Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Moderate curing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing adhesive for grade-E0 medium density fiberboards

InactiveCN102134468ALow free formaldehyde contentModerate curing timeAldehyde/ketone condensation polymer adhesivesAdhesivePolyvinyl alcohol

The invention provides an adhesive for grade-E0 medium density fiberboards. The raw materials of the adhesive include formaldehyde, polyvinyl alcohol, urea and tripolycyanamide. The production process of the adhesive comprises: firstly, adding all formaldehyde into a reaction kettle, regulating the pH value of formaldehyde solution to 7.5 to 8.5 by using sodium hydroxide solution, adding the 40 to 50 percent of polyvinyl alcohol and urea and adding 80 to 90 percent of tripolycyanamide and adding the 10 to 20 percent of urea; secondly, adjusting the pH value to 5 to 6 by using formic acid, reacting for 20 to 30 minutes till a cloud point, regulating the pH value to 705 to 8.5 with caustic soda solution, and adding the 10 to 20 percent of tripolycyanamide and 20 to 30 percent of urea; and finally, adding 10 to 20 percent of urea, regulating the pH value of the adhesive to 6.6 to 7.5, and discharging. The adhesive has the advantages that: the free formaldehyde content is very low, and the manufactured medium density board is of grade E0; the curing time is proper, the storage stability is high, and the normal-temperature storage period is about 1 month; and the manufactured medium density board has high internal combining strength and high waterproof and dampproof performance.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

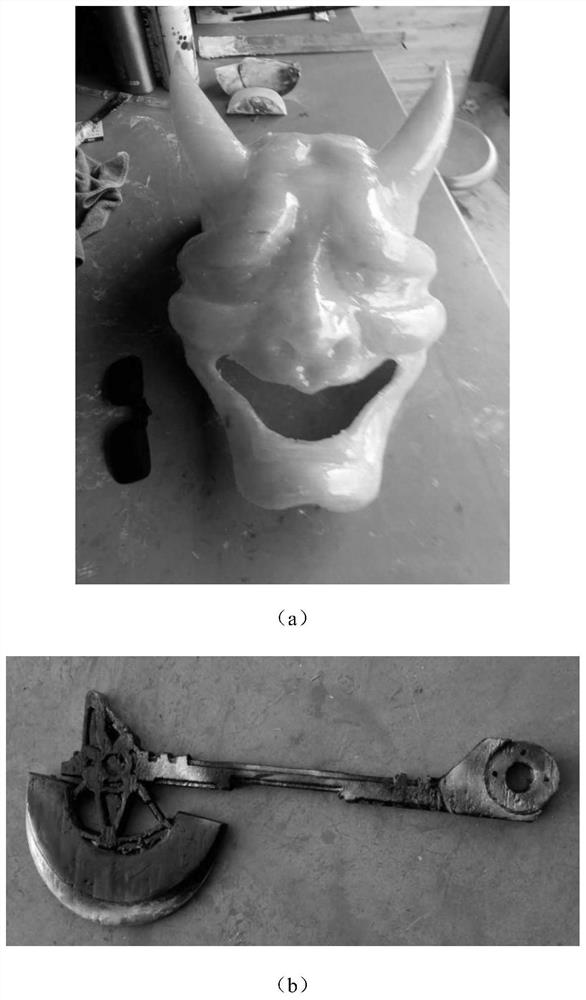

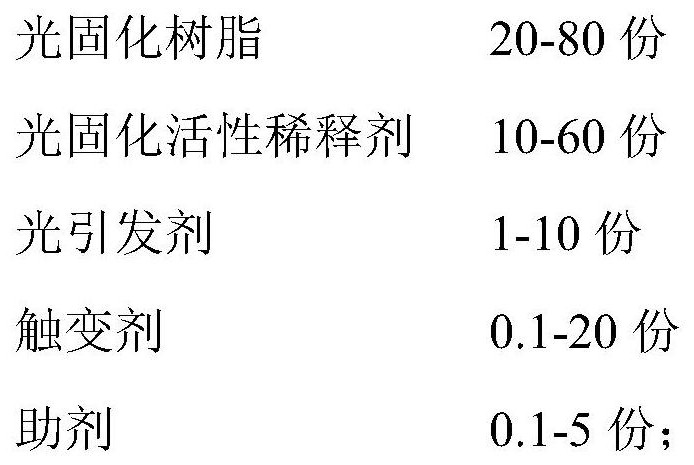

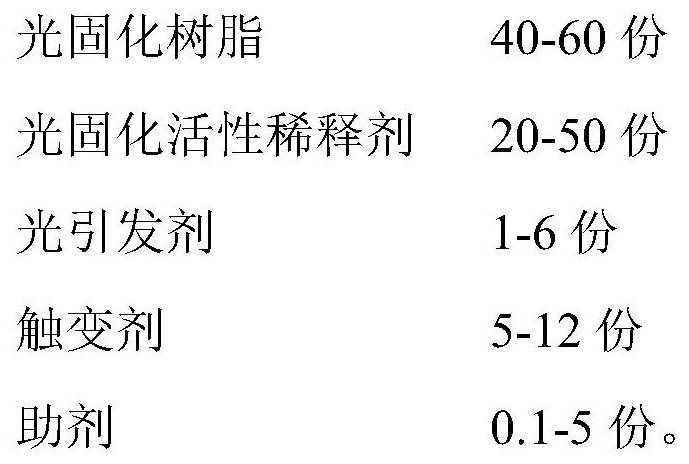

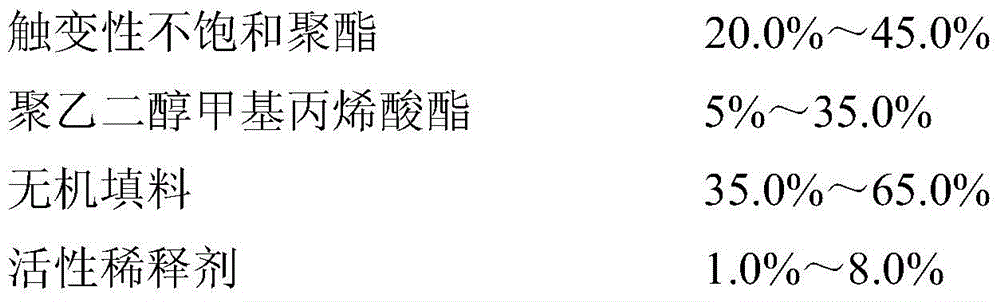

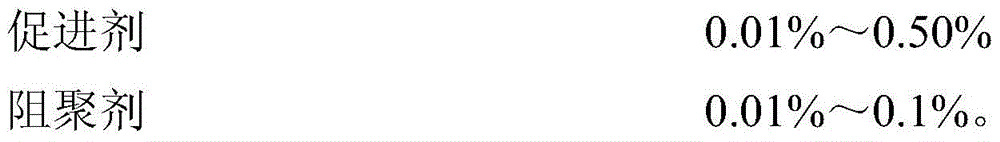

Photocurable 3D printing material as well as preparation method and application thereof

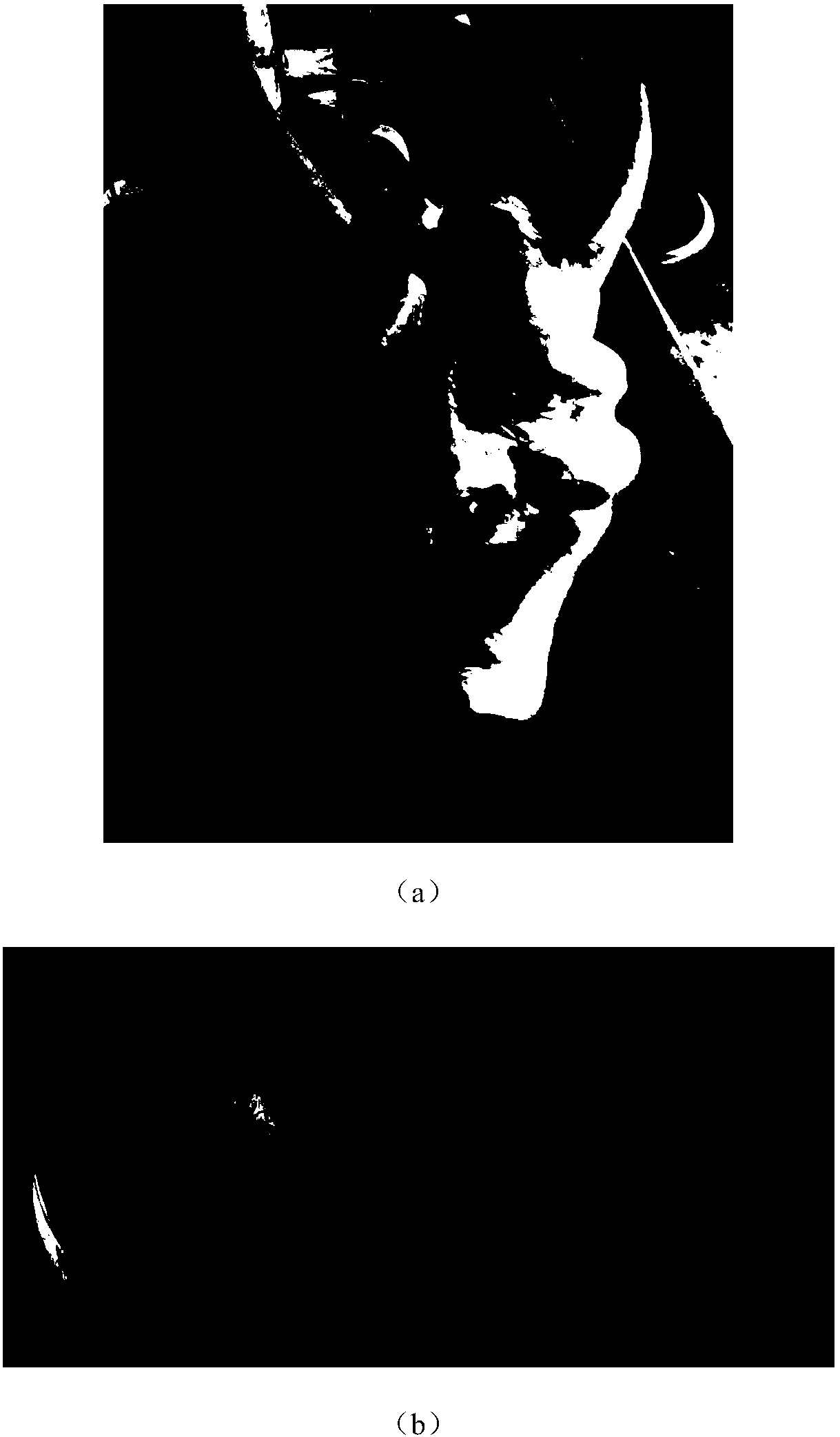

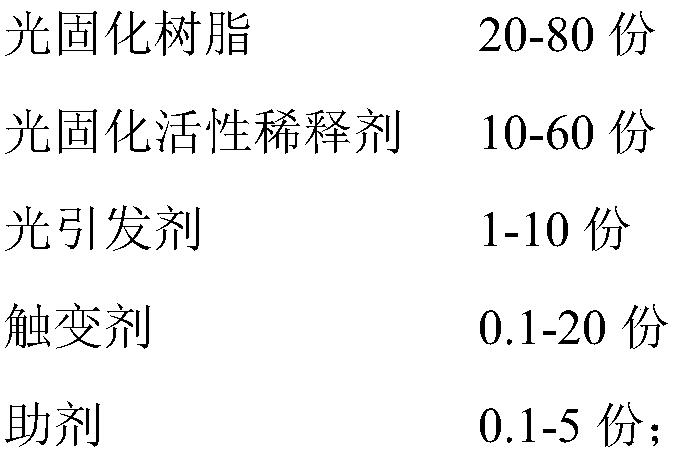

ActiveCN108410162AImprove thixotropyHigh forming precisionAdditive manufacturing apparatusSodium BentonitePolyamide

The invention relates to a photocurable 3D printing material as well as a preparation method and application thereof. The photocurable 3D printing material is prepared from the following raw materialcomponents in parts by weight: 20 to 80 parts of photocurable resin, 10 to 60 parts of photocurable active diluent, 1 to 10 parts of photo-initiator, 0.1 to 20 parts of thixotropic agent and 0.1 to 5parts of auxiliaries, wherein the thixotropic agent is at least one of attapulgite, montmorillonite, bentonite, fumed silica, polyamide wax and mica powder; the photocurable resin is at least one of aliphatic polyurethane and aliphatic epoxy resin. The photocurable 3D printing material has high thixotropy, and can be applied to the nozzle printing process of FDM (Fused Deposition Modeling). Compared with an SLA (Stereolithigraphy Apparatus), the photocurable 3D printing material has the advantages that the production cost of 3D printing products can be lowered effectively, high molding speed and high precision are achieved, complex-contour or large-sized 3D printing products can be made.

