Method for improving weather resistance and mechanical property of bamboo plywood

A bamboo plywood, weather resistance technology, applied to other plywood/plywood utensils, adhesives, adhesive types, etc., can solve the problem of not improving the bonding strength and mechanical properties of materials, effectively improving the bonding strength and mechanical strength, and not being effective Improve the mechanical properties of plywood materials to achieve the effect of improving the bonding strength and mechanical properties, saving production steps, and shortening the hot pressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0044] Example 1 and Comparative Example 1 are set in this specific embodiment.

Embodiment 1

[0045] A kind of method of improving bamboo plywood weather resistance and mechanical properties of embodiment 1, the steps are as follows:

[0046] (1) After the flattened bamboo piece is dried in an oven at 70°C for 48 hours, the final moisture content is 10%, and its front and back sides are sanded 0.3mm, and the size of the flattened bamboo piece is length×width×height=50mm×20mm×7.5 mm.

[0047] (2) One side of the green bamboo is coated with an adhesive, the adhesive is urea-formaldehyde resin, the viscosity is 200 mPa·s (room temperature is 23°C), the molar ratio (F:P) is 2:1, and the solid content is 50% , the amount of double-sided glue is 300g / m 2 .

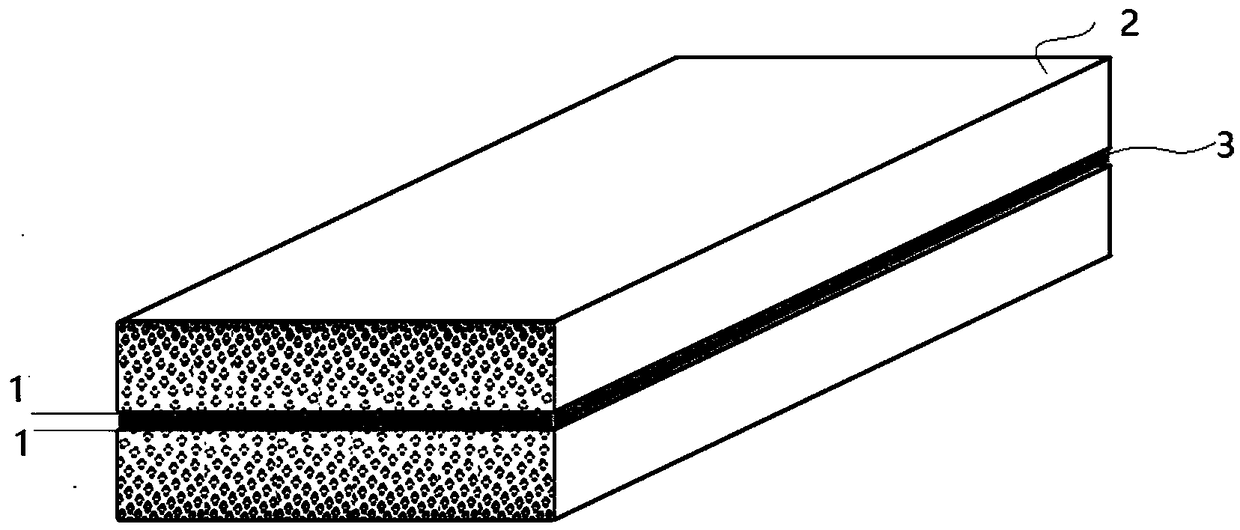

[0048] (3) if figure 1 As shown, the blanks are stacked in pairs, and the bamboo green surface is opposite to the bamboo green surface.

[0049] (4) Put into the hot press, apply high-voltage electric field while hot-pressing, the negative pole of high-voltage electric field generator is connected to the upper side m...

specific Embodiment approach 2

[0057] Embodiment 2 and Comparative Example 2 are set in this specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com