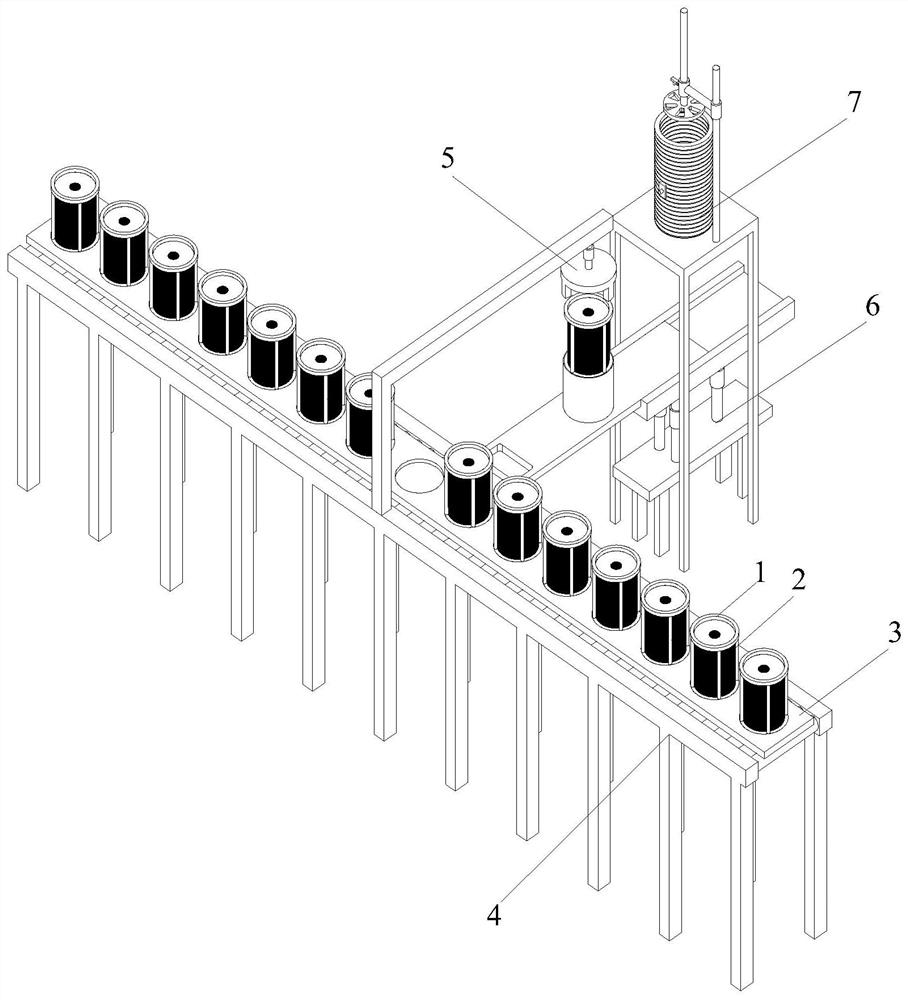

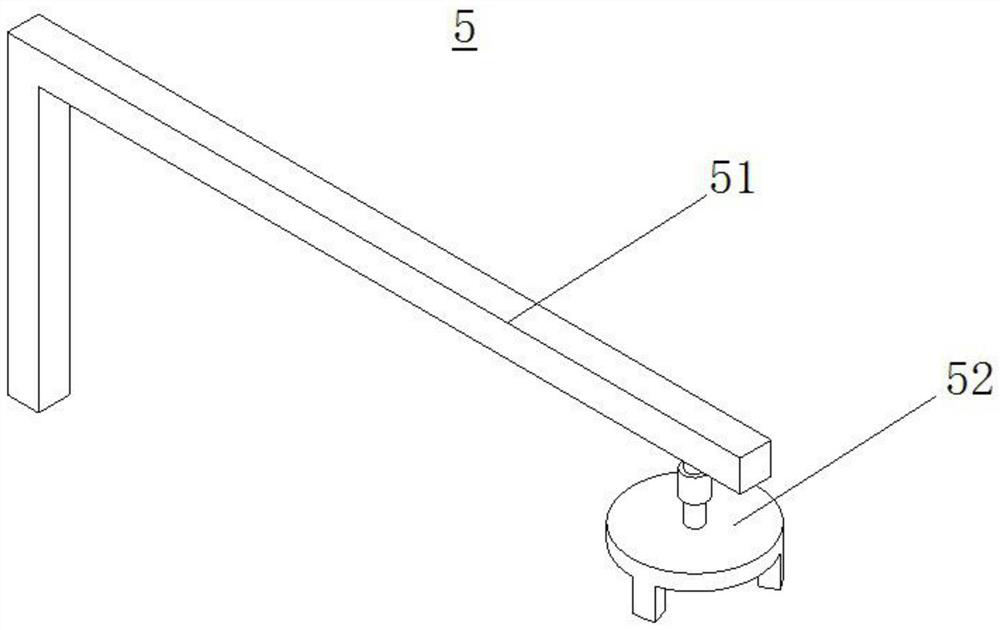

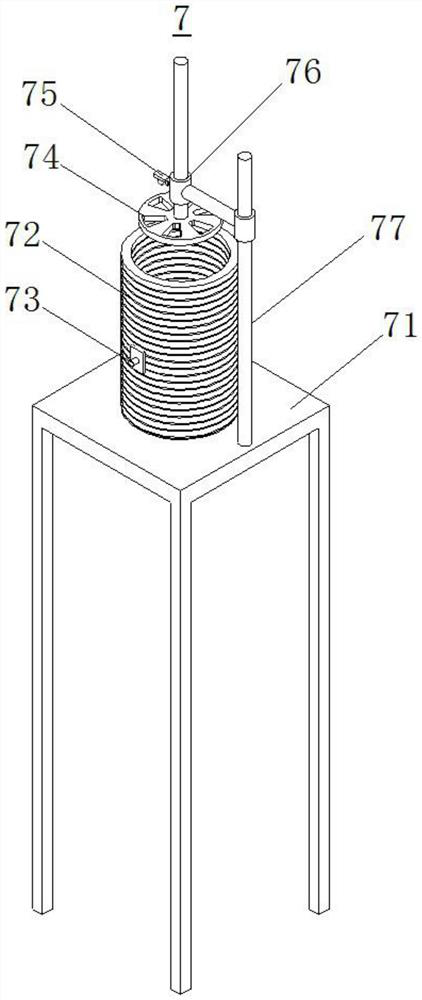

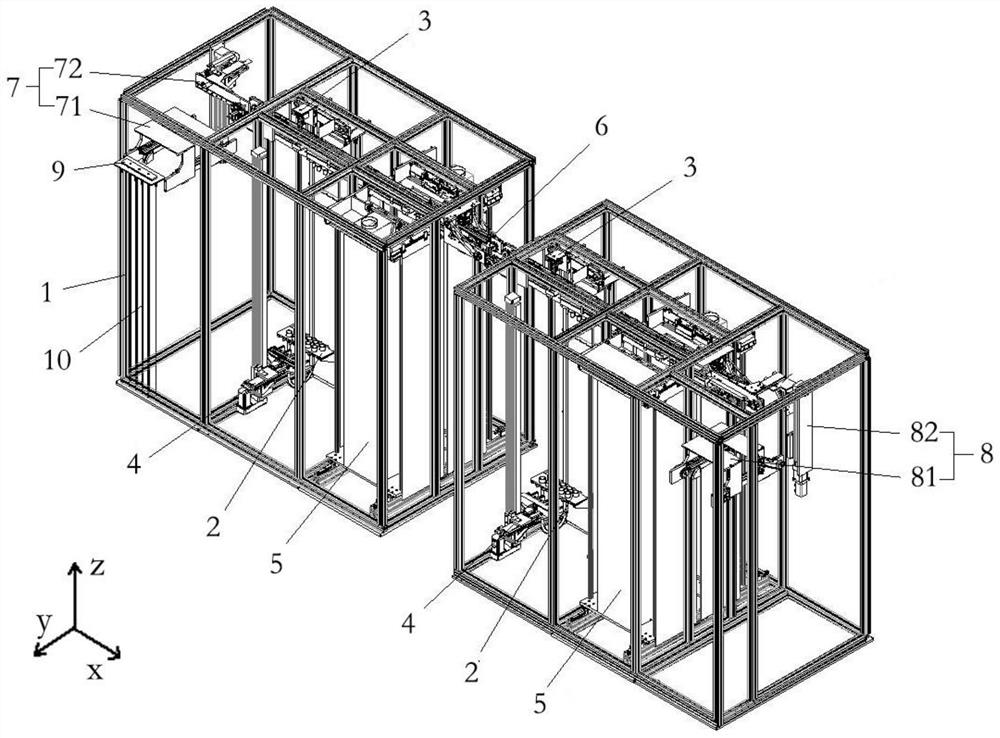

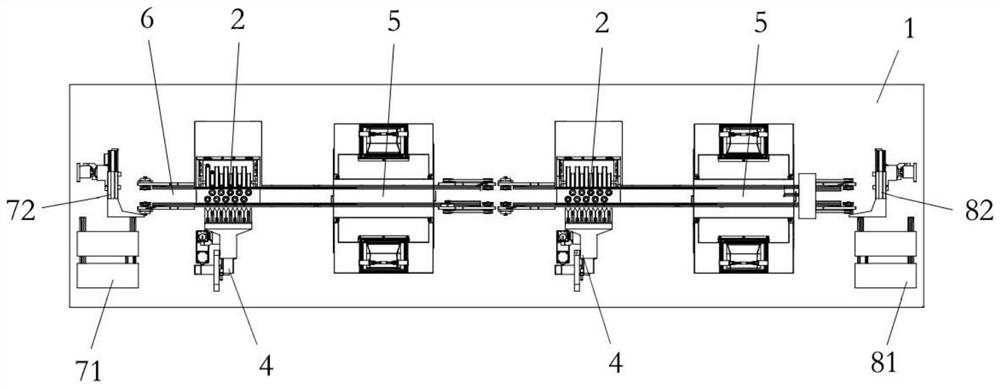

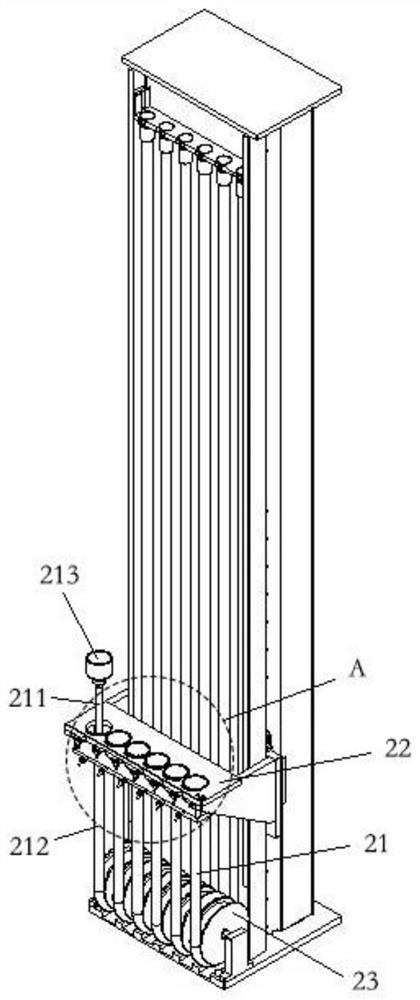

Induction heating system and method for rapid curing of silicon steel self-adhesive coating iron core

ActiveCN110808670AFast curingGuaranteed curing qualityCoil arrangementsManufacturing dynamo-electric machinesThermodynamicsMechanical engineering

The invention discloses an induction heating system for rapid curing of a silicon steel self-adhesive coating iron core. The induction heating system comprises a conveying roller table; an induction heating device comprising a cylindrical induction heating coil having a hollow cavity and a temperature measuring element, wherein the induction heating coil adopts 6-20KHz intermediate frequency to perform induction heating of the silicon steel sheet; a feeding and discharging device; a loading and unloading device which is arranged to transport the stacked mold directly below the induction heating coil in the horizontal direction and to transport the stacked mold into the hollow cavity of the induction heating device in the vertical direction or to remove the stacked mold from the hollow cavity after the induction heating is completed; and a control device which is respectively connected with the conveying roller table, the feeding and discharging device and the loading and unloading device to control their respective actions and is also connected with the induction heating coil and the temperature measuring element to control the induction heating process.

Owner:BAOSHAN IRON & STEEL CO LTD

A method of vacuum filling glue for permanent magnet motor rotor

ActiveCN109698590BReduce gapAvoid churnPretreated surfacesManufacturing stator/rotor bodiesEpoxyVacuum pumping

The invention discloses a vacuum glue pouring method for permanent magnetism motor rotors. The method includes the following steps: S1, a step of iron core profiling processing, namely the step of applying pressure to compress iron core punching sheets in an axial direction of a permanent magnetism motor; S2, a step of glue solution configuration, namely the step of uniformly mixing an A componentand B component of a two-component epoxy resin adhesive; S3, a step of vacuum glue pouring, namely the step of placing a rotor into a vacuum cavity to perform vacuum pumping, and then performing gluepouring; and S4, a step of heating and curing, namely the step of placing the rotor after glue pouring into a tunnel type baking channel to perform segment drying. The method has high glue pouring efficiency, tooth tension and glue loss phenomenon is not easy to occur, and the quality of products can meet the filling technical requirements of the permanent magnetism motor rotor.

