Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117results about How to "With anti-ultraviolet function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

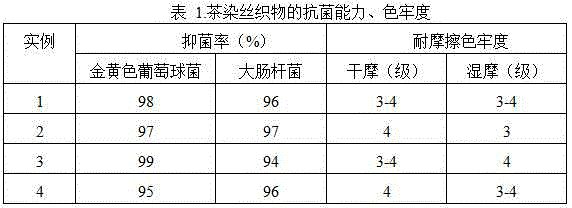

Modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide

ActiveCN102677465AImprove adsorption efficiencyRealize functional fillingLiquid/gas/vapor removalDry-cleaning apparatus for textilesUltravioletEngineering

The invention relates to modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide. The modified tussah silk fabric is prepared by the steps in sequence: weaving the tussah silk fabric by utilizing tussah filament, preparing finishing liquor and finishing tussah silk fabric; and the technical problems that the existing textile materials in the modification technology can not effectively improve the properties that the tussah silk fabric has damage to the environment, is easy to wrinkle, not anti-bacterial and easy to shrink, has poor dyeing property, poor comfortableness and function, and the like can be solved, the comprehensive properties that the tussah silk fabric is anti-wrinkle, soft, anti-bacterial, shrink-proof, self-cleaning and ultraviolet ray-resistant, as well as the adsorption efficiency of dye, and the like can be improved and enhanced, and the tussah silk fabric has the technical benefits of being lower in preparation cost, simple in process, environment-friendly and easy to realize, etc.

Owner:EASTERN LIAONING UNIV

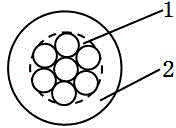

Method for preparing functional composite woolly elastic fiber

The invention relates to a method for preparing functional composite woolly elastic fiber, comprising the following steps: (1) preparing uvioresistant fine-denier polyester pre-oriented yarn (a) with the method of adding uvioresistant masterbatch; (2) carrying out composite spinning with low viscosity polyester (PET) or modified PET and polyethylene terephthalate (PTT) to prepare fully-drawn self-winding composite elastic fiber (b); and (3) stretching and false twisting the uvioresistant fine-denier polyester pre-oriented yarn (a) on a false-twisting texturing machine, converging the uvioresistant fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) in the position of a second roller, combining the uvioresistant the fine-denier polyesterpre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) through an interlacing machine, shaping the uvioresistant the fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) through a second heating box, and winding the uvioresistant the fine-denier polyester pre-oriented yarn (a) and the fully-drawn self-winding composite elastic fiber (b) into a composite yarn, contracting the PET / PTT self-winding composite elastic fiber with the elasticity and the contractibility in the core layer of the composite woolly elastic fiber to show the elasticity of the composite yarn, and making the uvioresistant fine-denier polyester pre-oriented yarn to float on the surface layer of the composite yarn to show the uvioresistant performance of the composite yarn. Therefore, the uvioresistant composite woolly elastic fiber is prepared.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

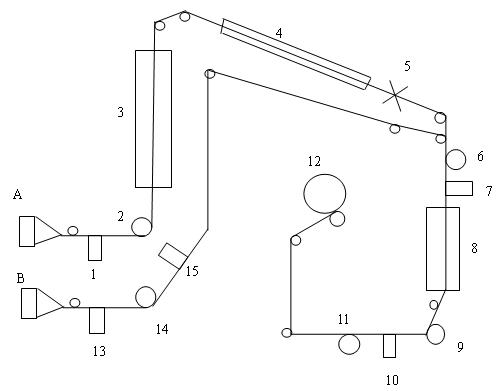

Multi-agent melanin precursor hair dye and utilization method thereof

ActiveCN106038411AReduce harmGood for healthCosmetic preparationsHair cosmeticsCarboxylic acidNuclear chemistry

The invention discloses a double-agent melanin precursor hair dye and a three-agent melanin precursor hair dye. The double-agent melanin precursor hair dye comprises an agent A and an agent B; the three-agent melanin precursor hair dye comprises an agent A, an agent B and an agent C; the agent A and the agent C both comprises melanin precursors, common hair dye auxiliaries and water; the common hair dye auxiliaries refer to one or more of a wetting agent, a thickening agent, a surfactant, a moisturizing agent and a pH value regulating agent. By combination of advantages of chemical synthesized hair dye and natural hair dye, compound enzyme liquor in natural edible fungi is extracted, amino acids are subjected to bioconversion to synthesize melanin precursor substances such as hallachrome, 5,6-dyhydroxyindole and 5,6-dyhydroxyindole-2-carboxylic acid, skin irritation and allergization are avoided, high safety is achieved, and natural black hair dyeing effects are kept. In addition, due to various agent type choices, the multi-agent melanin precursor hair dye has a great popularization and application value in the field of hair dye preparation.

