Anti-ultraviolet unidirectional-moisture-permeable fiber composite and preparing method thereof

A composite fiber, unidirectional moisture-conducting technology, applied in the direction of artificial filament made of cellulose derivatives, fiber type, fiber processing, etc., can solve the problems of complex material composition and structure, consumption of raw materials, and cumbersome preparation process, etc. To achieve the effect of good unidirectional moisture and anti-ultraviolet function, broad application prospect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

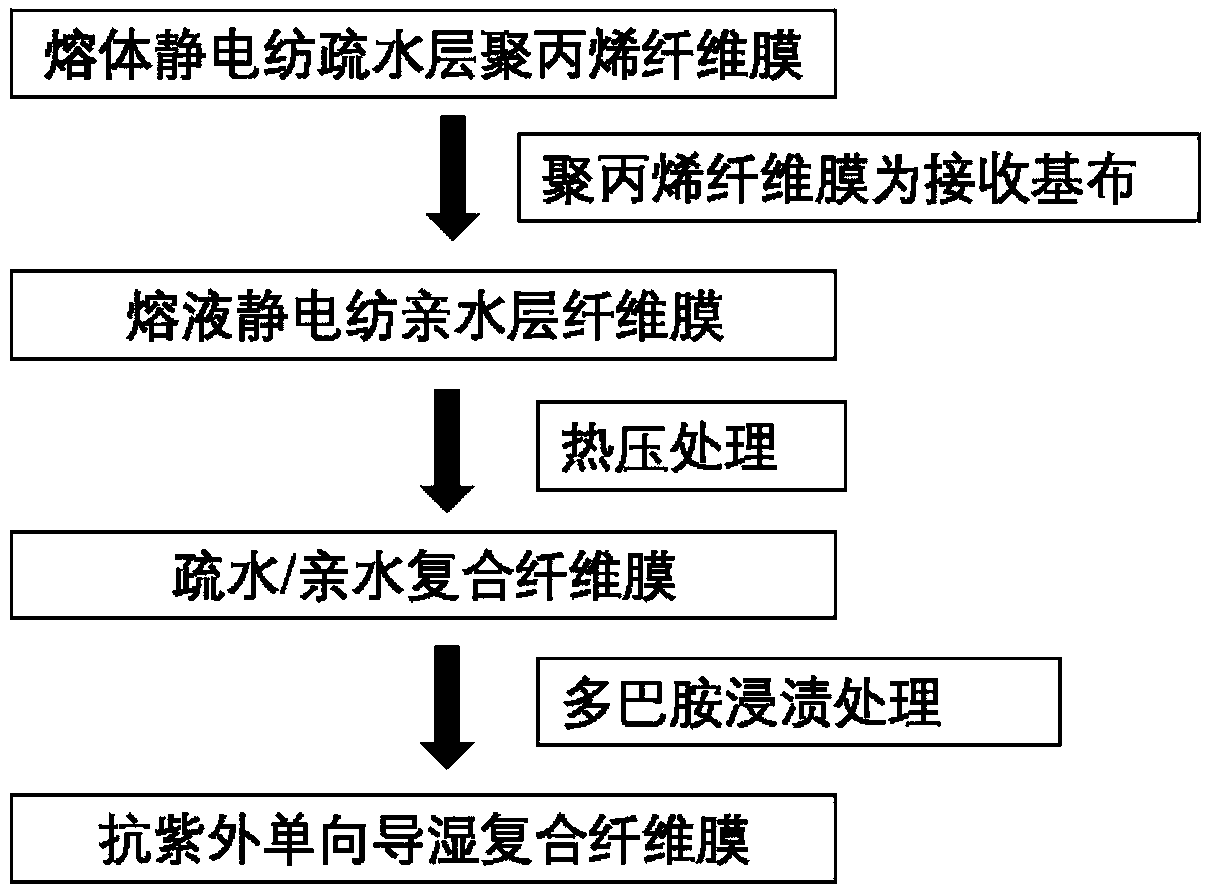

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of polypropylene fiber membrane: the hydrophobic polymer polypropylene particles are heated and melted, and melt electrospinning is performed to obtain a polypropylene fiber membrane. The feed rate is 15g / h, the heating temperature is 300°C, the voltage applied to the receiving device is -30kV through a high-voltage DC power supply, and the receiving distance is set to 15cm. The diameter of the obtained polypropylene fiber is 5-8μm, and the thickness of the polypropylene fiber film is 0.4mm.

[0035] (2) Preparation of UV-resistant hydrophilic spinning solution: disperse the UV-shielding agent UV531 in acetone, magnetically stir, and ultrasonically disperse the particles uniformly to prepare UV531 dispersion A1 with a mass fraction of 0.1 wt%. The hydrophilic polymer cellulose acetate was dissolved in an acetone / N-methylpyrrolidone mixed solvent with a volume ratio of 7:3 to obtain a cellulose acetate spinning solution A2 with a mass fraction of 10 wt%. ...

Embodiment 2

[0041] (1) Preparation of polypropylene fiber membrane: Same as step (1) of Example 1, except that the heating temperature is 350°C, the applied voltage at the receiving device is -15kV through a high-voltage DC power supply, and the receiving distance is set to 20cm. The diameter of the obtained polypropylene fiber is 2-8 μm, and the thickness of the polypropylene fiber film is 0.5 mm.

[0042] (2) Preparation of anti-ultraviolet hydrophilic layer spinning solution: with the step (2) of embodiment 1, the difference is that the ultraviolet shielding agent UV531 is dispersed in N, and the mass fraction obtained in N-dimethylacetamide is 0.5 wt% UV531 dispersion A1. The hydrophilic polymer polyamide was dissolved in N,N-dimethylacetamide to obtain a polyamide spinning solution A2 with a mass fraction of 20 wt%.

[0043] (3) Preparation of composite fiber membrane: same as step (3) of Example 1, the difference is that the electrospinning parameters are: the spinning voltage is 1...

Embodiment 3

[0048] (1) Preparation of polypropylene fiber membrane: Same as step (1) of Example 1, except that the heating temperature is 400°C, the voltage applied at the receiving device by a high-voltage DC power supply is -50kV, and the receiving distance is set to 10cm. The diameter of the obtained polypropylene fiber is 1-10 μm, and the thickness of the polypropylene fiber film is 0.6 mm.

[0049] (2) Preparation of anti-ultraviolet hydrophilic layer spinning solution: with step (2) of embodiment 1, the difference is that the ultraviolet shielding agent UV531 is dispersed in N, and the mass fraction obtained in N-dimethylformamide is 0.1 wt% UV531 dispersion A1. The hydrophilic polymer polyamide was dissolved in N,N-dimethylformamide to obtain a polyamide spinning solution A2 with a mass fraction of 10 wt%.

[0050] (3) Preparation of composite fiber membrane: same as step (3) of Example 1, the difference is that the electrospinning parameters are: the spinning voltage is 30kV, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com