Preparation method of impact-resistant strain-corrosion-resistant continuously-wound glass steel tube

The technology of glass fiber reinforced plastic and glass fiber reinforced plastic is applied in the field of preparation of continuous winding glass steel pipe, which can solve the problems of many structural layers and low curing efficiency of glass fiber reinforced plastic PE composite pipe, and achieve the effects of good impact resistance, improving curing speed and avoiding air bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

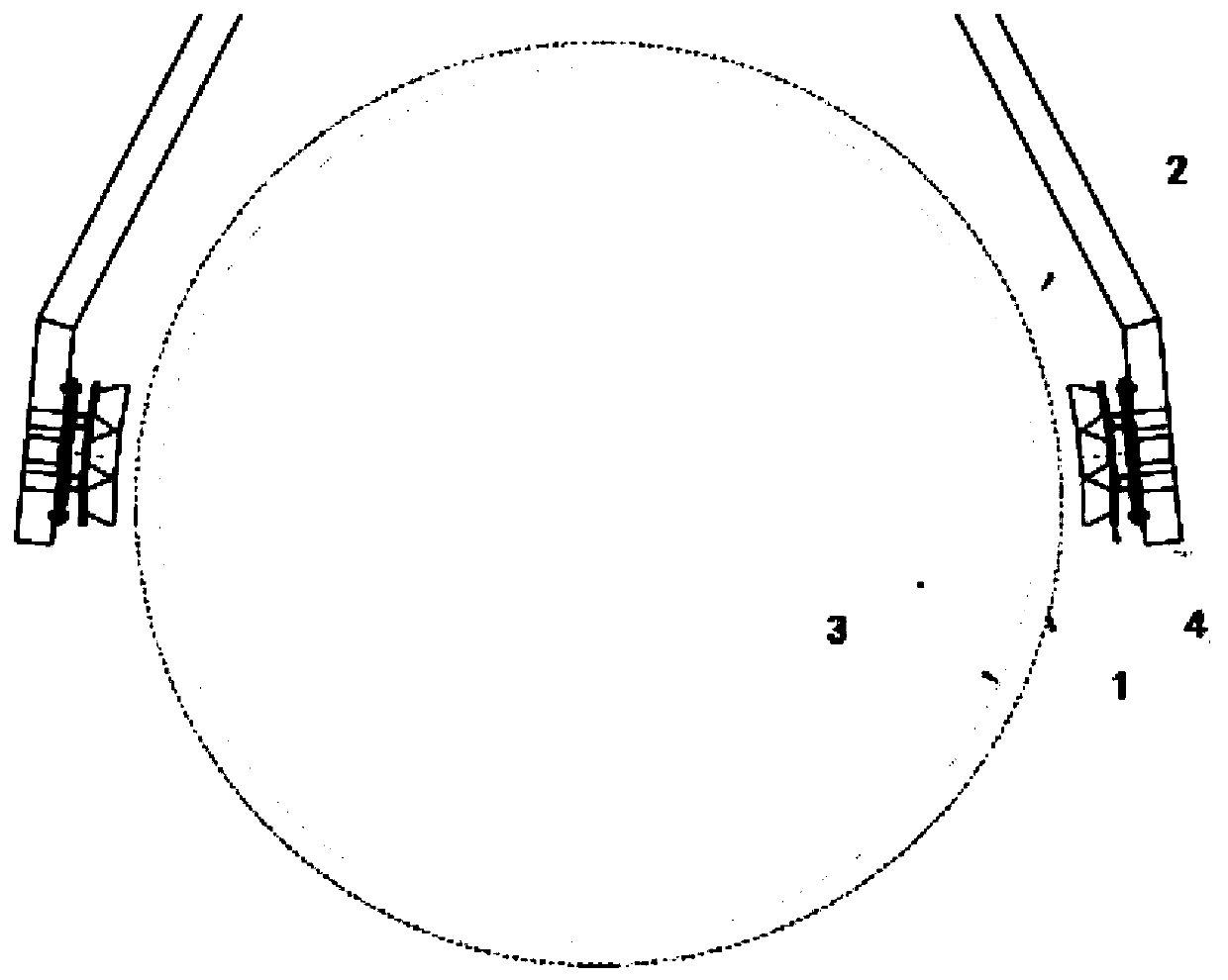

Image

Examples

Embodiment 1

[0031] A kind of preparation method of continuous winding glass steel pipe with impact resistance and strain corrosion resistance

[0032] Including raw material preparation, continuous winding of FRP lining layer and FRP structural layer, curing and setting, cutting;

[0033] Specific steps are as follows:

[0034] Step 1, raw material preparation: prepare respectively the fiberglass inner liner compound and the fiberglass structure layer material, for subsequent use;

[0035] Among the above, the preparation method of the FRP inner lining layer mixture is: mix the flexible unsaturated polyester resin, initiator, cyclohexanone peroxide dibutyl phthalate paste, and after fully stirring for 5 minutes, the FRP inner lining layer is obtained. Mixture; Wherein, contain tetrahydrophthalic anhydride group in flexible unsaturated polyester resin molecular chain; The mass ratio of flexible unsaturated polyester resin, initiator, cyclohexanone peroxide dibutyl phthalate paste is 10: ...

Embodiment 2

[0040] A kind of preparation method of continuous winding glass steel pipe with impact resistance and strain corrosion resistance

[0041] Including raw material preparation, continuous winding of FRP lining layer and FRP structural layer, curing and setting, cutting;

[0042] Specific steps are as follows:

[0043]Step 1, raw material preparation: prepare respectively the fiberglass inner liner compound and the fiberglass structure layer material, for subsequent use;

[0044] Among the above, the preparation method of the FRP inner liner compound is: mix the flexible unsaturated polyester resin, auxiliary agent, initiator, cyclohexanone peroxide dibutyl phthalate paste, and fully stir for 1min to obtain FRP Inner liner mixture; wherein, the flexible unsaturated polyester resin molecular chain contains tetrahydrophthalic anhydride groups; flexible unsaturated polyester resin, auxiliary agent, initiator, dibutyl peroxide cyclohexanone phthalate paste The mass ratio is 10:1.6:...

Embodiment 3

[0049] A kind of preparation method of continuous winding glass steel pipe with impact resistance and strain corrosion resistance

[0050] Including raw material preparation, continuous winding of FRP lining layer and FRP structural layer, curing and setting, cutting;

[0051] Specific steps are as follows:

[0052] Step 1, raw material preparation: prepare respectively the fiberglass inner liner compound and the fiberglass structure layer material, for subsequent use;

[0053] Among the above, the preparation method of the FRP inner liner compound is: mix the flexible unsaturated polyester resin, auxiliary agent, initiator, cyclohexanone peroxide dibutyl phthalate paste, and stir fully for 3 minutes to obtain FRP Inner liner mixture; wherein, the flexible unsaturated polyester resin molecular chain contains tetrahydrophthalic anhydride groups; flexible unsaturated polyester resin, auxiliary agent, initiator, dibutyl peroxide cyclohexanone phthalate paste The mass ratio is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com