Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

208results about How to "Promote cross-linking reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide

ActiveCN102677465AImprove adsorption efficiencyRealize functional fillingLiquid/gas/vapor removalDry-cleaning apparatus for textilesUltravioletEngineering

The invention relates to modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide. The modified tussah silk fabric is prepared by the steps in sequence: weaving the tussah silk fabric by utilizing tussah filament, preparing finishing liquor and finishing tussah silk fabric; and the technical problems that the existing textile materials in the modification technology can not effectively improve the properties that the tussah silk fabric has damage to the environment, is easy to wrinkle, not anti-bacterial and easy to shrink, has poor dyeing property, poor comfortableness and function, and the like can be solved, the comprehensive properties that the tussah silk fabric is anti-wrinkle, soft, anti-bacterial, shrink-proof, self-cleaning and ultraviolet ray-resistant, as well as the adsorption efficiency of dye, and the like can be improved and enhanced, and the tussah silk fabric has the technical benefits of being lower in preparation cost, simple in process, environment-friendly and easy to realize, etc.

Owner:EASTERN LIAONING UNIV

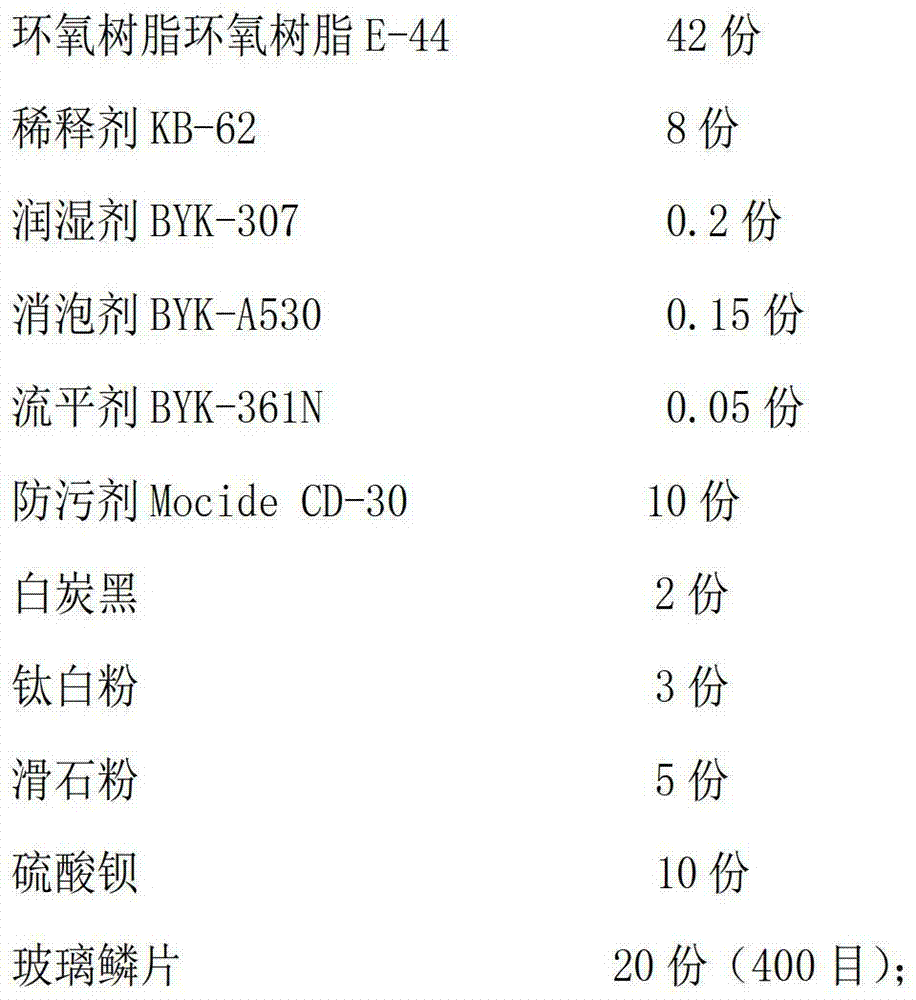

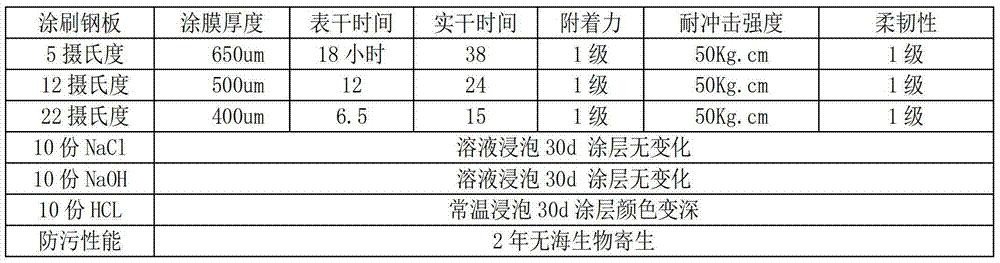

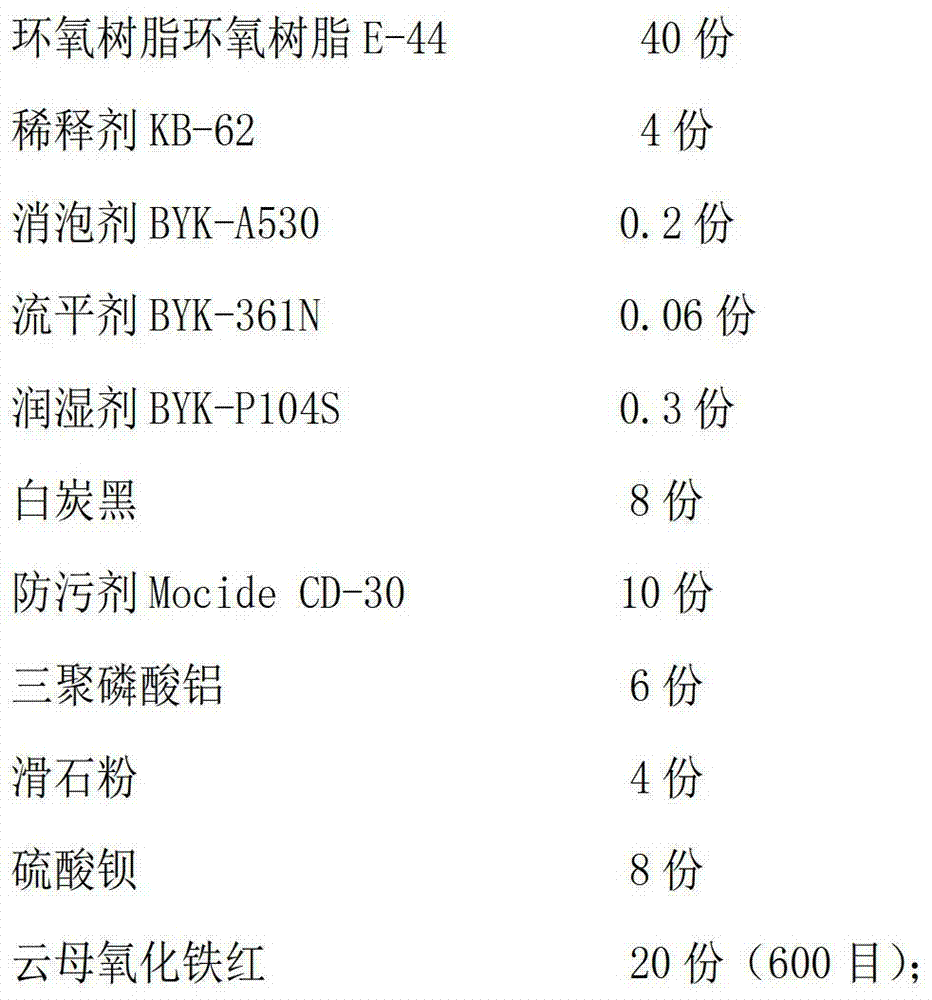

Underwater coating anti-pollution and anti-corrosion epoxy coating and preparation method thereof

InactiveCN103289531ALow halogen contentNon-irritatingAntifouling/underwater paintsPaints with biocidesUnderwaterCarbonate

The invention discloses an underwater coating anti-pollution and anti-corrosion epoxy coating and a preparation method thereof. The underwater anti-pollution and anti-corrosion epoxy coating provided by the invention can solve the difficult problem that an amine type curing agent which is matched with the epoxy coating used at normal temperature for underwater coating reacts with water and carbon dioxide in the water or air to generate carbonates, so that a bonded layer is isolated by the carbonates, the adhesion is greatly reduced, the bonding force is reduced by above 50% in comparison with a dry environment, a coat is easy to shed, and the anti-corrosion capability is poor. The anti-pollution and anti-corrosion coating disclosed by the invention has the advantages of good underwater coating anti-corrosion performance, strong adhesion, great impact resistance and good flexibility, and can effectively prevent the problems that a paint film is damaged, and the damages and corrosion of a steel plate and concrete are accelerated due to the parasitic attachment of marine organisms.