Owner:珠海丝彩生物科技有限公司

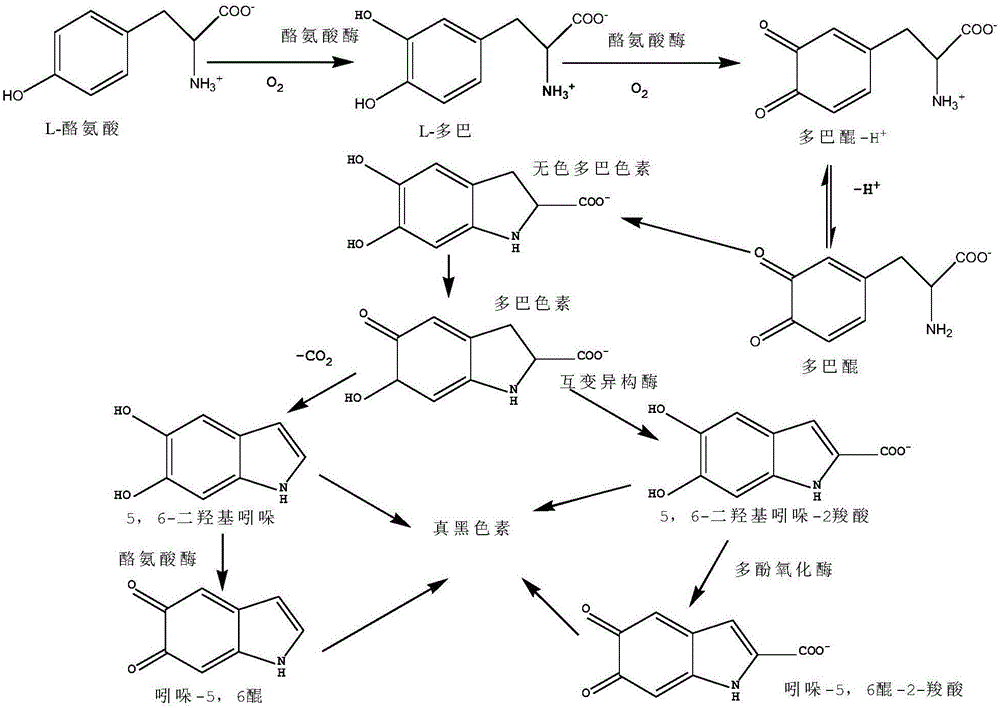

Tooling fabric with cooling function and uvio-resistant function

The invention relates to tooling fabric with a cooling function and an uvio-resistant function. A method for manufacturing the tooling fabric with the cooling function and the uvio-resistant function comprises a first step of using cooling master batch as raw materials and manufacturing the cooling master batch to slicing sheets, a second step of drying the slice sheets, a third step of carrying out spinning on the slicing sheets through a spinning box to manufacture nylon base cooling fibers, a fourth step of adopting a siro spinning technology to spin cotton fibers and the nylon base cooling fibers into blended yarn, and a fifth step of adopting technological measures of 'early opening, later weft insertion and on-machine tension slightly larger' to carry out weaving. A formula of the cooling master batch comprises PA6, bowlder powder, zirconium dioxide powder, silicon dioxide powder, stearic acid dispersants, polystyrene dispersants, low molecular wax dispersants and titanate coupling agents. The tooling fabric has functions of fast heat absorption and fast heat dissipation, and an everlasting cooling feature is guaranteed. Meanwhile, the tooling fabric further has a notable uvio-resistant feature.

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

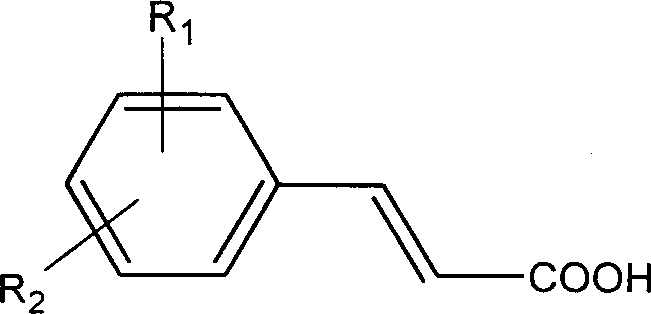

Organosilicon modified cinnamate as reactive ultraviolet ray absorbent and its prepn and application

InactiveCN1506367AWith anti-ultraviolet functionGroup 4/14 element organic compoundsFibre treatmentUltravioletUv absorber

The present invention relates to organoslicon modified cinnamate as reactive ultraviolet ray absorbent and its preparation process and application in preparing organic siloxane polymer and composite ultraviolet ray resisting material.

Owner:河南省科学院同位素研究所

Anti-ultraviolet black master batch and preparation method thereof

The invention relates to an anti-ultraviolet black masterbatch, the mass percentage of each component is: carbon black 30%-50%; carrier resin 25%-45%; dispersant 0.5%-8%; high temperature stabilizer 3%- 8%; anti-ultraviolet stabilizer 0.5%-13%, also relates to the preparation method of this color masterbatch, comprises the following steps: take each component by weight ratio, and add in the high-speed mixer respectively, at 1500-1800r / Stir for 10-20 minutes at a speed of 1 min, and after mixing evenly, discharge the material into a twin-screw extruder, melt and knead at a temperature of 180°C to 260°C, extrude and granulate, cool, dry, and pack to obtain The required black masterbatch, the black masterbatch has anti-ultraviolet function and can meet the needs of use.

Owner:TIANJIN HONGDA COLOR MASTERBATCH CO LTD

Preparation technology of far-infrared cotton fiber

ActiveCN104695227AGood antibacterial effectImprove adsorption capacityBiochemical fibre treatmentVegetal fibresCross-linkApocynum venetum

The invention discloses a preparation technology of far-infrared cotton fiber. The preparation technology comprises the steps of preparing raw materials, treating the raw materials, preparing a far-infrared mixed solution, carrying out coating treatment and spinning. The preparation technology is simple in method; the far-infrared coating mixed solution is prepared by mixing far-infrared ceramic powder with a resin bonding agent, a cross-linking agent, a dispersing agent and the like; the treated raw material fiber is coated with the far-infrared coating mixed solution, and the far-infrared coating mixed solution is firmly combined with the raw material fiber, so that the far-infrared fiber is good in effect. An ultraviolet light absorber is also added to the far-infrared coating mixed solution and is dipped into the cotton fiber, so that the finished product fiber has an ultraviolet resistant function. The cotton fiber is refined by alkaline biological enzyme, and alkali treatment is replaced, so that the preparation technology is low in damage to fiber and is beneficial to maintaining fiber strength; apocynum venetum fiber and activated carbon fiber are added into the raw material fiber for use, so that the finished product fiber also has a good antibacterial effect.

Owner:浙江世纪晨星纤维科技有限公司

Polyamide-based cooling fiber and yarn

The invention relates to functional fiber and particularly relates to polyamide-based cooling fiber and yarn. The polyamide-based cooling fiber is prepared by the following method: (1) taking cooling masterbatch as a raw material, and cutting the cooling masterbatch into slices; (2) drying the slices; and (3) spinning the slices through a spinning box to produce the polyamide-based cooling fiber, wherein a formula for the cooling masterbatch comprises the following components: PA6, jade powder, zirconium dioxide powder, silica powder, stearic acid dispersant, polystyrene dispersant, low molecular wax dispersant and titanate coupling agent. The polyamide-based cooling fiber and yarn have the functions of fast heat absorption and fast heat dissipation so as to ensure lasting cooling characteristic.

