Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Reduce free aldehyde content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of aqueous polyurethane for middle-high-density fiberboard

ActiveCN103320083AImprove stabilityLow costPolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesPolyesterFiberboard

The invention relates to a preparation method of aqueous polyurethane for a middle-high-density fiberboard. The preparation method comprises the steps of synthesis of a hydrophilic polyurethane prepolymer and blending and modifying of low-molecular-weight amino resin, wherein the hydrophilic polyurethane prepolymer comprises the following components in percentage by weight: 8-15% of polyester polyol, 40-60% of isocyanate a, 1.5-6% of hydrophilic chain extender, 0.5-3% of catalyst, 10-25% of isocyanate b, 0.5-3% of amino silane coupling agent and 4-10% of neutralizer. According to the aqueous polyurethane prepared by utilizing the preparation method, a -NCO group in the resin is reasonably closed; and due to the introduction of MUF (melamine-modified urea formaldehyde) resin, a microstructure of the resin is improved, the molecular weight of the aqueous polyurethane is reduced and the stability of the resin is improved. The aqueous polyurethane is synthesized by utilizing manners of inner-crosslikining and blending dual-modifying, the cost is much lower than that of the commercially available PMDI (polydiphenylmethane diisocyanate) resin, and the pressed fiberboard can meet emission loads of formaldehyde and VOC (volatile organic compounds) in export requirements of automotive trims.

Owner:DONGYING ZHENGHE WOOD IND

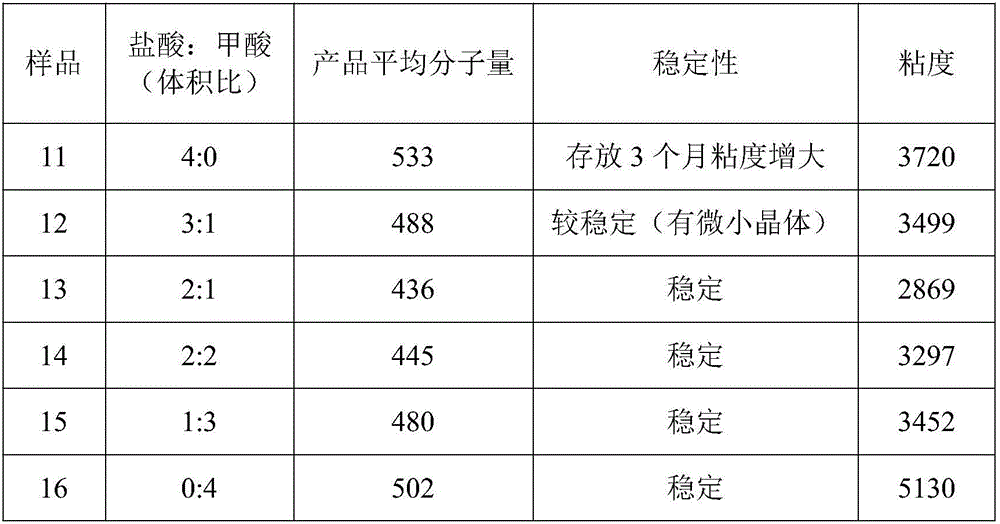

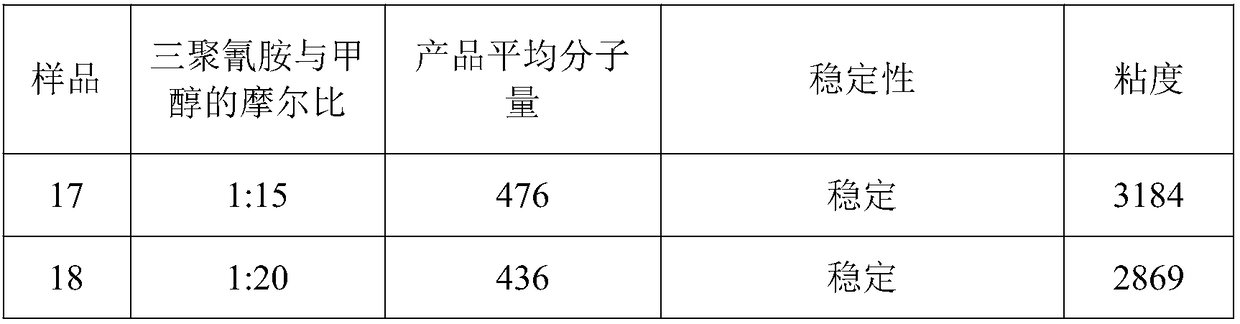

Preparation method of high-imido and high-methoxylation melamine resin capable of being cured at low temperature

The invention discloses a preparation method of a high-imido and high-methoxylation melamine resin capable of being cured at low temperature. According to the method, the high-imido and high-methoxylation melamine resin capable of being cured at low temperature is obtained by reacting melamine, a formaldehyde solution and methanol, paraformaldehyde is not required to be added, the step of synthesis of hydroxymethylation melamine as an intermediate product is omitted, preparation costs are reduced, links of crystallization, drying and the like of the intermediate product are omitted, energy consumption is low, a technological process is simple, the methanol only needs to be added at one step in reaction, and the preparation method is easy to control. In addition, a mixture of hydrochloric acid and formic acid is used as an etherification catalyst, and the effect of the obtained product is better than that of a single acid catalyst.

Owner:重庆建峰新材料有限责任公司

Method for preparing environment-friendly bamboo recombinant material

InactiveCN102528893ANo chemical meansImprove wettabilityWood working apparatusDomestic articlesPlasma technologyPhysical well being

The invention discloses a method for preparing an environment-friendly bamboo recombinant material. The method comprises the following steps of: cutting various bamboo serving as raw materials into sections, or crackling and removing inner bamboo joints; calendaring and defibering; drying at the temperature of between 60 and 80 DEG C until the moisture content is 8 to 14 percent; processing the surfaces of bamboo bundles by using a low-temperature plasma processor; taking out and draining; spreading the bamboo joints which are dried after gum dipping in the same fiber direction or filling the bamboo joints which are dried after gum dipping into a die to form slabs; and hot-forming. According to the method, bluish yellow surfaces are removed without any chemical means, and the comprehensive utilization rate of the bamboo can reach over 95 percent. The wetting property of the bamboo is improved by a low temperature plasma technology, the size stability of a recombinant bamboo product is effectively improved, and the surface performance of various polymer materials can be changed quickly, and efficiently in a pollution-free and non-destructive way. The recombinant bamboo is prepared by using a peanut shell liquefied resin adhesive, so the cost is reduced, and the content of free aldehyde is low; and production environment can be improved effectively, the phenomenon of allergic reaction of workers is reduced or eliminated, and the method is beneficial to body health of the workers.