Owner:CHANGSHA SHENGKANG HIGH POLYMER MATERIAL TECH

Flexible carbon fiber and preparation method thereof

ActiveCN106012110AImprove flexibilityImprove conductivityArtifical filament manufactureCarbon fibersCarbonization

The invention relates to a flexible carbon fiber and a preparation method thereof. The carbon fiber is prepared by carrying out spinning on a graphite flake / polyacrylonitrile complex solution and carrying out super-high drafting, pre-oxidation and carbonization treatment. The carbon fiber has highly oriented graphite flakes and graphite crystal structures generated through induction of the graphite flakes, wherein graphite crystallite is arranged and oriented along the surfaces of the graphite flakes. The carbon fiber has the characteristics of high order degree, compact structure, small average grain size and few defects. The rigidity / softness, resistivity, strength and axial thermal conductivity of the prepared flexible carbon fiber are respectively 10<-4>-10mN .cm, 10<-3>-100omega .cm, 1000-5000MPa and 0.5-50W / m .k. The prepared flexible carbon fiber has the beneficial effects that the flexible carbon fiber is low in production cost and wide in raw material sources; the structural properties of the carbon fiber can be substantially improved; and the flexible carbon fiber has very high market application values and can be widely applied to the fields of electrode materials, functional materials, energy materials, and the like.

Owner:DONGHUA UNIV

Hydroscopic cellulose hydrogel and preparation method thereof

The invention relates to a hydroscopic cellulose hydrogel and a preparation method thereof. The preparation method of the hydrogel is as follows: carboxymethyl cellulose and cellulose are respectively dissolved in the water solution of NaOH / urea in which the concentration of NaOH is 6-10wt%, and the concentration of the urea is 4-12wt%; the NaOH / urea mixed water solution of 1-5wt% of the carboxymethyl cellulose and the NaOH / urea mixed water solution of 1-5wt% of the cellulose are obtained; then the NaOH / urea mixed water solution of the carboxymethyl cellulose and the NaOH / urea mixed water solution of cellulose are mixed according to the weight ratio: 9:1-1:9 and stirred evenly, and the mixed solution is obtained; the mixed solution is also added with certain amount of cross linker epoxy chloropropane; after the chemical cross linking reaction, the mixed solution is placed at the gelatin temperature until the hydroscopic cellulose hydrogel is formed, wherein, the water absorbing capacity is 50-1,000g / g. The hydrogel has very good salt sensitivity and high hydroscopicity and is capable of being widely used in the fields of agriculture, health care and medicine.

Owner:WUHAN UNIV

Luminescent fibre hydrogel and preparation method thereof

The invention relates to a luminescent cellulose hydrogel and a preparation method thereof. The preparation method for the luminescent cellulose hydrogel is as follows: firstly, cellulose is dissolved in an aqueous solution of NaOH / urea to obtain a NaOH / urea combined aqueous solution which is dissolved with the cellulose, wherein the mass percent concentration of NaOH is between 6 and 10 percent, the mass percent concentration of urea is between 4 and 12, and the mass percent concentration of the cellulose in the combined aqueous solution is between 1 and 6 percent; secondly, CdSe / ZnS quantum dots the surfaces of which are provided with carboxyl groups are added into the combined aqueous solution, wherein a mol ratio of the cellulose to the quantum dots is between 10 to 1 and 1,000 to 1, the dimension of the CdSe / ZnS quantum dots is between 2 and 7 nanometers, and the concentration of the CdSe / ZnS quantum dots is between 0.1 and 200 mu M; and thirdly, a crosslinking agent - epichlorohydrin with required amount is added into the combined aqueous solution, and the combined aqueous solution is subjected to chemical crosslinking reaction and placed at a gel temperature until the luminescent cellulose hydrogel is formed. The luminescent cellulose hydrogel can be widely applied in the fields of optical elements, biomedicine, control and release of medicines, etc.

Owner:WUHAN UNIV

Anti-salting-out and anti-whiskering seal primer and preparation method thereof

InactiveCN106147485AReduce surface tensionPromote cross-linking reactionCoatingsAnti freezingEmulsion

The invention discloses anti-salting-out and anti-whiskering seal primer and a preparation method. The anti-salting-out and anti-whiskering seal primer is prepared from, by mass, 25-40 parts of deionized water, 0.5-0.7 part of a thickening agent, 0.1-0.3 part of a PH regulating agent, 0.5-1 part of a dispersing agent, 0.1-0.2 part of a wetting agent, 0.5-1 part of a defoaming agent, 5-8 parts of titanium dioxide, 5-8 parts of mica powder, 6.3-11 parts of calcium carbonate, 36-45 parts of cationic styrene-acrylic emulsion, 0.8-1.5 parts of a film forming aid and 1-2.5 parts of an anti-freezing agent. According to the anti-salting-out and anti-whiskering seal primer, the adhesive force and the alkali resistance of a coating and a substrate can be enhanced, and meanwhile capillary pores of mortar are sealed to prevent alkali and salts from being separated out.

Owner:林金溪

Polyolefin cable material and preparation method thereof

InactiveCN106543517AIncrease alkalinityPromote cross-linking reactionPlastic/resin/waxes insulatorsElastomerPolymer science

The invention discloses a polyolefin cable material and a preparation method thereof. The polyolefin cable material is prepared from, by weight, 20-40 parts of ethylene-vinyl acetate copolymer resin, 10-30 parts of polyolefin elastomers, 20-50 parts of ultralow-density polyethylene, 0-15 parts of functional polyolefin resin, 0-180 parts of a flame retardant, 0.5-1.5 parts of a crosslinking sensitizer, 0.5-2 parts of an auxiliary crosslinking agent, 0.1-0.5 part of a chain extender, 0.5-2 parts of an antioxidant and 3-9 parts of a processing aid. The polyolefin cable material is wide in application range, the flame-retardant polyolefin cable material or the non-flame-retardant polyolefin cable material can be prepared, and extrusion moulding is easy; in addition, the polyolefin cable material has the high crosslinking sensitization activity, volatilization is not prone to occur and no smoke is generated during extrusion, health of production personnel can be protected, and the operation environment is improved.