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

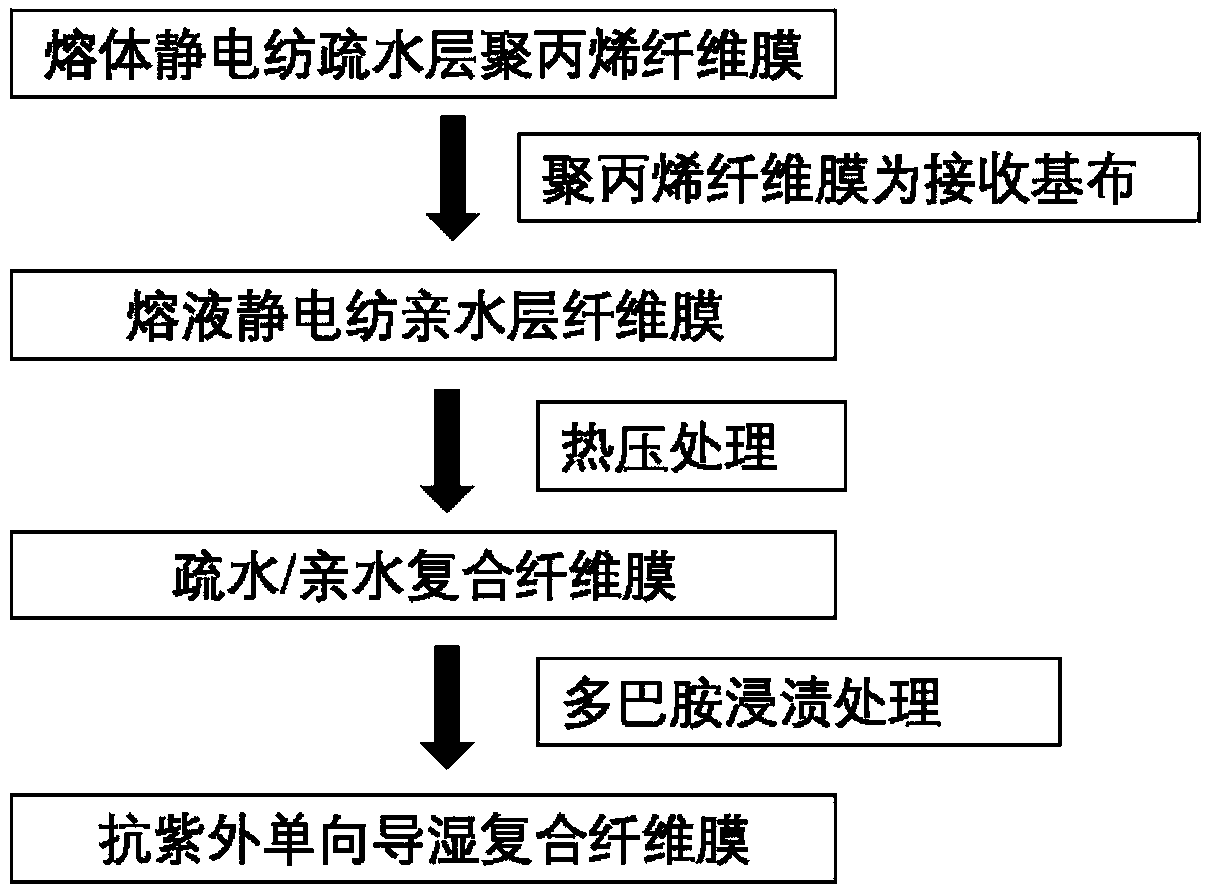

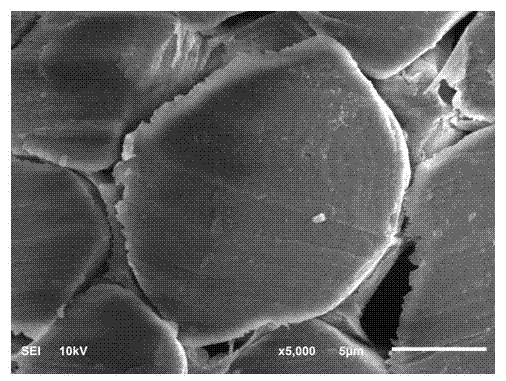

Anti-ultraviolet unidirectional-moisture-permeable fiber composite and preparing method thereof

InactiveCN109322058AGood one-way moisture transferFunction increaseArtificial filaments from cellulose derivativesNon-woven fabricsMicro nanoPolymer science

The invention belongs to the field of functional micro-nano fiber composites, and particularly relates to an anti-ultravoilet unidirectional-moisture-permeable fiber composite and a preparing method thereof. The fiber composite comprises a polypropylene layer and a hydrophilic polymer and ultraviolet absorber mixture layer which are integrally combined. Polydopamine deposits on and adheres to thesurfaces and the interiors of the polypropylene layer and the hydrophilic polymer and ultraviolet absorber mixture layer. The preparing method includes the steps of dissolving an ultraviolet absorberand a hydrophilic polymer in an organic solvent to form a spinning solution, conducting static spinning and then hot-pressing treatment with a melt static spinning polypropylene fiber material as thereceiving substrate, and placing the material in a Tris-HCl buffer solution with dissolved dopamine for impregnation modification to prepare the anti-ultravoilet unidirectional-moisture-permeable fiber composite. The material has good unidirectional moisture-permeable and anti-ultraviolet functions and is stable in integration structure, simple in composition and structure, simple in preparing process and wide in application prospect.

Owner:SHANGHAI UNIV OF ENG SCI

Modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide

ActiveCN102677465BImprove adsorption efficiencyRealize functional fillingLiquid/gas/vapor removalDry-cleaning apparatus for textilesUltravioletEngineering

The invention relates to modified tussah silk fabric with functionalized nanometer chitosan and nanometer titanium dioxide. The modified tussah silk fabric is prepared by the steps in sequence: weaving the tussah silk fabric by utilizing tussah filament, preparing finishing liquor and finishing tussah silk fabric; and the technical problems that the existing textile materials in the modification technology can not effectively improve the properties that the tussah silk fabric has damage to the environment, is easy to wrinkle, not anti-bacterial and easy to shrink, has poor dyeing property, poor comfortableness and function, and the like can be solved, the comprehensive properties that the tussah silk fabric is anti-wrinkle, soft, anti-bacterial, shrink-proof, self-cleaning and ultraviolet ray-resistant, as well as the adsorption efficiency of dye, and the like can be improved and enhanced, and the tussah silk fabric has the technical benefits of being lower in preparation cost, simple in process, environment-friendly and easy to realize, etc.