Owner:JIANGXI KANGTILONG BAMBOO PRODS

Modified urea-formaldehyde glue and preparation method thereof

InactiveCN102618198AImprove initial tack performanceGood water solubilityAldehyde/ketone condensation polymer adhesivesCellulose adhesivesThermal insulationPolyvinyl alcohol

The invention relates to modified urea-formaldehyde glue and a preparation method thereof. The invention aims to solve the problems that traditional urea-formaldehyde glue is low in stability and is short in storage time. The urea-formaldehyde glue consists of formaldehyde, urea, tripolycyanamide, p-methylphenol, sodium cellulosate, ammonia water and polyvinyl alcohol. The preparation method comprises the following steps of: I-, weighing all components, heating to 30-35 DEG C, regulating a pH value and adding the sodium cellulosate; II-, heating, adding the first part of urea to regulate the pH value; III-, heating to 92 DEG C, regulating the pH value and then performing thermal insulation reaction; and IV-, regulating the pH value, observing the end point of the reaction; regulating the pH value to end the reaction; adding the second part of urea; mixing; cooling to 70 DEG C; adding the third part of urea; then, adding the residual components; cooling; regulating the pH value; and putting glue to obtain the modified urea-formaldehyde glue. The free formaldehyde content of the urea-formaldehyde glue is lower than 0.1 percent. The storage time is 2 months. The invention is applied to the field of the urea-formaldehyde glue.

Owner:HEILONGJIANG UNIV

Method for preparing urea formaldehyde fiber through copolymerization modification

ActiveCN110387022AHigh limiting oxygen indexImprove flame retardant safety performanceMonocomponent synthetic polymer artificial filamentFiberCross-link

The invention discloses a method for preparing a urea formaldehyde fiber through copolymerization modification. The method comprises the steps that a modifier, urea and aldehydes are added into a polymer aqueous solution, and then a base catalyst is added for reaction for different times; then an acid catalyst is added for continuous reaction, a base catalyst and remaining aldehyde compounds are added for reaction, after the reaction is completed, a wet spinning machine is used for spinning, a nascent fiber wounded through coagulation bath is heated and cured in a drying oven, after natural cooling, the nascent fiber is taken out, and thus the urea formaldehyde subjected to copolymerization modification is obtained. According to the method, by reasonably designing the reaction process, themodified urea formaldehyde fiber is prepared through wet spinning, the modified urea formaldehyde fiber serves as a three-dimensional cross-linked fiber, thus has the advantages of being low in cost,flame retardant in fiber, capable of realizing thermal insulation, free of melting drops, free of toxicity during combustion, and the like, and has broad application prospects.

Owner:ZHONGYUAN ENGINEERING COLLEGE

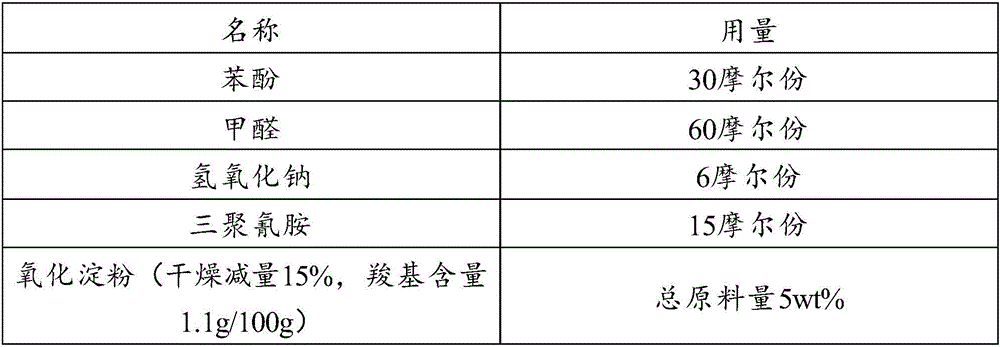

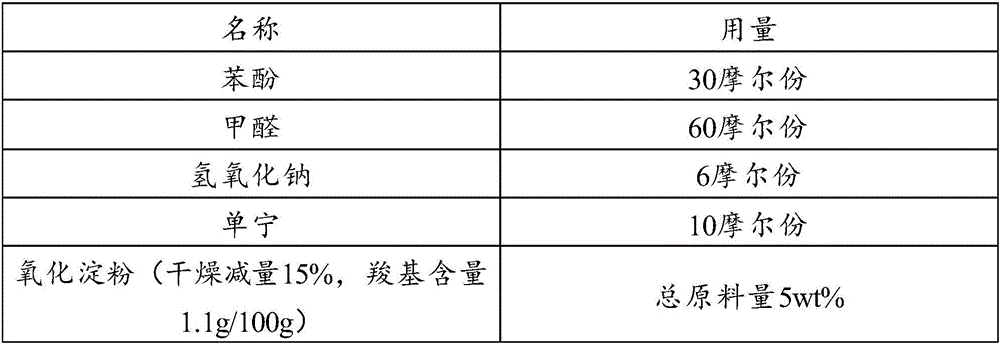

Modified phenolic resin adhesive

InactiveCN106750065AHigh adhesive strengthImprove adhesion strengthAldehyde/ketone condensation polymer adhesivesFree phenolAldehyde

The invention belongs to the field of phenolic resins and in particular relates to a modified phenolic resin adhesive. The modified phenolic resin adhesive is prepared by the method of heating phenol, formaldehyde, alkali and a modifying agent for reaction so as to obtain the modified phenolic resin adhesive, wherein the modifying agent contains multiple ones of cyanamide compound, eleostearate, oxidized starch and tannin. As multiple specific modifying agents are added in the preparation process of the phenolic resin adhesive, the modified phenolic resin adhesive has the advantages that the residue amounts of free phenol and aldehyde in the prepared adhesive can be obviously reduced and the adhesive strength of the adhesive can be obviously improved. The experiment result shows that the content of the free aldehyde in the modified phenolic resin adhesive is lower than 0.3 wt%, the content of the free phenol in the modified phenolic resin adhesive is lower than 4 wt% and the adhesive strength of the modified phenolic resin adhesive is higher than 3 MPa.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

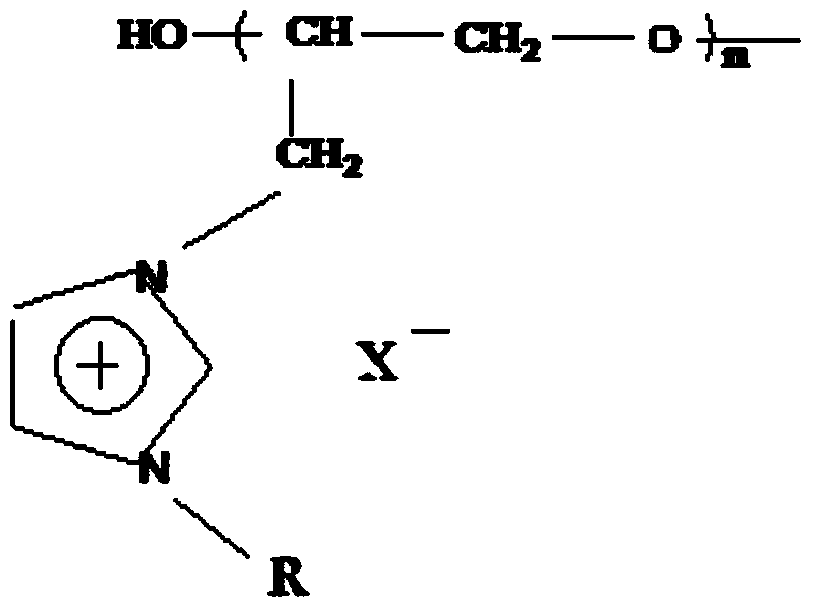

High-adhesiveness phenol aldehyde composite adhesive and preparation method thereof

