Rapid replacing method and restoring method for bridge expansion joint

A replacement method and expansion joint technology, which is applied in the field of bridge expansion joints, can solve problems such as poor interface bonding effect, interference with road traffic, and short service life, and achieve strong interface bonding, improved service life, and short curing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

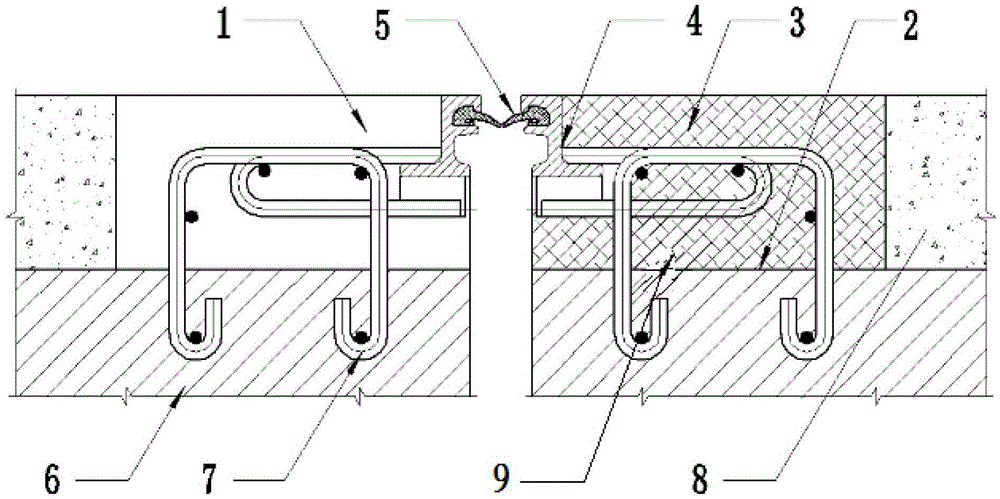

[0042] figure 1 It is a schematic diagram of the structure after the bridge expansion joint device 4 is replaced or repaired in the present invention, the expansion joint notch 9 is arranged on the surface of the connection end of the two bridge girder bodies 6, and is at the same height as the asphalt concrete layer or cement concrete layer 8 of the original road surface. The beam body pre-embedded steel bars 7 inserted in the bridge beam body 6 are pre-buried in the concrete in the slot notch 9, and the expansion joint device 4 is pre-buried in the expansion joint notch 9, and the two adjacent expansion joint slots Expansion joint sealing strips 5 are fixed between the expansion joint devices 4 in the opening 9 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com