Preparation device and method for dissimilar resin gradient continuous woven carbon fiber composite material

A composite material and preparation device technology, which is applied in the field of dissimilar resin gradient continuous weaving carbon fiber composite material preparation device, can solve the problems such as the discount of the mechanical properties of the composite material at the interface, and achieve high consistency, quality assurance, and curing quality assurance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

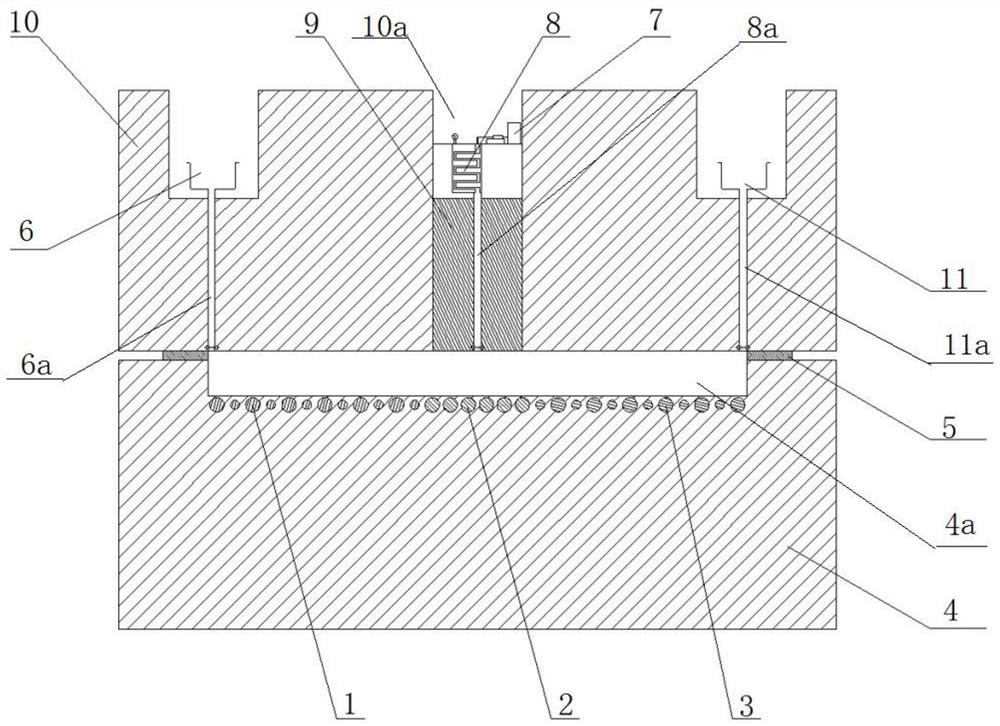

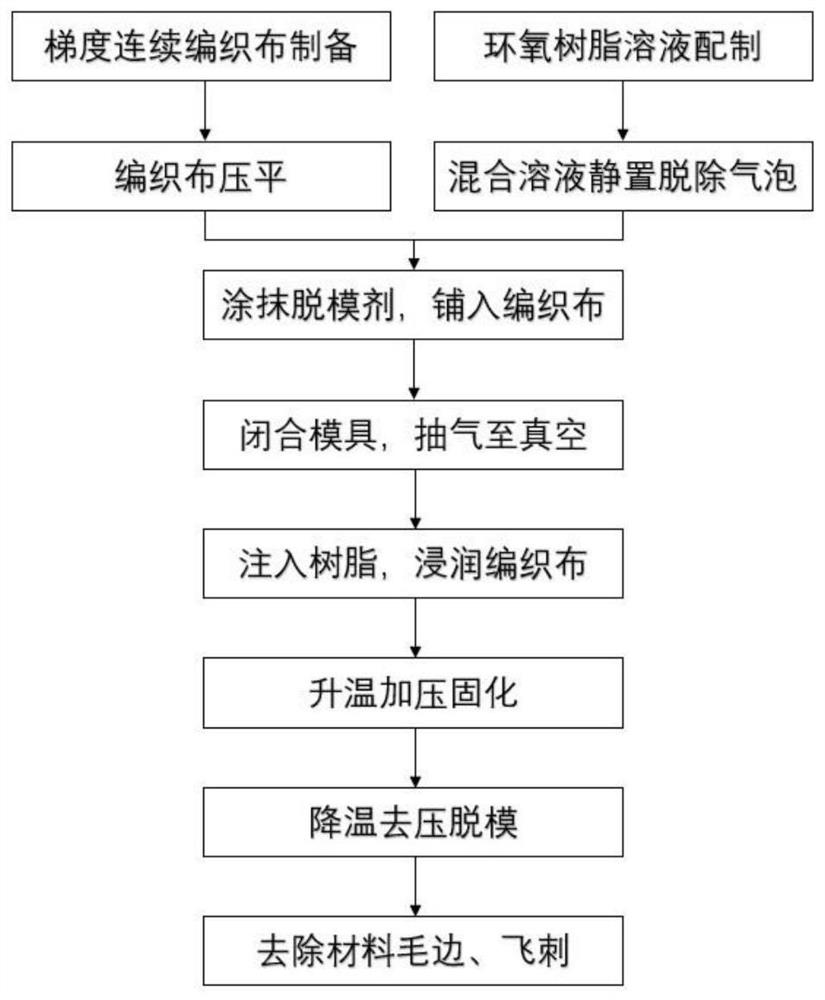

[0070] Such as Figure 2-6 As shown, the present invention also provides a method for preparing a heterogeneous resin gradient continuous weaving carbon fiber composite material. Using the heterogeneous resin gradient continuous weaving carbon fiber composite material preparation device mainly includes the following steps:

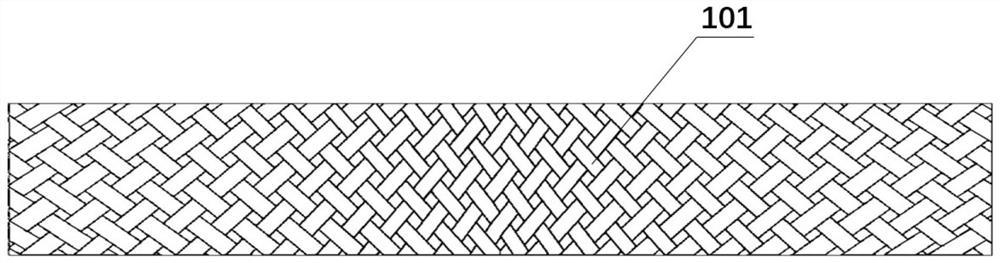

[0071] Step 1, preparing a carbon fiber woven cloth 101 whose braiding angle continuously changes in a gradient.

[0072] Step 2: apply a release agent on the inner wall of the mold cavity 4a, and place multiple pieces of the carbon fiber woven cloth 101 layer by layer in the mold cavity 4a; move the upper mold down to the upper end of the lower mold, close the mold cavity 4a and place the multiple pieces of carbon fiber The woven cloth 101 is compacted and evacuated to a vacuum.

[0073] Step 3: Place the first resin solution and the second resin solution in the first liquid storage tank 6 and the second liquid storage tank 11 respectively, and open the ...

Embodiment 1

[0078] (1) Preparation of Gradient Continuous Woven Fabric

[0079] The preparation process of the woven cloth 101 whose angle is continuously changing in a gradient is as follows: firstly, a gradient fabric weaving device is used to input fabric structure parameters to weave a gradient continuous weaving carbon fiber round tube, according to the formula Control the feeding speed of the mandrel and the rotational angular velocity of the bobbin track to weave a gradient continuous braided tube with a change in the braiding angle; cut the braided tube along the axial direction, and place it under the flattening device to maintain pressure and flatten it, and wait until it is normal Press down the flat carbon fiber woven cloth 101.

[0080] (2) Preparation of epoxy resin solution

[0081] Prepare 100 parts of epoxy resin A (first epoxy resin), 10-15 parts of curing agent a (first curing agent); 100 parts of epoxy resin B (second epoxy resin), curing agent b (second curing agent...

Embodiment 2

[0098] The difference between this embodiment and embodiment 1 is that (3) is changed into six layers of gradient carbon fiber woven cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com