Owner:EASTERN LIAONING UNIV

Multifunctional one-way moisture guiding fabric

InactiveCN109208165AEasy to dyeWith one-way moisture directionWeft knittingArtifical filament manufactureYarnFiber

The invention discloses a multifunctional one-way moisture guiding fabric, and belongs to the technical field of weaving. A double-side knitting machine carries out weaving to form a grey fabric witha double-side structure, the inner layer of the grey fabric includes a mesh structure formed by a tucking method, the surface area of the outer layer of the grey cloth is larger than that of the innerlayer, yarns forming the inner layer are polyethylene yarns or polyethylene combined fiber yarns, and yarns forming the outer layer has a high water absorption performance. The multifunctional one-way moisture guiding fabric serves as a double-side knitting mesh cloth, feels cool, is easy to dye and has one-way moisture guiding and ultraviolet resistant functions.

Owner:QINGDAO JECELONG HIGH TECH CO LTD

Waterproof crack-resisting coating and preparation method thereof

InactiveCN107987647AHigh elongationResponsiveAntifouling/underwater paintsPaints with biocidesCelluloseCrack resistance

The invention discloses a waterproof crack-resisting coating and a preparation method thereof, and relates to the field of coating materials. The waterproof crack-resisting coating is prepared from the following components in parts by weight: 40 to 80 parts of elastic emulsion, 15 to 20 parts of ZnO-CeO2 particles, 10 to 30 parts of Portland cement, 20 to 40 parts of quartz sand, 10 to 30 parts ofcomplexing agent, 10 to 30 parts of cellulose, 10 to 30 parts of water reducing agent, 3 to 5 parts of defoaming agent, 3 to 5 parts of dispersing agent, 3 to 5 parts of leveling agent and 3 to 5 parts of thickening agent. The waterproof crack-resisting coating provided by the invention has the advantages of excellent waterproof and crack resistance, scrubbing resistance, pulverization resistance, stain resistance, weather fastness, good aging resistance, storage stability, low cost, greenness and environment friendliness.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Preparation method and usage of special tea dye for silk

InactiveCN102911517ASimple and elegant colorHas antibacterial functionNatural dyesMordantsColour fastnessSocial benefits

The invention provides a preparation method and usage of special tea dye for silk. The method comprises the steps of making tea for dye through instant fixation, cell disruption, low temperature storage or rapid drying with fresh tea leaves, taking alkalescent salt or alcohol as a solvent, extracting silk tea dye with the tea polyphenol content greater than 0.3% from the tea for the dye, selecting appropriate dyeing conditions, and dyeing the silk with the dye. According to the method, the tea shape can be faded so that the cost can be lowered; the tea dye can be combined with a mordanting assistant on a fibre for color fixation; the color fastness can be improved; summer and autumn tea resources can be utilized to research and develop tea dye silk fabrics which are environment-friendly and have simple, unsophisticated and quietly elegant colors as well as antibacterial and uvioresistant functions; the market prospect is wide; great economic benefits can be produced; and great social benefits can also be achieved.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Method for preparing nano-TiO2 nylon 66 resin and fibre having anti-ultraviolet function

InactiveCN104629042AWith UV shielding functionWith sun protection and heat insulationMelt spinning methodsMonocomponent polyamides artificial filamentPolyesterYarn

The invention discloses a method for preparing nano-TiO2 nylon 66 resin and fibre having an anti-ultraviolet function, belonging to the technical field of fibre and textiles. The method disclosed by the invention comprises the following steps: injecting TiO2 suspension into a polymer melt at the outlet of a flash evaporation pump in the condensation polymerization process of nylon 66 at first, and then, carrying out post condensation polymerization of the polymer melt injected with the TiO2 suspension so as to obtain nano-TiO2 nylon 66 resin; and then, carrying out melt spinning of the nano-TiO2 nylon 66 resin so as to obtain nano-TiO2 nylon 66 fibre. The nylon 66 fibre having excellent properties and the anti-ultraviolet protection function can be manufactured from the nylon 66 resin manufactured by the invention through a POY-DTY (Polyester Pre-Oriented Yarn-Draw Texturing Yarn) spinning technology; and the fibre can be processed into high-quality clothes or costume materials having gentle lustre, soft hand feeling and comfort, good air permeability, abrasion resistance and easy rinsing property and having anti-ultraviolet and nursing functions.

Owner:LIAONING YINZHU CHEMTEX GROUP

Ultraviolet-resistant fiber and production method thereof

InactiveCN102443875AStrong UV resistanceWith anti-ultraviolet functionMonocomponent polyesters artificial filamentArtifical filament manufactureYarnFiber

The invention discloses ultraviolet-resistant fiber which comprises fiber yarns, wherein the fiber yarns contain ultraviolet-resistant nano particles TiO2; and the ultraviolet protection factor (UPF) of the fiber yarns is greater than 50. A production method of the ultraviolet-resistant fiber, designed by the invention, comprises a section fusing step. The section fusing step comprises the following measure: polymerizing the ultraviolet-resistant nano particles TiO2 into polyester to form ultraviolet-resistant polyester sections, wherein the addition amount of the nano particles TiO2 accounts for 22.5% of the total weight of the ultraviolet-resistant polyester sections; and the particle diameter of the nano particles TiO2 is 50nm-80nm. The ultraviolet-resistant fiber obtained in the invention has the UPF greater than 50, is high in ultraviolet-resistant capability, can meet the life needs of people, simultaneously is good in favorable wool-like effect, has an ultraviolet-resistant function and simultaneously has the hand feeling and efficacy of wool. The production method of the ultraviolet-resistant fiber obtained in the invention is simpler in production process and can be generally used.

Owner:TAICANG RONGWEN SYNTHETIC FIBER

Anti-termite cable material and cable using same

InactiveCN103980605AWith anti-ultraviolet functionNo yellowing phenomenonPlastic/resin/waxes insulatorsInsulated cablesBifenthrinCorrosion resistant

The invention relates to the technical field of wires and cables and in particular relates to an anti-termite cable material. The cable material is characterized by being prepared from the following raw materials in parts by weight: 30-40 parts of ethylene-tetrafluoroethylene copolymer, 30-40 parts of propylene-tetrafluoroethylene copolymer, 12-18 parts of glass fibers, 2-4 parts of magnesium hydroxide, 2-4 parts of mica powder, 2-4 parts of carbon black or titanium dioxide, 1-3 parts of bifenthrin and 3-5 parts of methylbenzene. The invention further discloses a manufacturing method of the cable material. The cable material mainly has the beneficial effects of being outstanding in anti-termite and anti-mouse performance and excellent in anti-ultraviolet-aging performance, has the advantages of being high in electrical insulativity, relatively heat-resistant, relatively corrosion-resistant, relatively steam-resistant, relatively oil-resistant, relatively fire-resistant, relatively flame-retardant, relatively high in mechanical strength and the like, and is easy to manufacture; the production speed is relatively high and the thickness can be accurately controlled when the cable material is used for producing the wires and the cables.

