Method for preparing oxidization starch modified urea-formaldehyde resin

A technology of oxidized starch and urea-formaldehyde resin, which is applied in the field of modification and preparation of urea-formaldehyde resin, can solve the problems of expensive raw materials and increased production costs, and achieve the effects of reducing free aldehyde content, improving stability and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

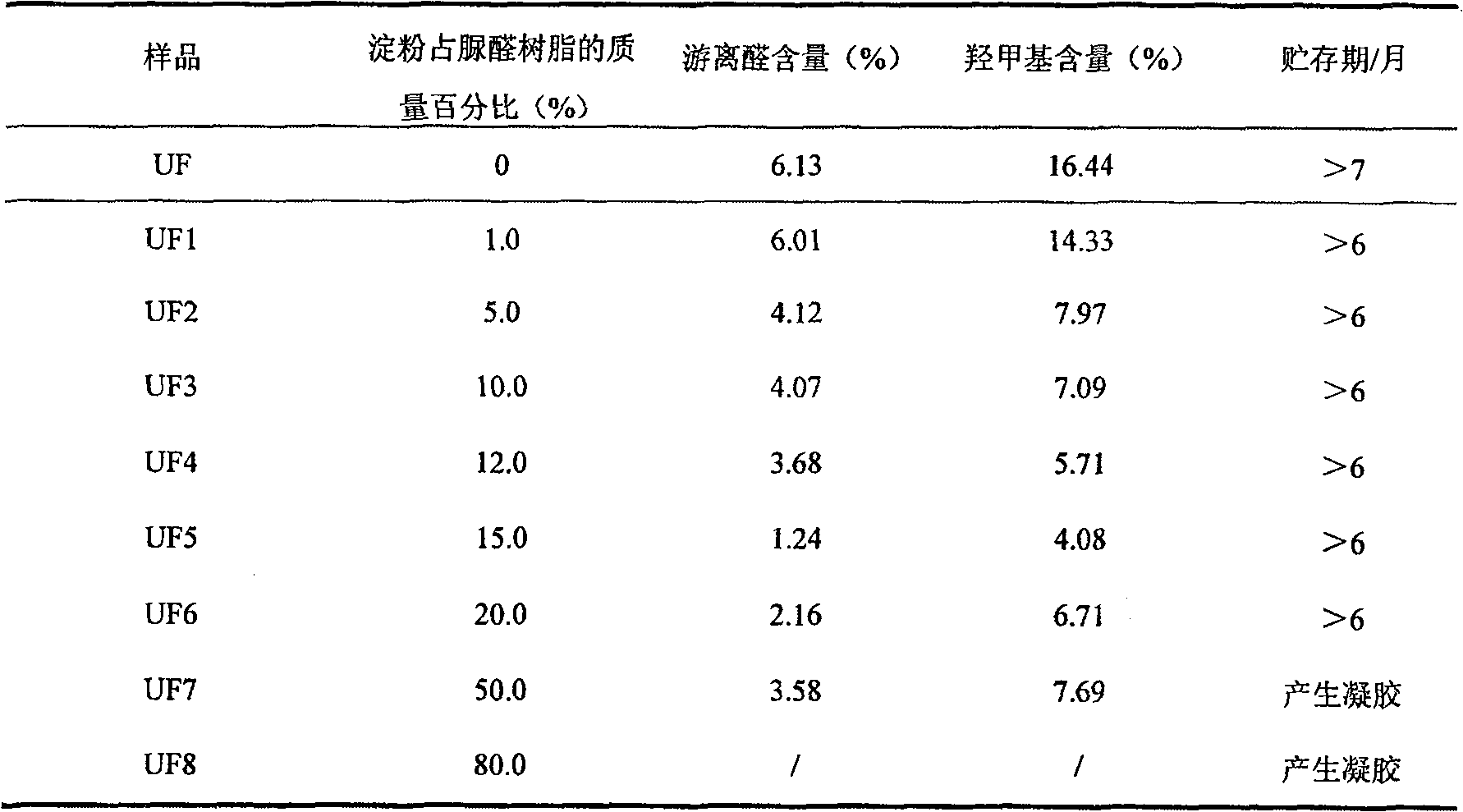

Embodiment 1

[0016] Under vigorous stirring, weigh 405 g of 37% formaldehyde aqueous solution and 0.004 g of catalytic ammonia water, add them into a three-necked flask and mix them. After mixing evenly, add 60g of urea, 1653g of water and 2.1g of perchloric acid oxidized starch, heat up to 45°C, add 0.02g of acetic acid during reflux, and continue the reaction for 40 minutes to maintain the pH of the solution at about 6.5. Then use 0.02g of sodium bicarbonate to adjust the pH value to about 7.2, continue to stir for 15 minutes, then stop heating, and the reaction ends to obtain a modified urea-formaldehyde resin product UF1 with a solid content of 10%.

Embodiment 2

[0018] Under vigorous stirring, 243 g of 37% formaldehyde solution and 0.04 g of catalyst ammonium chloride were weighed, added to a three-necked flask and mixed. After mixing evenly, add 60g of urea, 10g of water and 7.5g of hydrogen peroxide oxidized starch, heat up to 85°C, add 0.1g of formic acid during the reflux process, and continue the reaction for 1.5 hours to maintain the pH value of the solution at about 4.8. Then adjust the pH value to about 8.2 with 0.1g ammonium chloride, stop heating after continuing to stir for 15 minutes, and the reaction ends to obtain a modified urea-formaldehyde resin product UF2 with a solid content of 49%.

Embodiment 3

[0020] Under strong stirring, 105 g of 37% formaldehyde solution and 0.03 g of catalyst diethanolamine were weighed, added to a three-necked flask and mixed. After mixing evenly, add 60g of urea and 7g of water, raise the temperature to 90°C, add 0.2g of formic acid during the reflux process, and continue the reaction for 2 hours to maintain the pH value of the solution at about 3.0. Then adjust the pH value to about 9.8 with 0.2g sodium bicarbonate, add 9.9g potassium permanganate oxidized starch, stop heating after continuing to stir for 15 minutes, and the reaction ends to obtain a modified urea-formaldehyde resin product UF3 with a solid content of 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com