Owner:WUXI JAKE PLASTIC

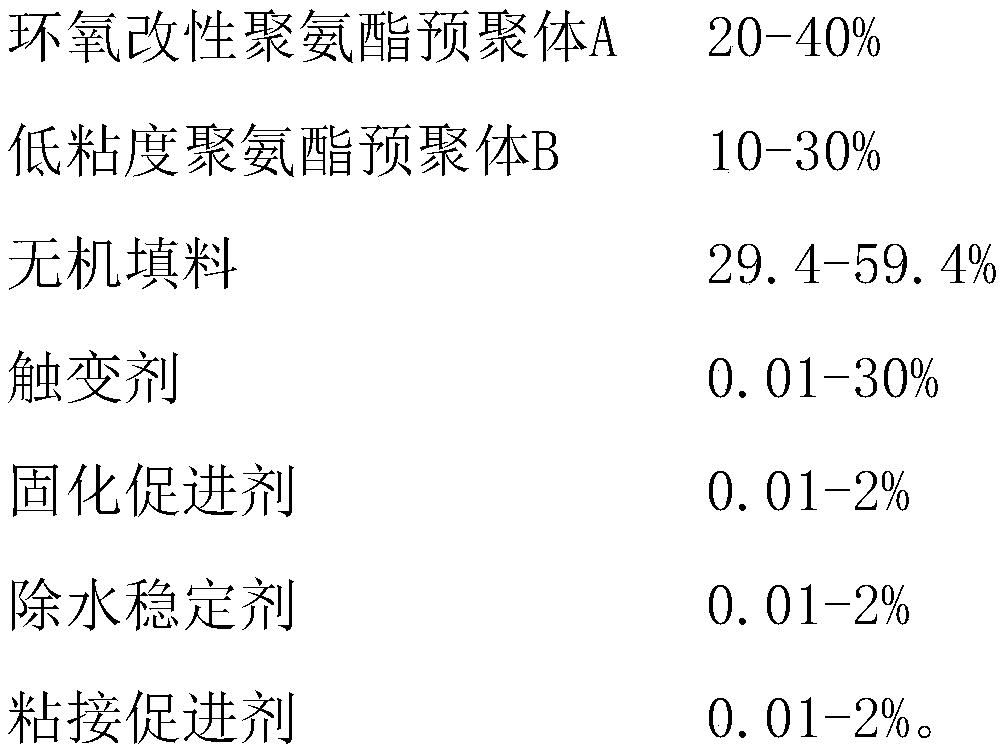

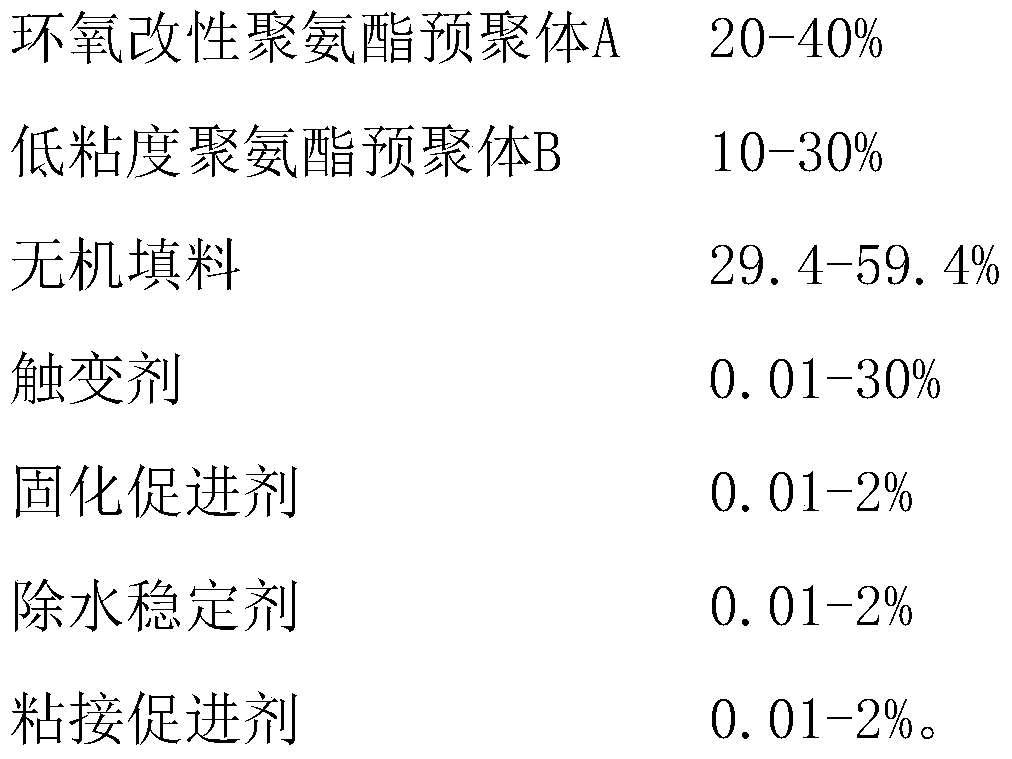

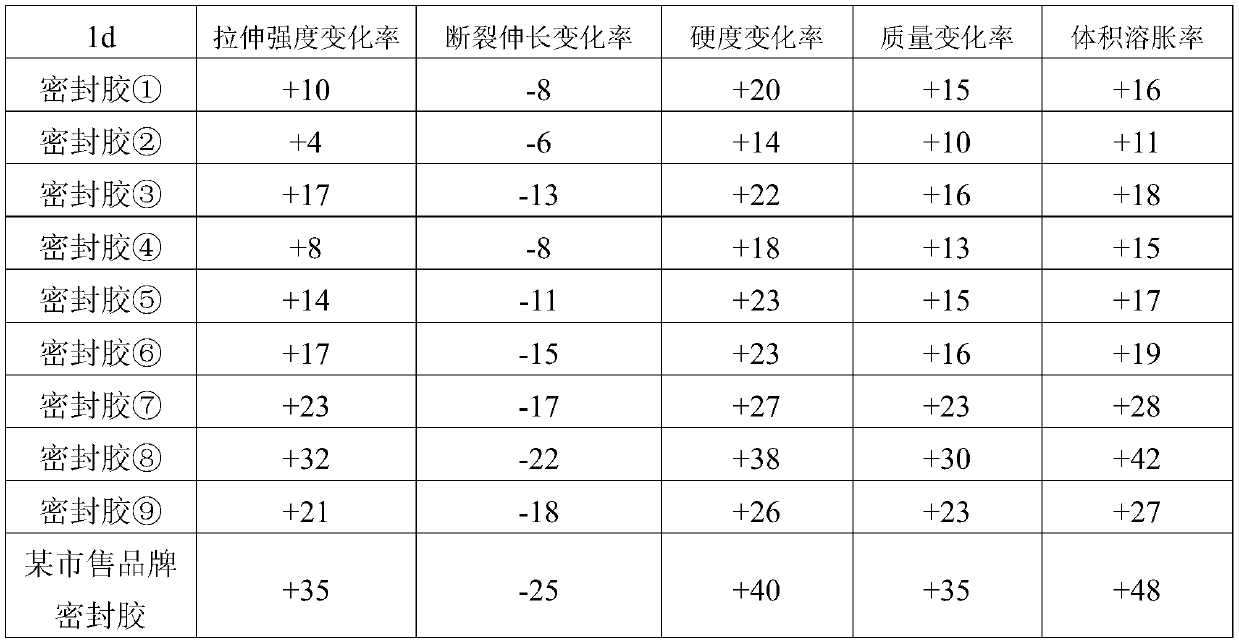

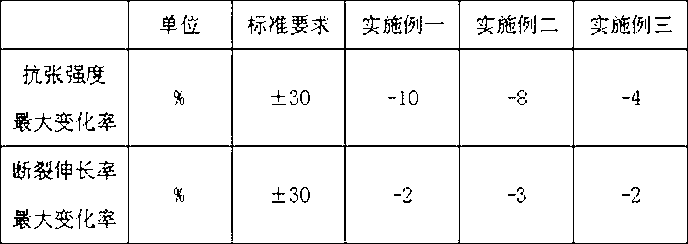

Solvent-resistant epoxy modified polyurethane sealant and preparation method thereof

ActiveCN110172323AGood chemical resistanceGood mechanicalNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxySolvent

The invention relates to the technical field of sealants, in particular to a solvent-resistant epoxy modified polyurethane sealant and a preparation method thereof. The sealant is prepared from, by weight, 20-40% of an epoxy modified polyurethane prepolymer A, 10-30% of a low-viscosity polyurethane prepolymer B, 29.4-59.4% of an inorganic filler, 0.01-30% of a thixotropic agent, 0.01-2% of a curing promoter, 0.01-2% of a water removal stabilizer and 0.01-2% of an adhesion promoter. The epoxy modified polyurethane sealant has excellent chemical corrosion resistance and mechanical properties, through a chemical corrosion test in the industry standard of a membrane-type gas meter, after liquid immersion, the mechanical properties, mass change rate and volume change rate of the sealant can allbe kept at a very small change rate, the adhesive sealing effect is good, and the sealant can keep the good adhesive sealing function during long-term use in the gas meter.