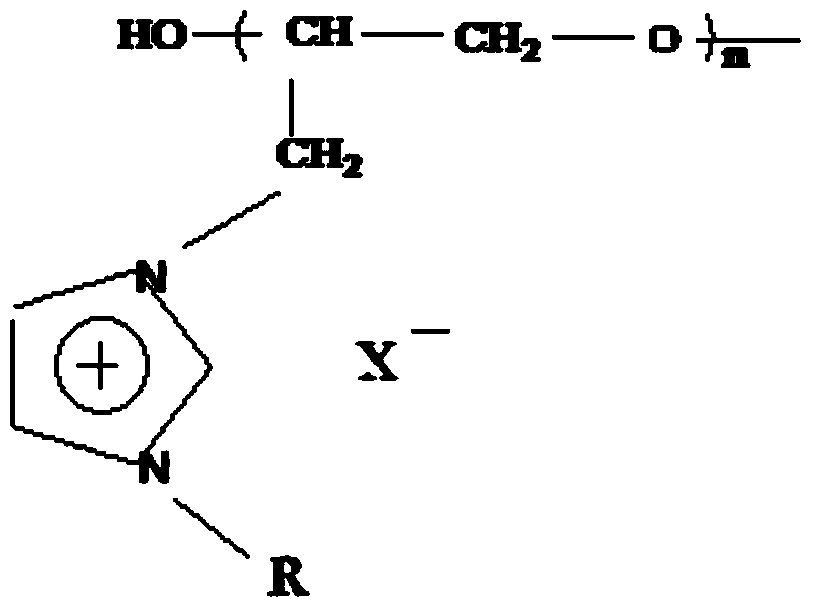

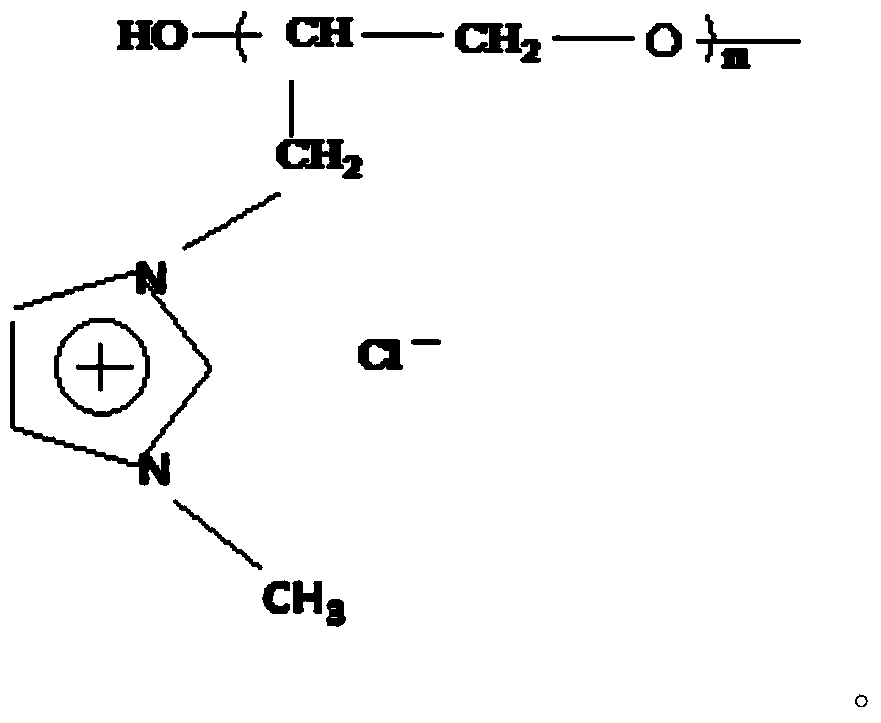

InactiveCN103555236AMild reaction conditionsEasy to controlMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesiveIonic liquid

The invention belongs to the field of preparation of high-performance high polymer materials, and relates to a preparation method of a novel composite adhesive product, particularly a method for preparing a phenol aldehyde composite adhesive from an ionic liquid and a phenol aldehyde resin prepolymer by in-situ blending. The preparation method comprises the following steps: firstly synthesizing a phenol aldehyde resin prepolymer from raw materials phenol and formaldehyde in the presence of an alkali catalyst; by using an imidazole polyether ionic liquid with characteristic group as a modifier, heating, stirring under reflux, carrying out stage heating and temperature control, dehydrating under reduced pressure and the like to obtain the phenol aldehyde composite adhesive containing the imidazole polyether ionic liquid structure; and adding ethanol to regulate the viscosity of the composite adhesive to obtain the alcohol-soluble phenol aldehyde composite adhesive with acceptable viscosity. The method can further enhance the binding property and curing property of the phenol aldehyde adhesive, lower the free aldehyde content, and effectively solve the problems of low heat stability, deep color, high cracking tendency and the like in the phenol aldehyde adhesive.

Owner:SHENYANG POLYTECHNIC UNIV

Preparation method of melamine modified urea formaldehyde fibers

ActiveCN110359120ARaw materials are cheap and easy to getHigh functionalityMonocomponent synthetic polymer artificial filamentWet spinning methodsFiberThermal insulation

The invention discloses a preparation method of melamine modified urea formaldehyde fibers. The preparation method includes: adding melamine and aldehydes (solution I) into one macromolecule aqueous solution, adding urea and aldehydes (solution II) into another macromolecule aqueous solution, respectively adding alkaline catalysts to perform reaction for a certain period of time; mixing the solution I and the solution II, adding an acidic catalyst to continue the reaction, adding an alkaline catalyst and the rest of aldehyde compounds to perform reaction, spinning with a wet spinning frame after the reaction, heating and curing the as-spun fibers subjected to coagulating bath winding in a drying oven, naturally cooling, and taking out to obtain the modified urea formaldehyde fibers. The preparation method has the advantages that the modified urea formaldehyde fibers are prepared through wet spinning by reasonably designing the reaction process, and the fibers serving as three-dimensional crosslinked fibers are low in cost, flame-retardant, thermal-insulation, free of melting drops, nontoxic when being combusted, promising in application prospect and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Preparation method of pulping waste liquid adhesive

InactiveCN102516909ATake advantage ofRealize resource utilizationAldehyde/ketone condensation polymer adhesivesEnvironmental resistanceLiquid waste

The invention provides a preparation method of a pulping waste liquid adhesive and belongs to the technical field of adhesives. The preparation method comprises the following steps of: firstly carrying out phenolic modification on pulping waste liquid at a temperature of 90-140 DEG C under the action of a basic catalyst and phenol by adopting a normal-pressure or high-pressure heating method; and then adding aldehyde and the basic catalyst into the pulping waste liquid subjected to the phenolic modification, reacting for 1.0-3.0 hours at a temperature of 55-70 DEG C under the condition of continuous agitation, adding urea accounting for 0.2-2.0 percent of the total weight of the phenol, aldehyde and the pulping waste liquid, raising the temperature to 80-95 DEG C, continuously reacting for 0.5-3.0 hours, stop heating when the viscosity conforms to the requirements, cooling to below 40 DEG C and discharging. The invention has the beneficial effects that compared with a traditional phenolic resin adhesive, the prepared adhesive has the characteristics of lower production cost, low free phenol and free aldehyde content and environment friendliness; and in the preparation method, the pulping waste liquid is fully utilized, the pollution caused by the waste liquid to the environment is solved, and the resource utilization of the pulping waste liquid is realized.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of melamino-formaldehyde resin with ultra-low formaldehyde content