Owner:广州有得新材料科技有限公司

A new maintenance material of pavement crack, preparation and application thereof

ActiveCN101555352AAdapt to expansion and contraction requirementsAvoid enteringPaving detailsUltravioletCross linker

The invention relates to a new maintenance material of pavement crack, comprising the raw materials according to weight part as follows: 100 parts of 107 base glue, 1-10 parts of cross linker, 1-5 parts of tackifier, 5-50 parts of plasticiser, 1-100 parts of reinforcing filler, 0.1-0.5 parts of catalyst. The preparation method of the material is as follows: putting dimethyl silicone polymer base glue, reinforcing filler, plasticizer, tackifier and cross linker into a vacuum kneader to be uniformly mixed, obtaining component A; uniformly mixing catalyst and cross linker, obtaining component B; mixing components A and B according to the proportion of 1: 0.01-0.03, obtaining the material. The material has good weather resistance, aging resistance, ultraviolet resistance and self-levelling performance; the material does not need heat construction, has good repairing function for the pavement crack; the preparation method is simple; the invention can be widely applied to repairing and maintaining crack on asphalt, cement concrete pavement and correlative building.

Owner:WUHAN UNIV OF TECH

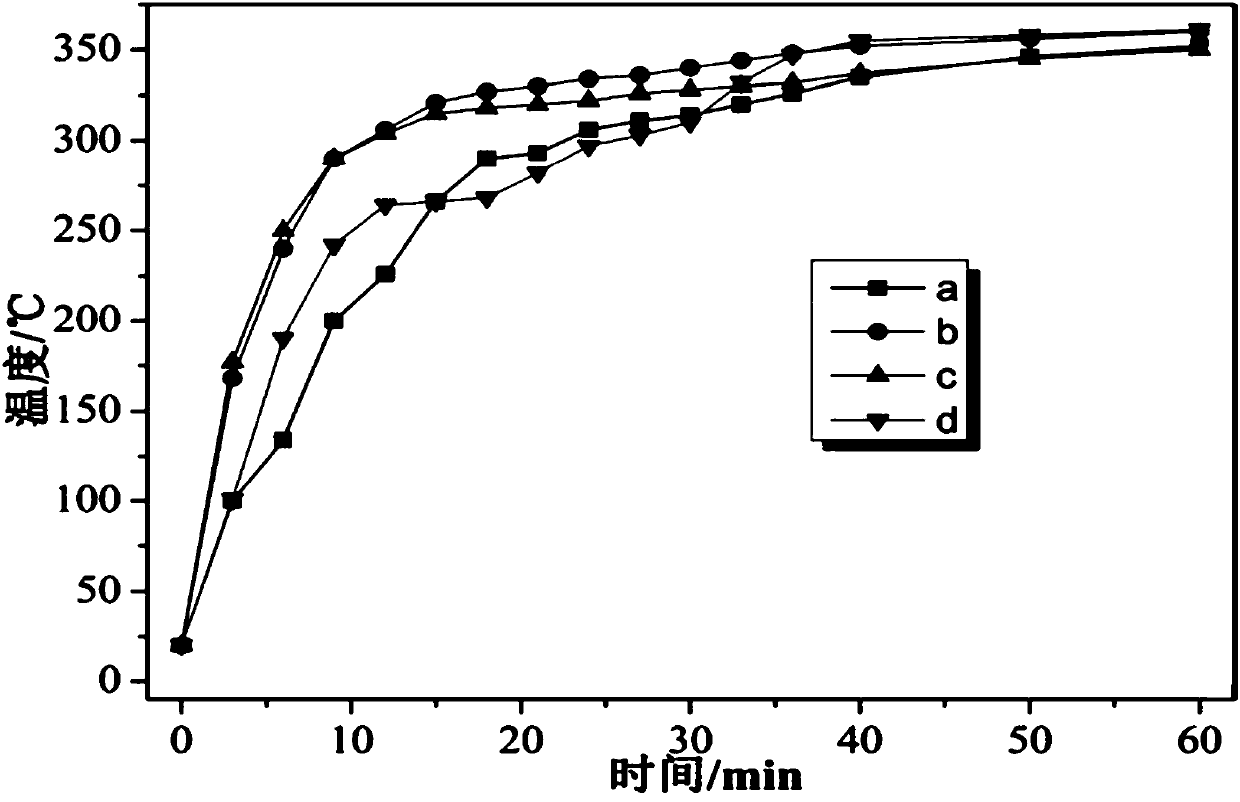

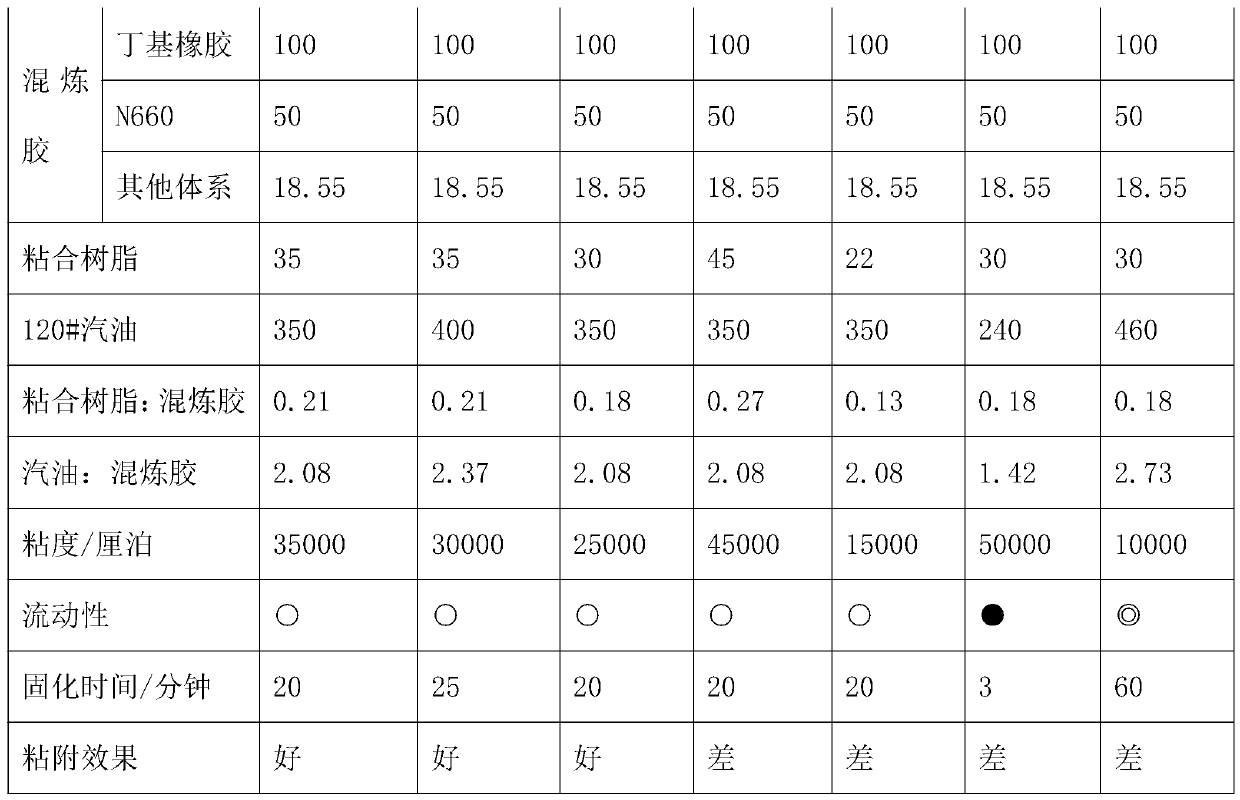

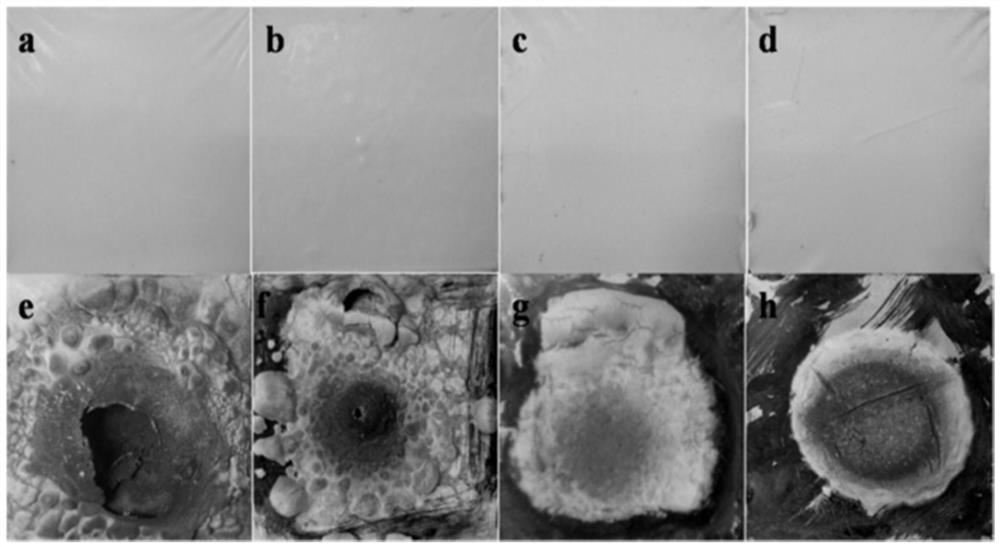

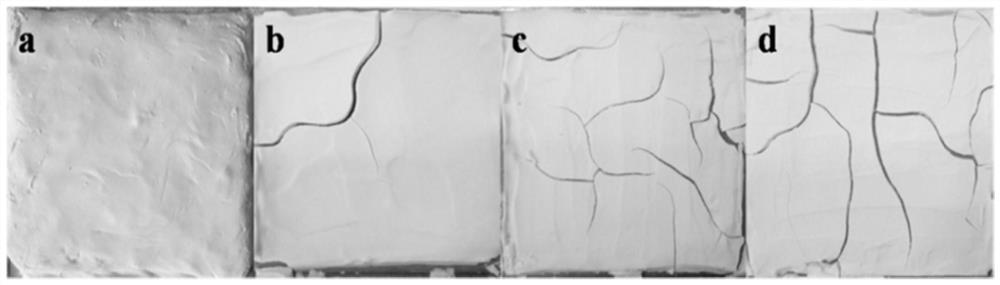

Novel inorganic intumescent steel structure fireproof coating and preparation method thereof

ActiveCN109651856AMatching scienceSimple preparation processFireproof paintsAlkali metal silicate coatingsAluminium hydroxideUltimate tensile strength

The invention discloses a novel inorganic intumescent steel structure fireproof coating and a preparation method thereof, and belongs to the field of fireproof coatings, and the novel inorganic intumescent steel structure fireproof coating is characterized in that the fireproof coating mainly comprises the following raw materials in parts by dry weight: 5 to 6 parts of solid sodium silicate, 25 to44 parts of liquid sodium silicate, 20-40 parts of aluminum hydroxide, 3-10 parts of low-melting-point glass powder, 5-20 parts of magnesium oxide, 0-10 parts of redispersible latex powder, 0.1-5 parts of a waterproof agent, 0.1-1 part of a defoaming agent and 0-20 parts of water. Compared with the prior art, the method has the advantages of high expansion layer strength, small smoke amount, good film forming and fireproof performance, low cost, simple preparation process, convenient operation and the like.