Owner:广东盛业化学科技有限公司

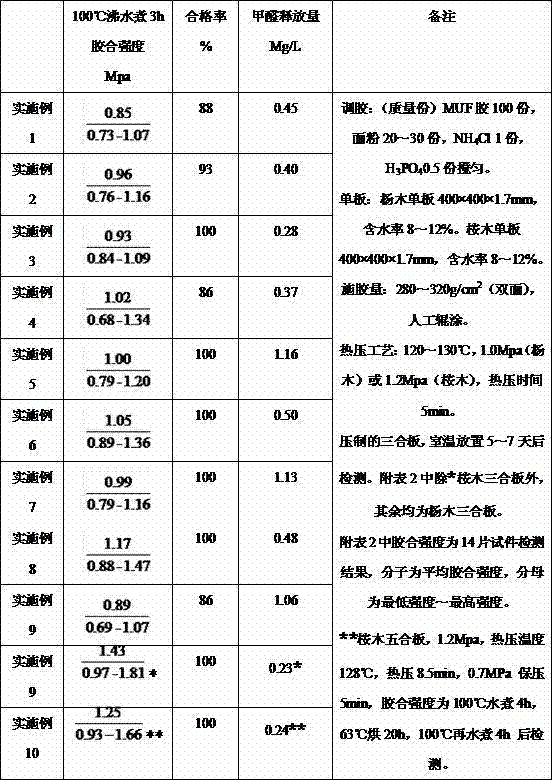

Method for preparing melamine-urea-formaldehyde resin adhesives for outdoor plywood low in formaldehyde release

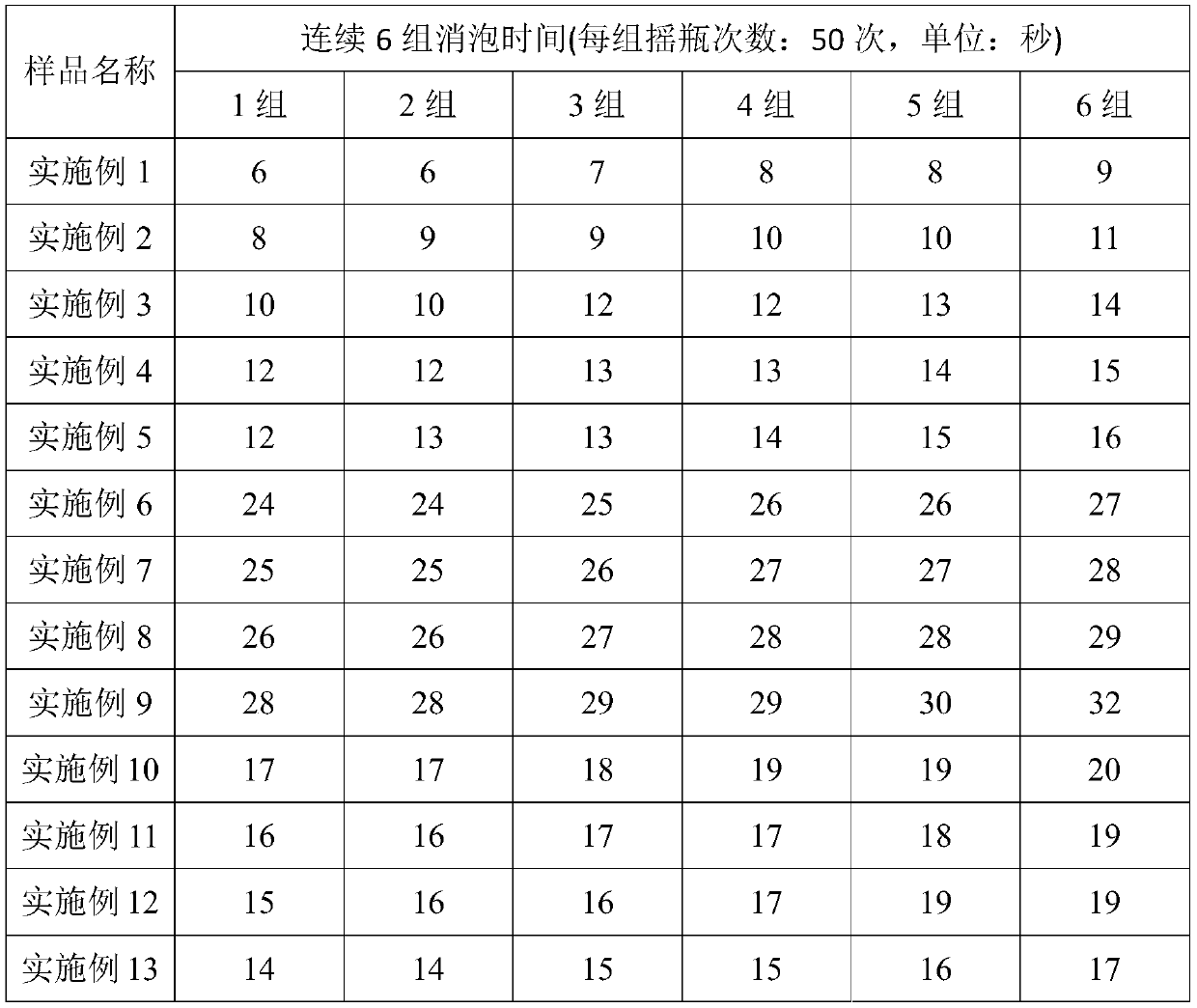

InactiveCN102775571AExtended shelf lifeFast curingAldehyde/ketone condensation polymer adhesivesWood veneer joiningPolymer scienceResin adhesive

The invention discloses a method for preparing melamine-urea-formaldehyde resin adhesives for outdoor plywood low in formaldehyde release. The method includes adding formaldehyde solution, melamine and urea into a reactor, adjusting pH value to the cloud point; adding urea and melamine for reaction; adding melamine, adding urea for subsequent reaction, and cooling before discharging. According to the convention process of alkali-acid-alkali, the melamine and the urea are added by three steps, ply bond of plywood made of plying the MUF (melamine, urea and formaldehyde) resin adhesives made of 16-20% of modified melamine is accordant with the requirements of the first type of plywoods. According to difference of usage the melamine and F / (M+U) mole ratio, the formaldehyde release of the plywood is accordant with the E1 level or E0 level. The method for preparing melamine-urea-formaldehyde resin adhesives is mild in reaction, easy to control and fine in repeatability, storage life of the adhesives is longer than 15 days. The MUF resin adhesives are lacte and faster in curing and are lower in temperature and cost than those of phenol glue.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

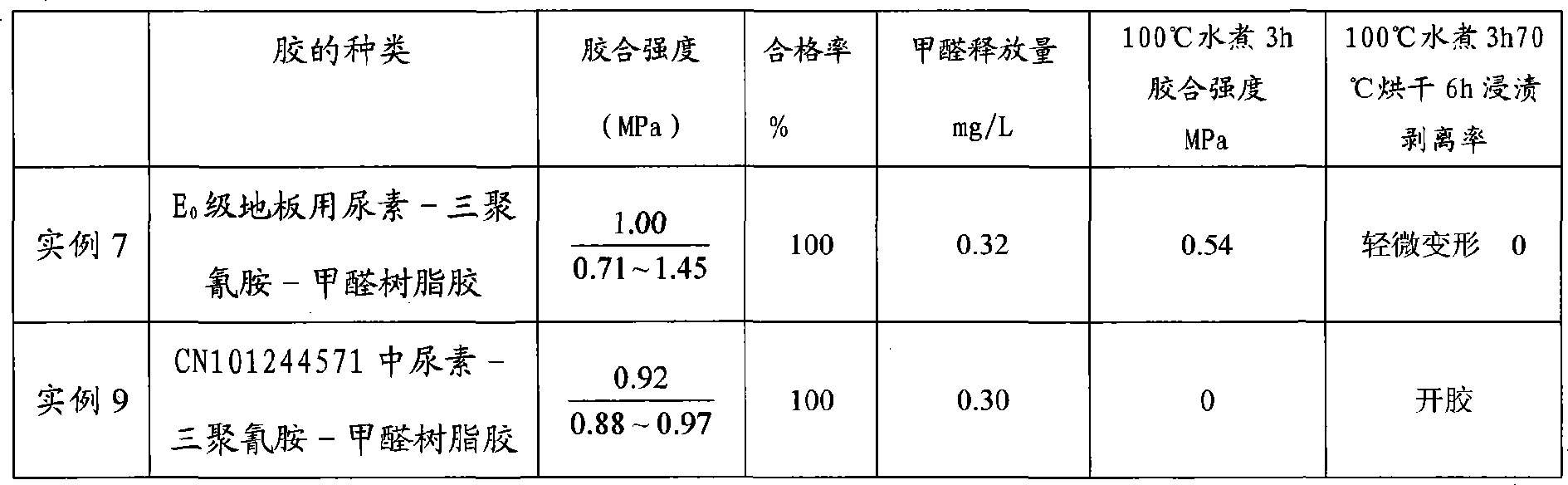

Defoaming agent

PendingCN110681187AImprove defoaming abilityLong foam suppression timeFoam dispersion/preventionPtru catalystPreservative