Owner:湖南中车商用车动力科技有限公司

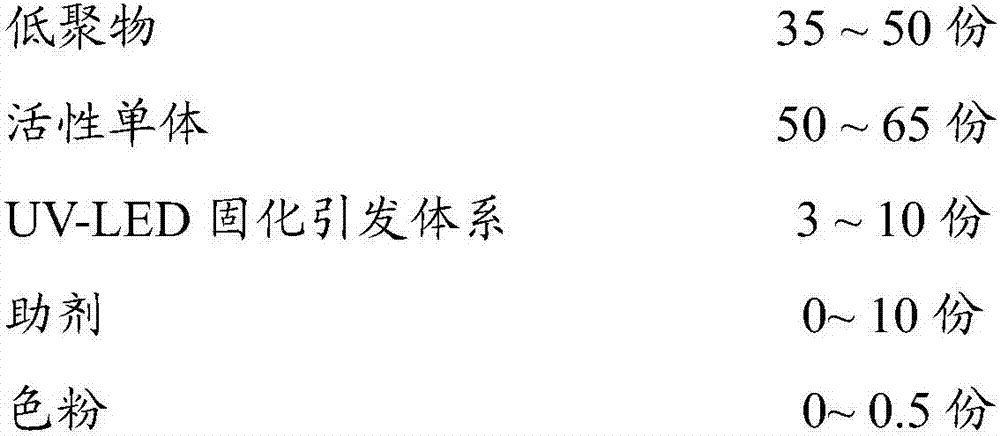

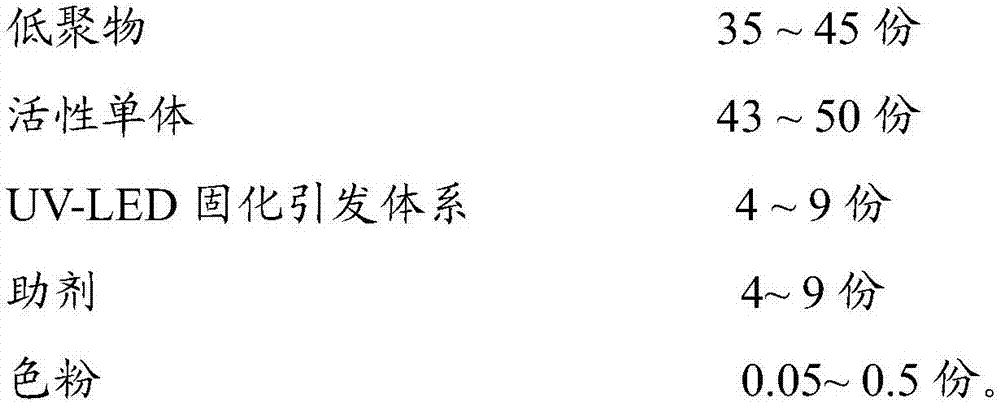

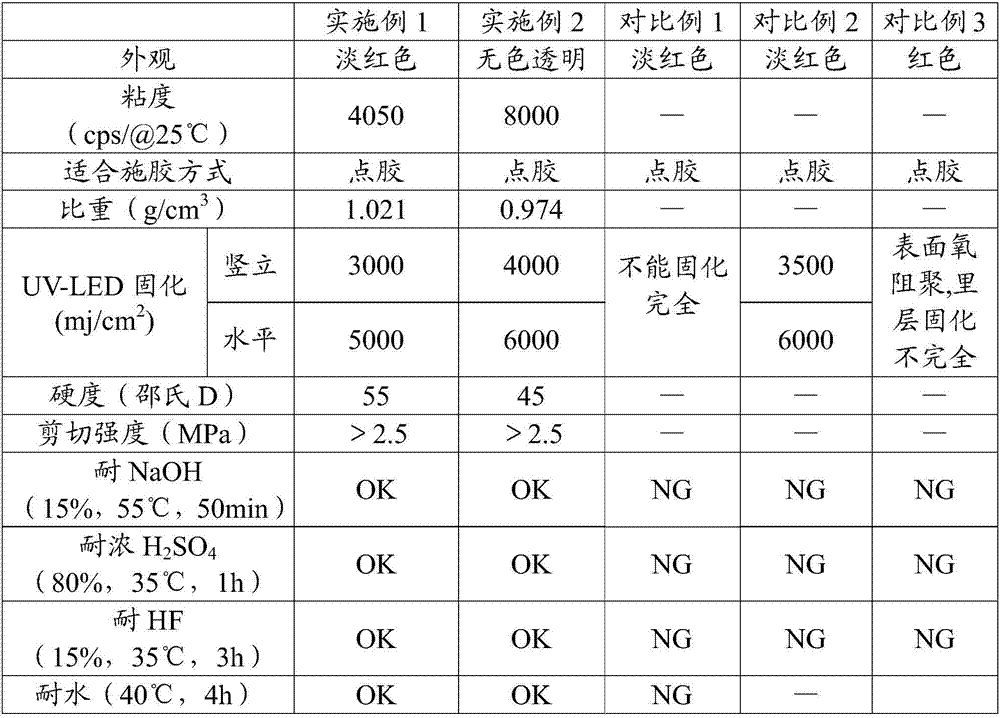

UV-LED curing initiation system, sealing glue, and preparation method and application of sealing glue

ActiveCN107964057AIdeal three-dimensional structureMeet the use requirementsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSurface layerHydrogen

The invention relates to a UV-LED curing initiation system, a sealing glue, and a preparation method and an application of the sealing glue, and belongs to the technical field of chemical materials. The UV-LED curing initiation system is prepared mainly from the following raw materials in parts by weight: 2-8 parts of a cracking type free radical photoinitiator and 2-5 parts of a hydrogen abstracting type free radical photoinitiator; the cracking type free radical photoinitiator is at least one of alpha-hydroxyketone derivatives and acyl phosphine oxides; the hydrogen abstracting type free radical photoinitiator is at least one of thioxanthone or thioxanthone derivatives. The UV-LED curing initiation system is used with combination of short-wave photoinitiators and long-wave photoinitiators, can ensure the curing efficiency of a surface layer and an inner layer of the glue, ensures the curing quality and solves an oxygen polymerization inhibition phenomenon. Moreover, the UV-LED curinginitiation system itself is OK to acid and alkali tolerance, and cannot affect the tolerance of the sealing glue to acids and alkalis, so as to meet the use requirements of the sealing glue in a glass thinning process.

Owner:广州惠利电子材料有限公司

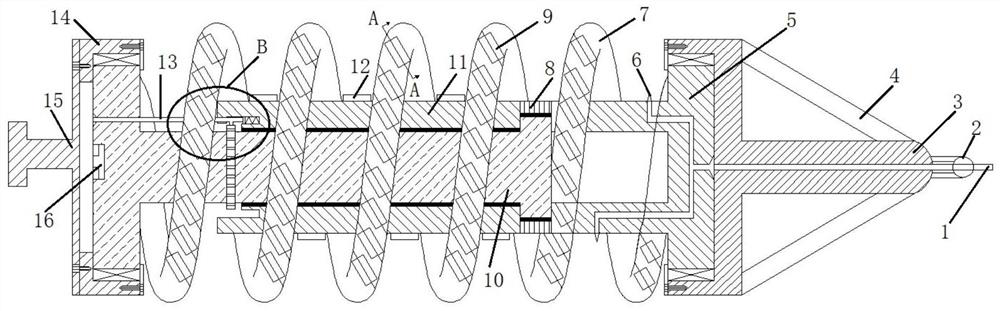

Non-excavation type pipeline repairing integrated device and repairing method

The invention provides a non-excavation type pipeline repairing integrated device and a repairing method, and relates to the technical field of pipeline repairing. The non-excavation type pipeline repairing integrated device comprises a traction part, a supporting part and a connecting part; the supporting part comprises an outer sleeve, an inner rotating shaft and a spiral elastic cage fixed between the outer sleeve and the inner rotating shaft, the outer sleeve sleeves the spiral elastic cage, an inclined wheel is arranged at the outer side of the spiral elastic cage, and the included angle between a rotating shaft of the inclined wheel and the axis direction of the spiral elastic cage is 30-60 degrees; the inner rotating shaft is arranged in the outer sleeve and is rotatably connected with the outer sleeve, and a clamping mechanism for locking the inner rotating shaft is arranged between the inner wall of the outer sleeve and the outer wall of the inner rotating shaft; the inner rotating shaft is rotatably connected with the connecting part; the outer sleeve is rotatably connected with the traction part; and a curing lamp and a nozzle are arranged on the outer sleeve. In order to overcome the defects in the prior art, the device can adapt to various pipeline inner diameter specifications, it is guaranteed that a repairing pipe is completely attached to the inner wall of a to-be-repaired pipeline, and repairing steps are reduced.

Owner:四川兴辉腾集团有限公司

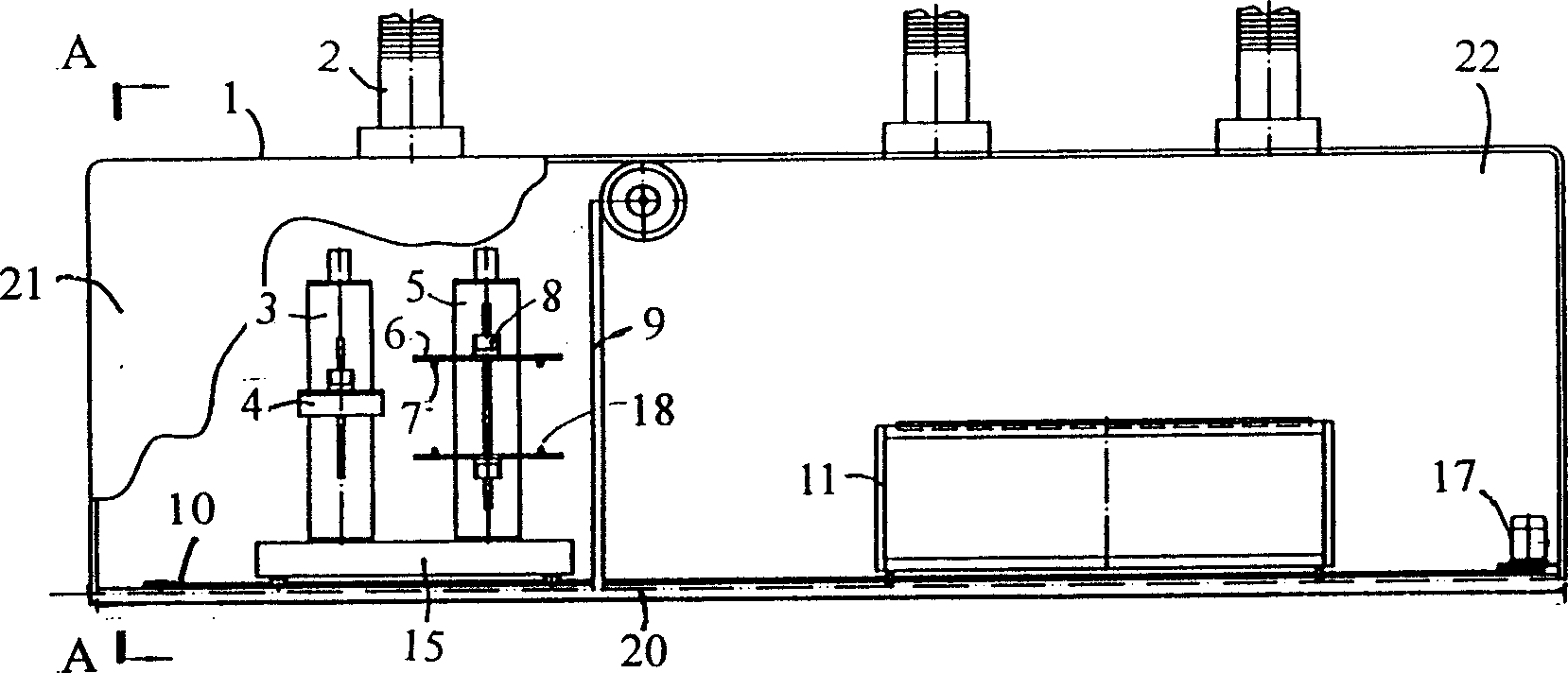

UV-LED curing machine with light measurement device

InactiveCN105396768ASimple control processGuaranteed curing qualityPretreated surfacesCoatingsMeasurement deviceElectricity

The invention discloses a UV-LED curing machine with a light measurement device. The light measurement device comprises a sensor, an irradiatometer and a controller. The sensor is used for sensing ultraviolet light sent by an ultraviolet lamp; the irradiatometer is used for receiving a detection signal of the sensor and calculating the illuminance of ultraviolet rays currently sent out by the ultraviolet lamp and the light accumulation amount increased along with irradiation time and is electrically connected with the sensor; and the controller is used for sending switching control signals of the irradiatometer and the ultraviolet lamp and is electrically connected with the irradiatometer and the ultraviolet lamp. A minimum single chip microcomputer structure is used in the controller, and the irradiatometer which is used for receiving the detection signal of the sensor and calculating the illuminance of the ultraviolet rays currently sent out by the ultraviolet lamp and the light accumulation amount increased along with irradiation time is electrically connected with the sensor through an amplifying circuit; and the inner surface and the outer surface of a shell of a bearing platform are each provided with light absorption paper. According to the curing machine, the control process is more convenient, rapid and precise; the curing quality is ensured; and meanwhile, an operator can be protected against ultraviolet ray radiation, and safety is achieved.

Owner:WUHU CHUNYUAN PHOTOELECTRIC EQUIP TECH CO LTD

Novel plate veneer compounding machine

InactiveCN111791570AEasy to transfer and apply glueFreeze fastLaminationLamination apparatusComposite plateWoodchips

The invention discloses a novel plate and veneer compounding machine, and belongs to the technical field of composite plate veneer forming equipment. The novel plate and veneer compounding machine comprises a rack, which is provided with a rolling and gluing assembly, a film releasing assembly, an ironing and flattening assembly and a UV irradiation assembly, wherein the film releasing assembly ismounted on the rack behind the rolling and gluing assembly, the ironing and flattening assembly is mounted on the rack behind the film releasing assembly, and the UV irradiation assembly is installedon the rack behind the ironing and flattening assembly. According to the invention, by arranging the rolling and gluing assembly, the film releasing assembly, the ironing and flattening assembly andthe UV irradiation assembly on the rack, plate conveying and gluing operation is convenient; and the veneer covers the glued thin wood sheet to be flattened, and under ironing and UV irradiation, theUV glue is rapidly solidified to ensure the solidification quality of the UV glue, so that the multi-layer composite veneer can be rapidly bonded, and the long process waiting for solidification is omitted so as to improve the efficiency to improve the composite forming quality of the veneer of the plate.