Owner:STATE GRID CORP OF CHINA +1

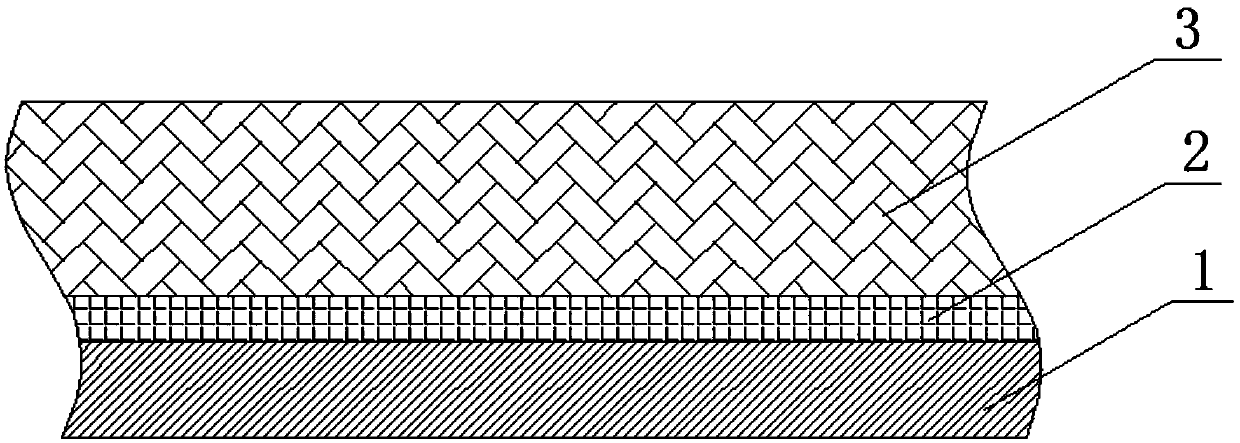

Ultraviolet-proof fabric

InactiveCN109514942AImproves UV protectionImprove breathabilitySynthetic resin layered productsClothingsYarnGraphene coating

The invention provides an ultraviolet-proof fabric. The fabric comprises a moisturizing inner layer, an ultraviolet-proof middle layer and a breathable outer layer in turn from inner to outer; all thelayers are bonded together through adhesives in the manner of hot melt adhesive hot-pressing compounding; the moisturizing inner layer is made of a spunlace nonwoven fabric; the ultraviolet-proof middle layer is made of a polytetrafluoroethylene film with a graphene coating on the outer layer; the breathable outer layer is weaved from ultraviolet-proof yarns. The fabric has an excellent ultraviolet-proof property and has excellent antistatic, moisture-absorbing, heat-radiating and antimicrobial effects.

Owner:SWOTO PROTECTION & TECH CO LTD +1

Silver-containing graphene slurry, preparation method thereof and product prepared from slurry

ActiveCN110004713AImprove conductivityImprove antibacterial propertiesBiochemical fibre treatmentDyeing processSlurryGraphene

The invention relates to the technical field of clothing processing, in particularly relates to silver-containing graphene slurry, a preparation method thereof and a product prepared from the slurry.The silver-containing graphene slurry comprises, by weight, 0.2-10 parts of graphene, 0.1-15 parts of emulsifying agents, 10-18 parts of polar solvents, 1-10 parts of Tollens' reagents, 0.1-5 parts ofreducing agents, 5-40 parts of binding agents and 0.2-8 parts of thickening agents. The prepared silver-containing graphene slurry has excellent electrical conductivity and antibacterial property, bacteria on clothing can be greatly decreased, human health is protected, and static electricity is removed. Besides, the prepared silver-containing graphene slurry has the functions of electrifying, heating, transmitting far infrared rays, resisting ultraviolet rays, insulating heat and the like, and the slurry can be used for textile, leather and plastic products by modes such as printing and coating and has a wide application range.

Owner:BEIJING JLSUN HIGH TECH CO LTD

Preparation method of waterborne strippable coating

InactiveCN106833342AGood flexibilityFeel goodAnti-corrosive paintsPolyurea/polyurethane coatingsDrying timeMaterials science

The invention discloses a preparation method of a waterbornestrippable coating and belongs to the field of coatings. The preparation method comprises following operation steps: deionized water is added to a container, a wetting agent, a dispersing agent and a thickening agent are added sequentially under stirring at a rotating speed of 200-600 r / min, and the materials are stirred for 5-10 min; inorganic filler is added, and dispersion is performed for 20-40 min at a rotating speed of 1,500-2,500 r / min; the rotating speed is regulated to be 700-1,300 r / min, a polyurethane emulsion and a styrene-acrylic emulsion are added, and stirring is performed for 15-20 min; the rotating speed is regulated to be 200-600 r / min, a flatting agent, a coalescing agent, an organic silicon stripping agent and a waterborne corrosion inhibitor are added sequentially, and pH is regulated to be 8-9. According to the preparation method of the waterbornestrippable coating, tensile strength, breaking elongation and 180-degree stripping strength are greatly improved, drying time is short, and resistance to water and a 3% NaCl solution exceeds 24 h.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

Anti-ultraviolet method for cotton fibers

The invention relates to an anti-ultraviolet method for cotton fibers, and belongs to the technical field of textile materials. The method comprises the following steps: carrying out pad-roll treatment on a sol solution prepared from butyl titanate for the cotton fibers and ethanol, and carrying out steam treatment to form titanium dioxide in the cotton fibers. The method can be suitable for cotton spinning yarn dyeing, and is simple in process and low cost; a fabric prepared from the fibers has the advantages that titanium dioxide powder does not drop during washing and wearing, the anti-ultraviolet performance is durable, and the hand feel is good.