The invention relates to the technical field of chemical additives, and specifically discloses a defoaming agent. The defoaming agent is at least prepared from the following preparation raw materials:10 to 30 parts of an organic silicon composition, 1 to 10 parts of hydrogen-containing polysiloxane, 1 to 10 parts of vinyl polysiloxane, 2 to 12 parts of allyl polyether, 0.1 to 2 parts of a catalyst, 5 to 20 parts of an emulsifier, 1 to 5 parts of a thickener, 1 to 5 parts of a preservative and 50 to 90 parts of water. The organic silicon defoaming agent which is high in defoaming speed, long in foam inhibition time, excellent in dispersing performance and outstanding in defoaming durability is prepared through a special formula and process, and what's more important, the defoaming agent prepared through the preparation method is good in product stability, not prone to demulsification and free of oil floating under the conditions of high temperature and strong alkali, and the preparation method is simple and low in cost.

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

Method for preparing coupling agent modified starch paste

InactiveCN101100811APromote cross-linking reactionImprove bindingFibre treatmentYarnPolyvinyl alcohol

The invention relates to spinning starch slurry modified manufacturing technique. Its features are that it can add oxidized starch, organic silicon coupling agent, and sizing auxiliary agent at the same time to realize by one step, or fractional step method that putting oxidized starch and water into four port flask; adding organic silicon coupling agent; heating to 30-110 deg.C; holding and stirring for 40min-8h; adding sizing auxiliary agent acrylic resin and polyvinyl alcohol; heating to 45-150 deg.C to gain organic silicon modified starch slurry ST-Si. The invention can increase cross linking reaction, binding power, storage period, but reduce cost and environment pollution.

Owner:JIANGSU UNIV

Modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide

ActiveCN102677465BImprove adsorption efficiencyRealize functional fillingLiquid/gas/vapor removalDry-cleaning apparatus for textilesUltravioletEngineering

The invention relates to modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide. The modified tussah silk fabric is prepared by the steps in sequence: weaving the tussah silk fabric by utilizing tussah filament, preparing finishing liquor and finishing tussah silk fabric; and the technical problems that the existing textile materials in the modification technology can not effectively improve the properties that the tussah silk fabric has damage to the environment, is easy to wrinkle, not anti-bacterial and easy to shrink, has poor dyeing property, poor comfortableness and function, and the like can be solved, the comprehensive properties that the tussah silk fabric is anti-wrinkle, soft, anti-bacterial, shrink-proof, self-cleaning and ultraviolet ray-resistant, as well as the adsorption efficiency of dye, and the like can be improved and enhanced, and the tussah silk fabric has the technical benefits of being lower in preparation cost, simple in process, environment-friendly and easy to realize, etc.

Owner:EASTERN LIAONING UNIV

Preparation of urea-melamine-formaldehyde resin adhesive for E0 floor

InactiveCN101481593AReduce the content of ether linkagesReduce releaseAldehyde/ketone condensation polymer adhesivesUreaUrea melamine formaldehyde

The invention discloses a method for preparing a urea-melamine-formaldehyde resin adhesive for an E0-level floor. In the first step, formaldehyde solution, melamine and urea are mixed, the pH value of the mixture is regulated, the temperature is raised to 80-95 DEG C, and the reaction lasts 40-60 minutes, wherein, the mol ratio between formaldehyde and the total amount of the urea and the melamine is 2.05-2.12 : 1; in the second step, the pH value is regulated to be 5.0-6.0, and the reaction is underway till the turbidity point; in the third step, the pH value is regulated to be 6.0-6.9, the urea and the melamine are added, and the mol ratio between the formaldehyde and the total amount of the urea and the melamine which are added in the first step and the second step is 1.48-1.74 : 1, and the reaction lasts 30-70 min at a temperature of 90 DEG C; in the fourth step, the pH value is regulated to be 7.5-9.0, the melamine is added, and the reaction lasts 20-80 min at a temperature of 80-90 DEG C; and in the fifth step, the urea is added, the mol ratio between the formaldehyde and the total amount of all the urea and all the melamine is 1.02-1.30 : 1, and the material is cooled and discharged after the reaction is finished. A veneer formed by pressing the resin adhesive has good boiled-water resistance and low formaldehyde release, and the reaction is gentle and also easy to control.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

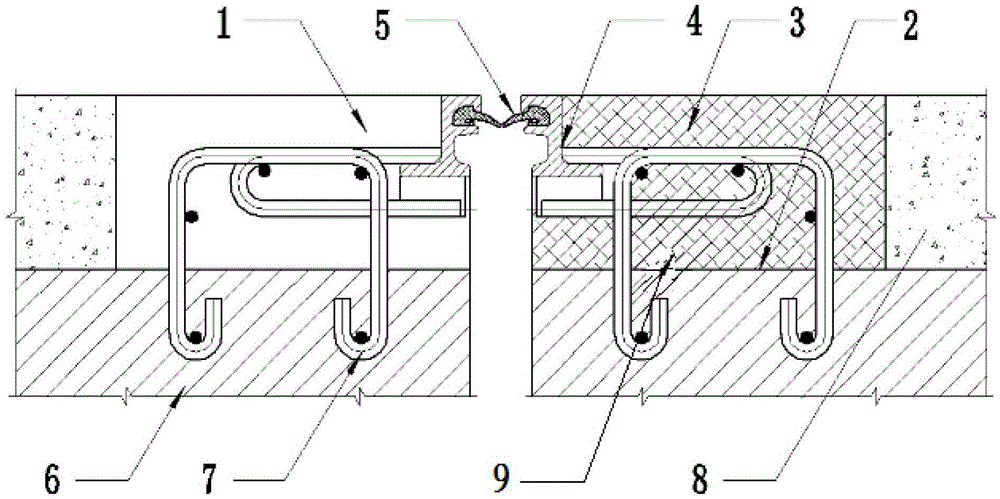

Rapid replacing method and restoring method for bridge expansion joint

InactiveCN105625169AHigh mechanical strengthEasy constructionBridge structural detailsBridge erection/assemblyEngineeringRebar

The invention relates to a rapid replacing method and a restoring method for a bridge expansion joint, which relates to the technical field of bridge expansion joints. The replacing method comprises the following steps of 1, cutting off original poured concrete in an expansion joint groove and dismantling the original expansion joint device and a beam body embedded reinforcement; step 2, cutting off and trimming the expansion joint groove, whose original poured concrete and expansion joint device are cut off, until the edge of the expansion joint groove is neat; 3, embedding a new beam body embedded reinforcement and a new expansion joint device in the expansion joint groove; 4, coating a bonding layer in the expansion joint groove; 5, pouring modified MMA composite concrete in the expansion joint groove and tamping the modified MMA composite concrete after the modified MMA composite concrete is poured; and 6, striking off the upper surface of the poured concrete and mounting an expansion joint sealing rubber strip on the poured concrete. According to the invention, as the adopted modified MMA composite concrete has the advantages of high mechanical strength, interface bonding force and high compressive strength, the service life of the replaced bridge expansion joint is obviously prolonged, the bridge expansion joint is simple and convenient in construction, and the curing time of the bridge expansion joint is short.

Owner:重庆博焱建设工程有限公司

Adhesive tape production process

InactiveCN105153952AEasy to produceStable physical propertiesFilm/foil adhesivesAdhesive beltMechanical engineering

The invention discloses an adhesive tape production process which comprises the following steps: (1) carrying out stirring of an adhesive; (2) carrying out coating; (3) carrying out drying; (4) carrying out compound rolling; (5) carrying out curing; and (6) carrying out slitting. Compared to the prior art, the preparation process is simple to operate and overcomes the defects of a complex process and a bad adhesive tape curing effect.

