A method of manufacturing an airbag-assisted composite material reinforced wall panel

A technology of reinforced wall panels and composite materials, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as uneven pressure on ribs, internal quality problems of parts, and axis deviation of surface quality, so as to prevent Resin loss, guaranteed thickness, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

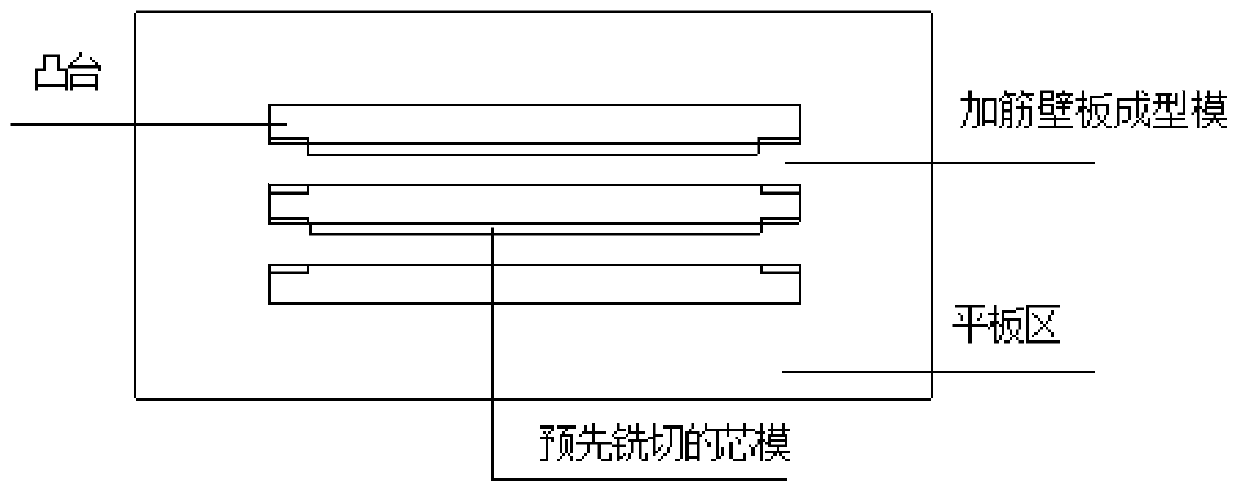

[0017] As shown in Figure 1, taking the forming of T-shaped ribs as an example, the main form of the reinforced wall panel forming mold is a convex flat plate forming die, and the bottom of the flat plate is a frame structure. The area is used for vacuum bag packaging, so the size of the boss is slightly larger than the size of the skin, and the size of the flat plate is slightly larger than the size of the boss. On the forming boss, groove is made according to the position and shape of the rib. The width of the groove is slightly larger than the width of the lying side of the rib, and the depth is slightly smaller than the height of the rib. The length is the through groove that runs through the entire boss. The two ends are provided with a cover plate that can cover the groove, and one side of the groove is directly milled out according to the length of the rib to form a rib forming mandrel integrated with the rib forming mold.

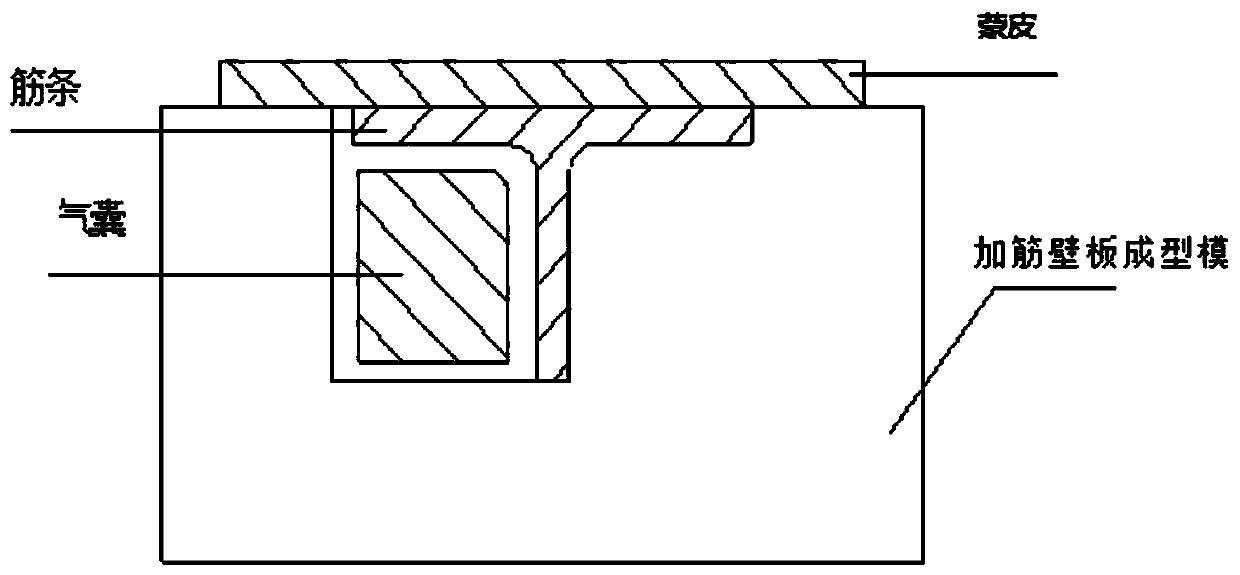

[0018] Such as figure 2 As shown, the airba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com