Owner:SHIHEZI UNIVERSITY

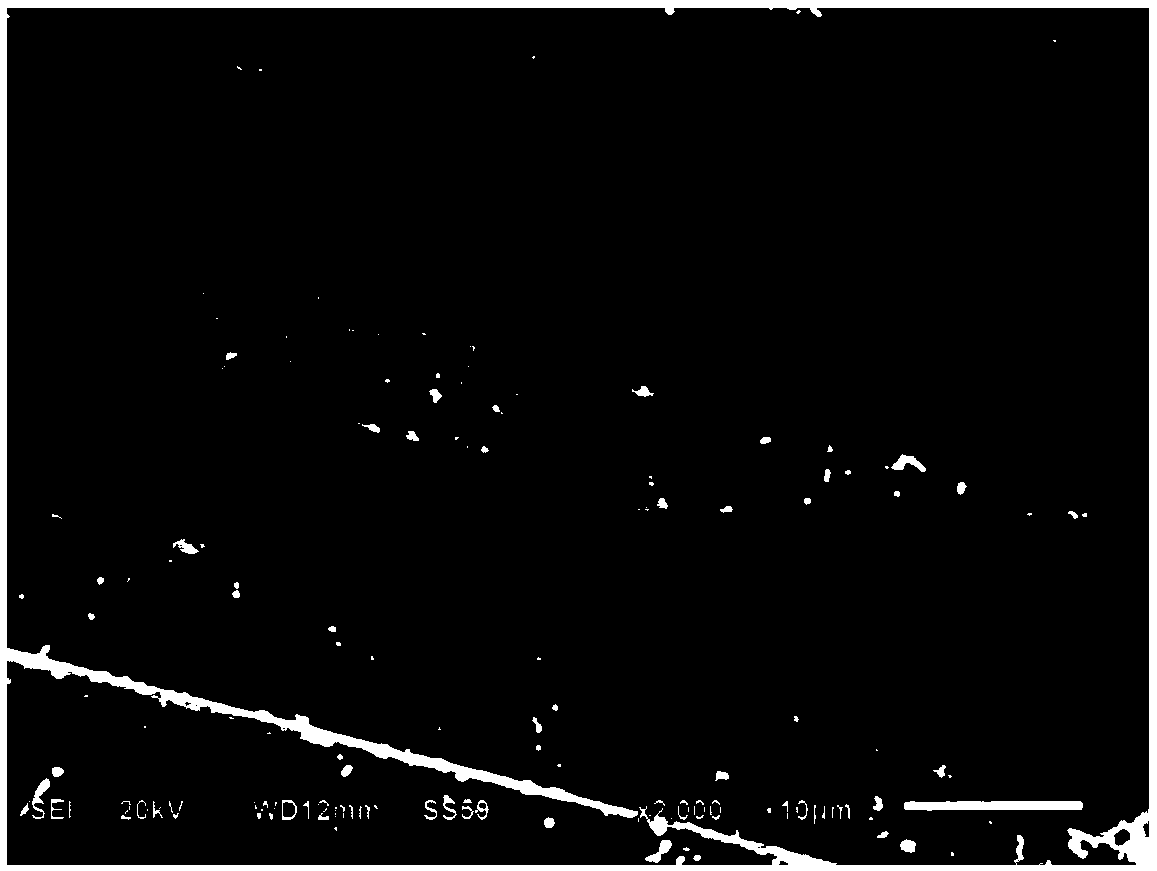

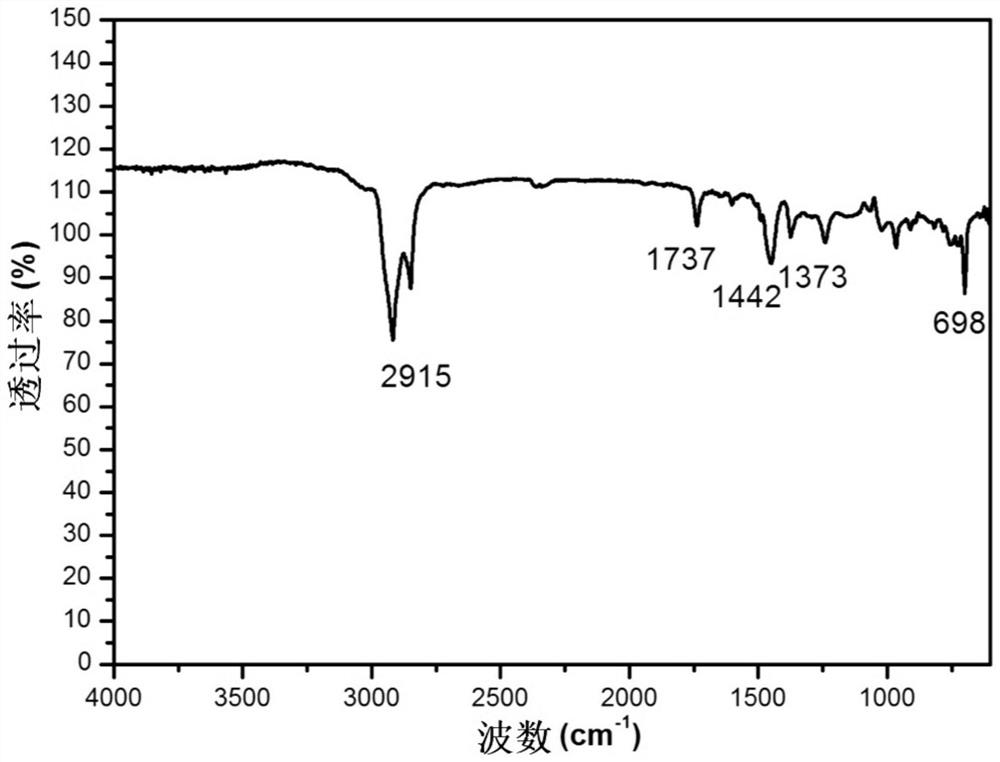

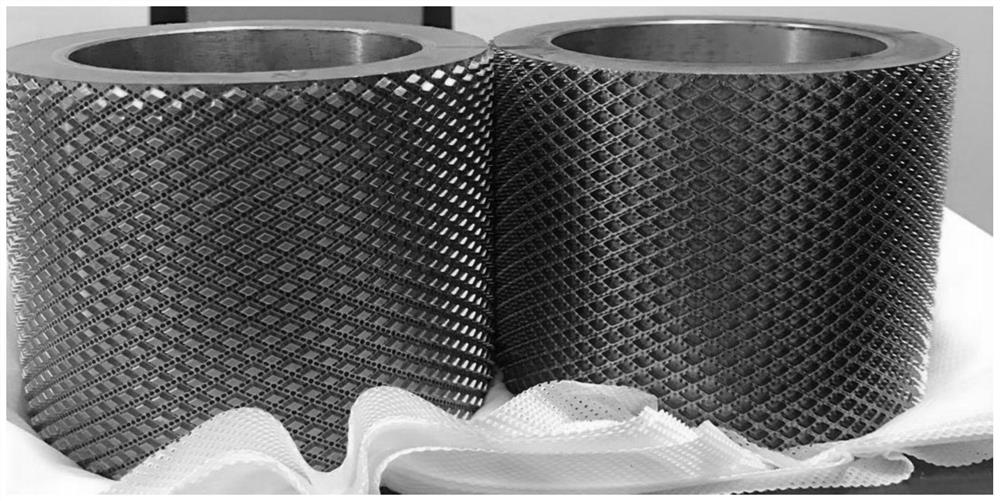

Preparation method of continuous carbon fiber reinforced aluminum-based composite material

The invention provides a preparation method of a continuous carbon fiber reinforced aluminum-based composite material. According to the preparation method provided by the invention, the thickness of an aluminum layer adhered to the surface of the carbon fiber can be controlled by adopting a method of adhering curing aluminum powder to the surface of continuous carbon fiber through organogel, so that the content and the spacing of the carbon fiber in a composite material after hot pressing sintering can be controlled, the carbon fiber can be parallelly distributed in an aluminum matrix, and analuminum-based composite material with high carbon fiber content can be prepared. The preparation method disclosed by the invention is low in cost and easy to operate and is capable of realizing industrialized production; the strength of the carbon fiber reinforced aluminum-based composite material obtained through the preparation method provided by the invention is obviously superior to that of the carbon fiber reinforced aluminum-based composite material prepared through an existing infiltration method, and a wide application prospect is obtained.

Owner:江苏戍卫新材料科技有限公司

Low-cost, long-reserved time and high-performance modified asphalt and preparation method thereof

ActiveCN105017787AMeet residence time requirementsControl timeBuilding insulationsProcess engineeringPolyethylene glycol

The invention discloses a low-cost, long-reserved time and high-performance modified asphalt and a preparation method thereof. The modified asphalt is an A and B dual-component system, wherein the component A is an epoxy resin and polyethyleneglycol diglycidylether mixture; and the component B comprises an emulsifier, matrix asphalt, a solidification agent and activated waste rubber powder. The preparation method comprises the following steps: adding the activated waste rubber powder into the matrix asphalt, adding the emulsifier and the solidification agent under a high temperature condition, carrying out shearing emulsification to obtain the component B, and fully mixing the component A and the component B of the modified asphalt to obtain the low-cost, long-reserved time and high-performance modified asphalt. Long reserved time is realized through selecting the specific epoxy resin solidification agent and regulating the solidifying rate of an epoxy system in order to meet road pavement and engineering maintenance with long reserved time requirements. The matrix asphalt and the waste rubber powder are used, so the production cost is reduced, and the low-temperature cracking resistance and stability of the modified asphalt are improved.