Owner:广州市添美装饰材料科技有限公司

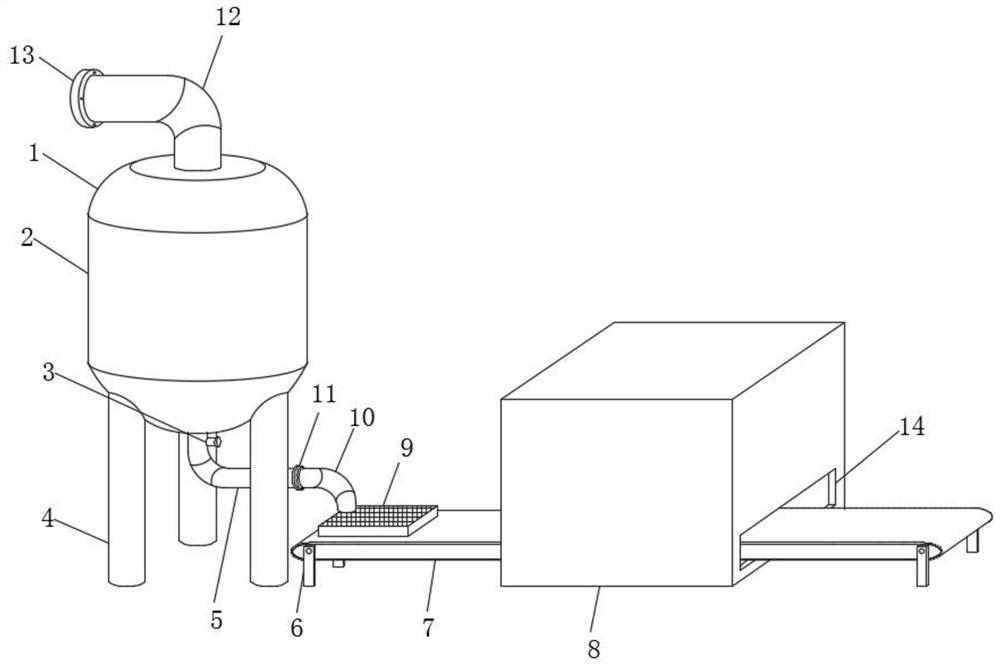

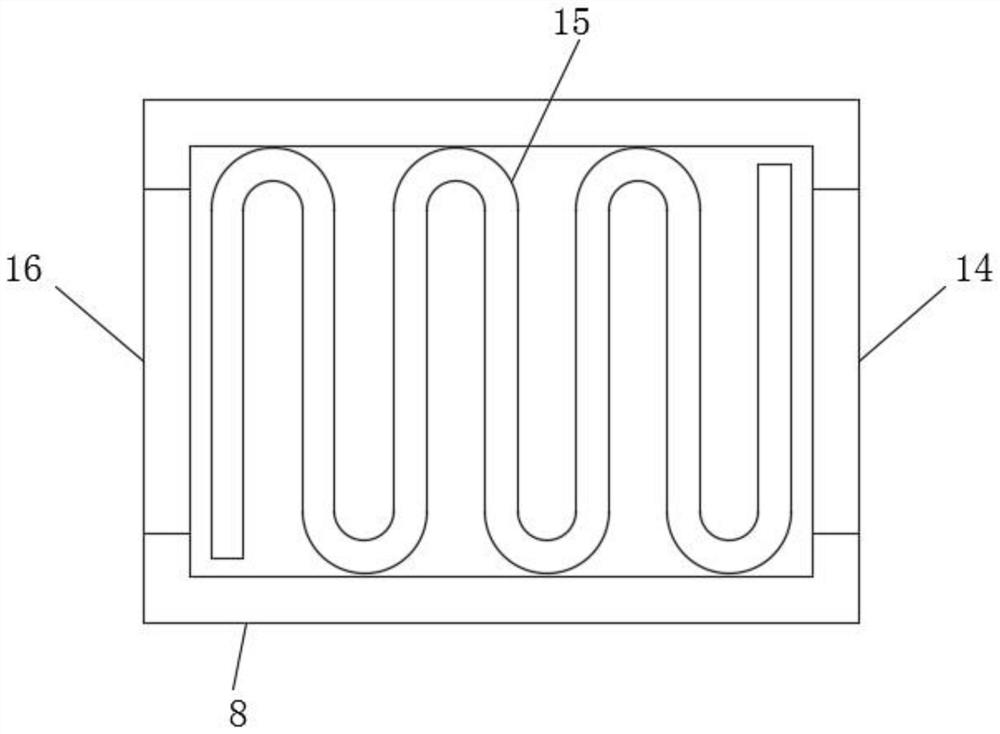

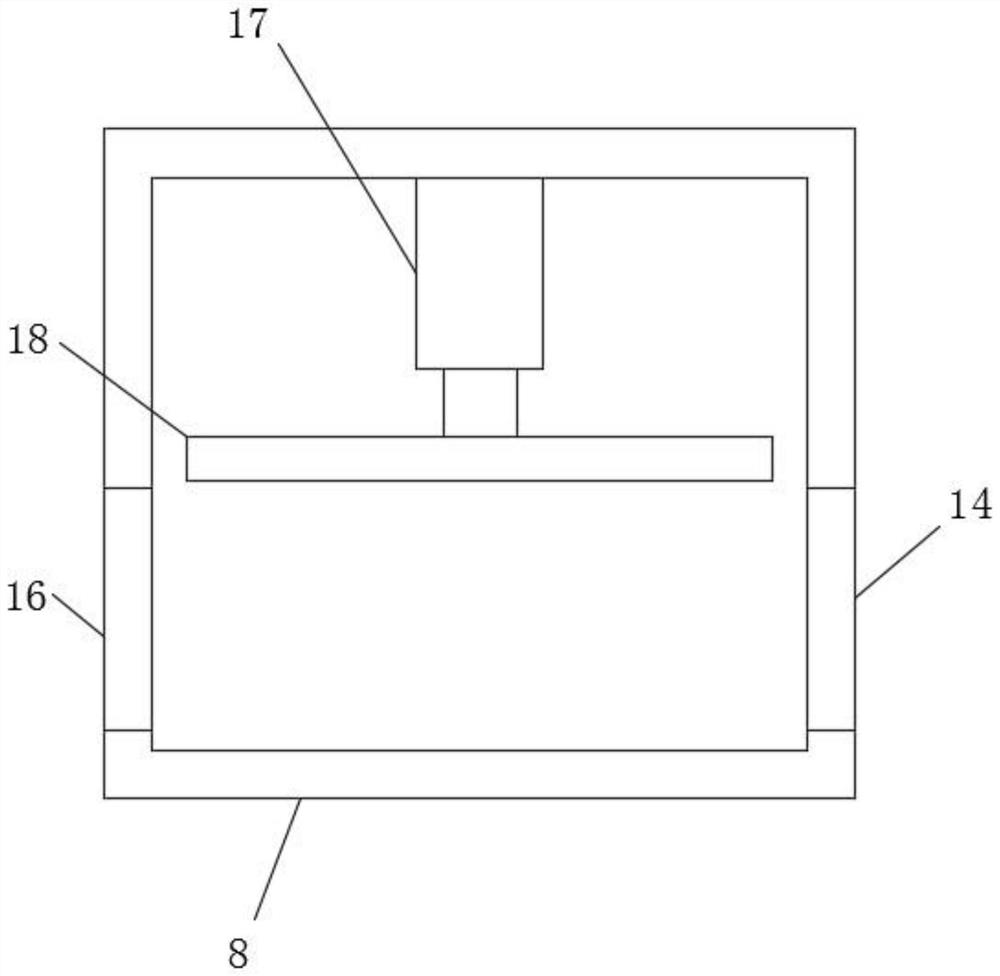

Lead-acid storage battery grid production equipment with good compaction effect and process thereof

InactiveCN111916759AImprove corrosion resistance and hardnessImprove overcharge resistanceElectrode carriers/collectorsGrid alloyEngineering

The invention discloses lead-acid storage battery grid production equipment with a good compaction effect and a process thereof. The equipment comprises a preparation furnace, a material conveying pipe, a conveyor, a cooling box, a forming mold, a cooling pipe electric telescopic rod and a compaction plate. According to the invention, metal additives such as selenium, sulfur and arsenic are addedinto a lead-acid storage battery grid alloy; therefore, the corrosion resistance and hardness of the grid of a lead-acid storage battery are effectively improved, the overcharge resistance is improved, the loss of the lead-acid storage battery is greatly reduced, and the problems of thermal cracking, shrinkage cavity and the like of a lead-acid storage battery grid caused by different surface tensions of various metal additives are avoided; the lead-acid storage battery grid is subjected to aging curing in an excellent environment, the interior of an external curing box is dehumidified throughsteam, the dehumidified lead-acid storage battery grid is dried for 2-22 hours, the grid curing effect is good, and the curing quality of the lead-acid storage battery grid is guaranteed; and throughcooperative use of an electric telescopic rod and a compaction plate, rapid compaction of the forming die span is facilitated, and the compaction effect is good.