The invention discloses a preparation method of melamino-formaldehyde resin with the ultra-low formaldehyde content. The ultra-low formaldehyde content is 0.05 wt% lower than the free formaldehyde content in resin, and preferentially 0.01wt%. The method comprises the following steps of putting poly-hydroxymethyl melamine and methyl alcohol are put into a reactor, inorganic acid is added for a catalysis etherification reaction, and an inorganic base is adopted for terminating the etherification reaction; after the etherification reaction is terminated, an oxidizing agent is added, and alkali liquor is added in time so that the pH value is maintained between 8.0 and 10.0. According to the method, the free aldehyde content of amino resin is lowered to 0.05 wt% or less and even lowered to 0.01wt%, and other mass indexes meet requirements.

Owner:CHONGQING JIANFENG INDAL GROUP

Wood-based panel glue that can reduce human toxic gas and free aldehyde content

InactiveCN104726043BPerformance is not affectedReduce free aldehyde contentNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesToxic gasActivated carbon

The invention relates to artificial board glue and particularly relates to artificial board glue capable of reducing contents of human poisonous gas and free formaldehyde. According to the artificial board glue capable of reducing contents of human poisonous gas and free formaldehyde, bamboo charcoal and activated carbon are added into the glue. The artificial board glue has the beneficial effects that the contents of poisonous gas and free formaldehyde can be effectively reduced and the property of the glue is not affected. Therefore, the artificial board glue is worth of popularization.

Owner:潘建朋

Method for preparing normal temp solidified high stvength glass fire reinforced plastics

Owner:SHANDONG ANALYSIS & TEST CENT

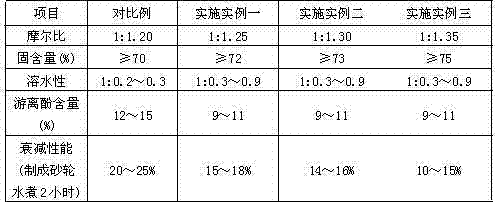

Furfuralcohol and urea composite modified water-soluble phenol-formaldehyde resin for resin grinding tool and preparation method of furfuralcohol and urea composite modified water-soluble phenol-formaldehyde resin

InactiveCN104497247AGood water solubilityHigh solid contentAbrasion apparatusPtru catalystAqueous solubility

The invention aims at providing furfuralcohol and urea composite modified water-soluble phenol-formaldehyde resin for a resin grinding tool and a preparation method of the furfuralcohol and urea composite modified water-soluble phenol-formaldehyde resin, wherein the furfuralcohol and urea composite modified water-soluble phenol-formaldehyde resin is proper in molar ratio, high in solid content, good in water solubility, low in free phenol content, stable in performance and reduced in performance degradation. The furfuralcohol and urea composite modified water-soluble phenol-formaldehyde resin comprises the following components in parts by mass: 100 parts of phenol, 10-35 parts of furfuralcohol, 120-180 parts of formaldehyde, 10-30 parts of urea, 1-10 parts of a moisturizing agent, 1.2-3.0 parts of an alkaline catalyst and 0.1-2 parts of a novel coupling agent. The preparation method of the phenol-formaldehyde resin comprises the following steps of (1) adding phenol, formaldehyde and part of furfuralcohol; (2) adding the alkaline catalyst; (3) heating; (4) adding part of the urea; (5) heating, adding the left furfuralcohol and urea, and stirring until the water solubility conforms to the standard; (6) cooling, reducing water, dehydrating, and adding the novel coupling agent; and (7) and carrying out reduced-pressure dehydration to obtain the furfuralcohol and urea composite modified water-soluble phenol-formaldehyde resin. The furfuralcohol and urea composite modified water-soluble phenol-formaldehyde resin is applied to the field of friction materials.

Owner:ZHUHAI BONDRIGHT SYNTHETIC MATERIAL

Modified urea-formaldehyde glue and preparation method thereof

InactiveCN102604576AReduce free aldehyde contentIncrease hot waterNon-macromolecular adhesive additivesMacromolecular adhesive additivesCellulosePVA - Polyvinyl alcohol

The invention relates to a modified urea-formaldehyde glue and a preparation method thereof. The invention aims to solve the problems of poor stability and short storage time in the existing urea-formaldehyde glue. The urea-formaldehyde glue provided by the invention is prepared from formaldehyde, urea, melamine, parachlorophenol, sodium cellulose, ammonia water and polyvinyl alcohol. The preparation method comprises the following steps: 1. weighing the components, heating to 30-35 DEG C, regulating the pH value, and adding the sodium cellulose; 2. heating, and adding the first part of urea to regulate the pH value; 3. heating to 92 DEG C, regulating the pH value, and keeping the temperature to react; and 4. regulating the pH value, observing the reaction end, regulating the pH value to finish the reaction, adding the second part of urea, mixing, cooling to 70 DEG C, adding the third part of urea, adding the rest of components, cooling, regulating the pH value, and discharging the glue. The free formaldehyde content of the urea-formaldehyde glue is lower than 0.1%. The storage time is 2 months. The invention is applicable to the field of urea-formaldehyde glues.

Owner:HEILONGJIANG UNIV

Modified thermoplastic phenolic resin adhesive and production method

InactiveCN102786899AStrong adhesionGood rigidityAldehyde/ketone condensation polymer adhesivesFree phenolComposite material

The invention relates to a modified thermoplastic phenolic resin adhesive, which comprises the following components by weight: 1 part of phenol, 0.7-0.8 parts of aldehyde, 0.0008 parts of acidity and 0.02-0.04 parts of methyl glucoside. A production method comprises the following steps: adding aldehyde and phenol according to proportion into a reaction vessel, adding 10% of acidity and heating to the temperature of 100 DEG C, reacting for 30 minutes, gradually adding residual acidity in 45 minutes, continuously reacting for 30 minutes, then adding methyl glucoside for reacting for 30 minutes, controlling the temperature of 100 DEG C, and simultaneously unlatching a vacuum pump to control the reaction vessel pressure at 0.07Pa, dehydrating for 5 hours to obtain the product. The modified thermoplastic phenolic resin adhesive can enhance the quality of the thermoplastic phenolic resin adhesive, and reduce the production cost without adding a softener in the product, and can effectively overcome the problem of large environmental pollution due to high content of free phenol and free aldehyde of a traditional thermoplastic phenolic resin adhesive.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