Owner:NANTONG KANGERLE MEDICAL MATERIALS CO LTD

Salt corrosion resistance twisted cable insulation rubber used for ocean wind power and preparation method thereof

ActiveCN103224669AIncrease working temperatureAnti-aging propertiesPlastic/resin/waxes insulatorsInsulated cablesRubber materialVulcanization

The invention discloses salt corrosion resistance twisted cable insulation rubber used for ocean wind power and a preparation method of the salt corrosion resistance twisted cable insulation rubber. By weight, raw materials comprise 8 parts of Keltan5508, 12 parts of DutralTER4044, 5-7 parts of EP-20, 0.5-0.7 part of DCP, 0.3-0.5 part of TAC, 0.2-0.4 part of HVA-2, 0.2-0.4 part of RD, 0.2-0.4 part of MB, 0.2-0.4 part of KH-550, 2.1-2.5 part of hydration zinc borate, 1-1.5 parts of antimony trioxide, 25-40 parts of aluminum hydroxide, 0.8-1.2 part of red lead, 0.5-1 part of stearic acid, 1.5-2 parts of nan-zinc oxide, 2-5 parts of paraffin oil Sunpar2280, 0.5-1 part of chlorinated paraffin-52, and 1-3 parts of hydration silicon dioxide. According to the method, firstly, the EPDM rubber Keltan5508, the DutralTER4044 and the EP-20 are mixed for 1-1.5 minutes, and then other components except for a vulcanizing agent and a co-vulcanization agent are added. After mixing is carried out for 7-8 minutes, discharging and airing are carried out for more than 24 hours. Then the rubber materials are mixed for 2-3 minutes, the vulcanizing agent and the co-vulcanization agent are added at the last 20 seconds, and the mixed materials are loaded on an open mill for milling, triangular injection molding and square injection molding and then sheeted. The insulation rubber is good in mechanical performance, anti-corrosion performance and anti-aging performance and long in service life.

Owner:浙江华威设备制造有限公司

High-flame retardation solar energy cell organosilicon pouring sealant and preparation method thereof

InactiveCN107384305AHigh transparencyGood flexibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkAcrylic resin

The invention relates to a high-flame retardation solar energy cell organosilicon pouring sealant and a preparation method thereof. The high-flame retardation solar energy cell organosilicon pouring sealant comprises the following raw materials in parts by weight: 40 parts of methyl phenyl vinyl silicone rubber, 20 parts of room-temperature sulfured phenylene silicone rubber, 20 parts of addition-type heat vulcanized nitrile silicone rubber, 20 parts of phosphate silicone oil, 20 parts of polyoxypropylene glycerol ether silicone oil, 10 parts of mercapto silicone oil, 5 parts of low-molecular hydroxy silicone oil, 5 parts of hydrogen-containing silicone oil with hydrogen containing amount accounting for 0.5% of mass content, 10 parts of an ethene-vinyl acetate copolymer, 10 parts of otcamethylcyclotetrasiloxane-modified acrylic resin, 7 parts of hydrogenated castor oil, 1-3 parts of an adhesion agent, 1-3 parts of a strengthening agent, 0.1-0.4 parts of a catalyst, 1-3 parts of a silicon nitrogen cross-linking agent, 0.5-2.5 parts of an inhibitor, and 1-2 parts of a flame-retardation filling material.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

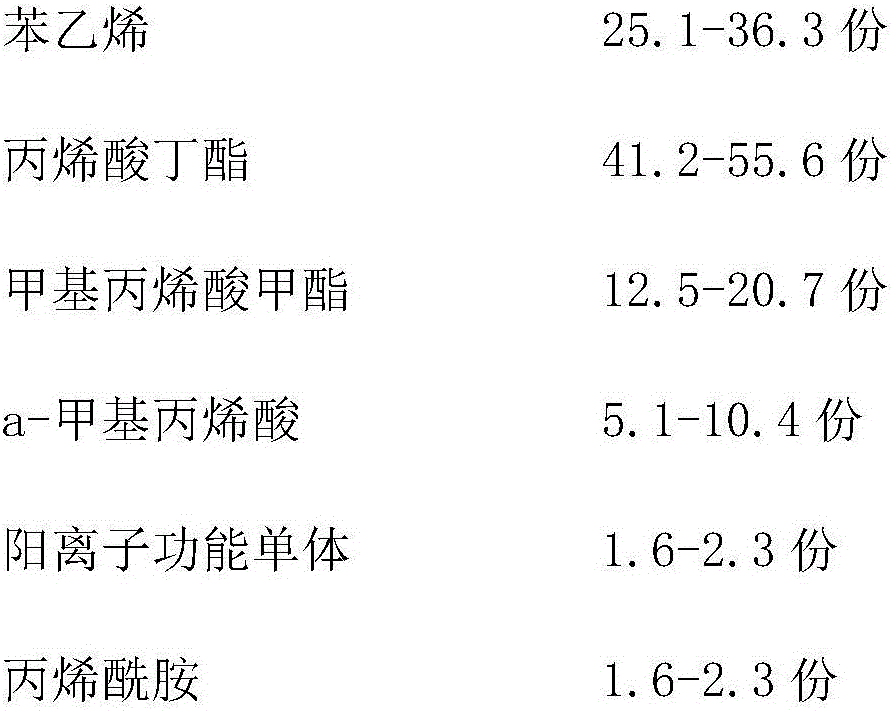

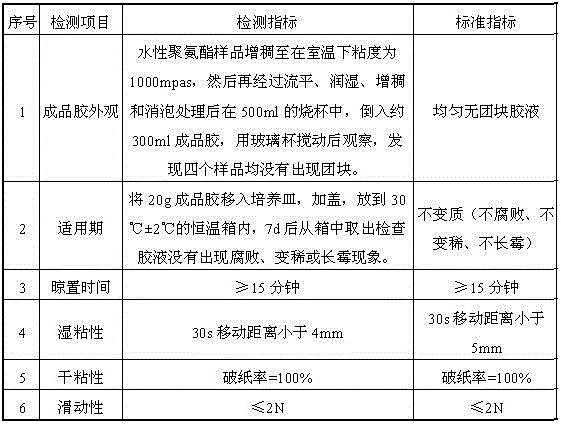

Cationic waterborne polyurethane resin for wallpaper glue

InactiveCN105331322AImprove permeabilityPromote cross-linking reactionPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention relates to cationic waterborne polyurethane resin for wallpaper glue. The waterborne polyurethane resin is prepared from, by weight, 70-100 parts of polyhydric alcohols, 50-90 parts of polyisocyanates, 3-30 parts of first chain extender, 3-18 parts of second chain extender and 2.5-8 parts of salt-forming agent. The invention further discloses a preparation method of the cationic waterborne polyurethane resin. The cationic waterborne polyurethane resin is non-toxic, good in performance and simple in preparation method and construction process.

Owner:LANZHOU SCISKY AQUEOUS POLYMER MATERIAL CO LTD

Flame-retardant fireproof wire and cable material and preparation method thereof

InactiveCN109456535ALow thermal degradation rateHigh oxygen indexPlastic/resin/waxes insulatorsAcrylic resinTributyl citrate

The invention belongs to the technical field of wires and cables and discloses a flame-retardant fireproof wire and cable material and a preparation method thereof. The flame-retardant fireproof wireand cable material is prepared from polypropylene resin, modified acrylic resin, methyl vinyl silicon rubber, tributyl citrate, nano silicon dioxide, dicumyl peroxide, platinic hydroxide, polyimide, zinc stearate, a silane coupling agent, white carbon black, an anti-aging agent and an accelerant, wherein a weight ratio of nano silicon dioxide to dicumyl peroxide to platinic hydroxide is (2.2-5.8):(1.5-3.6):(0.5-1.2). By adoption of a reinforcing system formed by nano silicon dioxide, dicumyl peroxide and platinic hydroxide, heat resistance and flame retardation of the flame-retardant fireproofwire and cable material are improved.