Owner:JIESHOU HUAYU POWER SUPPLY

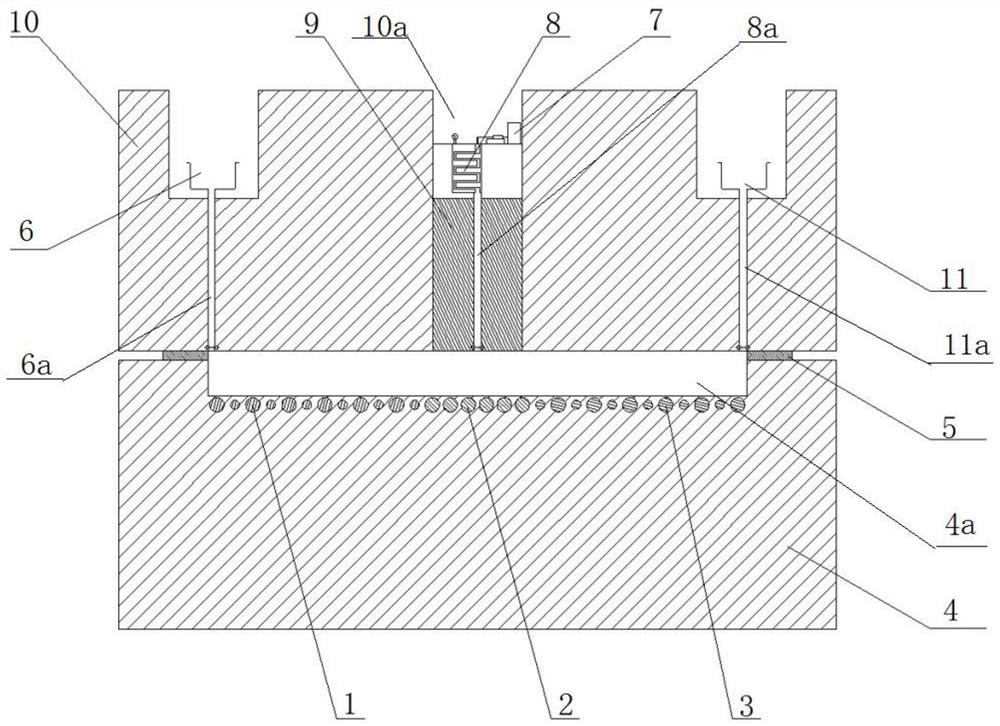

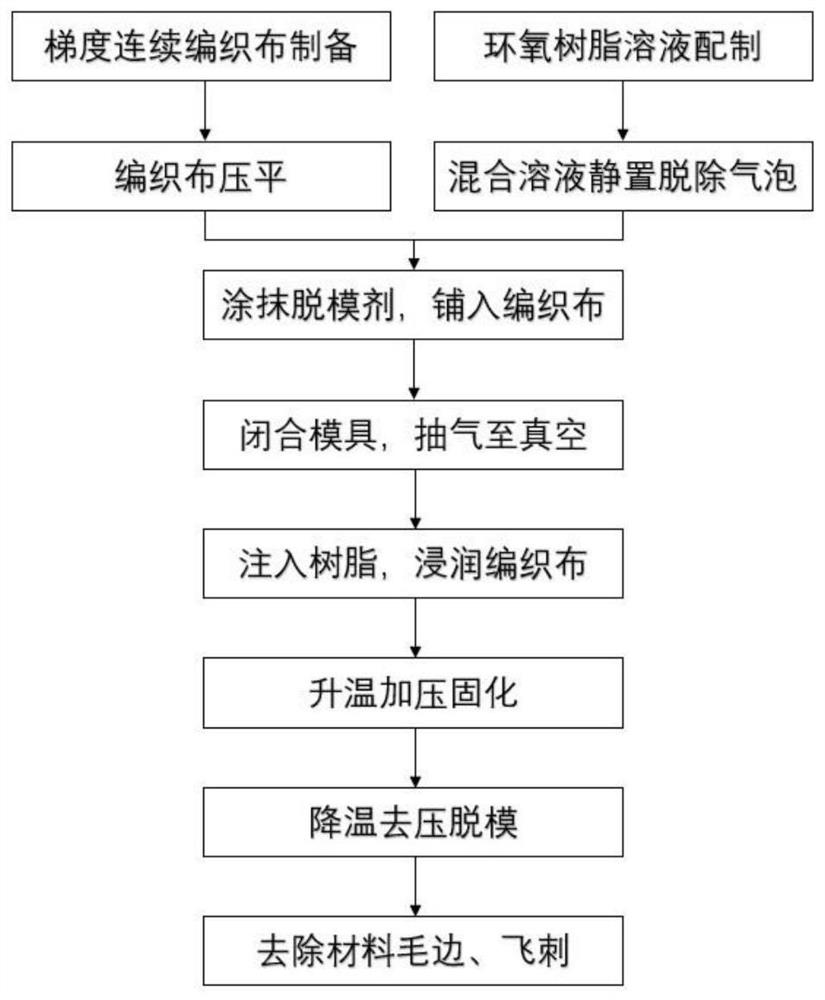

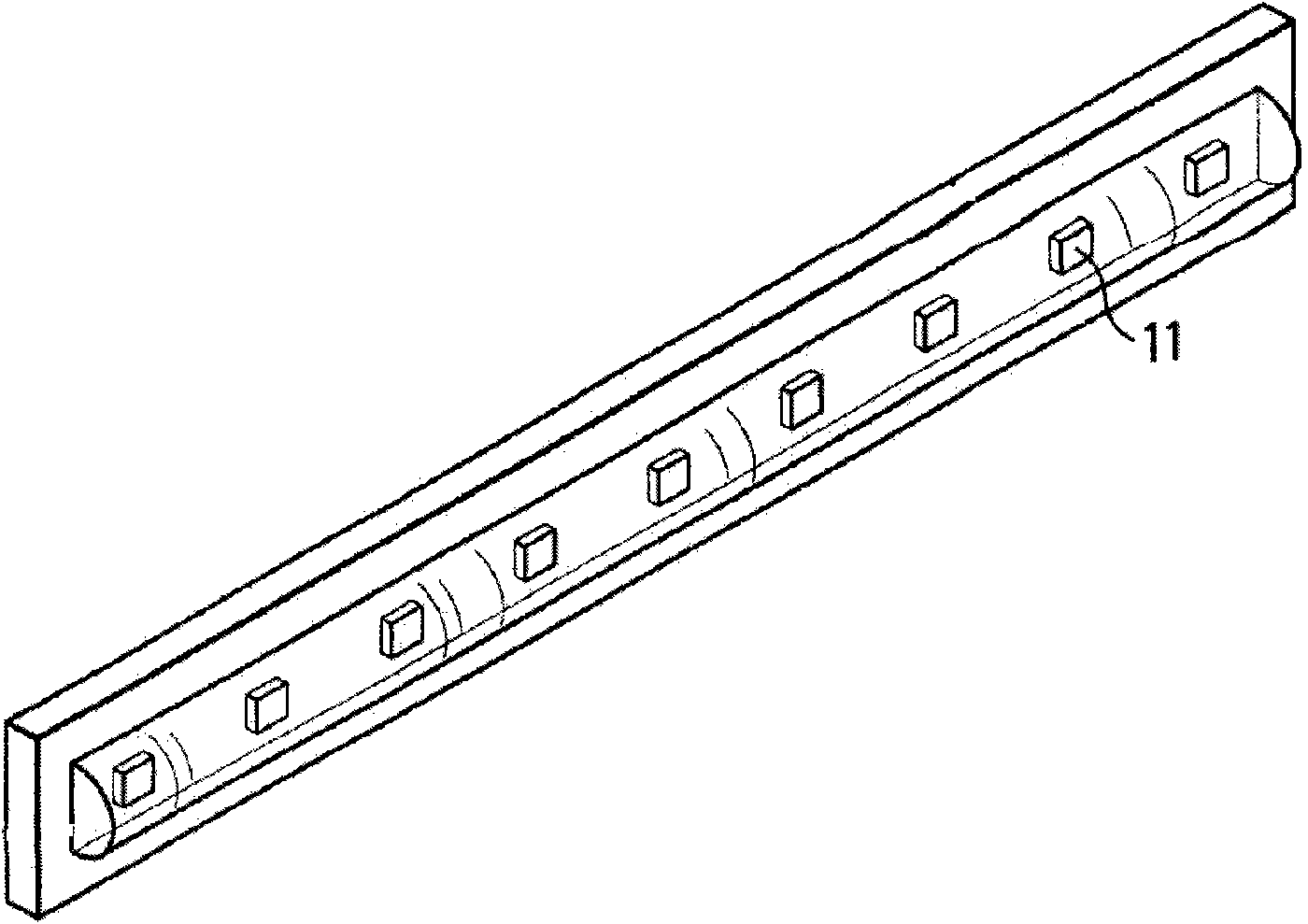

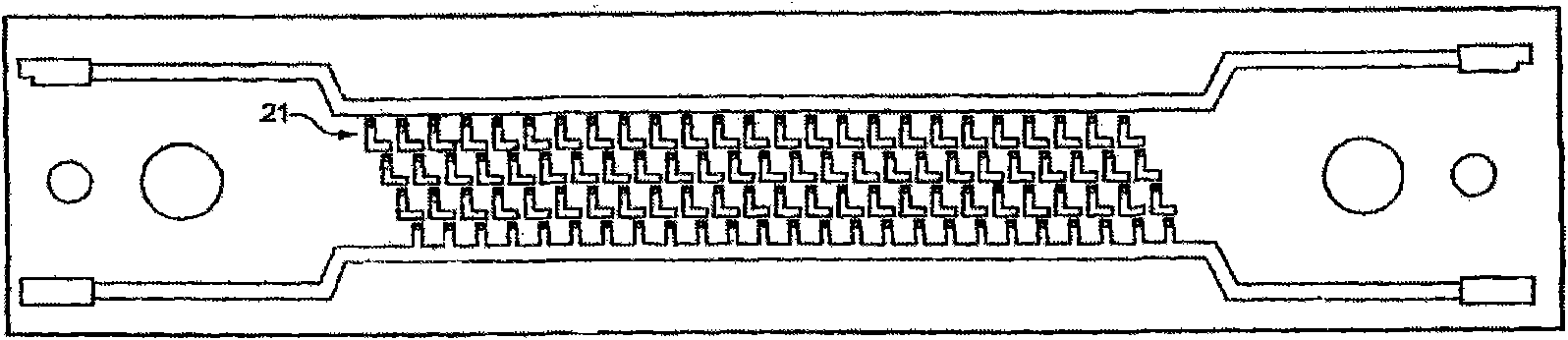

Preparation device and method for dissimilar resin gradient continuous woven carbon fiber composite material

The invention discloses a preparation device and method for a dissimilar resin gradient continuous woven carbon fiber composite material. The preparation device comprises a lower die which is provided with a concave die cavity in the center of the top, a sealing ring which is fixedly arranged at the top of the lower die and surrounds the die cavity, an upper die which is coaxially arranged above the lower die and is provided with a central through hole, a pressure head which is coaxially arranged in the central through hole and can axially move along the central through hole under driving of a driving device, a first liquid storage tank which communicates with one end of the die cavity through a first guide pipe, a second liquid storage tank which communicates with the other end of the die cavity through a second guide pipe, an air extractor, and an exhaust pipe which is arranged in the pressure head in an embedded manner; one end of the exhaust pipe is connected to the exhaust device, and the other end communicates with the center of the top of the die cavity; three groups of heating pipes are arranged in the lower die in an embedded manner and are close to the bottom surface of the die cavity; one group of heating pipes corresponds to the pressure head in position, and the other two groups of heating pipes correspond to areas on two sides of the pressure head.

Owner:JILIN UNIV

Device and method for monitoring abnormal state of light-emitting diode

InactiveCN102118913BAccurate real-time monitoringRealize real-time monitoringElectric light circuit arrangementLight-emitting diodeThreshold voltage

The invention relates to a device and method for monitoring the abnormal state of a light-emitting diode. The device is connected to both ends of the light-emitting diode and can be used for monitoring the abnormal state of the light-emitting diode by detecting the change of the working voltage of the light-emitting diode. The device and the method can be used for monitoring the working voltage VF of each light-emitting diode in a light-emitting diode matrix in real time, judging whether the working voltage VF is higher than a determined high threshold voltage VH or not and whether the working voltage VF is lower than a determined low threshold voltage VL or not, and accordingly judging whether a current light-emitting diode abnormally works or not, or short circuit or open circuit faults are already generated or not; and in addition, the positions of the light-emitting diodes which abnormally work and go wrong can be positioned quickly under the working state of the light-emitting diode matrix so as to facilitate maintenance and replacement.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

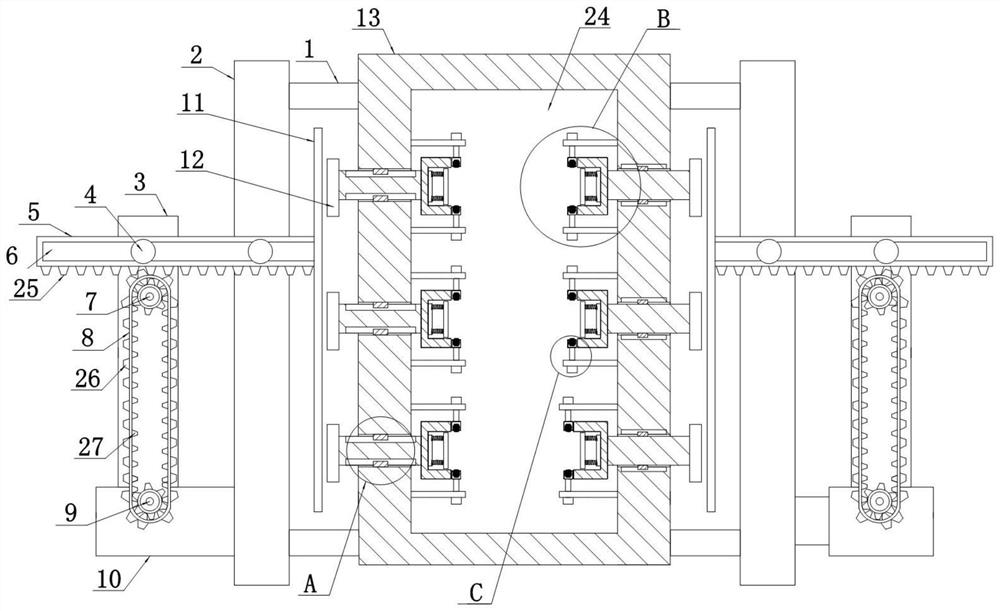

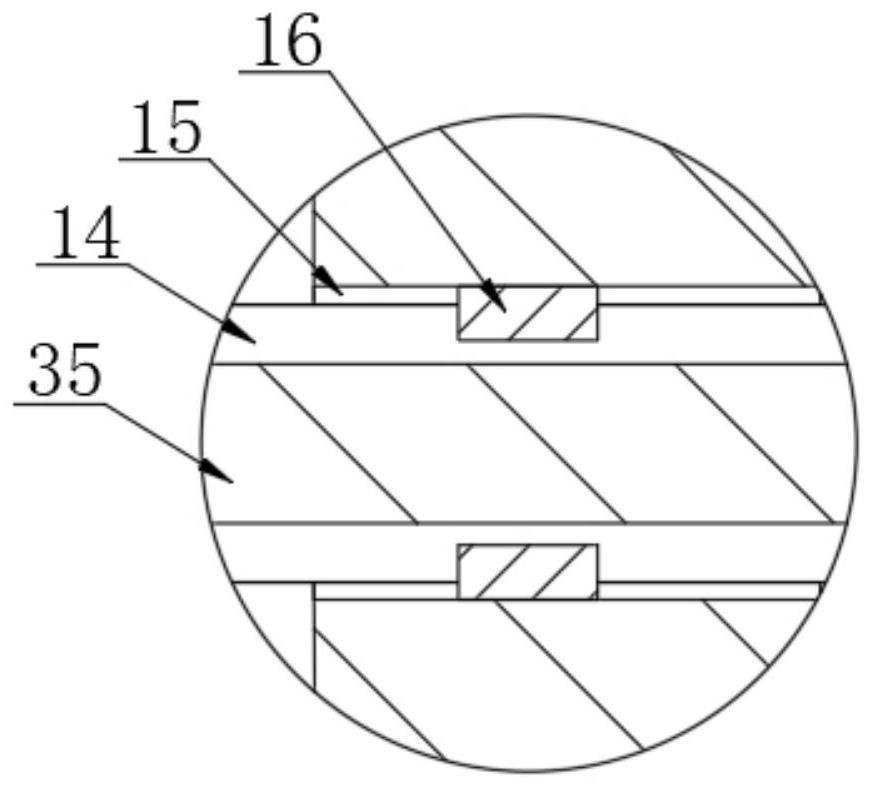

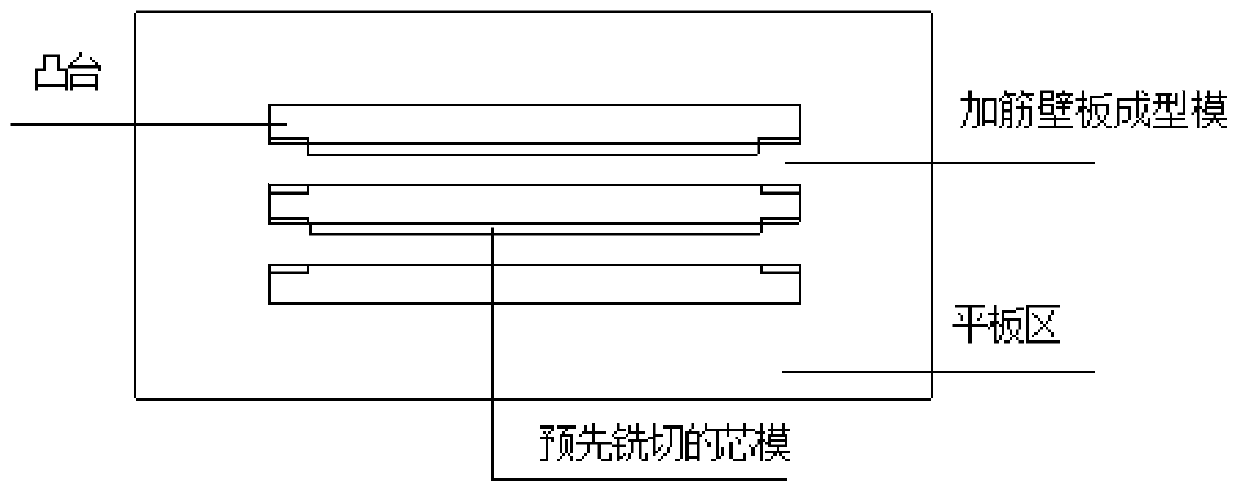

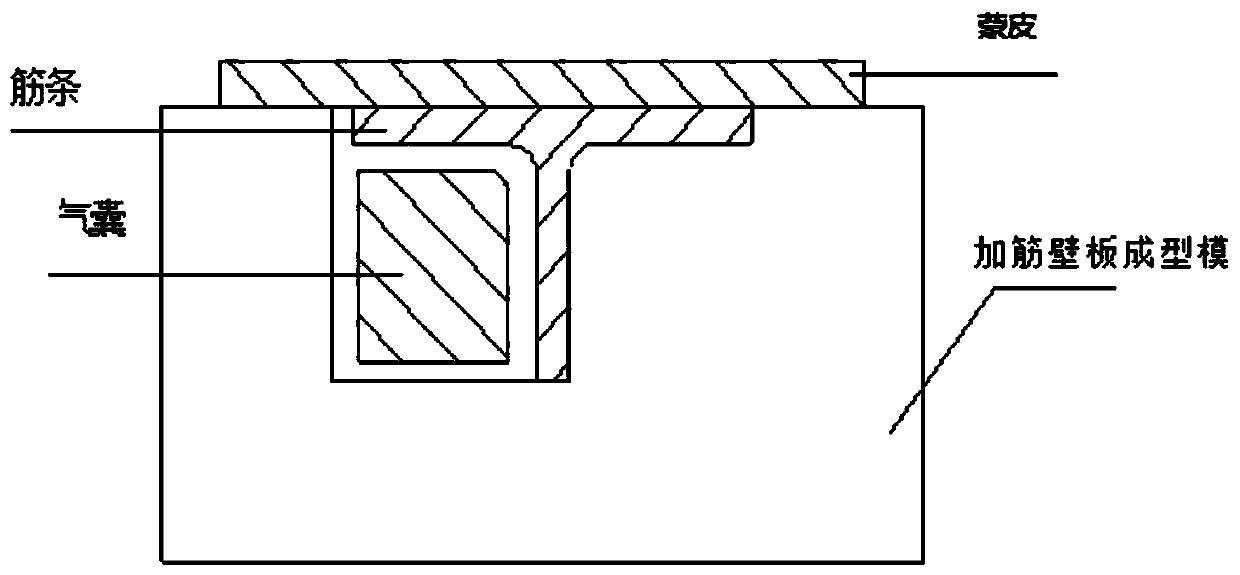

Composite material reinforced bulkhead and manufacturing mold and forming method thereof

PendingCN114526438AReduce weightHigh structural efficiencyFuselage framesSheets/panelsIsolation membraneUltimate tensile strength

The invention discloses a composite material reinforced bulkhead, a manufacturing mold of the composite material reinforced bulkhead and a forming method of the composite material reinforced bulkhead, and relates to the technical field of bulkhead structure equipment. The reinforcing bulkhead comprises a frame body, a foam core and reinforcing ribs, the frame body is formed by laying a composite material, and a reinforcing layer is arranged in the composite material laying layer. The manufacturing mold of the composite material reinforced bulkhead comprises a base plate, an outer mold and a base, and the base plate is provided with a protruding part consistent with a through hole in shape at the position of the through hole of the reinforced bulkhead. The forming method of the composite material reinforced bulkhead comprises the steps of overall laying of the composite material, laying of the reinforced layer and final laying of the part exceeding a pre-laying layer, and removing an isolating membrane, so that overall laying of the reinforced bulkhead is completed. The bulkhead has the advantages that the local strength and rigidity of the bulkhead are enhanced, the integrity is high, and the problems that the connecting strength with aircraft parts is insufficient, and the bulkhead is heavy are solved.