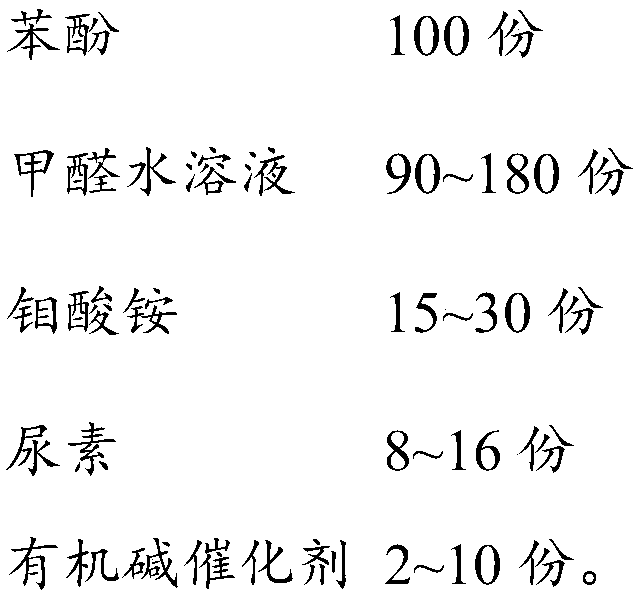

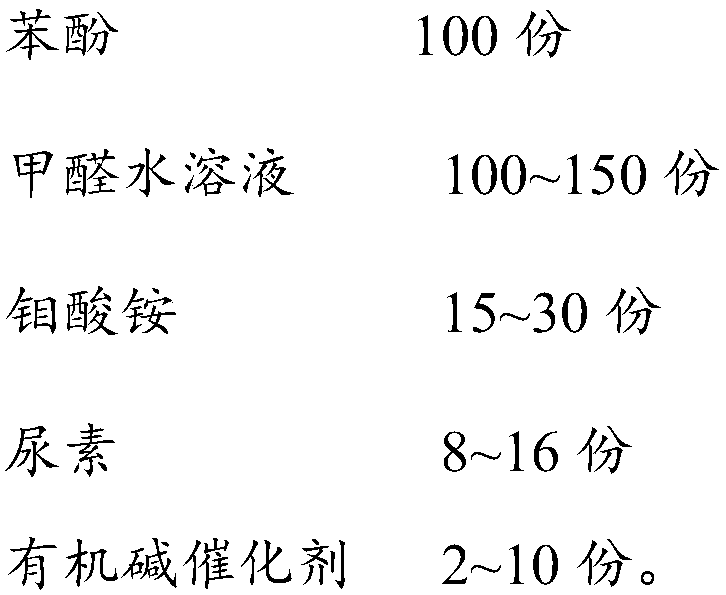

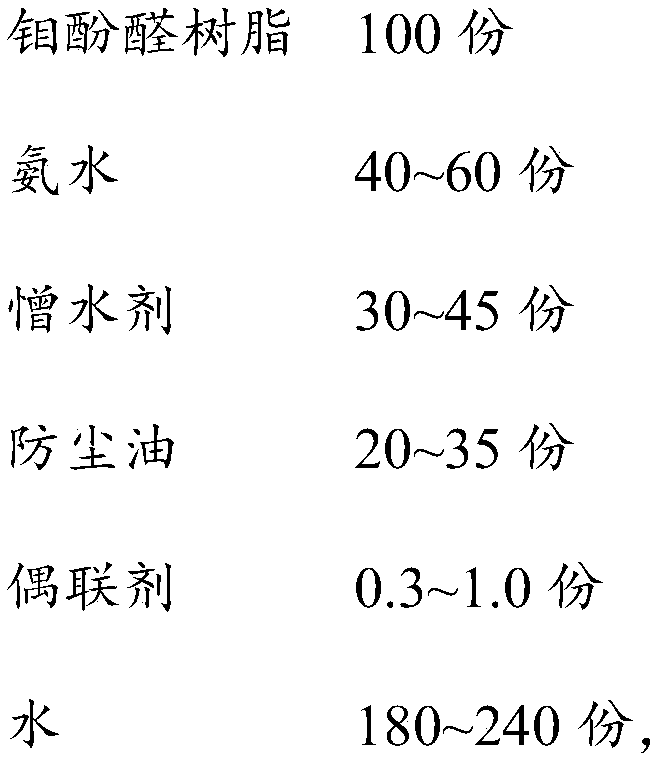

Molybdenum phenolic resin for water-soluble rock wool, adhesive, preparation method and application thereof

InactiveCN109180887AGood storage stabilityImprove thermal stabilityAldehyde/ketone condensation polymer adhesivesAdhesiveOrganic base

The invention discloses a molybdenum phenolic resin for a water-soluble rock wool, an adhesive, a preparation method and an application thereof and belongs to the field of materials of building external walls. The molybdenum phenolic resin contains the following raw materials in parts by weight: 100 parts of phenol, 90-180 parts of formalin, 15-30 parts of ammonium molybdate, 8-16 parts of urea and 2-10 parts of organic base catalyst. According to the invention, the molybdenum phenolic resin (Mo-PF) for the water-soluble rock wool is compounded by taking phenol, formaldehyde and ammonium molybdate as main raw materials and organic base as catalyst under a certain condition; molybdenum element is bonded in a PF molecule main chain in the form of chemical bond, so that the heat resistance ofPF is promoted; the Mo-PF has the characteristics of low content of free phenol and free aldehyde, higher strength, higher stability, and the like; the stability of rock wool is promoted; the molybdenum phenolic resin can be used as a heat-insulating material on the exterior of the building external wall and also can be applied to a rock wool adhesive to be operated under the environment of hightemperature.

Owner:北京新时代寰宇科技发展有限公司 +1

Liquid phenolic resin with high solid content and special for resin grinding tool and preparation method thereof

The invention aims at providing liquid phenolic resin with a high solid content and special for resin grinding tools and a preparation method thereof. The liquid phenolic resin is appropriate in molarratio, high in solid content and stable in technical index, and the resin grinding tools made of the liquid phenolic resin have excellent performance. The phenolic resin is prepared from, by mass, 100 parts of phenol, 94-170 parts of formaldehyde, 5-15 parts of composite alkali metal oxides, 1-10 parts of formaldehyde catching agent, 1.2-3.0 parts of basic catalysts and 0.1-2 parts of lactic acid, wherein the concentration of formaldehyde is 37%. The preparation method of the phenolic resin includes the following steps of adding phenol and formaldehyde; adding the basic catalysts; conductingheating by three steps, and then conducting vacuum dewatering; introducing icy water for fast cooling, adding composite alkali metal oxides, and then conducting depressurization and dewatering; addinga formaldehyde catching agent and lactic acid, and conducting stirring; detecting corresponding technical indexes, and if the indexes reach standards, obtaining a product. The liquid phenolic resin with the high solid content and special for the resin grinding tools and the preparation method thereof are applied to the field of phenolic resin.

Owner:ZHUHAI BONDRIGHT SYNTHETIC MATERIAL

A kind of preparation method of low-temperature curable high-imino high-etherified melamine resin

The invention discloses a preparation method of a high-imido and high-methoxylation melamine resin capable of being cured at low temperature. According to the method, the high-imido and high-methoxylation melamine resin capable of being cured at low temperature is obtained by reacting melamine, a formaldehyde solution and methanol, paraformaldehyde is not required to be added, the step of synthesis of hydroxymethylation melamine as an intermediate product is omitted, preparation costs are reduced, links of crystallization, drying and the like of the intermediate product are omitted, energy consumption is low, a technological process is simple, the methanol only needs to be added at one step in reaction, and the preparation method is easy to control. In addition, a mixture of hydrochloric acid and formic acid is used as an etherification catalyst, and the effect of the obtained product is better than that of a single acid catalyst.