Owner:JURONG NINGWU CHEM

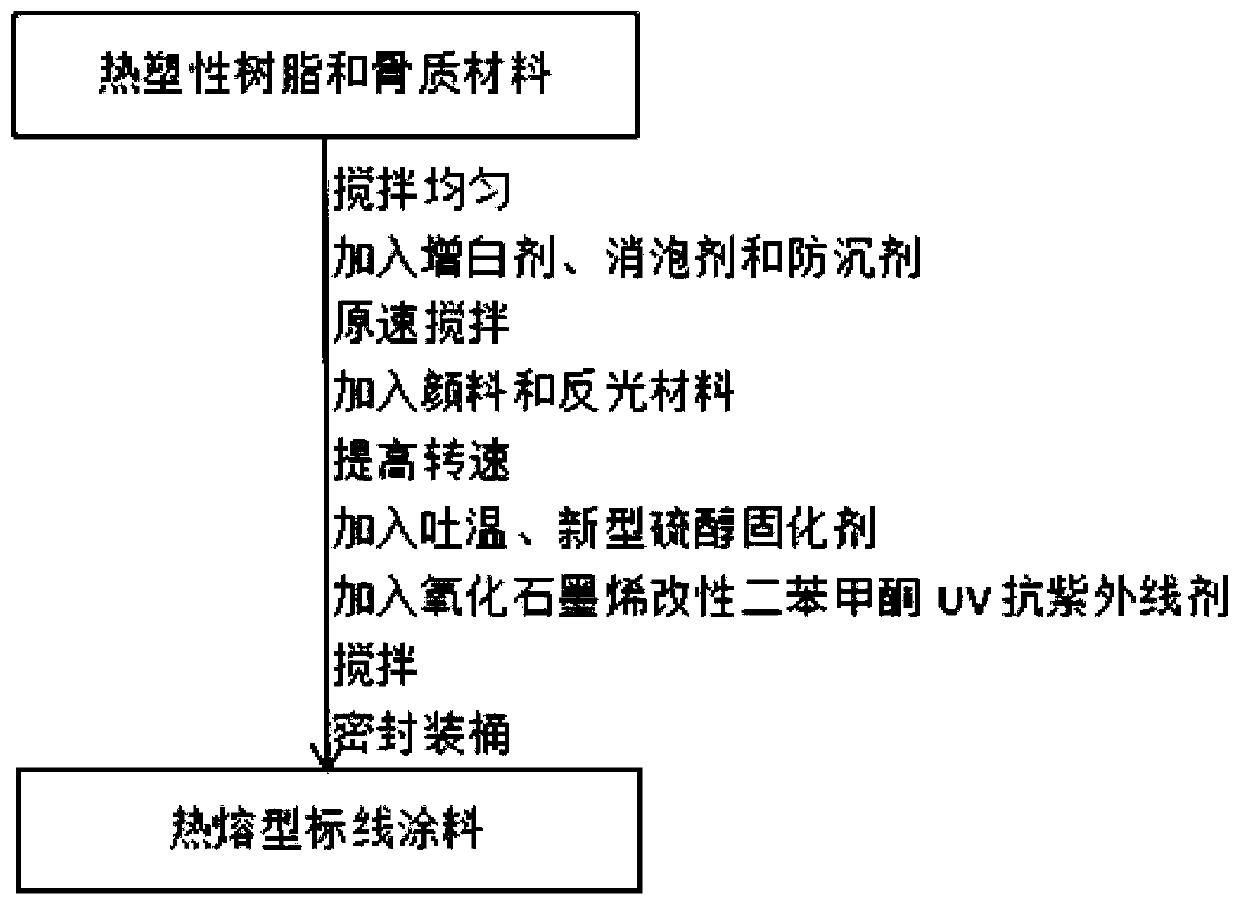

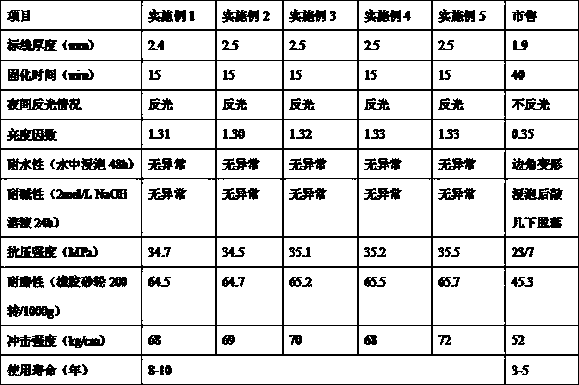

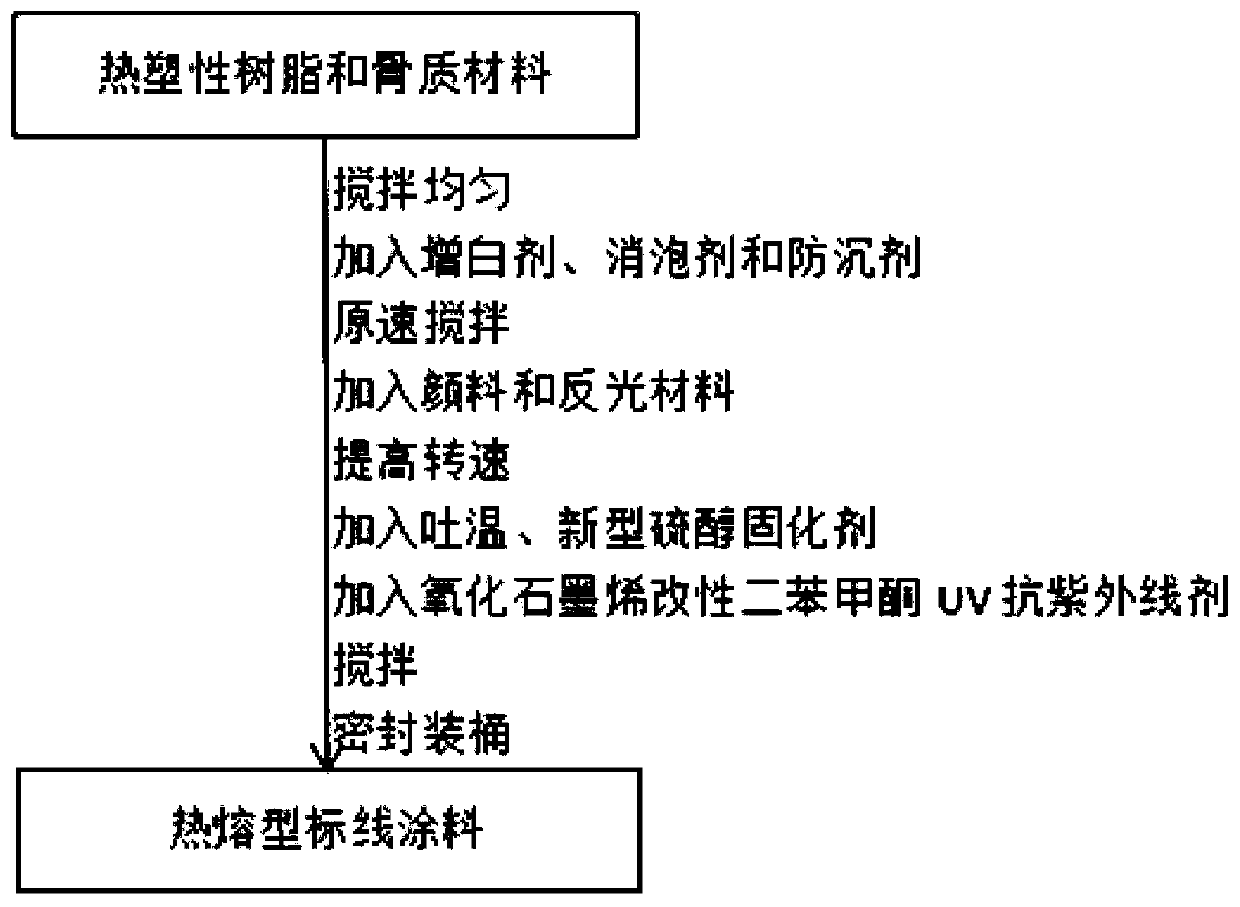

Hot-melt-type marking coating and preparation method thereof

InactiveCN109971296AImprove tensile propertiesIncrease elasticityAntifouling/underwater paintsRosin coatingsWhitening AgentsHot melt

The invention provides a hot-melt-type marking coating. The coating is prepared from, by weight, 80-120 parts of thermoplastic resin, 20-40 parts of a bone material, 5-15 parts of pigments, 3-10 partsof a reflective material, 0.02-0.05 part of a whitening agent, 0.01-0.03 part of a defoaming agent, 2-6 parts of a novel mercaptan curing agent, 1-2 parts of an anti-settling agent, 1-4 parts of Twain and 0.03-0.06 part of a graphene-oxide-modified benzophenone UV anti-ultraviolet agent. The hot-melt-type marking coating prepared by means of the method has the advantages of being short in film forming and curing time and drying time, good in stain resistance, great in dustproof property, excellent in reflection effect, uniform in viscosity and good in anti-shedding performance after long-termstorage, safe, environmentally friendly, long in service life and the like, and has a broad application prospect.

Owner:天华交通建设集团有限公司

High-elasticity aging-resistant waterproof adhesive and preparation method thereof

InactiveCN111334231AHigh bonding strengthImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesThermal dilatationPolymer science

The invention, which relates to the field of building materials, discloses a high-elasticity aging-resistant waterproof adhesive and a preparation method thereof. The waterproof adhesive is prepared by mixing a component A and a component B according to a weight ratio of 1: 1. The component A is prepared from 1200 to 2000 parts of bisphenol A type epoxy resin, 150 parts of reactive diluent, 120 to190 parts of non-reactive diluent, 45 to 80 parts of toughening agent and 120 to 140 parts of fumed silica; and the component B comprises 1200-2000 parts of modified phenolic aldehyde amine, 45-90 parts of a silane coupling agent, 2-6 parts of a defoaming agent, 24-30 parts of a flow stopping agent and 80-190 parts of fumed silica. The waterproof adhesive can reduce the thermal expansion coefficient and the shrinkage rate of a cured product, improve the surface hardness and the compression strength, reduce the heat release temperature in the curing process and play a thickening role, and canbe used in vertical wall surfaces, inclined roofs, ceilings and the like; and the mechanical strength, the elasticity modulus, the thermal aging performance and the weather resistance after curing areoptimized.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

