Novel plate veneer compounding machine

A new type of sheet metal and laminating machine technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of high difficulty, poor lamination effect, poor stability of molding quality, etc., to improve quality, improve efficiency, guarantee The effect of curing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

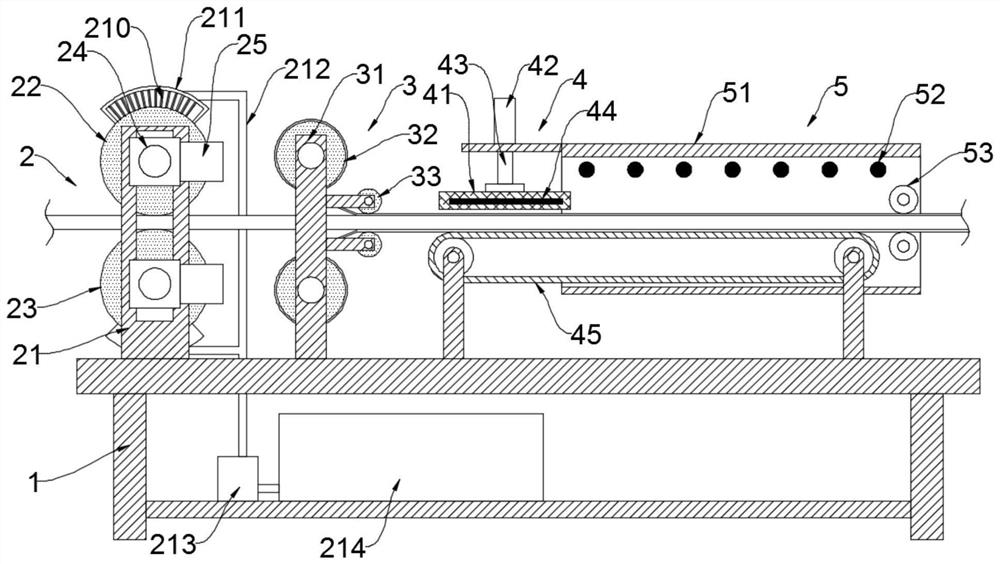

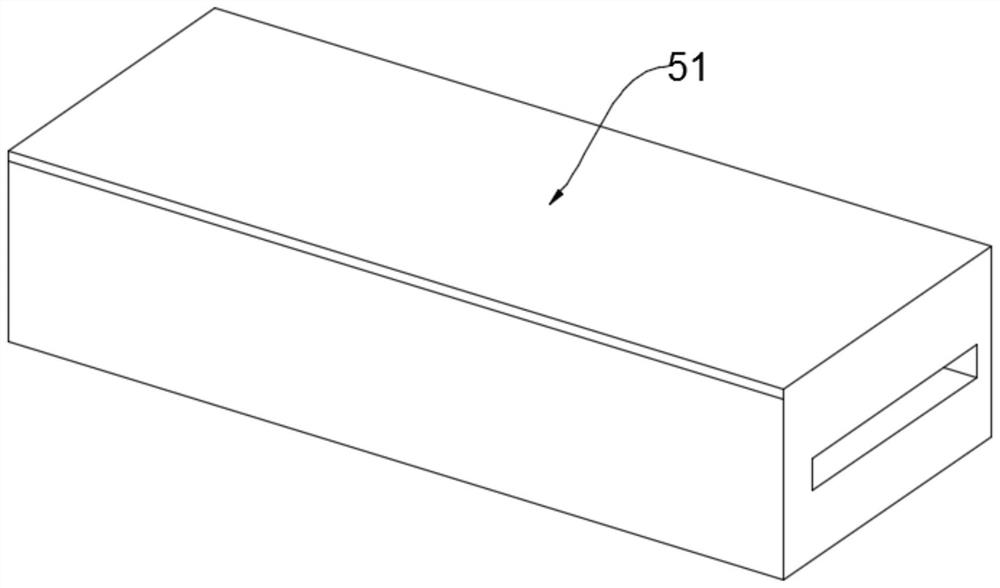

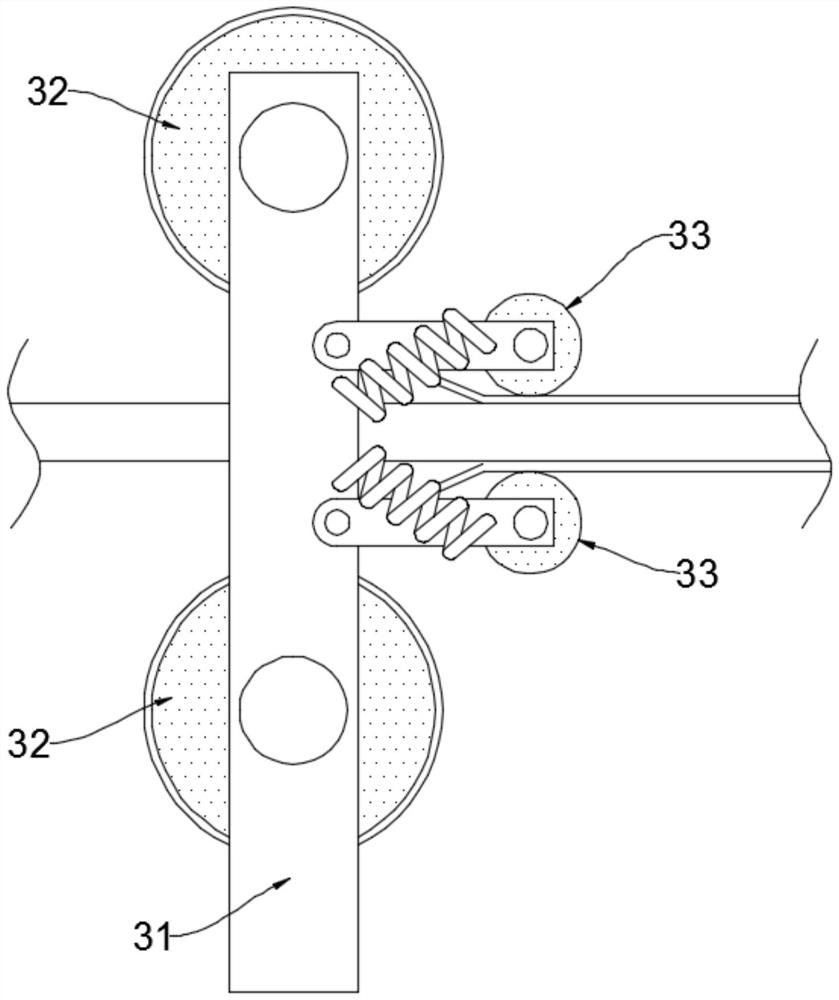

[0029] see Figure 1 ~ Figure 3 , a new board wood veneer compound machine, including a frame 1, on which a roll glue coating assembly 2, a film release assembly 3, an ironing flattening assembly 4 and a UV irradiation assembly 5 are installed.

[0030] The roll-pressing gluing assembly 2 includes a mounting frame 21, a rotating pressure roller 22, a rotating idler roller 23, a gluing brush 210, a gluing cover 211, a gluing pipe 212, a gluing pump 213 and a gluing tank 214, wherein the installation The frame 21 is fixed at one end above the frame 1, and the rotating pressure roller 22 and the rotating idler roller 23 are installed on the mounting frame 21, and the rotating pressing roller 22 is arranged directly above the rotating idler roller 23. The same and symmetrical arrangement, one end of the roller shaft 24 of the rotating pressure roller 22 and one end of the roller shaft 24 of the rotating idler roller 23 are connected with a driving motor 25, and the two driving mot...

Embodiment 2

[0040] The novel veneer veneer composite machine as described in Example 1 includes a frame 1 on which a roll glue application assembly 2 , a film release assembly 3 , an ironing flattening assembly 4 and a UV irradiation assembly 5 are installed.

[0041] The roll-pressing gluing assembly 2 includes a mounting frame 21, a rotating pressure roller 22, a rotating idler roller 23, a gluing brush 210, a gluing cover 211, a gluing pipe 212, a gluing pump 213 and a gluing tank 214, wherein the installation The frame 21 is fixed at one end above the frame 1, and the rotating pressure roller 22 and the rotating idler roller 23 are installed on the mounting frame 21, and the rotating pressing roller 22 is arranged directly above the rotating idler roller 23. The same and symmetrical arrangement, one end of the roller shaft 24 of the rotating pressure roller 22 and one end of the roller shaft 24 of the rotating idler roller 23 are connected with a driving motor 25, and the two driving m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com