Owner:常州启赋安泰复合材料科技有限公司

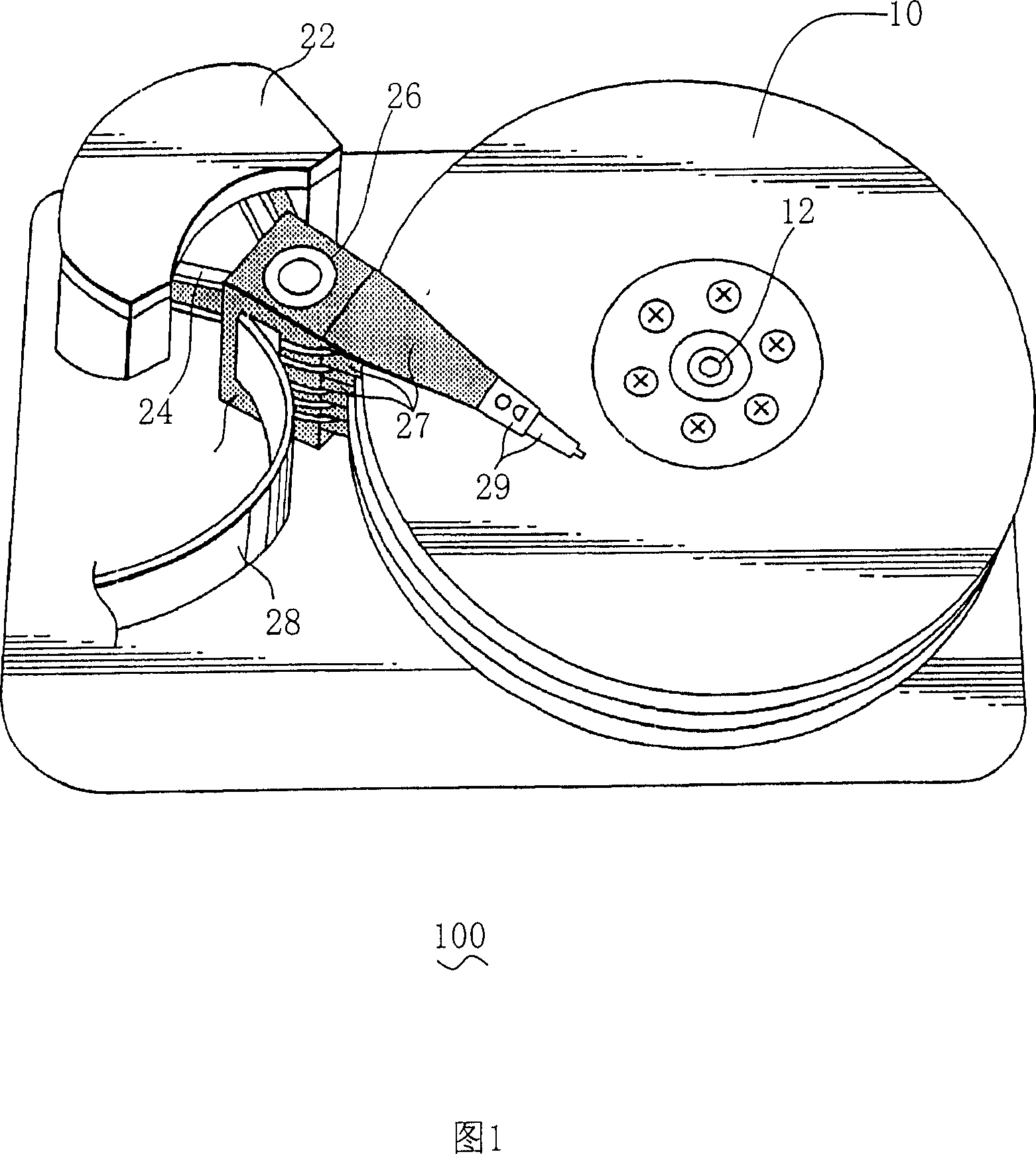

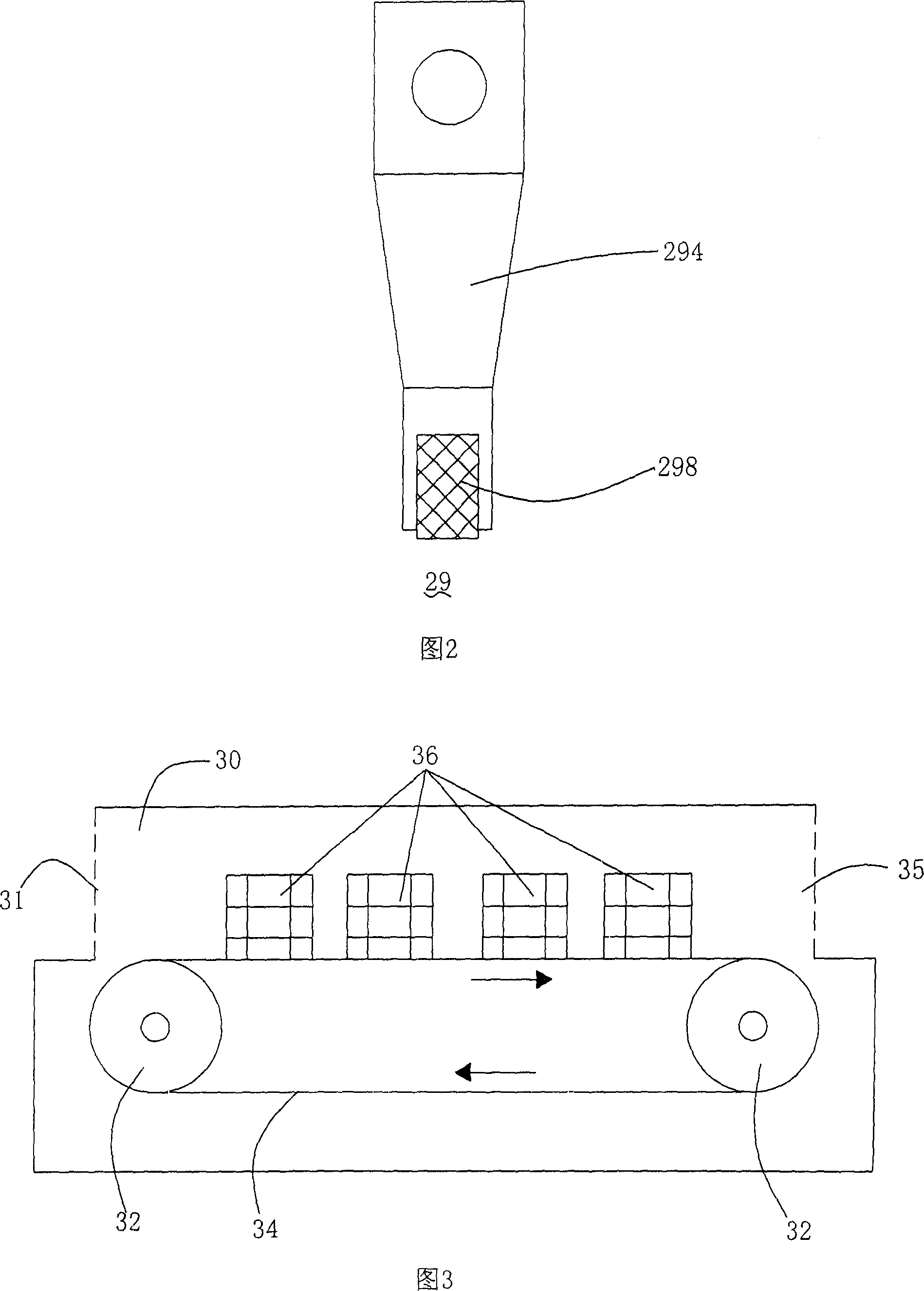

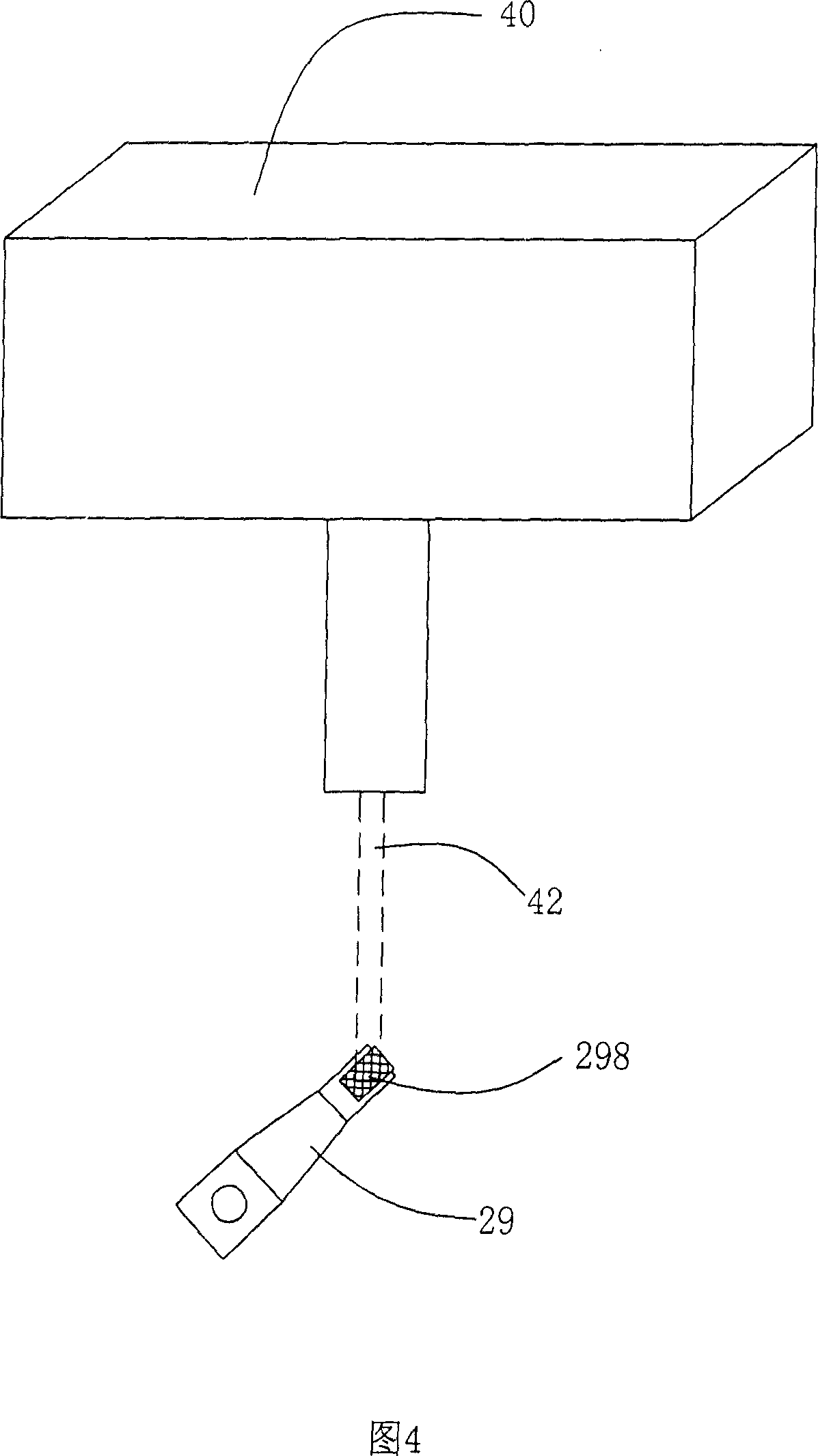

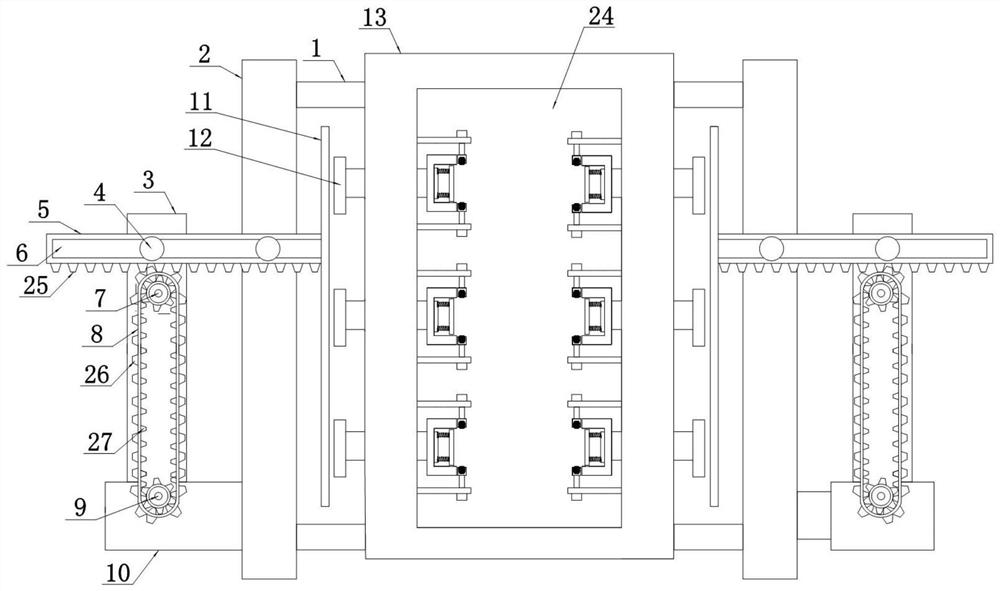

Magnetic head folding-piece combination and its magnetic disc drive unit assembling method

InactiveCN1937036AEasy to assembleLow positioning accuracy requirementsDisposition/mounting of recording headsRecord information storageInfraredEngineering

The method includes following steps: (1) providing a magnetic head and suspension in use for bearing the magnetic head; (2) placing glue with thermosetting property between magnetic head and suspension; (3) using infrared heat source to irradiate the magnetic head so that the glue is solidified by heat energy transferred from the magnetic head. Thus, the magnetic head is fixed on the suspension. Using infrared heat source to solidify glue, the method possesses features of shorter solidified time, easy of controlling temperature, high safety, small volume, and low cost. The invention also includes method of assembling disk drive system of containing the composition of folded piece of magnetic head.