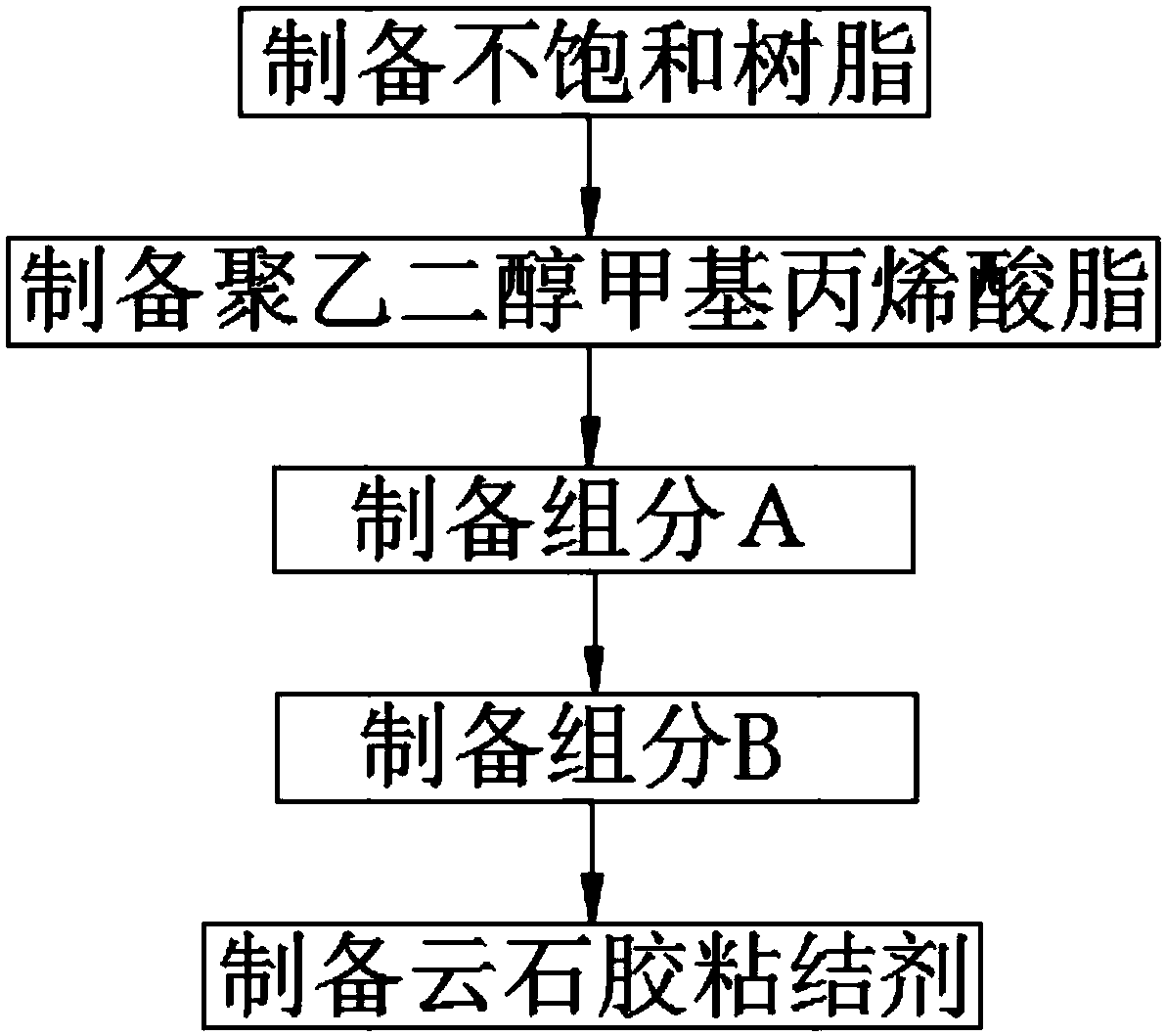

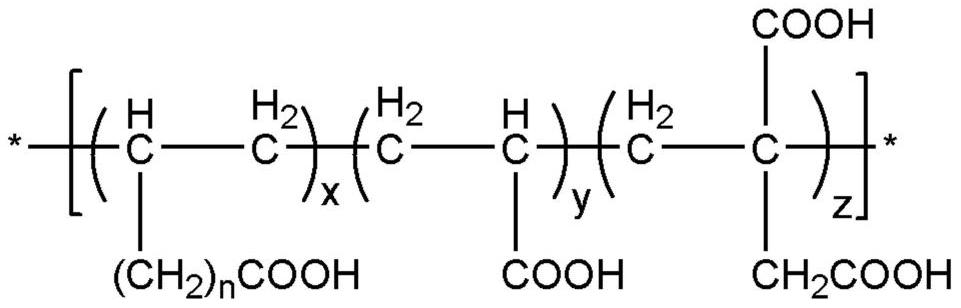

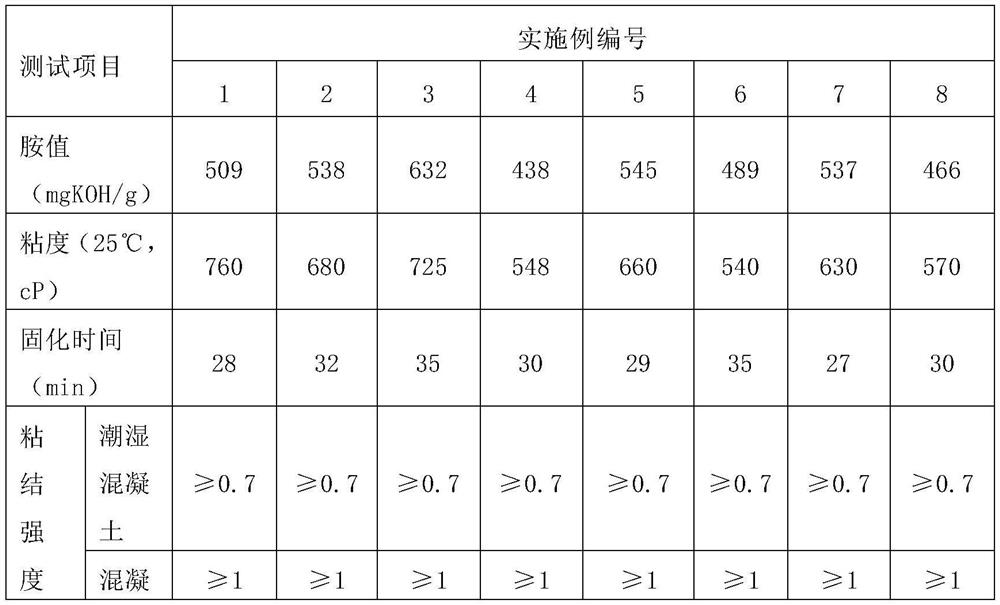

Marble glue adhesive for construction engineering and preparation process thereof

InactiveCN107629751AConvenient sourceHigh strengthNon-macromolecular adhesive additivesMethacrylateFiber

The invention discloses a marble glue adhesive for construction engineering and a preparation process thereof. The marble glue adhesive comprises a component A and a component B, wherein the weight ratio of the component A to the component B is 10:3; the component A consists of the following raw materials in parts by weight: unsaturated polyester resin, a reinforcing filler, a polymerization inhibitor, an accelerant, reinforcing chopped fiber, polyethylene glycol methacrylate, a diluent and a thixotropic agent; and the component B consists of the following raw materials in parts by weight: a filler curing agent, a plasticizer, an emulsifier and a thixotropic agent. The preparation method disclosed by the invention comprises the following steps: preparing the unsaturated resin, polyethyleneglycol methacrylate, the component A, the component B and the marble glue adhesive. The marble glue adhesive disclosed by the invention has excellent tensile shearing strength and impact strength, and has the advantages of convenient source of raw materials, simple production process, moderate curing time for obtained products, stable storage, small odor, high hardness, good toughness, excellentadhesive strength, good elasticity, excellent resistance to yellowing, moisture and heat, and the like.

Owner:福州市承亨建材有限公司

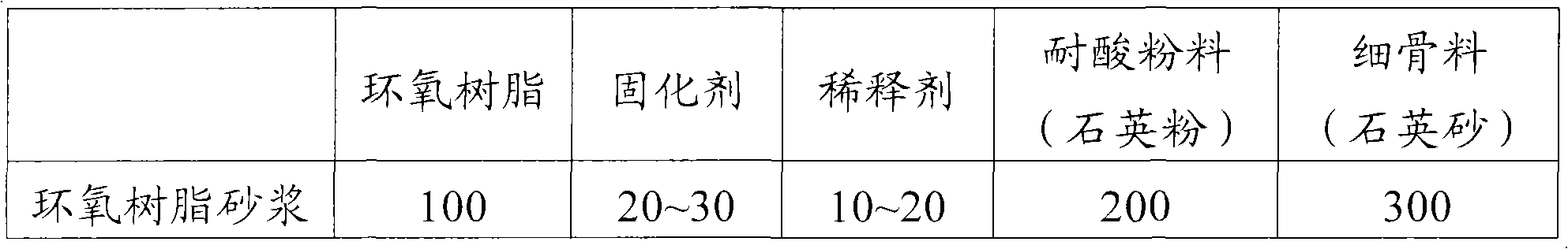

Epoxy resin mortar and preparation method thereof

The invention discloses an epoxy resin mortar comprising the following materials by weight: 90 parts of epoxy resin, 23-25 parts of curing agents, 26-28 parts of diluents, 170-190 parts of acid-resisting powder materials and 310-330 parts of aggregates. The epoxy resin mortar has appropriate curing time under high-temperature and dry climates and also has good compression strength and insulating property.

Owner:PANGANG GRP ENG TECH +1

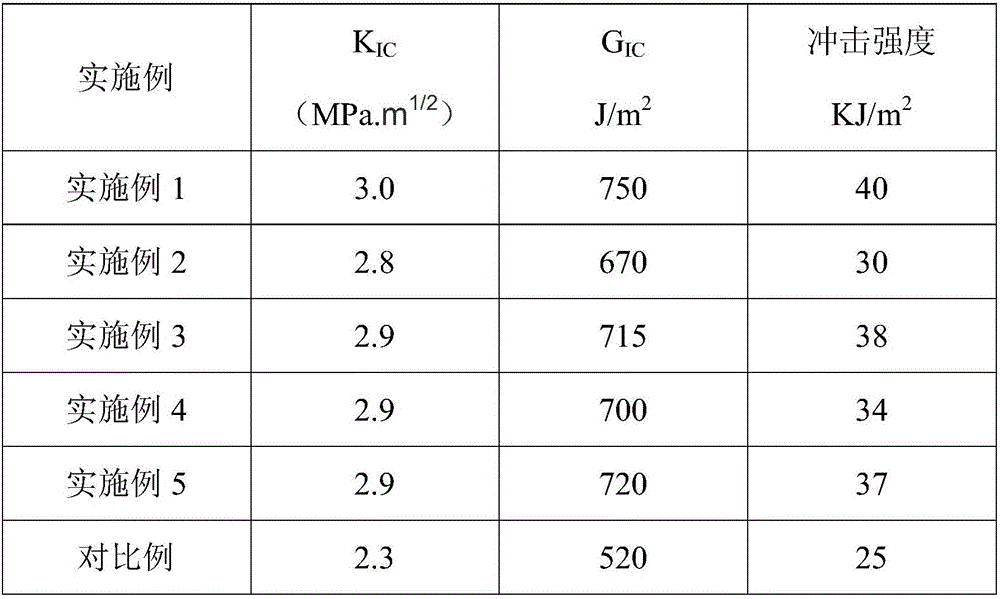

Vacuum infusion resin and preparation method and application thereof

The invention discloses vacuum infusion resin and a preparation method and application thereof. The vacuum infusion resin comprises toughening epoxy resin accounting for 50-70% of the total mass of the vacuum infusion resin and a curing agent accounting for 30-50% of the total mass of the vacuum infusion resin. The vacuum infusion resin has the advantages that the toughening epoxy resin enhances the toughness of the vacuum infusion resin and lowers the viscosity of the vacuum infusion resin, and later process operations are facilitated; tetramethyl guanidine is used as the curing agent of the toughening epoxy resin and is moderate in curing time and curing temperature, and the cured vacuum infusion resin is low in viscosity and excellent in performance; the vacuum infusion resin is low in viscosity, high in toughness, simple in preparation method and widely applicable to pouring field of medium- and high-voltage electric insulating parts and has a long working life under 40 DEG C.