Owner:长沙浩然医疗科技有限公司

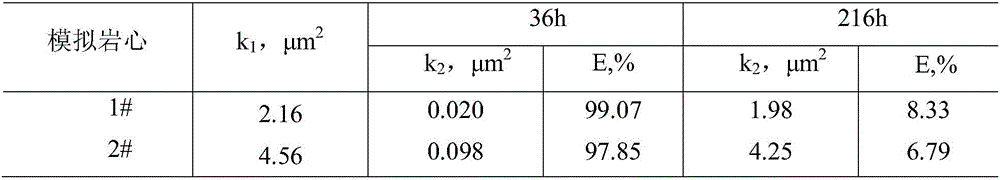

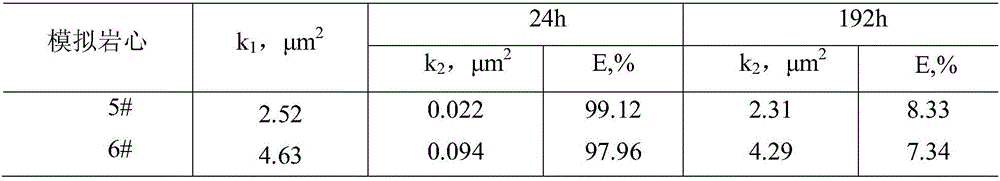

Gel temporary plugging agent

InactiveCN106590560AAvoid toxicityAvoid irritationDrilling compositionAntioxidantHexamethylenetetramine

The invention discloses a gel temporary plugging agent. The gel temporary plugging agent is prepared from, by mass, 0.3-0.4% of partially hydrolyzed polyacrylamide, 0.03-0.08% of phenol crosslinking agent, 0.03-0.08% of aldehyde crosslinking agent, 0.05-0.2% of water soluble polyvinyl alcohol, 0.05-0.5% of hydrochloric acid or acetic acid, 0.2-0.5% of antioxidant and the balance water, and the sum of the mass percents of all the components is 100%, wherein the phenol crosslinking agent is one of combination of resorcinol and hydroquinone, the aldehyde crosslinking agent is urotropin, and the antioxidant is one or combination of diphenylamine, p-phenylenediamine and sodium fluoborate. The gelling time of the gel temporary plugging agent is adjustable in the range of 5-50 h, the gel breaking time is adjustable in the range of 120-240 h, after gel breaking, the viscosity is measured by a rotational viscometer at the shear rate of 70 / s to be 5-10 mPa.s, which indicates thorough gel breakage, and therefore the gel temporary plugging agent can be suitable for most conventional oil deposit.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method of promoting polyolefin grafting reaction

The invention discloses a method of promoting polyolefin grafting reaction. The method includes following steps: performing plasma treatment on polyolefin to obtain surface-modified olefin; well mixing the surface-modified olefin, polar monomer, a solution containing an initiator and an antioxidant, putting into an extruder for reaction, and subjecting extrudate to traction, cooling, drying and cutting into particles to obtain polar compound graft modified polyolefin particles. Plasma is utilized to modify polyolefin, so that number of polar groups on the surface of polyolefin can be increased, polarity of polyolefin can be improved, and improving of compatibility with a polar compound in the extruder is facilitated; the polar groups introduced by the plasma can be utilized for condensation reaction with the polar compound in the extruder to graft the polar compound onto polyolefin, and the polar compound can be further grafted onto polyolefin by utilizing the initiator, so that grafting efficiency can be improved greatly.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI +1

Preparation method of titaniferous montmorillonite nanocomposite

InactiveCN104326481AFully dispersedHigh activityPhysical/chemical process catalystsOther chemical processesCross-linkSlurry

The invention discloses a preparation method of a titaniferous montmorillonite nanocomposite. The preparation method is characterized by comprising the following steps: (1) naturally airing the raw ores of calcium-based montmorillonite, and soaking the raw ore powder in water so that montmorillonite particles can be dispersed in water; (2) adding sodium pyrophosphate to the solution and stirring, standing, and then extracting the top slurry and abandoning medium residue; (3) drying the high-purity top slurry to obtain the high-purity montmorillonite product; (4) weighing the high-purity montmorillonite, adding acetone and water to prepare a suspension and stirring; slowly and dropwise adding an appropriate amount of Ti(n-C4H9O)4 to an appropriate amount of hydrochloric acid solution to have a reaction, and then standing at a room temperature; (5) slowly and dropwise adding the prepared titanium cross-linking agent solution to the montmorillonite suspension under the condition of stirring, reacting at a crosslinking temperature, stopping stirring and standing overnight; (6) centrifugally separating the overnight product, and washing by use of deionized water until no chloride ion is left through inspecting by use of an AgNO3 solution; (7) drying the separated solid in a vacuum drying oven; (8) crushing the dried solid to obtain a primary Ti-PILCs product, and then baking at a high temperature to obtain the final product.

Owner:GUIZHOU UNIV

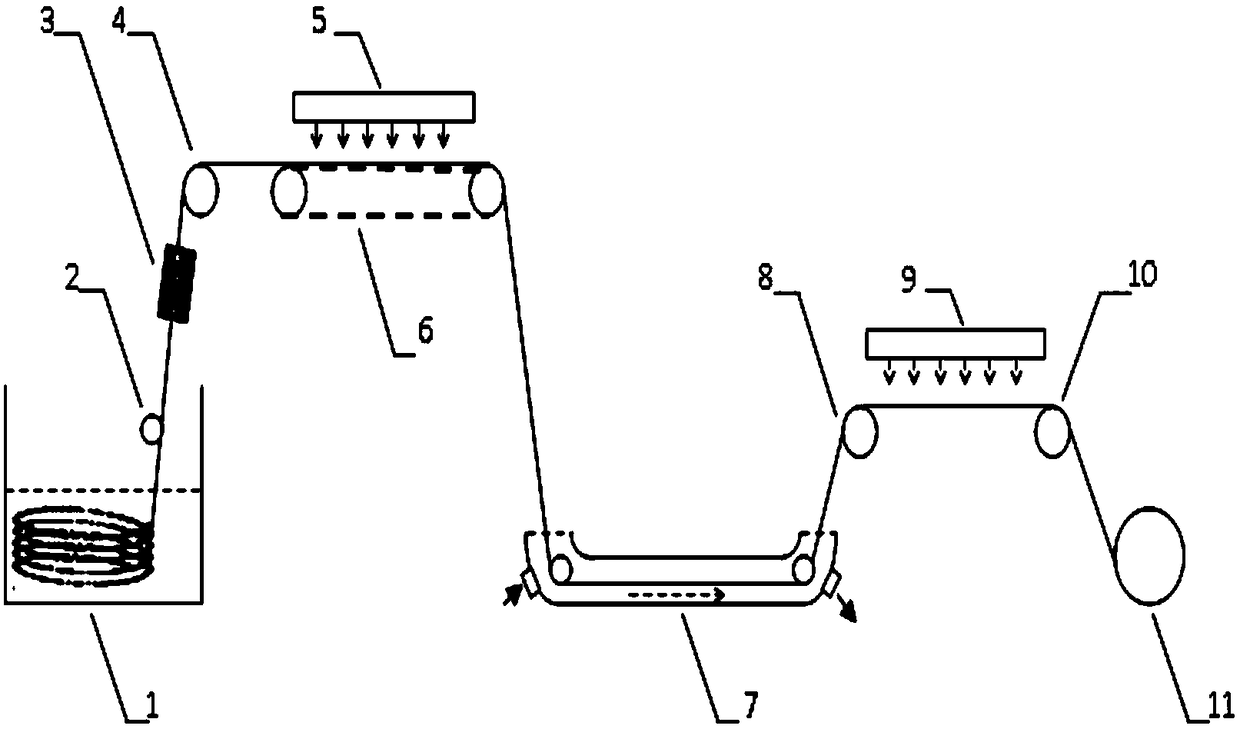

Apparatus and method for continuously preparing hollow fiber composite membrane

The invention relates to an apparatus and a method for continuously preparing a hollow fiber composite membrane. The method comprises: placing a hollow fiber composite membrane in a dip coating devicefilled with a water phase monomer solution, carrying out infiltrating treatment for a certain time, and drying; transferring to a pressure-resistant glass pipe filled with a cross-linking agent organic phase solution, wherein the water phase monomer on the fiber membrane surface and the cross-linking agent are subjected to an interface polymerization functionalization reaction, such that a polyamide and polyimide functional layer is attached onto the surface of the fiber membrane; immobilizing the new coating by using a certain method; and finally winding the hollow fiber composite membrane into a bundle. According to the present invention, with the apparatus and the method, the problem that the hollow fiber composite membrane cannot be industrially continuously produced in the prior artis solved, the consumption of the organic solution is low, the energy consumption is low, the method is simple and easy to perform, the maneuverability is strong, the running cost is low, and the continuous production can be achieved.