Owner:SAE TECH DELEVOPMENT DONGGUAN

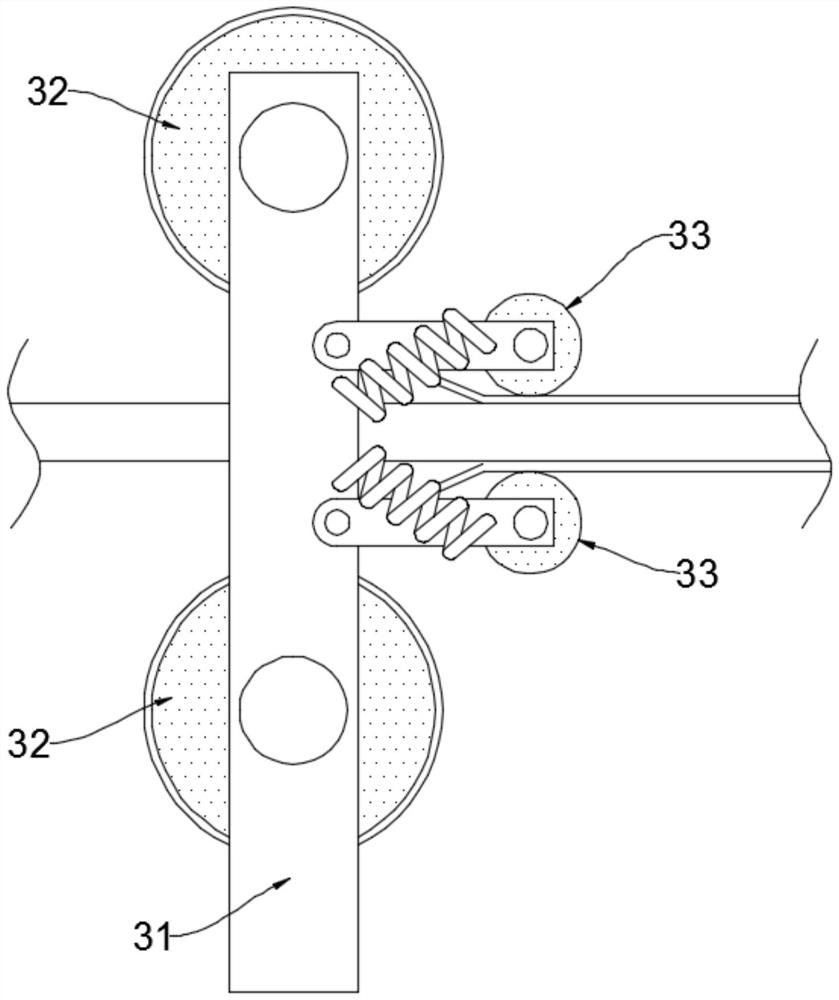

A clamping and fixing bracket for LED lamp processing based on 5g technology

ActiveCN111871720BAddressing VulnerabilityGuaranteed curing qualityPretreated surfacesCoatingsLED lampMechanical engineering

The invention discloses a clamping and fixing bracket for LED lamp processing based on 5G technology. The clamping mechanism is composed of two clamping assemblies respectively, the clamping assembly includes a fixed block, a clamping groove is opened in the fixed block, a vertical block one is fixedly arranged inside the clamping groove, and the vertical block one by one An upper telescopic rod, a lower telescopic rod, and a first compression spring are arranged on the side, and two horizontal correction assemblies are symmetrically arranged on the upper and lower sides of the clamping assembly. The through hole extends outward and is fixedly connected with the limit block, and the two sides of the outside of the workbench are respectively fixed with limit mechanisms. The present invention solves the problem that the existing clamping and fixing brackets are difficult to clamp and fix LED lights of different specifications. The LED lamp is easily damaged during the clamping process and cannot be automatically leveled to ensure the curing quality.

Owner:胡俏俊

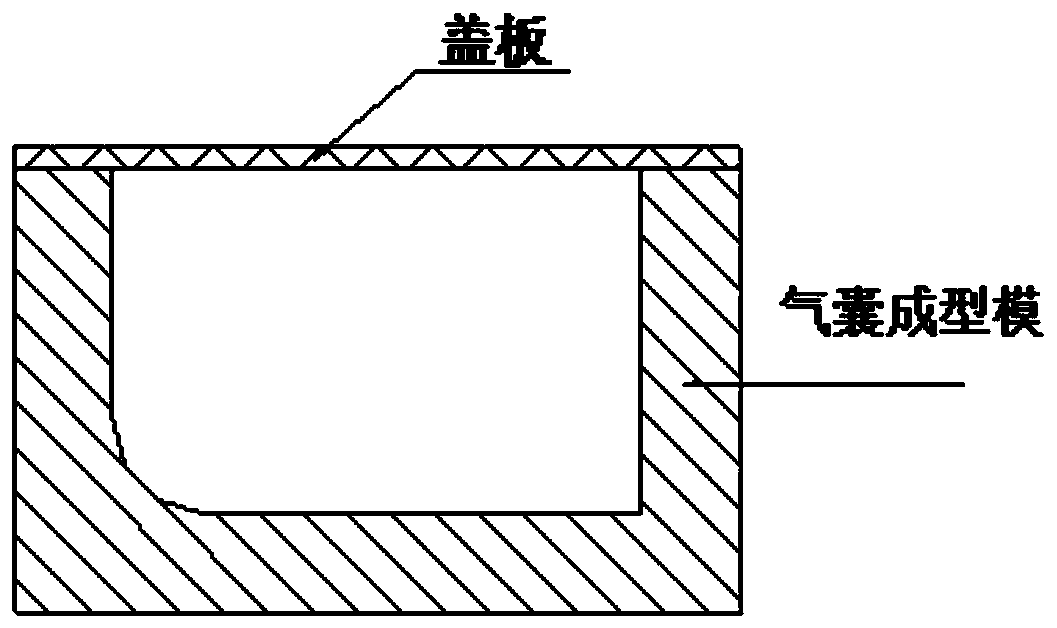

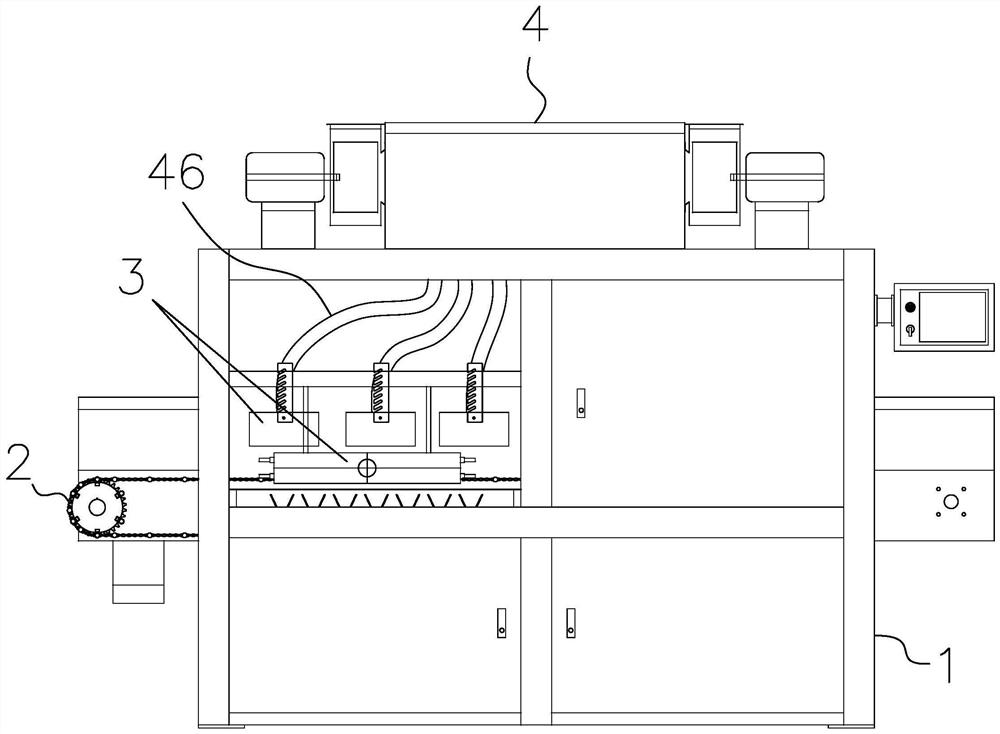

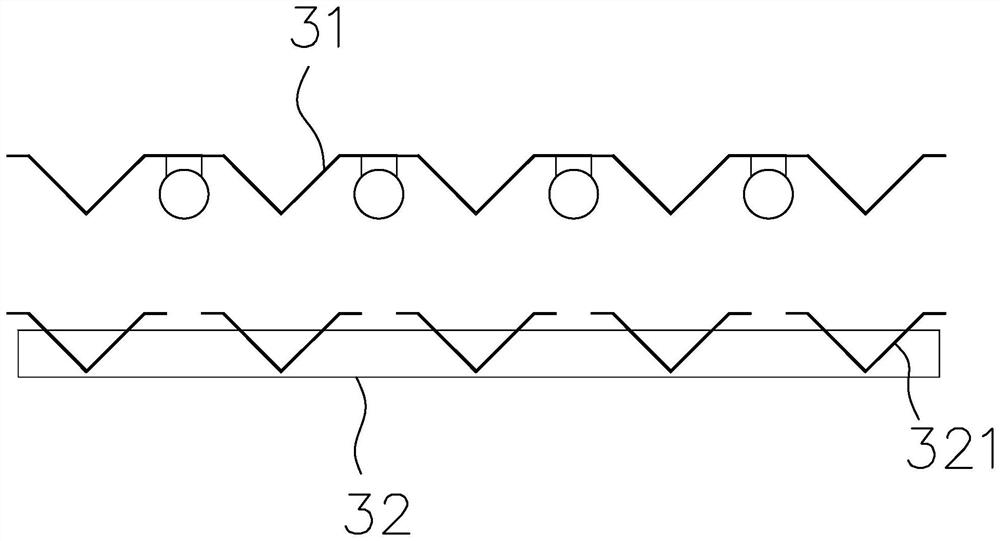

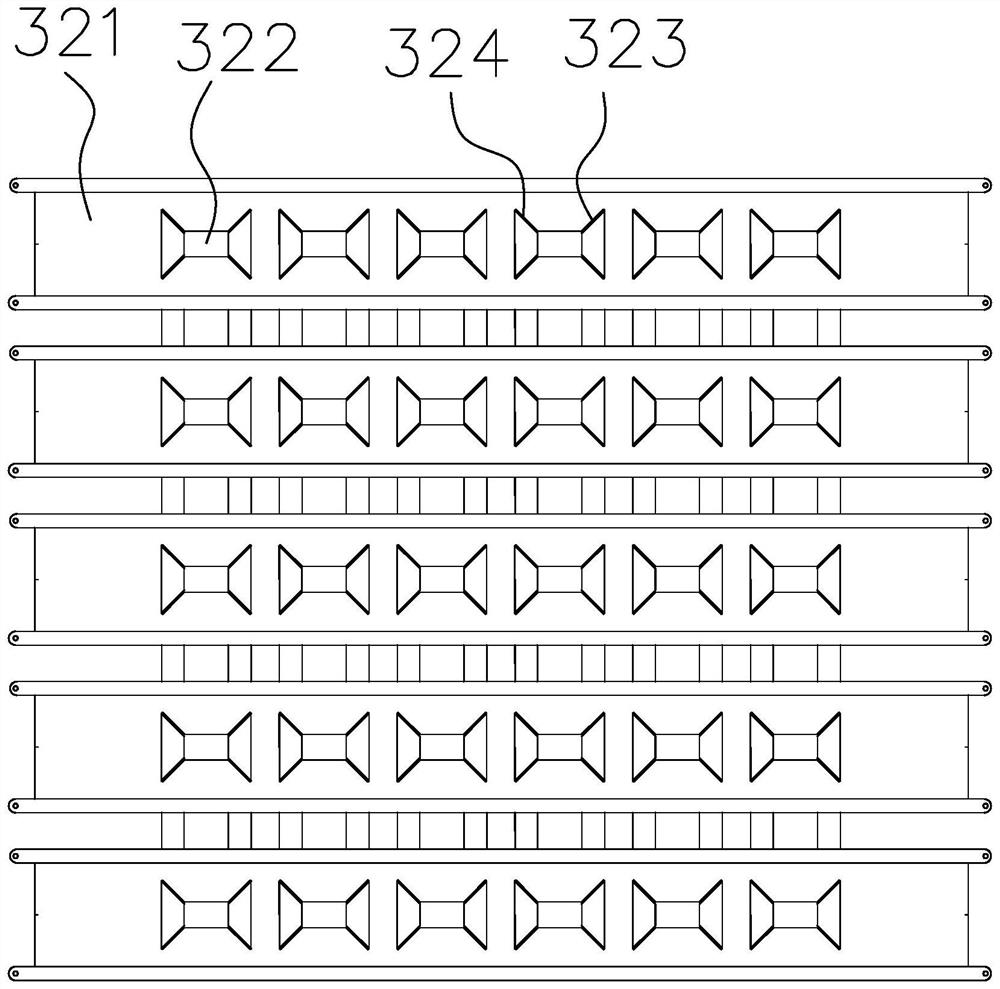

A method of manufacturing an airbag-assisted composite material reinforced wall panel