Owner:GOODE EIS SUZHOU CORP LTD

Composition of two-component marking coating and preparation method thereof

InactiveCN111574920AAppropriate curing timeImproves Strength and ToughnessPolyurea/polyurethane coatingsWeather resistanceBonding strength

The invention provides a composition of a two-component marking coating and a preparation method thereof. The composition of the two-component marking coating comprises a component A and a component B, and the mass ratio of the component A to the component B is 3-3.5: 1. The component A is prepared from the following raw materials, by weight: 17 to 20 parts of acrylic resin, 15 to 18 parts of polycaprolactone polyol,1 to 1.8 parts of nano-zinc oxide loaded graphene oxide, 10 to 15 parts of modified hollow glass beads, 5 to 8 parts of titanium dioxide, 0.3 to 0.6 part of a silane coupling agent, 30 to 35 parts of fillers, 0 to 1.5 parts of pigment, 0.5 to 0.8 part of a dispersing agent, 0.2 to 0.3 part of a leveling agent and 0.1 to 0.3 part of a defoamer. The component B is a hexamethylenediisocyanate tripolymer. A coating film corresponding to the two-component marking coating is high in strength, toughness and hardness, has relatively high wear resistance and weather resistance, ishigh in bonding strength with a pavement, and is long in service life.

Owner:云南独树林涂料有限公司

Long-acting anti-icing coating for high-pressure facilities and preparation method of long-acting anti-icing coating

InactiveCN113755096AHigh mechanical strengthHigh dielectric strengthPriming paintsPtru catalystAluminium hydroxide

The invention provides a long-acting anti-icing coating for a high-pressure facility and a preparation method of the long-acting anti-icing coating. The long-acting anti-icing coating is prepared from the following raw materials in parts by weight: 1) a primer comprising 100 parts of hydroxyl-terminated polysiloxane, 10 to 20 parts of fumed silica, 5 to 15 parts of aluminum hydroxide, 5 to 15 parts of decabromodiphenyl ethane, 2 to 5 parts of a cross-linking agent, 0.1 to 0.5 part of a catalyst, 0.3 to 1.0 part of a coupling agent and 100 to 150 parts of 120# gasoline; and (2) a surface coating comprising 3-10 parts of low surface energy resin, 3-8 parts of nano silicon dioxide, 1-3 parts of a cross-linking agent, 0.1-0.3 part of a catalyst and 50-80 parts of ethyl acetate. According to the long-acting anti-icing coating disclosed by the invention, the primer and the surface coating are combined, so that the long-acting anti-icing coating has excellent super-hydrophobic property and good durability.

Owner:ZHUHAI LING HANG ELECTRIC

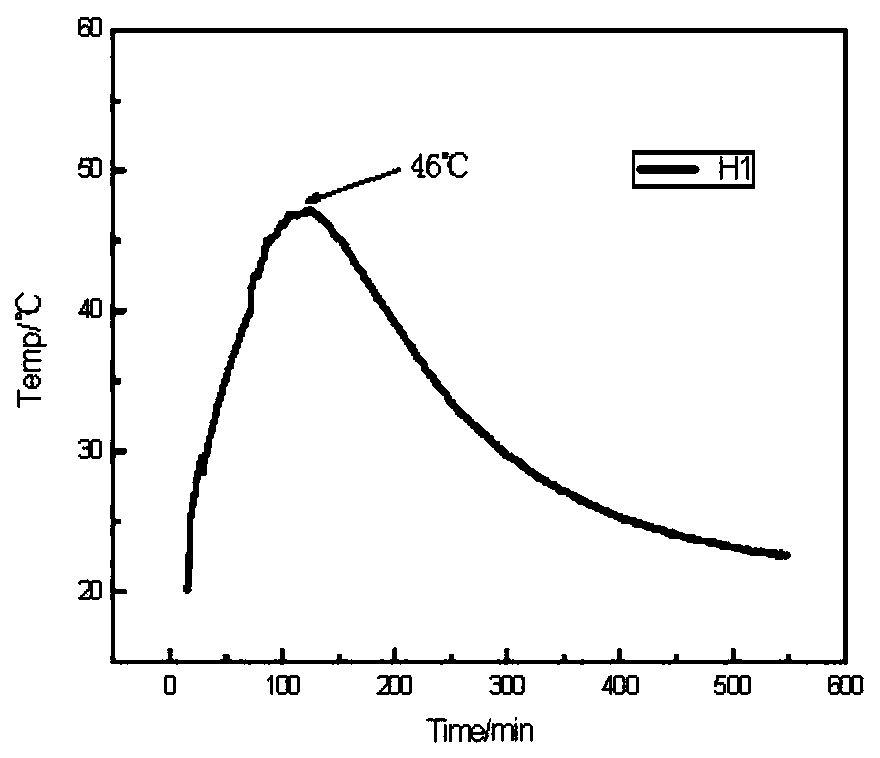

Large-volume and room-temperature cured epoxy resin glue filling material

InactiveCN109777334ASolve the problem of explosive polyLow gas leak rateEpoxy resin adhesivesReaction temperatureFatty amine

The invention discloses a large-volume and room-temperature cured epoxy resin glue filling material which is divided into glue filling formulas of different quality grades and can reach a maximum of grade 150 kg. The formula of grade 150 kg is prepared by the following raw materials by weight: 100 parts by weight of epoxy resin, 12 parts by weight of dibutyl phthalate, 8 parts by weight of acetone, 4.15% of triethylene tetramine and 0.2 percent of DMP-30. The epoxy resin glue filling material disclosed by the invention adopts a manner of mechanical mixing and stirring of bisphenol A epoxy resin, a non-reactive diluent, a fatty amine curing agent and an accelerant at a normal temperature; through performing an amplification experiment step by step, the dosages of a diluent and a curing agent are optimized; on the premise of ensuring the appropriate curing time, the curing reaction temperature is reduced to below 55 DEG C, so that the curing reaction heat and the curing temperature riseare greatly reduced, and the problem of high explosive polymerization possibility of the epoxy resin in the normal-temperature curing under large volume is solved.

Owner:63653 FORCES PLA

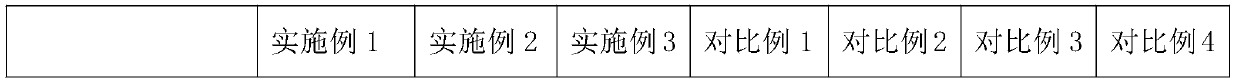

Adhesive and preparation method thereof

ActiveCN110128974AModerate fluidityModerate curing timeMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAdhesiveRoom temperature

The invention discloses an adhesive and a preparation method thereof. The adhesive comprises the following ingredients (by mass): 168.55 phr of a rubber compound, 25-40 phr of bonding resin and 250-450 phr of gasoline. The rubber compound comprises the following ingredients (by mass): 100 phr of butyl rubber, 50 phr of N660 and 18.55 phr of other systems. According to the invention, the rubber compound, bonding resin and gasoline are adopted, and the mass ratio of the rubber compound to bonding resin to gasoline is strictly controlled within the range of 1:0.15-0.24: 1.48-2.67. Thus, it can beensured that fluidity of the prepared adhesive is appropriate and viscosity of the adhesive at room temperature is within the range of 20,000-40,000 centipoises. In addition, when the prepared adhesive is in use, the curing time as required is proper, the adhesive effect is good, and the adhesive can meet the use requirement.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

A new type of inorganic expansion steel structure fireproof coating and its preparation method

ActiveCN109651856BMatching scienceSimple preparation processFireproof paintsAlkali metal silicate coatingsAluminium hydroxideLatex rubber

The invention discloses a novel inorganic intumescent steel structure fireproof coating and a preparation method thereof, and belongs to the field of fireproof coatings, and the novel inorganic intumescent steel structure fireproof coating is characterized in that the fireproof coating mainly comprises the following raw materials in parts by dry weight: 5 to 6 parts of solid sodium silicate, 25 to44 parts of liquid sodium silicate, 20-40 parts of aluminum hydroxide, 3-10 parts of low-melting-point glass powder, 5-20 parts of magnesium oxide, 0-10 parts of redispersible latex powder, 0.1-5 parts of a waterproof agent, 0.1-1 part of a defoaming agent and 0-20 parts of water. Compared with the prior art, the method has the advantages of high expansion layer strength, small smoke amount, good film forming and fireproof performance, low cost, simple preparation process, convenient operation and the like.

Owner:SHIHEZI UNIVERSITY

A new maintenance material of pavement crack, preparation and application thereof

ActiveCN101555352BAdapt to expansion and contraction requirementsAvoid enteringPaving detailsUltravioletRoad surface

The invention relates to a new maintenance material of pavement crack, comprising the raw materials according to weight part as follows: 100 parts of 107 base glue, 1-10 parts of cross linker, 1-5 parts of tackifier, 5-50 parts of plasticiser, 1-100 parts of reinforcing filler, 0.1-0.5 parts of catalyst. The preparation method of the material is as follows: putting dimethyl silicone polymer base glue, reinforcing filler, plasticizer, tackifier and cross linker into a vacuum kneader to be uniformly mixed, obtaining component A; uniformly mixing catalyst and cross linker, obtaining component B;mixing components A and B according to the proportion of 1: 0.01-0.03, obtaining the material. The material has good weather resistance, aging resistance, ultraviolet resistance and self-levelling performance; the material does not need heat construction, has good repairing function for the pavement crack; the preparation method is simple; the invention can be widely applied to repairing and maintaining crack on asphalt, cement concrete pavement and correlative building.

Owner:WUHAN UNIV OF TECH

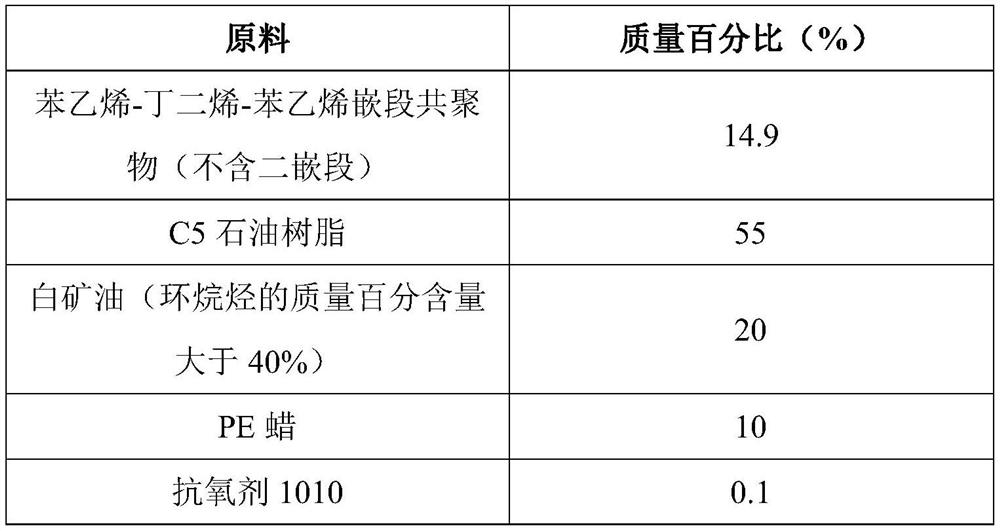

A kind of anti-penetration hot melt adhesive and coating scraping method for disposable sanitary products

ActiveCN110205064BReduce bleedingImprove product qualityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceAntioxidant

The invention discloses an anti-penetration hot melt adhesive for disposable sanitary products and a coating and scraping method. The hot melt adhesive is composed of a main polymer, a tackifying resin, white mineral oil, a processing aid and an antioxidant. The coating and squeegeeing method includes the following steps: melt the anti-seepage hot melt adhesive for disposable sanitary products and add it to the sizing device, the sizing surface on the sizing device matches the surface structure of the substrate, and then apply the glue On the perforated film or non-woven substrate, the substrate is laminated for bonding. The anti-seepage hot-melt adhesive for disposable sanitary products and the coating scraping method of the present invention can significantly reduce the glue seepage in the sizing process, improve the product quality, and will not increase the production cost and process difficulty at the same time, and will not affect the adhesive Junction performance is affected.