Owner:重庆建峰新材料有限责任公司

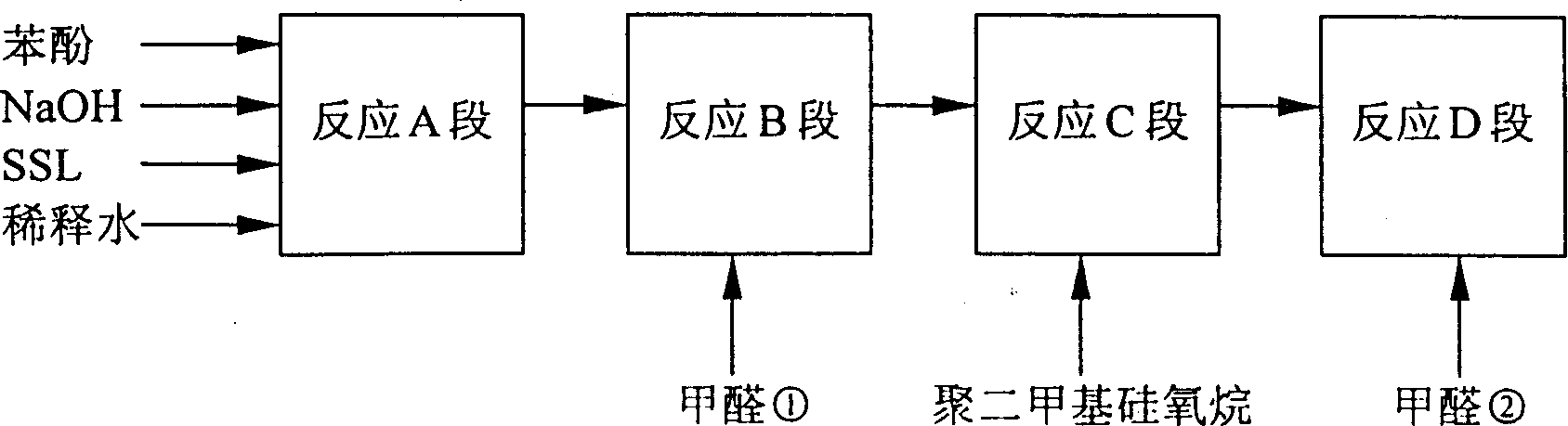

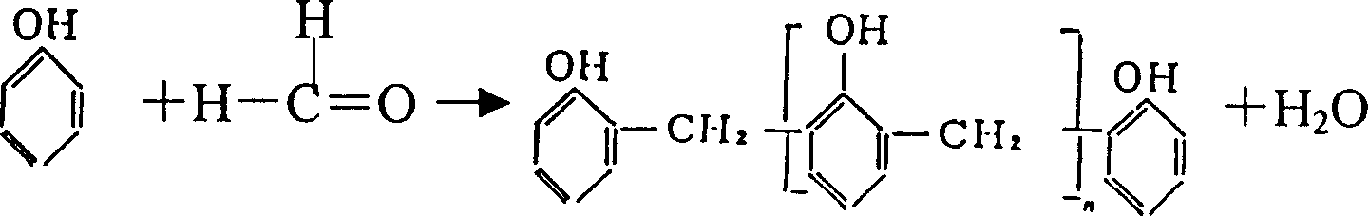

Composite phenolic resin glue producing method

InactiveCN1257244CWill not constitute pollutionMeet environmental protection requirementsAldehyde/ketone condensation polymer adhesivesReaction rateContamination

The invention discloses a production method of composite phenolic resin glue. NaOH is used as a catalyst, and phenol and formaldehyde are subjected to polycondensation reaction under normal pressure. Ratio: The molar ratio of phenol to formaldehyde is 1:1.7~2.23, the weight ratio of sodium lignosulfonate SSL, NaOH, dilution water to phenol is 1:0.8~1.16; the reaction speed is controlled by polydimethylsiloxane , The reaction is carried out in four sections in a reactor. Its advantage is that there is no formaldehyde and phenol sewage treatment problem in the production process, and it will not pollute the environment. Only 160-180kg phenol is used to produce one ton of composite phenolic resin glue, and the production cost is reduced by 20%-30%. Adding it overcomes the shortcomings of high brittleness and high shrinkage of the general phenolic resin glue used as an adhesive to press the board. Experiments show that the strength of the board does not change after being boiled in boiling water for 4 hours, and the board is placed outdoors for four months without cracking.

Owner:曲韵丰

Colorless phenolic impregnated resin, preparation method and application thereof

InactiveCN101659738AReduce free aldehyde contentSimple preparation processWood impregnation detailsAdhesivePhenol

The invention discloses a colorless phenolic impregnated resin, a preparation method and application thereof, which belong to the technical field of chemical adhesives. The colorless phenolic impregnated resin is prepared from phenol, water solution of sodium hydroxide, formaldehyde solution and water solution of strong reducing agent. The preparation method comprises the following steps: stirringthe formaldehyde solution; the phenol and the water solution of sodium hydroxide; heating the temperature of the mixture to be 85-90 DEG C; cooling the mixture; slowly dropping the water solution ofstrong reducing agent; and discharging. The preparation process is simple, easy to operate, increases the production efficiency and low raw material cost and obvious industrial economic benefit. The colorless phenolic impregnated resin is applied to impregnation of fast growing wood of artificial forest; on one hand, natural grains and color and luster of wood are preserved; and on the other hand,the physical and mechanical properties of densified wood by impregnation and hot press are obviously improved.

Owner:UNIV OF JINAN

Method for preparing urea formaldehyde fiber through circulating acid-alkali process

ActiveCN110359119ARaw materials are cheap and easy to getReduce free aldehyde contentMonocomponent synthetic polymer artificial filamentWet spinning methodsFiberAqueous solution

The invention discloses a method for preparing urea formaldehyde fiber through a circulating acid-alkali process. The method includes: adding urea, aldehyde and alkaline catalyst into a high molecularwater solution for reaction, sequentially adding aldehyde and acidic catalyst, adding alkaline catalyst and remaining aldehyde compound, adjusting to be acidic, finishing reaction, and subjecting a solution to spinning and thermosetting to obtain the urea formaldehyde fiber. By reasonably designing reaction process, molecular weight and structural controllability are improved, and spinnability and stability of the spinning solution are improved; the fiber serving as three-dimensional crosslinked fiber has the advantages of being low in cost, flame-retardant, heat-insulating, free of melting drop and nontoxic in burning and has wide application prospect.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for preparing lignin-based phenolic resin

PendingCN111484587AHigh reactivityNo generationAldehyde/ketone condensation polymer adhesivesAlkaline earth metalRenewable biomass

The invention belongs to the field of renewable biomass resource development and utilization, and particularly relates to a method for preparing lignin-based phenolic resin by using nano lignin as a raw material. The method comprises the following step: (S2) adding formaldehyde into nano lignin or a mixture of the nano lignin and phenol, carrying out heating reaction in the presence of an alkalinesubstance, and cooling after the reaction is finished, wherein the alkaline substance used in the step S2 is alkali metal or alkaline earth metal salt. According to the preparation method disclosed by the invention, the nano lignin-based phenolic resin is effectively prepared through a simple preparation method, and various properties of the obtained nano lignin-based phenolic resin accord with the national standard GB / T 14732-2006.

