Polyamide 6 composite and preparation method thereof

A composite material and polyamide technology, applied in the field of materials, can solve problems such as poor fluidity, and achieve the effects of improving appearance, reducing warpage and deformation, and maintaining length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

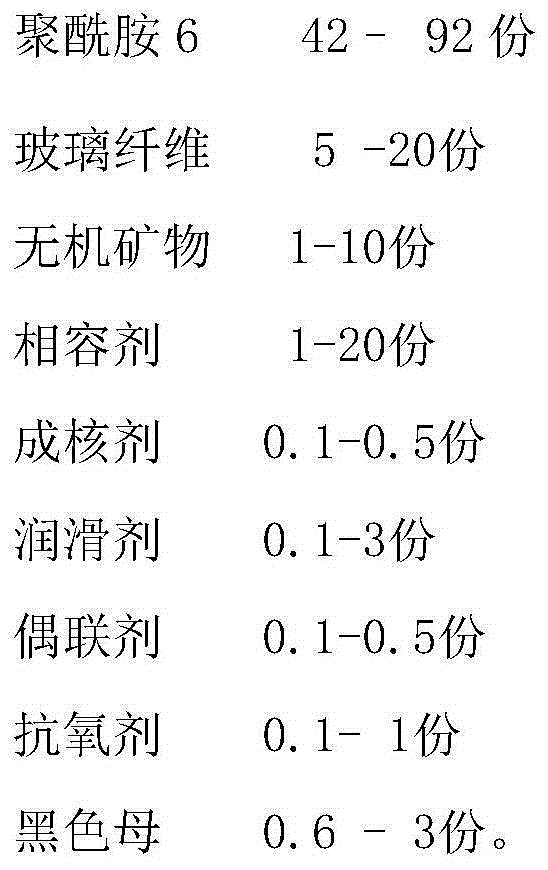

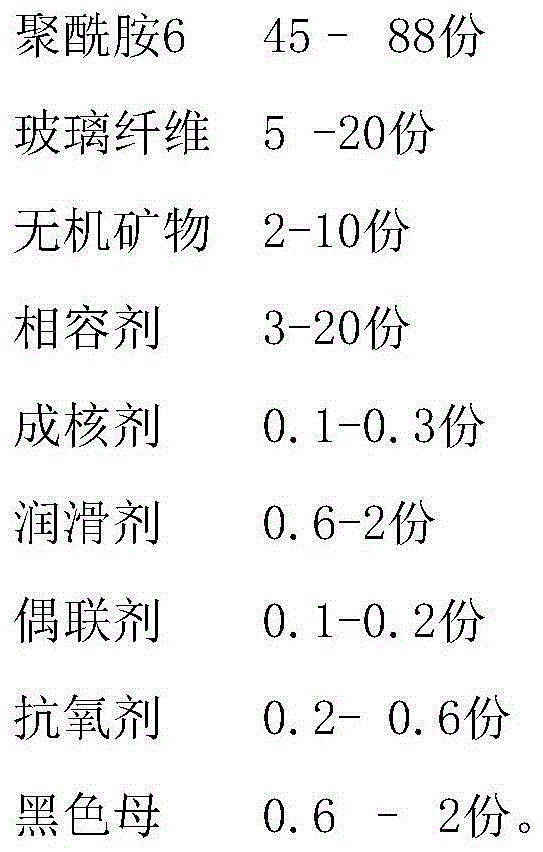

Method used

Image

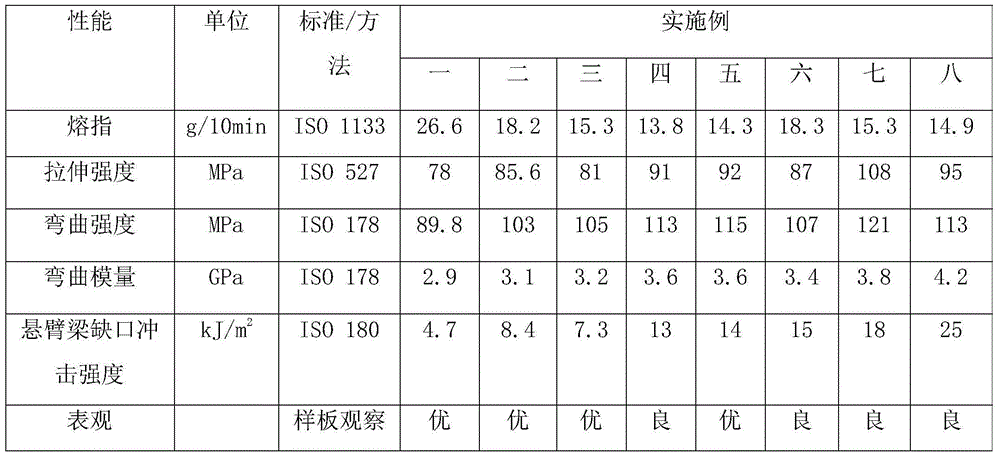

Examples

Embodiment 1

[0035] A polyamide 6 composite material, each raw material comprises the following parts by weight: polyamide 6: 87.6 parts, alkali-free chopped glass fiber: 5 parts, mica: 2 parts, maleic anhydride grafted polyethylene: 3 parts, titanium Ester coupling agent: 0.1 part, antioxidant: 0.6 part, hypophosphite: 0.1 part, black masterbatch is a mixture of polyethylene carrier inorganic black masterbatch and polyamide 6 carrier organic black masterbatch, wherein polyethylene carrier inorganic black masterbatch 0.5 parts, polyamide 6 carrier organic black masterbatch 0.5 parts, stearic acid amide: 0.6 parts.

[0036] The relative viscosity of polyamide 6 is 2.8; the fiber diameter of alkali-free chopped glass fiber is 13 μm, and the fiber length is 4.5 mm; the particle size of mica is 80 μm; the antioxidant is compounded with 1098 and 168, and the weight ratio is 1:1 .

[0037] A kind of preparation method of polyamide 6 composite material comprises the following steps:

[0038] St...

Embodiment 2

[0042] A polyamide 6 composite material, each raw material comprises the following parts by weight: polyamide 6: 82.6 parts, alkali-free chopped glass fiber: 10 parts, calcium carbonate: 2 parts, maleic anhydride grafted EPDM: 3 parts, aluminum Ester coupling agent: 