ActiveCN107139514BGuaranteed appearanceGuaranteed curing qualityDomestic articlesNumerical controlAirbag

Owner:SHENYANG AIRCRAFT CORP

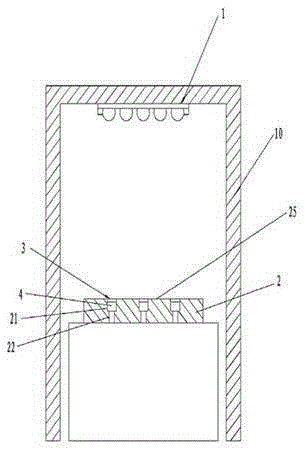

Colored paint UVC curing process

PendingCN114160393AGuaranteed curing speedGuaranteed curing qualityPretreated surfacesCoatingsUva lightUltraviolet lights

According to the colored paint UVC curing technology, automatic curing is achieved through curing equipment, the curing equipment comprises a machine box, a product conveying roller used for conveying a paint spraying workpiece into the curing equipment for ultraviolet curing and an ultraviolet light source set used for emitting ultraviolet light to cure the paint face of the paint spraying workpiece, and the ultraviolet light source set comprises a UVC light source and a UVA light source; the paint surface of the paint-sprayed workpiece is jointly cured through a UVC light source and a UVA light source, and the ultraviolet wavelength of the UVC light source is within the range of 250-260 nm; the ultraviolet wavelength of the UVA light source is within the range of 395-420 nm, the UVC light source is used for colored paint surface layer curing, the UVA light source is combined for colored paint deep layer curing, the curing speed of the colored paint can be guaranteed, the curing quality of the colored paint can also be guaranteed, and after the colored paint is cured, the appearance of a paint surface yellowing image is few.

Owner:中紫光源科技(广州)股份有限公司

Raw material for preparing lens with good safety

The invention discloses a raw material for preparing a lens with good safety. The raw material comprises the following components in parts by weight: 36-62 parts of ethyl acrylate, 10-15 parts of isocyanate, 8-15 parts of ethyl silicate, 4-9 parts of cubic boron nitride powder, 2-4 parts of lithium nitrate powder, 2-5 parts of strontium carbonate powder, 10-18 parts of isopropanol and 80-130 parts of deionized water. Monomers are mixed with ethyl acrylate, isocyanate and ethyl silicate, matched with ground cubic boron nitride powder, lithium nitrate powder and strontium carbonate powder mixed powder and finally stirred and mixed in isopropyl alcohol and deionized water, the lens raw material is prepared, the light transmittance and abrasion resistance are improved, the lens curing quality is guaranteed, the reject ratio is reduced, and safety is good.

Owner:JIANGSU MAAT OPTICAL CO LTD

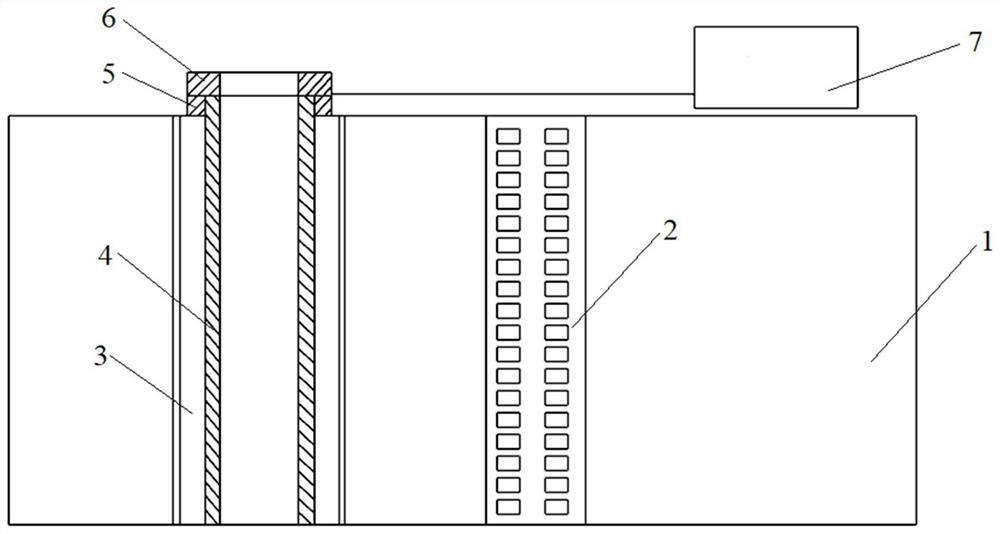

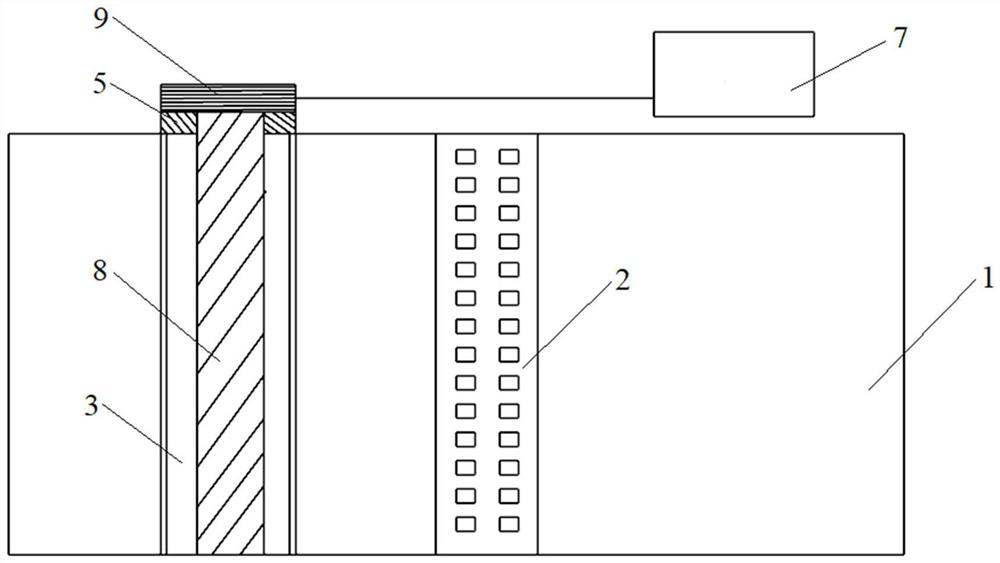

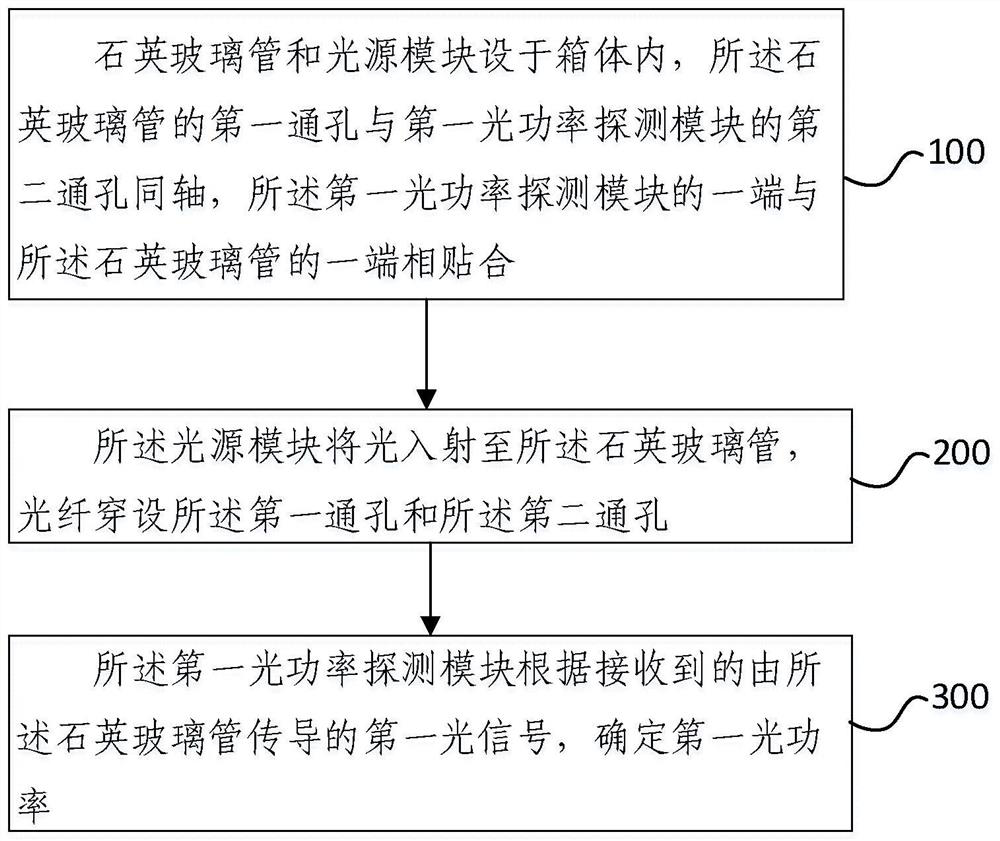

Optical fiber curing optical power detection device and detection method

PendingCN114459739AGuaranteed curing qualityReal-time acquisition of optical powerTesting optical propertiesOptical powerLight signal

The invention provides an optical fiber curing optical power detection device and detection method. The optical fiber curing optical power detection device comprises a box body, a quartz glass tube, a light source module and a first optical power detection module, the quartz glass tube and the light source module are arranged in the box body, and the light source module is used for enabling light to enter the quartz glass tube; the quartz glass tube is provided with a first through hole, the first optical power detection module is provided with a second through hole, the second through hole and the first through hole are coaxially arranged, and the first through hole and the second through hole are used for optical fiber penetration; one end of the first optical power detection module is attached to one end of the quartz glass tube, and the first optical power detection module is used for determining first optical power according to a received first optical signal transmitted by the quartz glass tube. According to the optical fiber curing optical power detection device, the first optical power of the first optical signal can be obtained in real time while the optical fiber is cured, so that the overall optical power of the light source module in the box body is detected in real time, and the curing quality of the optical fiber is guaranteed.