Owner:SHIHEZI UNIVERSITY

Anti-aging modified urea-formaldehyde glue and preparation method thereof

InactiveCN103666349APrevent agingLong storage periodAldehyde/ketone condensation polymer adhesivesMacromolecular adhesive additivesCelluloseAmmonia

The invention relates to an anti-aging modified urea-formaldehyde glue and a preparation method thereof, and solves the problems of poor anti-aging performance, poor stability and short storing time in the conventional anti-aging modified urea-formaldehyde glue. The urea-formaldehyde glue is composed of formaldehyde, urea, melamine, 2-isonaphthol, cellulose sodium, ammonia water and polyving akohol. The preparation method comprises the following steps: 1, weighing all components, heating to 30 to 35 DEG C, adjusting the pH value, and adding the cellulose sodium; 2, heating, adding a first part of urea and adjusting a pH value; 3, increasing the temperature to 92 DEG C, adjusting the pH value and then carrying out thermal reaction; 4, adjusting the pH value, observing a reaction final point, adjusting the pH value to finish the reaction, adding a second part of urea, mixing, then lowering the temperature to 70 GED C, adding a third part of urea and then adding the left components, lowering the temperature, adjusting the pH value, and releasing the gule. The content of free formaldehyde in the urea-formaldehyde glue is lower than 0.1 percent, and the storage time is more than 2 months. The anti-aging modified urea-formaldehyde glue provided by the invention is applied to the field of urea-formaldehyde glue.

Owner:HEILONGJIANG UNIV

Urea formaldehyde preparation method adopting batch adding

ActiveCN110359116AMild reaction conditionsReduce free aldehyde contentMonocomponent synthetic polymer artificial filamentThermal insulationAldehyde

The invention discloses a urea formaldehyde preparation method adopting batch adding. The method includes: adding urea, aldehydes and an alkaline catalyst into a macromolecule aqueous solution to perform reaction, sequentially adding aldehydes, an acidic catalyst, an alkaline catalyst and the rest of aldehyde compounds, spinning with a wet spinning frame after the reaction, heating and curing theas-spun fibers subjected to coagulating bath winding in a drying oven, naturally cooling, and taking out to obtain the urea formaldehyde fibers. The method has the advantages that the spinnability andstability of the spinning solution are increased by reasonably designing the reaction process, and the fibers serving as three-dimensional crosslinked fibers are low in cost, flame-retardant, thermal-insulation, free of melting drops, nontoxic when being combusted, promising in application prospect and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

A kind of modified urea-formaldehyde glue and preparation method thereof

InactiveCN102618198BIncrease hot waterReduce formaldehyde contentAldehyde/ketone condensation polymer adhesivesCellulose adhesivesThermal insulationMelamine

The invention relates to modified urea-formaldehyde glue and a preparation method thereof. The invention aims to solve the problems that traditional urea-formaldehyde glue is low in stability and is short in storage time. The urea-formaldehyde glue consists of formaldehyde, urea, tripolycyanamide, p-methylphenol, sodium cellulosate, ammonia water and polyvinyl alcohol. The preparation method comprises the following steps of: I-, weighing all components, heating to 30-35 DEG C, regulating a pH value and adding the sodium cellulosate; II-, heating, adding the first part of urea to regulate the pH value; III-, heating to 92 DEG C, regulating the pH value and then performing thermal insulation reaction; and IV-, regulating the pH value, observing the end point of the reaction; regulating the pH value to end the reaction; adding the second part of urea; mixing; cooling to 70 DEG C; adding the third part of urea; then, adding the residual components; cooling; regulating the pH value; and putting glue to obtain the modified urea-formaldehyde glue. The free formaldehyde content of the urea-formaldehyde glue is lower than 0.1 percent. The storage time is 2 months. The invention is applied to the field of the urea-formaldehyde glue.