Owner:XINJIANG DELAND

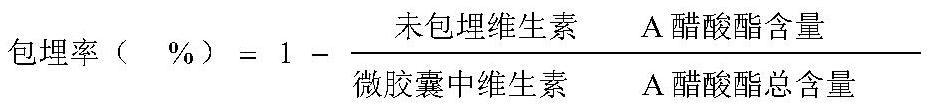

Vitamin A acetate microcapsule and preparation method thereof

ActiveCN112107555AEasy to optimizePromote carbonyl reactionOrganic active ingredientsCosmetic preparationsAntioxidantEmulsion droplet

The invention discloses a vitamin A acetate microcapsule and a preparation method thereof. The method comprises the following steps: uniformly mixing gelatin with sugar, an emulsifying agent, a thickening agent, metal inorganic salt and water, adding vitamin A acetate molten oil containing an antioxidant, performing high-speed shearing, performing high-pressure homogenizing emulsification and performing micron filtration to obtain an emulsion; performing spray drying on the obtained emulsion, and embedding emulsion droplets in starch to obtain microcapsule particles; and performing drying, screening and crosslinking to obtain the vitamin A acetate microcapsule. According to the preparation method, emulsion preparation is mainly improved, so that particle size distribution is more uniform,the embedding effect on the vitamin A is better, the loss rate of vitamin A acetate is low in the spray drying process, the particle uniformity is good, the embedding effect is good, and the product storage stability is high. Especially, the metal inorganic salt added into the formula can promote crosslinking, effectively reduce the crosslinking temperature and shorten the crosslinking time.

Owner:WANHUA CHEM GRP CO LTD

Method for manufacturing photocatalysis self-cleaning mask

ActiveCN103989269AImprove bindingPromote cross-linking reactionProtective garmentRespiratorEngineering

The invention provides a method for manufacturing a photocatalysis self-cleaning mask. The method is characterized by including the specific steps of firstly, preparing TiO2 / SiO2 mixed sol; secondly, removing impurities on the mask, cleaning the mask, and conducting radio frequency plasma preprocessing on the mask; thirdly, soaking the mask where radio frequency plasma preprocessing is conducted in the TiO2 / SiO2 mixed sol, conducting the twice-soaking and twice-rolling process, drying the mask for three minutes to eight minutes at the temperature of 70 DEG C to 90 DEG C, curing the mask for one minute to five minutes at the temperature of 100 DEG C to 150 DEG C, cleaning the mask through deionized water, drying the mask under the natural condition, and obtaining the photocatalysis self-cleaning mask. The photocatalysis self-cleaning mask manufactured through the method is good in self-cleaning effect and durable in effect. The method can be applied to industrial production.

Owner:DONGHUA UNIV

Liquid bandage used in field

InactiveCN105797200AReasonable formulaPlay an antibacterial and hemostatic effectBandagesAntibiosisCellulose acetate

The invention discloses a liquid bandage used in field. The liquid bandage used in field comprises chitosan, cellulose acetate, bullfrog antibacterial peptide, polyvinyl alcohol, polyvinylpyrrolidone, ovalbumin and glycerin. A preparation method of the field liquid bandage comprises dissolving the bullfrog antibacterial peptide in a protein solution with content of 6% to obtain a chitosan-acetic acid solution with content of 2%, taking polyvinyl alcohol and polyvinylpyrrolidone, uniformly stirring the polyvinyl alcohol and polyvinylpyrrolidone, dissolving the mixture in injection water according to a W / V ratio of 1.0-1.5: 100 to obtain a solution, dissolving cellulose acetate in a solvent, carrying out magnetic stirring to obtain a uniform solution, blending the above solutions, dropwisely adding a glycerinum solution into the mixed solutions and adjusting pH to 5.5-6.8 so that the liquid bandage is obtained. The liquid bandage used in field has a reasonable formula. The bullfrog antibacterial peptide has effects of antibiosis, haemostasis and ovalbumin crosslinking reaction promotion and improves a film forming rate. Cellulose acetate is a film forming material and a good slow release material and improves bullfrog antibacterial peptide use effects.

Owner:TIANJIN PHARMACN MEDICAL TECH

Method for improving weather resistance and mechanical property of bamboo plywood

ActiveCN109015954AHigh strength propertiesExcellent mechanical propertiesOther plywood/veneer working apparatusAldehyde/ketone condensation polymer adhesivesWeather resistanceAdhesive

The invention discloses a method for improving the weather resistance and the mechanical property of bamboo plywood, and belongs to the technical field of bamboo processing. The method for improving the weather resistance includes the steps that a high-voltage electric field is applied when bamboo pieces coated with adhesives are assembled and hot-pressed, and the direction of the electric field is the same as the pressing direction of hot-pressing, and further includes the following steps of drying bamboo pieces, coating the treated bamboo pieces with the adhesives, assembling the bamboo pieces, hot-pressing and applying the high voltage electric field, shutting the high voltage electric field after reaching the hot-pressing time, pressure relief, cooling, and pre-forming and standby application. The method for improving the weather resistance and the mechanical property of the bamboo plywood can solve the problems of poor weather resistance, poor gluing property and mechanical property of the bamboo plywood, and has the advantages of low cost and high production efficiency.

Owner:NANJING FORESTRY UNIV

Biological full-degradable plastic film and preparation method thereof

The invention discloses a biological full-degradable plastic film, which is mainly prepared from the following raw materials by weight: 48-72 parts of cassava starch, 35-45 parts of glycerin, 35-45 parts of polyvinyl alcohol, and 4-6 parts of hydrophilic nano-silica, wherein the cassava starch and hydrophilic nano-silica are in a weight ratio of 12:1. The preparation method of the biological full-degradable plastic film includes: conducting high-speed mixing, banburying and film casting on the raw materials, then subjecting the obtained plastic film to ultraviolet radiation treatment, and then performing drying. The biological full-degradable plastic film provided by the invention has the advantages of excellent mechanical properties, fast degradation speed, simple formula, and low production cost, etc.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Rubber crawler belt for excavator and preparation method thereof

The invention discloses a rubber crawler belt for an excavator, belonging to the technical field of rubber crawler belts. The rubber crawler belt comprises the following raw materials by weight: 50 to 60 parts of isoprene rubber, 20 to 25 parts of butadiene-acrylonitrile rubber, 15 to 18 parts of butadiene rubber, 10 to 15 parts of silicone rubber, 1 to 2 parts of paraffin, 5 to 8 parts of zinc oxide, 2 to 4 parts of stearic acid, 32 to 35 parts of silica-alumina carbon black, 1 to 2 parts of sulfur, 13 to 16 parts of plant oil, 1 to 2 parts of an anti-scorching agent, 1 to 3 parts of a promoter, 0.2 to 0.6 part of an anti-oxidant and 0.5 to 1 part of a plasticizer. The invention also discloses a preparation method for the rubber crawler belt. The rubber crawler belt provided by the invention has good physical properties and can meet demands on usage in severe environments.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

Method for preparing polarizer

InactiveCN102311552AImprove pinning efficiencyGood flexibilityPolarising elementsCross-linkPolarizer

The invention discloses a polarizer preparing method, specifically, a method for preparing a polarizer. The method comprises the following steps of performing first crosslinking through an inorganic cross-linking agents; performing second crosslinking through organic cross-linking agents so as to effectively enhance the crosslinking reactions; and then preparing a polarizer having multiple advantages. The advantages include, for example, excellent optical performances, film rupture and wrinkling prevention, area increase and thickness decrease, and stability of height size in the longitudinal and the horizontal directions, etc. The method disclosed in the invention can achieve desired technique processability and production efficiency.

Owner:DONGWOO FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com