Owner:宜昌佳润纺织有限公司

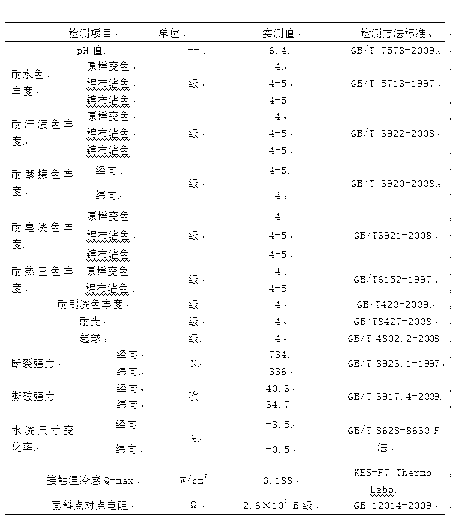

Printing paste containing laccaic acid pigment and printing technology thereof

The invention discloses printing paste containing laccaic acid pigment and a printing technology for cotton fabric and silk fabric thereof. The printing paste containing the laccaic acid pigment is prepared from, by weight, 50-65% of starch raw paste, 2-5% of the laccaic acid pigment, 2-5% of urea, 1-4% of mordant and the balance water. The printing paste containing the laccaic acid pigment is adopted for carrying out printing on the cotton fabric according to the technology of printing, drying, steaming and aftertreatment; the printing paste containing the laccaic acid pigment is adopted for carrying out printing on the silk fabric with a pH value adjusted to be 4-5 according to the technology of printing, drying, steaming and aftertreatment, the printed fabric is bright in color and has an anti-ultraviolet function, laccaic acid pigment printing meets the requirements for ecology and environmental protection, the cotton fabric and the silk fabric printed through the laccaic acid pigment have good color fastness, and colors of printed products can be enriched by using different kinds of the mordant.

Owner:依文服饰股份有限公司

Braid, braid manufacturing method and outdoor chair with braid

InactiveCN105780243AUniform color effectConsistent and uniform multi-color effectStoolsWoven fabricsPolyesterFiber

The invention discloses a braid, a braid manufacturing method and an outdoor chair with the braid. The braid comprises a braid body, wherein the braid body is formed by woven warps and wefts; the warps and the wefts are both made of polyester silk in a woven manner; and the polyester silk is made of a plurality of loose fibers of different colors in a combined manner. The loose fiber is covered by an ultraviolet layer. A chair back and a chair seat both comprise a plurality of warp-wise braids and weft-wise braids which are woven together; the warp-wise braids and the weft-wise braids are both made of the braids. By adopting the braid, the problems that in the prior art, a multi-color braid is not uniform in color, a finished product needs to be dyed, and the service life of an outdoor chair is short can be solved, and the invention provides the braid which is uniform in color and high in color fastness and an outdoor chair which is long in service life.

Owner:海宁市辉腾织带有限公司

Manufacturing process for novel functional fabric

ActiveCN108914622AReduce motion loadEasy to storeDyeing processArray data structureMoisture permeability

The invention discloses a manufacturing process for a novel functional fabric. The manufacturing process mainly comprises the following steps: 1) water spraying of a dyed fabric for setting; 2) calendering before sizing; and 3) one-knife PU resin functional coating treatment: performing one-knife PU resin functional coating treatment on a calendered surface, wherein a functional coating comprises,by mass, 60-70 parts of two-component polyurethane resin, 25-30 parts of one-component polyurethane resin, 5-10 parts of AC glue, 1-3 parts of a silicon-series dry agent, 1-2 parts of a bridging agent and a solvent X, and the usage amount of the solvent X is added with the viscosity of a rubber compound of 15000 CPS as the criterion. According to the invention, a one-knife coating process is adopted, so the novel functional fabric has the functions of low water pressure, high moisture permeability and UV resistance, and further has the advantages of light weight, thinness, easy storage, comfortable wearing, reduced environmental pollution, etc.

Owner:FUJIAN SUNTION TEXTILE SCI & TECH

Coffee carbon polyester fiber elastic carpet and preparation method thereof

InactiveCN103082827AEfficient and uniform dispersionSimple structureFibre treatmentSynthetic resin layered productsPolyesterUltraviolet

The invention relates to a coffee carbon polyester fiber elastic carpet and a preparation method of the coffee carbon polyester fiber elastic carpet. The coffee carbon polyester fiber elastic carpet is characterized by comprising a coffee carbon polyester fiber layer, a dacron non-woven fabric layer and a micro air sac elastic glue layer. The coffee carbon polyester fiber layer, the dacron non-woven fabric layer and the micro air sac elastic glue layer are sequentially stacked from top to bottom. The micro air sac elastic glue layer is used for fixation of coffee carbon polyester fibers. The coffee carbon polyester fiber layer is inserted into the dacron non-woven fabric layer through a tufting big weaving machine in a weaving mode. The micro air sac elastic glue layer coats the back face of the dacron non-woven fabric layer. The coffee carbon polyester fiber elastic carpet has the functions of environment protection, deodorization, ultraviolet resistance and anion diffusion, and has the advantages of being high in elasticity and good in stability and bringing healthy and comfortable touch to consumers.

Owner:DONGHUA UNIV +1

Mica fiber comfortable ecological knitted fabric and knitting method thereof

InactiveCN102433674AImprove thermal conductivityImprove water absorptionWeft knittingEngineeringAbsorption effect

The invention provides a mica fiber comfortable ecological knitted fabric and a knitting method thereof. The mica fiber comfortable ecological knitted fabric is characterized in that the mica fiber comfortable ecological knitted fabric is formed by weaving mica modified filament fibers (mica fiber for short) and polyester filaments and is a combination of plane stitch and double-sided tuck stitch so that the mica fibers finally appear on the back side of the knitted fabric. Therefore, excellent heat conduction and water absorption effect of the mica fibers can be functioned better. The mica fibers are 75D in specification and the polyester filaments are also 75D in specification. By means of raw material selection, reasonable stitch structure and weaving process lines, the heat conduction and water absorption performance of the knitted fabric can be improved obviously, and the knitted fabric has the functions of being anti-static, deodorized and uvioresistant.

Owner:QINGDAO XUEDA GRP

Preparation methods of fatty polyamide fiber fabric with an anti-ultraviolet function

InactiveCN109385885AWith anti-ultraviolet functionSimple processLight resistant fibresAcetic acidEcological environment

The invention provides a preparation method of a fatty polyamide fiber fabric with an anti-ultraviolet function. The method includes: mixing cedar leaf extract liquid, acetic acid, sodium sulphate andwater to obtain a finishing liquid; and after a fatty polyamide fiber fabric is finished in the finishing liquid, performing mordanting treatment to obtain the fatty polyamide fiber fabric with an anti-ultraviolet function. The invention also provides a preparation method of a fatty polyamide fiber fabric, including mixing cedar leaf extract liquid, a mordant, acetic acid, sodium sulphate and water to obtain a finishing liquid; and processing the fatty polyamide fiber fabric in the finishing liquid to obtain the fatty polyamide fiber fabric having an anti-ultraviolet function. The preparationmethods belong to green new techniques, and allow the extract liquid to be attached to the fatty polyamide fiber fabric so that the fatty polyamide fiber fabric has an anti-ultraviolet function. Themethods are simple in process, processing can be performed with dyeing and finishing devices, the production efficiency is increased, and the fabric can directly touch skin with good safety and without carcinogenicity, teratogenic effect or allergic reaction, is good in ecological environment compatibility and biologically degradable and has a broad market prospect.