Owner:HEILONGJIANG UNIV

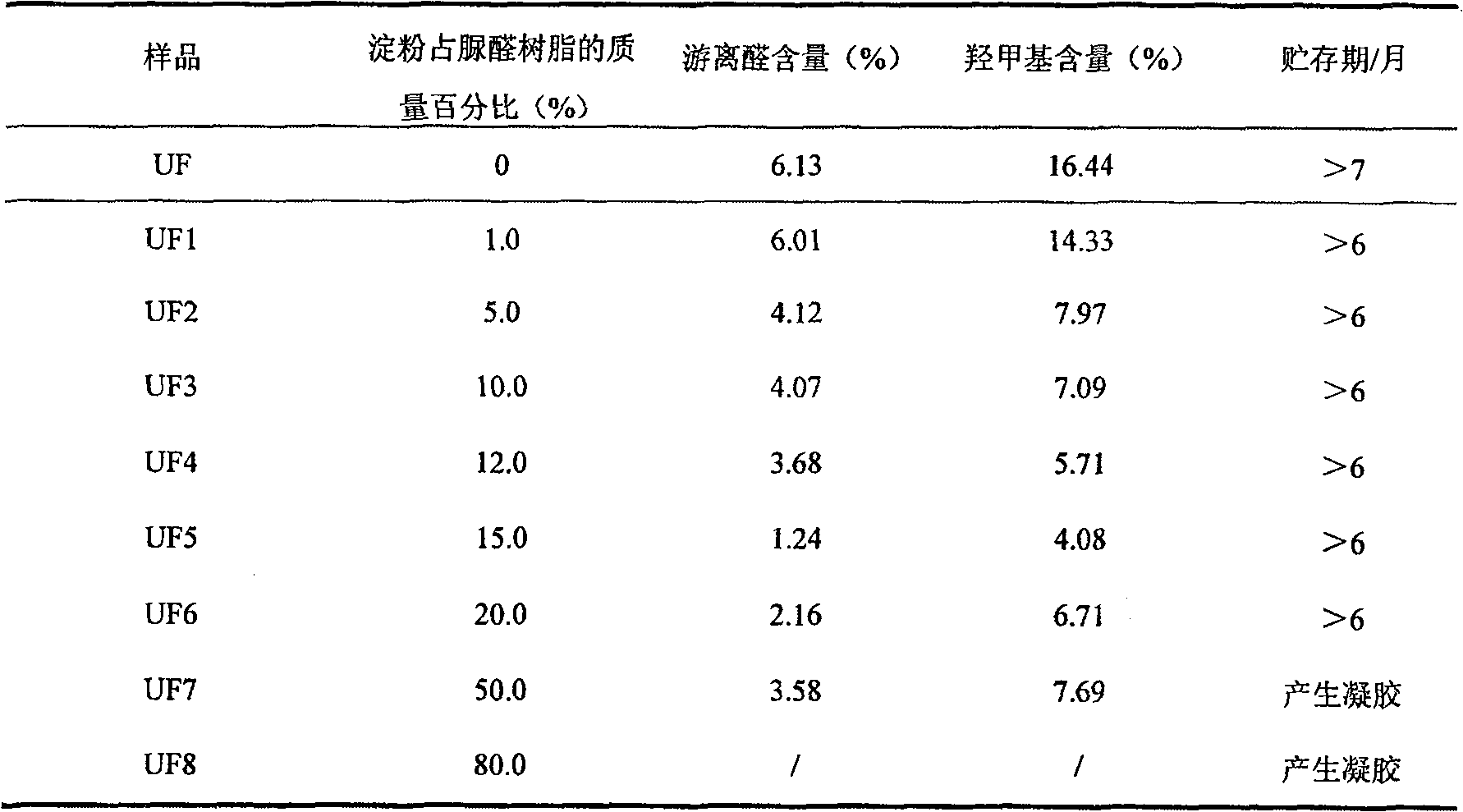

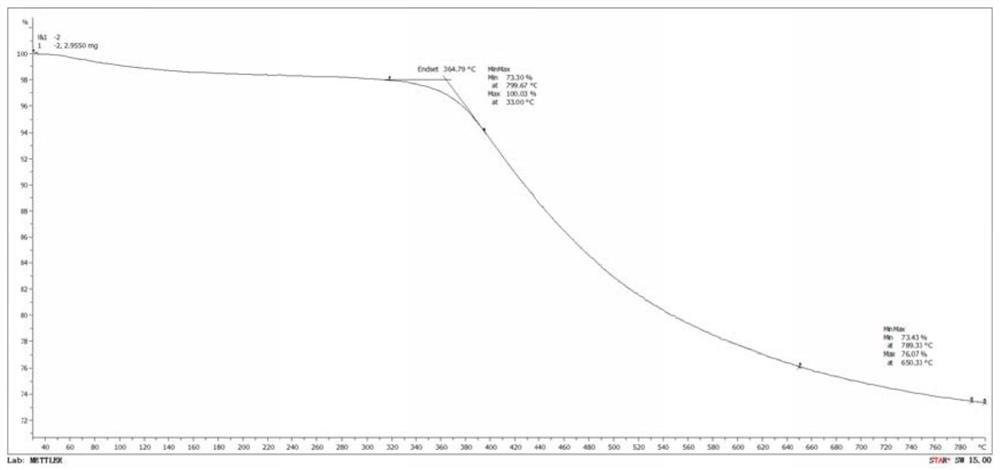

Method for preparing oxidization starch modified urea-formaldehyde resin

Owner:JIANGSU UNIV

Novel environment-friendly aluminum oxide refractory fiber and preparation method thereof

InactiveCN108085782AReduce free aldehyde contentAntistaticElectroconductive/antistatic filament manufactureInorganic material artificial filamentsFiberTitanium dioxide

The invention relates to the technical field of refractory fibers, in particular to a novel environment-friendly aluminum oxide refractory fiber. The novel environment-friendly aluminum oxide refractory fiber is prepared from the following raw materials in parts by weight: 65-75 parts of aluminum oxide, 30-50 parts of magnesium oxide, 10-15 parts of titanium dioxide, 4-8 parts of yttria, and 12.2-14.3 parts of an anti-electrostatic combined binder. According to the novel environment-friendly aluminum oxide refractory fiber, the formaldehyde catching agent containing anti-electrostatic combinedbinder is added and capable of decreasing free aldehyde content in the refractory fiber, so that the refractory fiber is green, environmentally friendly and anti-electrostatic; the preparation processes are simple; the parameters are easily controlled; the applicable fields are increased. Therefore, the enterprise benefit is increased.

Owner:长兴科创科技咨询有限公司

A kind of organic furfuryl alcohol modified amino resin-inorganic sol composite coating for casting filter screen, preparation method and application

ActiveCN109778552BReduce free aldehyde contentHeat resistantTextiles and paperAdhesive cementMelamine formaldehyde resin

The invention provides a method for preparing an organic resin-inorganic sol composite coating used for a filter screen for casting. Use furfuryl alcohol modified amino resin or furfuryl alcohol and low free aldehyde etherified melamine-formaldehyde resin or water-based urea-formaldehyde resin as the organic resin binder component, and use inorganic sol, silica sol, aluminum sol, etc. and pseudoboehmite as peptizers An organic-inorganic coating material compounded with an inorganic adhesive is used as the patented coating material to prepare filters for cast aluminum, cast copper and cast iron. Compared with the currently used alcohol solution thermoplastic phenolic solution as the coating material, the filter screen coating material has low toxicity and low cost, and the strength and heat resistance of the filter screen casted by alloys or metals with lower melting points can fully meet the requirements of pouring filtration. Requirements.

Owner:SHANDONG UNIV OF SCI & TECH +1

A method for preparing urea-formaldehyde fiber by adding in portions

ActiveCN110359116BRaw materials are cheap and easy to getHigh viscosityMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a method for preparing urea-formaldehyde fibers by adding in stages. After adding urea, aldehydes and basic catalysts into the polymer aqueous solution for reaction, aldehydes and acidic catalysts are added in sequence, and finally basic catalysts and remaining aldehydes are added. After the reaction, the raw fiber is spun with a wet spinning machine, and the raw fiber wound by the coagulation bath is heated and solidified in an oven, and the urea-formaldehyde fiber is obtained after cooling down naturally. The invention improves the spinnability and stability of the spinning solution by rationally designing the reaction process. As a three-dimensional cross-linked fiber, the fiber has the advantages of low cost, flame-retardant fiber, heat insulation, no melting drop, and non-toxic combustion. ,with broadly application foreground.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Modified urea formaldehyde adhesive and preparation method thereof

InactiveCN102604575BIncrease hot waterReduce formaldehyde contentNon-macromolecular adhesive additivesMacromolecular adhesive additivesCellulosePhenol

The invention discloses and relates to a modified urea formaldehyde adhesive and a preparation method of the modified urea formaldehyde adhesive. The modified urea formaldehyde adhesive disclosed by the invention solves the problems of poor stability and short storage time of the urea formaldehyde adhesive in prior arts. The urea formaldehyde adhesive disclosed by the invention comprises formaldehyde, urea, melamine, phenol, sodium cellulose, ammonia water, and polyvinyl alcohol. The preparation method comprises the following steps: (1) weighing each component, heating to 30-35 DEG C, regulating pH value, and adding sodium cellulose; (2) heating, adding the first part of urea, and regulating the pH value; (3) increasing the temperature to 92 DEG C, regulating the pH value, and holding temperature for reaction; and (4) regulating the pH value, observing the reaction end-point, regulating the pH value to finish the reaction, adding the second part of urea, mixing, decreasing the temperature to 70 DEG C, adding the third part of urea and the residual components, decreasing the temperature, regulating the pH value, and discharging to obtain the modified urea formaldehyde adhesive. The free formaldehyde content in the urea formaldehyde adhesive provided by the invention is less than 0.1%, and the storage time is two months. The modified urea formaldehyde adhesive provided by the invention is applied to the field of urea-formaldehyde adhesive.

Owner:HEILONGJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com