0.1 part, antioxidant: 0.6 part, hypophosphite: 0.1 part, black masterbatch is a mixture of polyethylene carrier inorganic black masterbatch and polyamide 6 carrier organic black masterbatch, wherein polyethylene carrier inorganic black masterbatch 0.5 parts, polyamide 6 carrier organic black masterbatch 0.5 parts; stearic acid amide: 0.6 parts.

[0043] The relative viscosity of polyamide 6 is 2.8; the fiber diameter of alkali-free chopped glass fiber is 13 μm, and the fiber length is 4.0 mm; the particle size of calcium carbonate is 40 μm; the antioxidant is compounded with 1098 and 168, and the weight ratio is 1:1.

[0044] A kind of preparation method of polyamide 6 composite material comprises the following st...

Embodiment 3

[0050] A polyamide 6 composite material, each raw material comprises the following parts by weight: polyamide 6: 80.2 parts, alkali-free chopped glass fiber: 10 parts, talcum powder: 5 parts, maleic anhydride grafted EPDM 3 parts, silane coupling Agent KH560: 0.1 parts, antioxidant: 0.4 parts, hypophosphite: 0.1 parts, black masterbatch is a mixture of inorganic carrier-free black masterbatch and polyamide 6 carrier organic black masterbatch, of which inorganic carrier-free black masterbatch 0.2 parts, polyamide 6 Carrier organic black masterbatch: 0.4 parts; silicone: 0.6 parts.

[0051] The relative viscosity of polyamide 6 is 2.8; the alkali-free chopped glass fiber has a fiber diameter of 13 μm and a fiber length of 4.0 mm; the particle size of talc powder is 10 μm; the antioxidant is a compound of 1098 and 168, and the weight ratio is 1:1 .

[0052] A kind of preparation method of polyamide 6 composite material comprises the following steps:

[0053] Step 1, mineral tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com