Owner:台华高新染整(嘉兴)有限公司 +1

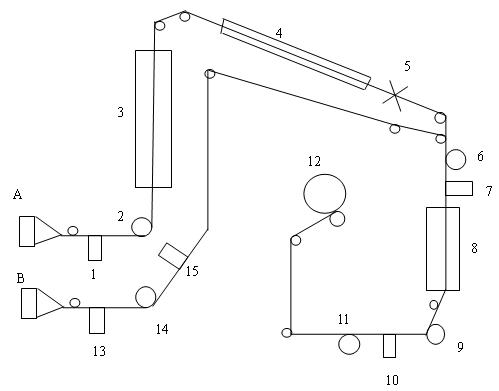

Method for manufacturing protective photocuring film of fingerprint unlocked mobile phone

PendingCN108943979AGood optical performancePrevent perpendicularLamination ancillary operationsLaminationFingerprintSolvent free

The invention discloses a method for manufacturing a protective photocuring film of a fingerprint unlocked mobile phone. The method comprises the following steps: 1, rolling a modified transparent PCbelt having a phase difference of less than 20 into a PC roll; 2, printing photocuring reflection ink to the surface of the PC roll; 3, rolling a transparent SRF belt having a phase difference of morethan 8000 into an SRF roll; 4, pulling the PC roll in the step 2 and the SRF roll in the step 3 with the same machine, and respectively coating solvent-free OCA optical colloid and hardening UV glueto faces to be adhered between the PC roll and the SRF roll, and compounding through photocuring, wherein the solvent-free OCA optical colloid has a refractive index of 1.608, and the hardening UV glue has a refractive index of 1.478; and 5, adhering two layers by a mode of adhering opposite sides in the same direction of the same roll. The protective photocuring film of a fingerprint unlocked mobile phone prepared by the method can combine advantages of PC and SRF optical materials, and is applicable to under-screen fingerprint unlocking.

Owner:东莞市赛越新材料科技有限公司

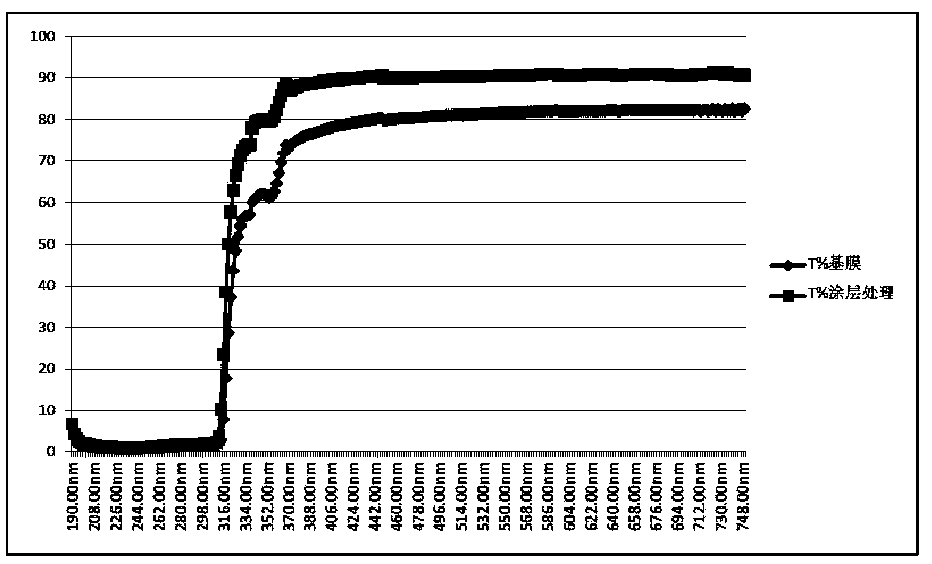

Yellow-resisting ultraviolet-proof real silk plus material

InactiveCN101260609AImprove light resistanceWith anti-ultraviolet functionAnimal fibresUltravioletTitanium dioxide

The invention discloses a silk fabric with functions of yellow resistance and ultraviolet prevention. The silk fabric is characterized in that the silk fabric is coated by titanium dioxide and ultraviolet isolating factors during the afterfinishing process. Accordingly, the silk fabric after the finishing has the functions of yellow resistance and ultraviolet prevention. The process flow is as follows: rolling the ultraviolet isolating factors, baking, coating a titanium dioxide layer, baking.