Owner:聚胶新材料股份有限公司

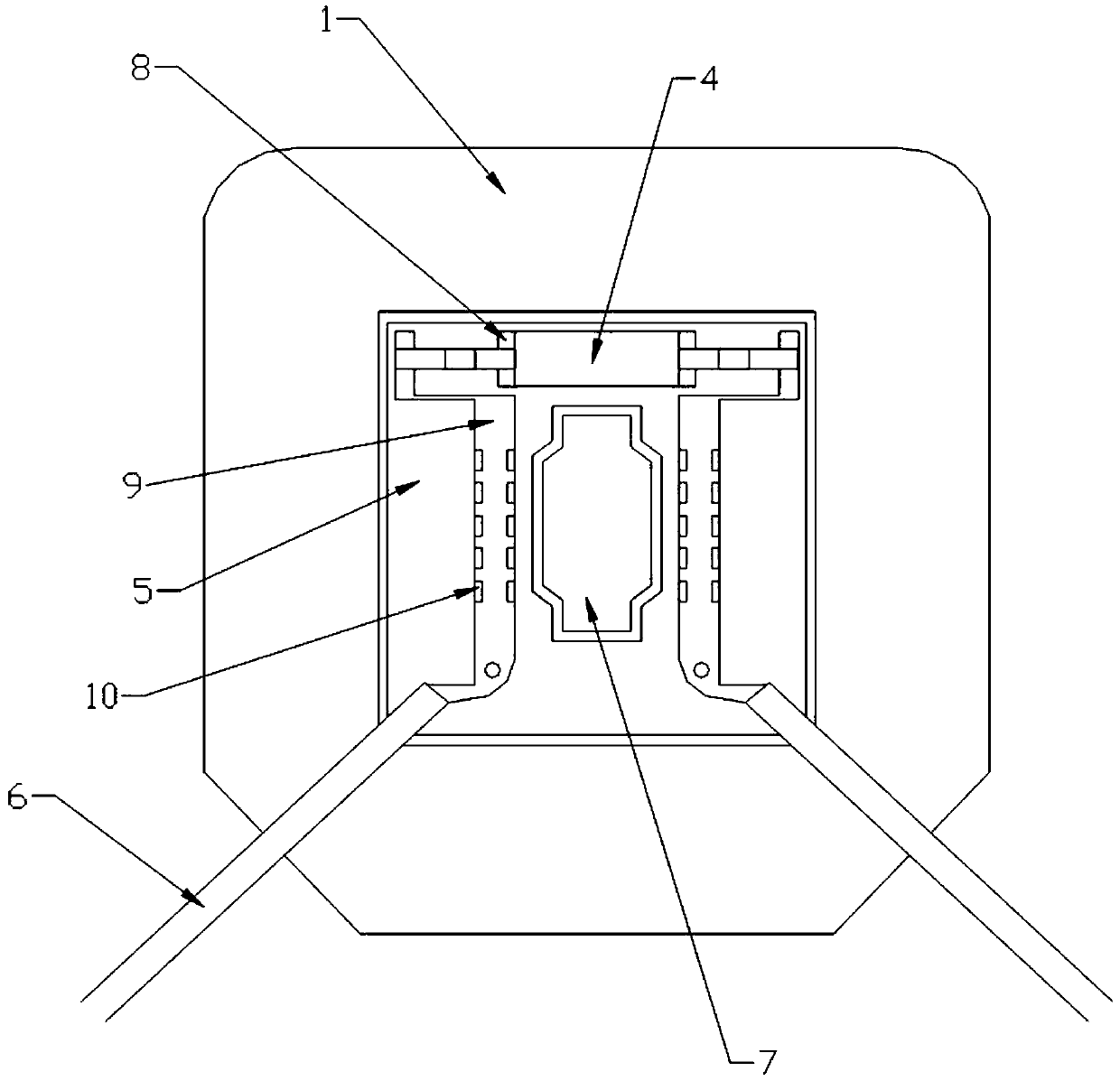

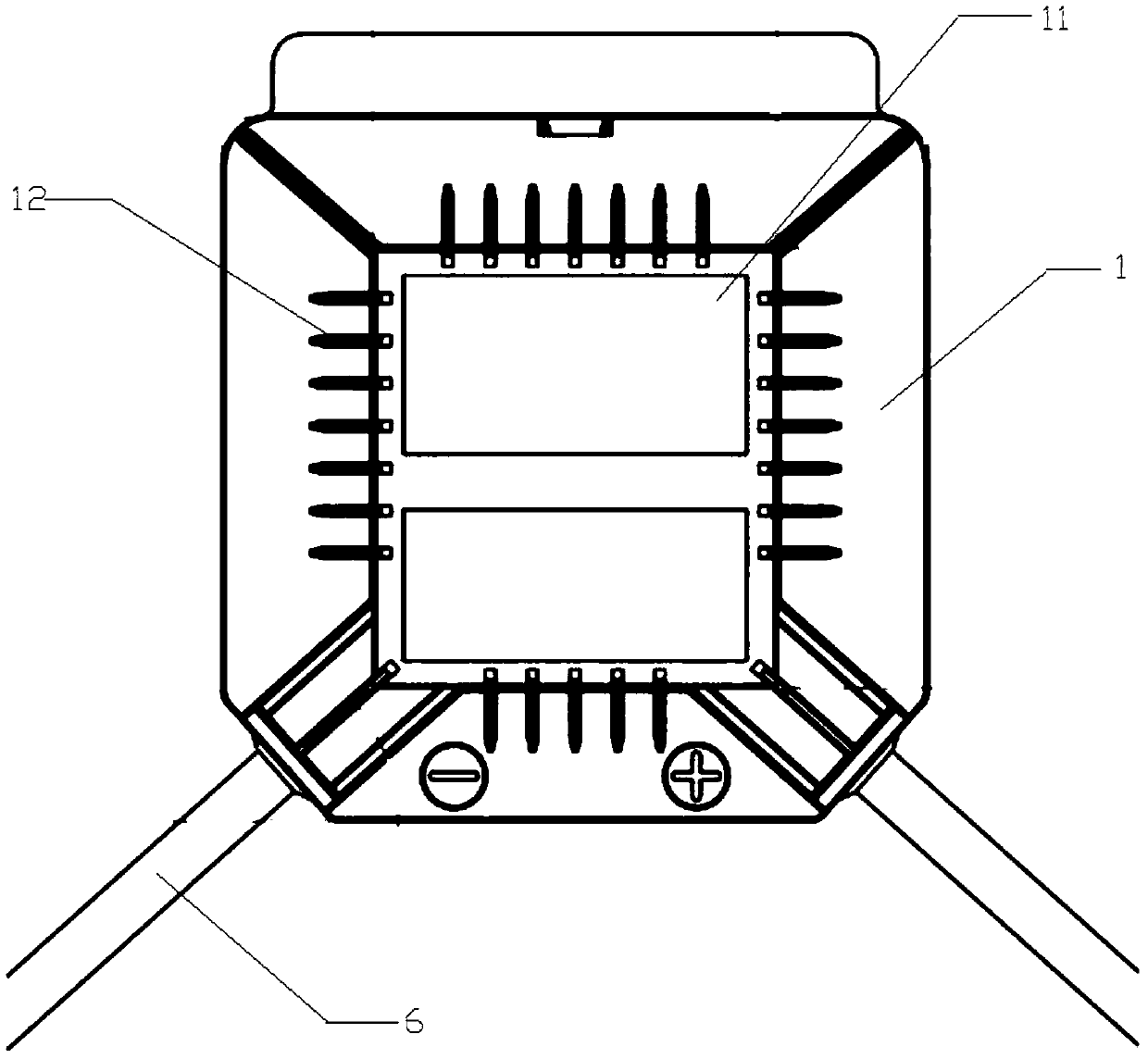

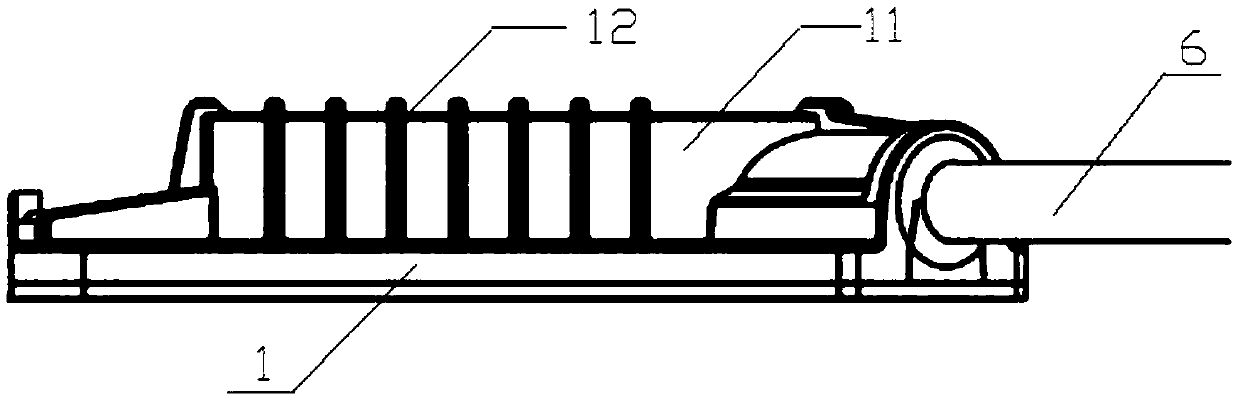

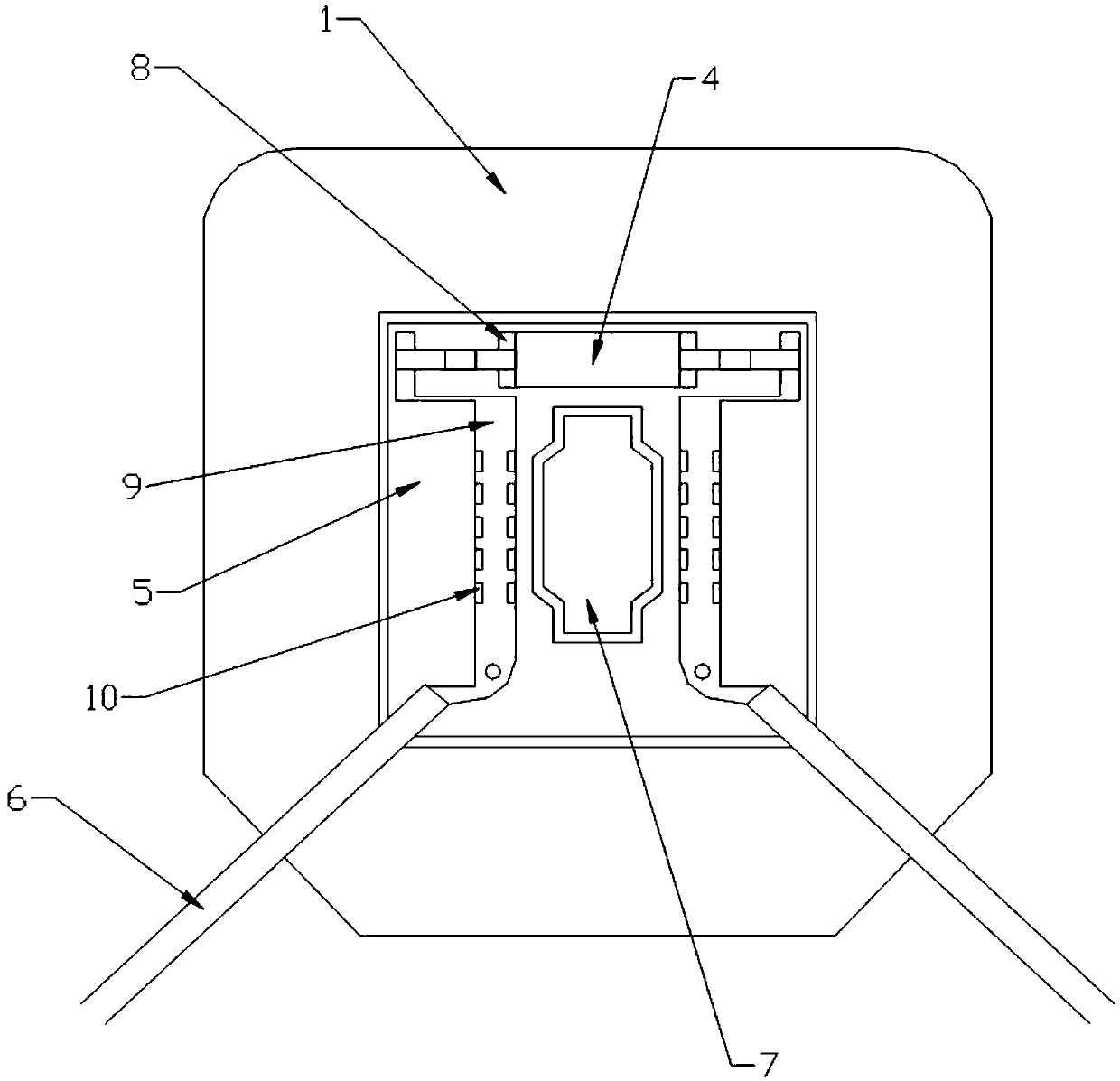

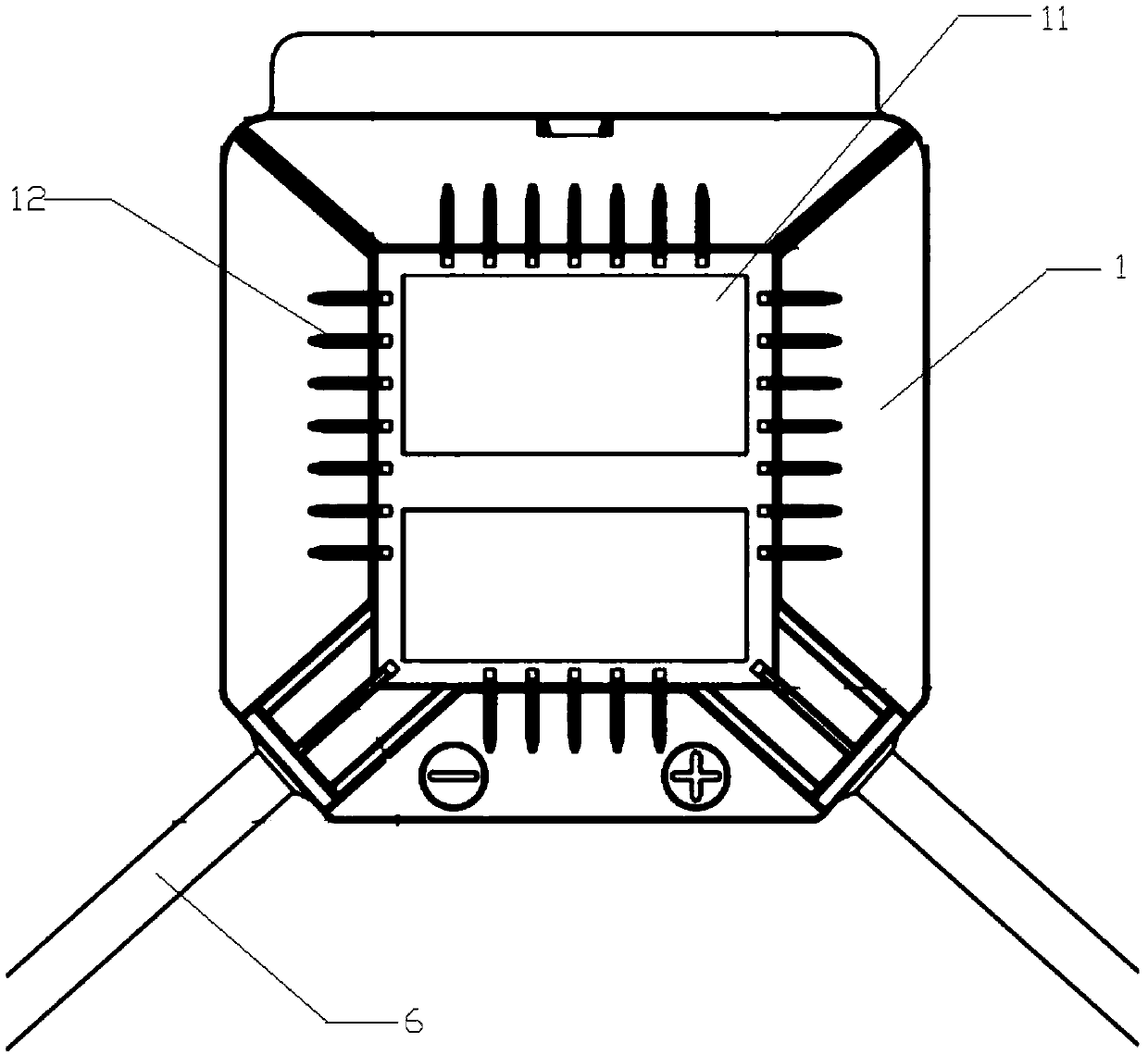

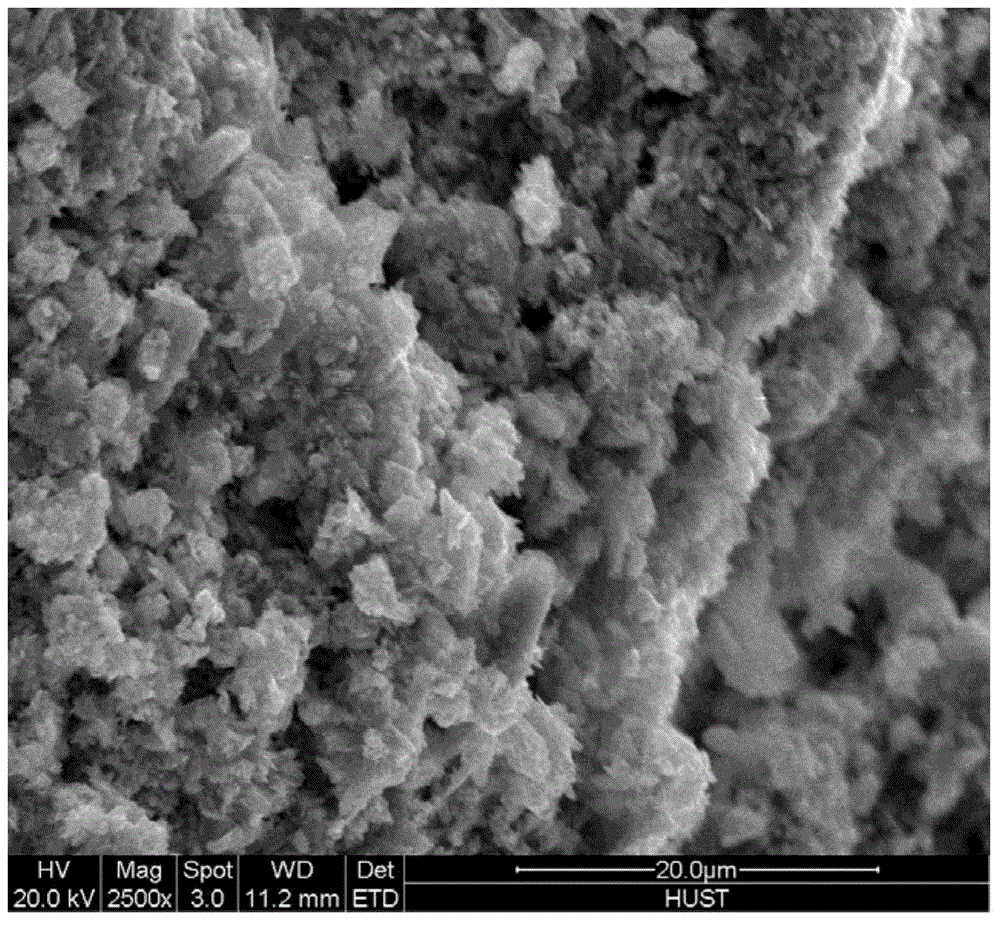

A press-button junction box dedicated to cadmium telluride thin film components

ActiveCN107911078BEasy to installPrecise positioningPhotovoltaicsPhotovoltaic energy generationCadmium CationJunction box

The invention discloses a dedicated press-clip type wiring box for a cadmium telluride thin film assembly. The wiring box includes a box body, a bottom board and a pedestal buckled to each other so asto form a mounting cavity. A diode is mounted in the mounting cavity. The box body is provided with a sunken mounting groove used for accommodating the diode. The mounting groove is provided with a boss protruding from the box body and formed on the back face of the box body. A plurality of radiating fins are arranged on the periphery of the boss. The box body is provided with a wire slot reaching the mounting groove from the edge of the box body. A cable is connected with the diode via the wire slot. The bottom board is in a shape corresponding to that of the mounting groove and can be nested in the mounting groove so as to form a plane with the bottom part of the box body. The middle part of the bottom board is provided with a sub box body which has a hollow bottom part. The box body with provided with a neck within the mounting groove. When the box body buckles with the bottom board, the neck is disposed in the bottom hollow part of the sub box. The edge of the bottom board is connected with a wire slot cover board capable of being spliced with the wire slot. The pedestal is provided with a pin, so that the pin is in associated connection with the neck when the pedestal is nested in the hollow part of the sub box.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