Owner:WUHAN BRIGHTCORE OPTICAL FIBER CO LTD

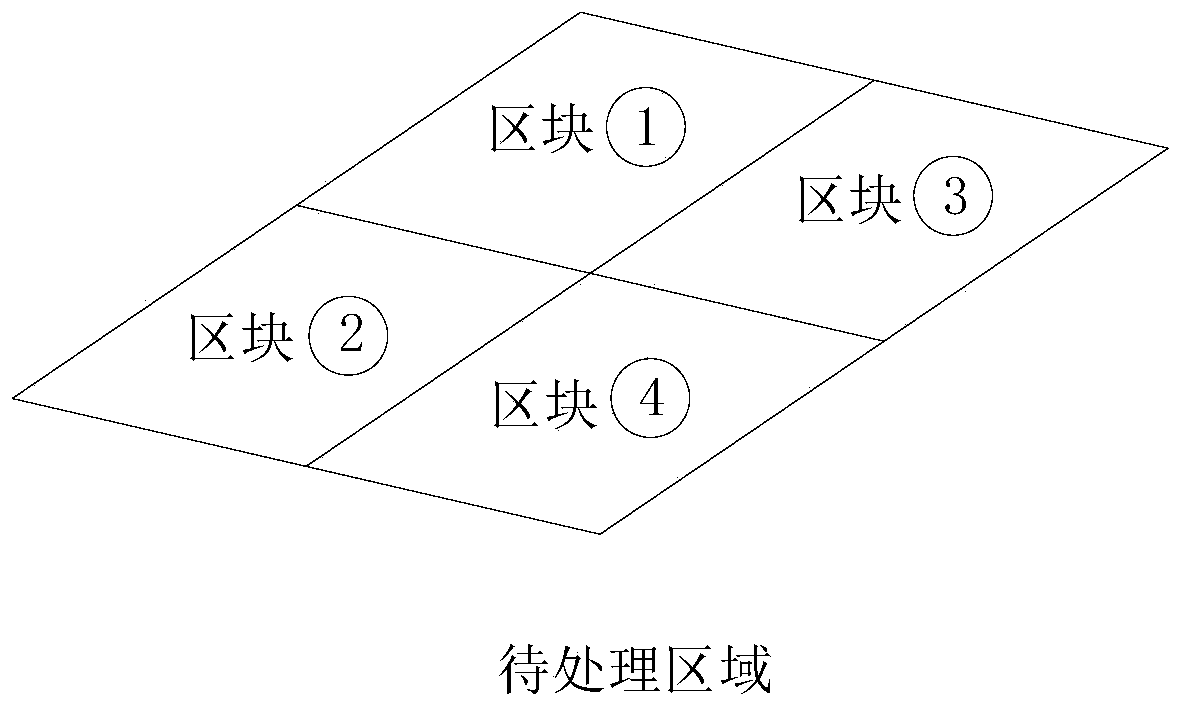

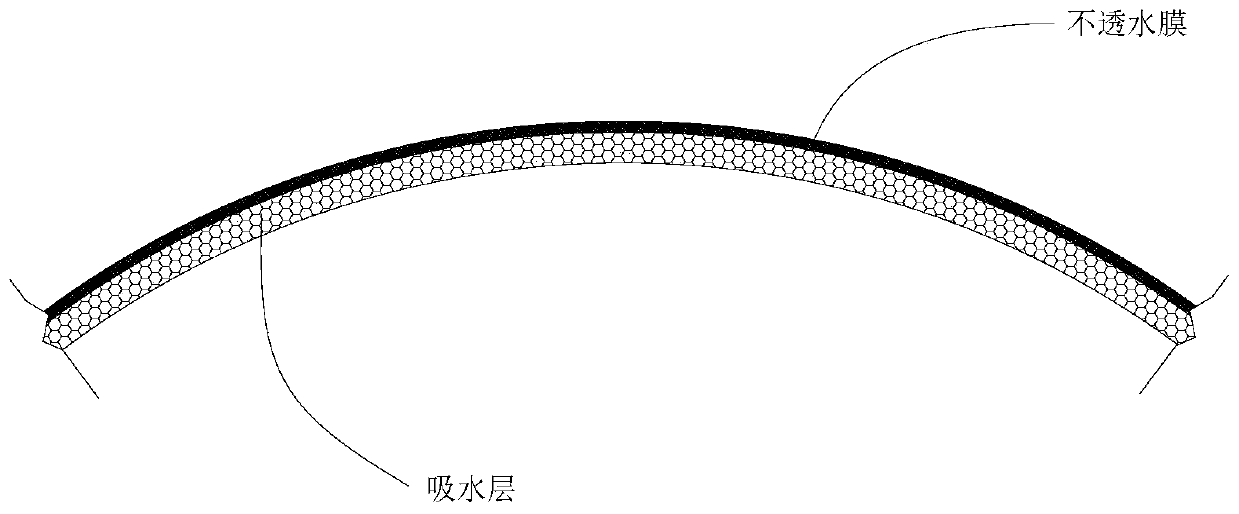

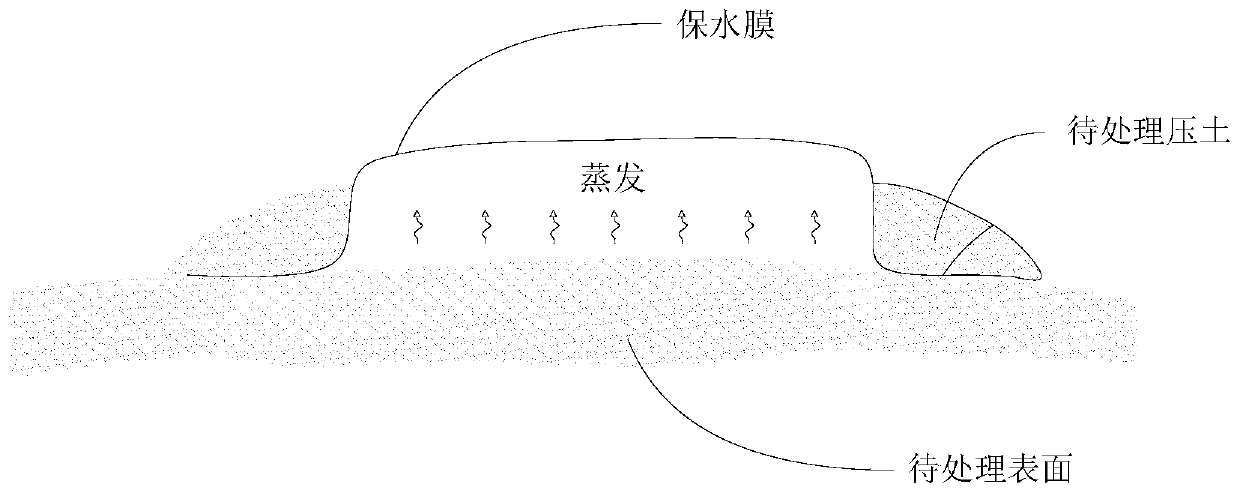

Construction method of anti-sand dust biological film in arid area

ActiveCN108842747BAchieve recyclingReduce dependenceSoil preservationEnvironmental engineeringBiology

The invention discloses a construction method of a biological coating for sand and dust prevention in arid areas. The construction method comprises the following steps that (1), an area to be processed is divided into a plurality of blocks; (2), the size of water retaining films is selected according to the size of the divided blocks, and sand fixation agents are configured; (3), the configured sand fixation agents in the step (2) are sprayed on the block to be treated within 30-180min; (4), the area to be treated which is sprayed with the sand fixation agents is covered with a water retainingfilm; and soil to be treated is pressed on the periphery of the water retaining film for fixation; (5), after 4-24 hours of reaction, the water retaining film is taken out and water in the water retaining film is recovered; (6), the recovered water in the step (5) is used for configuring the sand fixation agents; (7) the steps (3)-(5) are repeated multiple times until the surface to be treated forms a coating with the required strength, and the construction of the treatment block is completed; and (8), the steps (3)-(7) are repeated for the construction of the next block until the construction of all blocks are completed.

Owner:重庆大学建筑规划设计研究总院有限公司

Method for processing lumber-core board

InactiveCN100434245CShorten aging stacking timeQuality improvementWood treatment detailsCoating impregnationTrappingEngineering

The present invention relates to a production process of veneered strip-glued board. Said process includes the following steps: sawing raw material to obtain squared timber, drying, defining thickness and processing double faces, making strips by using multiblade saw, making board, coating adhesive, matching board, forced cooling, first sanding, sticking transverse single board, prepressing, hot-pressing, forced cooling, secondary sanding, sticking surface board, secondary prepressing, secondary hot-pressing, cutting edge, third sanding, sorting finished products and putting the finished products into storage. The urea-formaldehyde adhesive formula used in the adhesive-coating process is formed from (by weight portion) 100 portions of low-formaldehyde urea-formaldehyde resin, 20-35 portions of filling agent, 5-10 portions of formaldehyde trapping agent and 0.4-1.0 portion of solidifying agent.

Owner:CHANGLIN WOOD IND

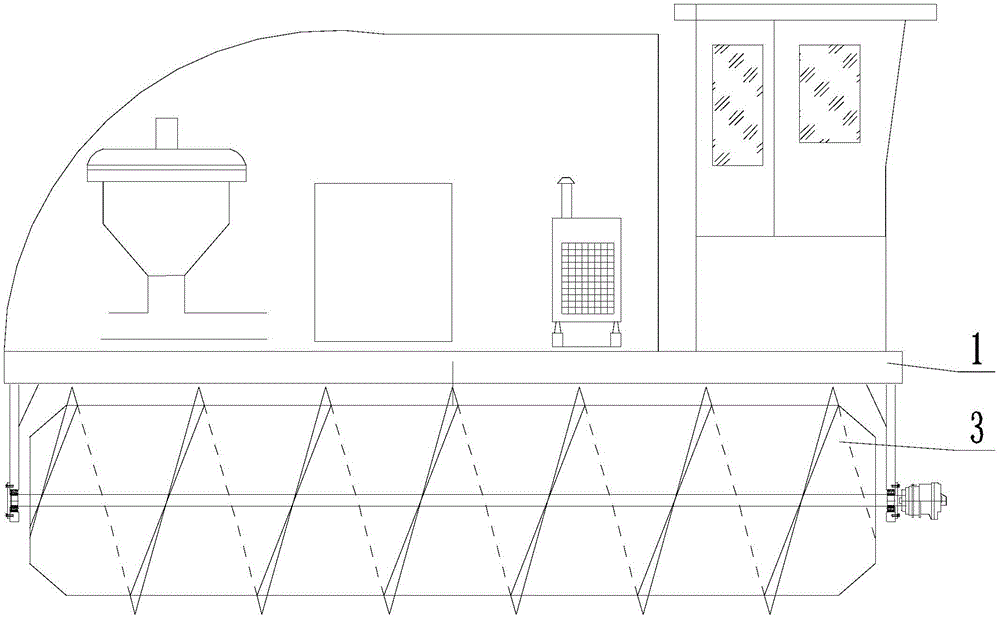

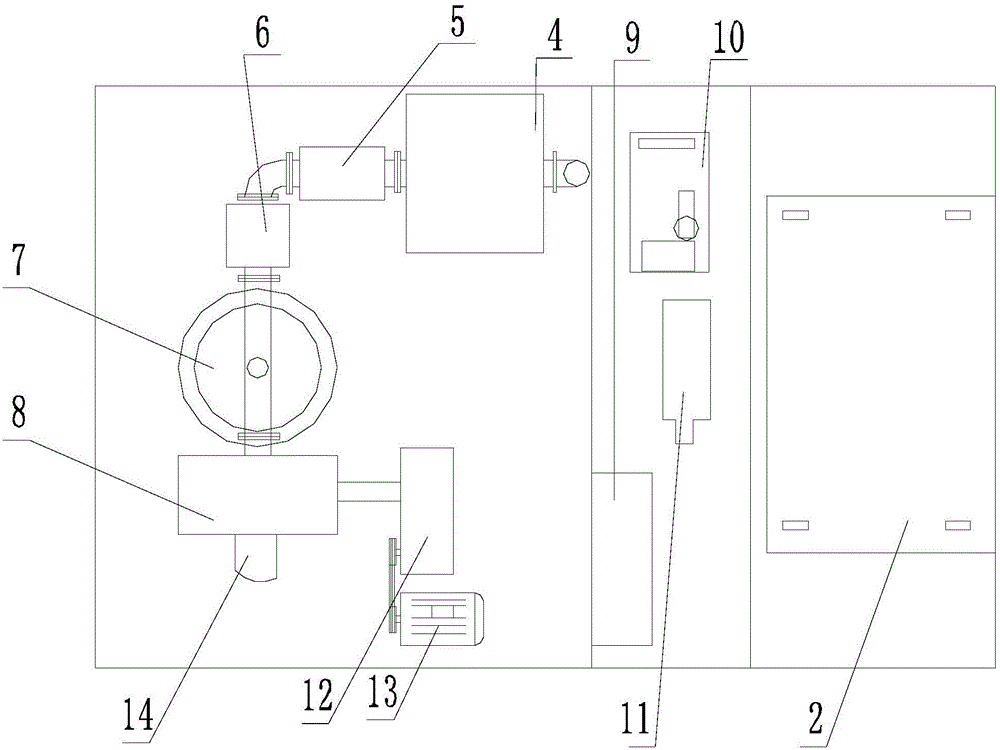

Integrated dehydration and solidification transport vehicle

InactiveCN106542278AReasonable subdivisionGuaranteed curing qualitySludge treatment by de-watering/drying/thickeningMechanical conveyorsPropellerAutomotive engineering

The invention brings forward an integrated dehydration and solidification transport vehicle. The vehicle comprises a vehicle body, on which an operation room is arranged. A propeller enabling the vehicle body to move forward is arranged below the vehicle body and connected with first power device for driving the propeller to rotate. The vehicle body communicates with a dehydration machine, a sludge modifier, an impurity removing machine, a solidification machine and a relay pump in order through a sludge conveying pipeline. The relay pump is connected with a second power device for driving the relay pump to rotate. The dehydration machine, the sludge modifier, the impurity removing machine, the solidification machine and the relay pump are arranged on the vehicle body. An electric control cabinet used for providing power control over the overall transport vehicle and a generating set used for providing power are arranged on the vehicle body. The integrated dehydration and solidification transport vehicle has following beneficial effects: the technical problem is solved so that sludge solidification and dehydration as well as transfer of solidification agents can be carried out on the vehicle; and the transport vehicle reaches the advanced level at home in terms of designed dehydration and solidification processes.

Owner:SHANDONG HAOHAI DREDGING EQUIP CO LTD

Preparation method of impact-resistant strain-corrosion-resistant continuously-wound glass steel tube

InactiveCN111497274AAvoid crackingHigh elongation at breakTubular articlesPolyester resinUnsaturated polyester

The invention discloses a preparation method of an impact-resistant strain-corrosion-resistant continuously-wound glass steel tube. The preparation method comprises the following steps of: preparing raw materials, continuously winding a glass steel lining layer and a glass steel structure layer, curing and shaping, and cutting. According to the impact-resistant strain-corrosion-resistant continuously-wound glass steel tube, a flexible unsaturated polyester resin lining is selected, a molecular chain contains tetrahydrophthalic anhydride groups, the elongation at break is up to 20% or above, the impact resistance is good, the lining is not easy to crack during external impact, and the strain level of 1.1% can reach 1000 hours or above during a sulfuric acid strain corrosion test.

Owner:福建安东实业有限公司 +2

Induction heating system and method for rapid curing of silicon steel self-adhesive coated iron core

ActiveCN110808670BFast curingGuaranteed curing qualityCoil arrangementsManufacturing dynamo-electric machinesThermodynamicsIntermediate frequency

The invention discloses an induction heating system for rapid curing of a silicon steel self-adhesive coated iron core, which includes: a conveying roller table; an induction heating device, which includes a columnar induction heating coil with a hollow cavity and a temperature measuring element; wherein , the induction heating coil adopts the intermediate frequency of 6-20KHz to inductively heat the silicon steel sheet; the feeding and discharging device; the loading and unloading device, which is set to transport the stacked mold to the right below the induction heating coil in the horizontal direction, and Transport the stacked mold into the hollow cavity of the induction heating device in the vertical direction or remove it from the hollow cavity after the induction heating is completed; the control device is connected with the conveying roller table, the feeding and discharging device, and the loading and unloading device respectively, In order to control their respective actions, it is also connected with the induction heating coil and the temperature measuring element to control the induction heating process.

Owner:BAOSHAN IRON & STEEL CO LTD

Coating and curing production line and coating and curing method thereof

PendingCN114345641AIncrease the number ofSolve the limitation of hanging materialPretreated surfacesCoatingsProduction lineCoating

The invention discloses a coating and curing production line and a coating and curing method thereof, the coating and curing production line comprises at least one operation part, the operation part comprises a coating auxiliary device, the coating auxiliary device comprises a clamping part, the clamping part can be driven to move in the length direction of a to-be-treated product, and the clamping part can clamp the to-be-treated product; the coating device comprises a plurality of liquid pipes used for containing coating liquid; and a curing device; wherein the clamping part straightens the to-be-treated product when moving in the length direction of the to-be-treated product, the coating device coats the to-be-treated product in a sectional mode, the clamping part clamps the to-be-treated product during coating, and the curing device cures the coated product. According to the coating and curing production line, the coating and curing efficiency is high, the coating auxiliary device is arranged, a product can be straightened before coating, the product can be clamped in the early stage of coating for sectional type coating, buoyancy of coating liquid in the liquid pipe is overcome, and a liquid replacing and supplementing device can be arranged to replace or supplement the coating liquid in the liquid pipe.

Owner:SUZHOU MICROBIT AUTOMATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com