Owner:JIANGSU HUAJIA SILK

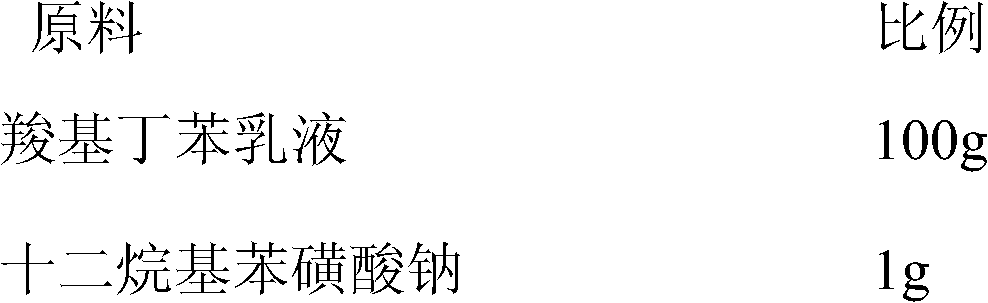

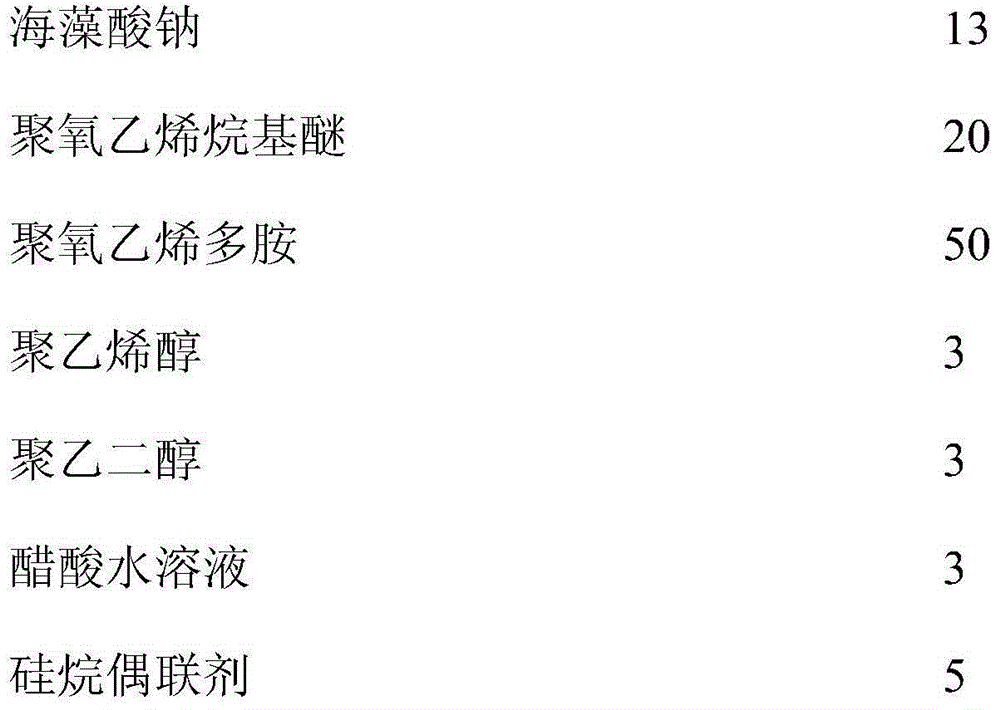

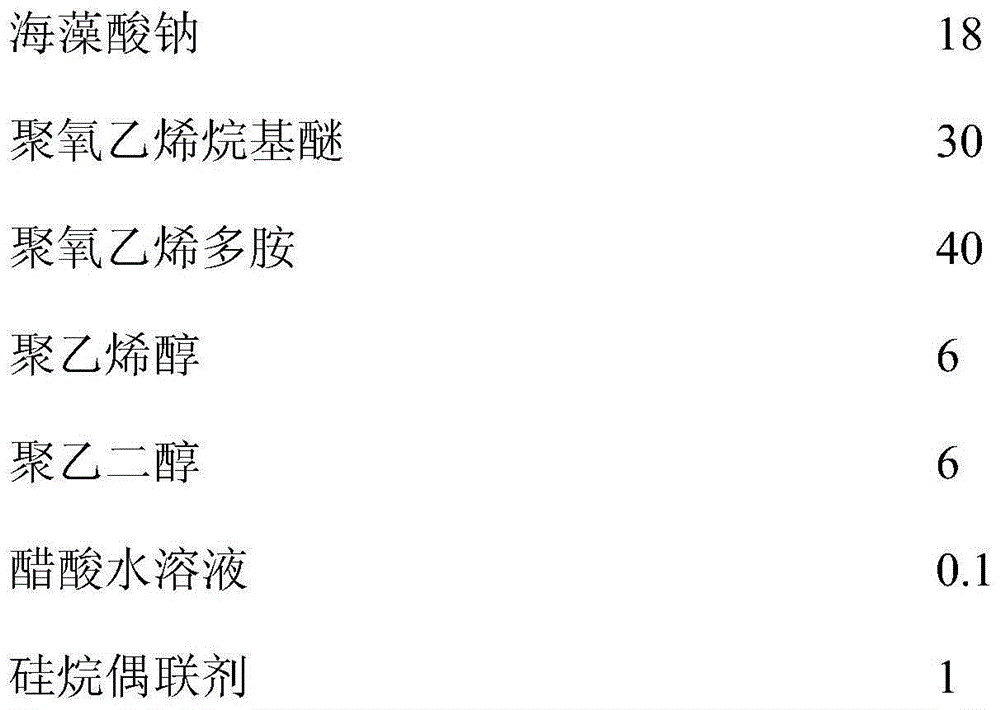

Antistatic agent and preparation method and application thereof

InactiveCN105200789AImprove antistatic performanceWith anti-ultraviolet functionAnimal fibresPolyvinyl alcoholPolyethylene glycol

The invention provides an antistatic agent. The antistatic agent is prepared from, by weight, 13-18 parts of sodium alginate, 20-30 parts of polyoxyethylene alkyl ether, 40-50 parts of polyoxyethylene polyamine, 3-6 parts of polyvinyl alcohol, 3-6 parts of polyethylene glycol, 0.1-3 parts of acetic acid solution and 1-5 parts of silane coupling agents. The friction live voltage of fabric treated by the antistatic agent is 230-260 V, the surface resistivity of the fabric is 5-6.5*10<6>, and therefore antistatic capacity is significantly improved. The antistatic agent has good antistatic performance and also has good softening and maintaining effects on clothes.

Owner:WUXI CHANGAN SHUGUANG GLOVE FACTORY

Sun-screening and skin-whitening fabric

InactiveCN102774058ASoft textureIncrease elasticityArtificial filaments from cellulose solutionsWeft knittingSkin whiteningBonding strength

The invention discloses a sun-screening and skin-whitening fabric. The sun-screening and skin-whitening fabric consists of a surface layer, a base layer and an inner layer, wherein the surface layer is an anti-ultraviolet coating, the coating is formed on the outside surface of the base layer, the inner layer is a skin-whitening fabric layer, the fabric layer is formed on the inside surface of the base layer by the single knit process, the surface layer is a PU (polyurethane) coating, and contains bamboo charcoal particles, the base layer is a terylene-spandex blended tatted fabric layer, and the inner layer is a pearl fiber tow-natural silk blended knitted layer. The sun-screening and skin-whitening fabric disclosed by the invention is a multifunctional composite fabric, the choice of the materials for the layers of the fabric is reasonable, the preparation process is simple, the bonding strength between the neighboring layers is high, and the produced fabric of the surface layer has an anti-ultraviolet function, while the produced fabric of the inner layer has a skin-whitening function; and meanwhile, the fabric also has the characteristics of soft texture, excellent elasticity, high washing fastness, long service life and the like.

Owner:北京吉芬时装设计股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com