Light-curing 3D printing material and its preparation method and application

ActiveCN108410162BImprove thixotropyHigh forming precisionAdditive manufacturing apparatusPolymer sciencePolyamide

The invention relates to a light-cured 3D printing material and its preparation method and application. The photocurable 3D printing material includes the following raw material components in parts by weight: 20-80 parts of photocurable resin, 10-60 parts of photocurable reactive diluent, 1-10 parts of photoinitiator, and 0.1-20 parts of thixotropic agent part, 0.1-5 parts of auxiliary agent; wherein, the thixotropic agent is at least one of attapulgite, montmorillonite, bentonite, fumed silica, polyamide wax, mica powder; the photocurable resin is At least one of aliphatic polyurethane and alicyclic epoxy resin. The light-curing 3D printing material has excellent thixotropy and can be applied to the FDM nozzle printing process. Compared with SLA, it can effectively reduce the production cost of 3D printing products, and has fast molding speed and high precision, and can perform complex contours or large-scale 3D printing. The production of products.

Owner:广州有得新材料科技有限公司

Epoxy resin curing agent and preparation method thereof

ActiveCN102898624BGood weather resistanceImproved resistance to accelerated agingEpoxy resin coatingsWaxEpoxy

The invention discloses epoxy resin curing agent and a preparation method thereof. The epoxy resin curing agent comprises the following components in percentage by mass: 40 to 50 percent of phenylcarbinol, 30 to 45 percent of isophorone diamine, 10 to 20 percent of epoxy resin, 0.1 to 1 percent of anti-scratch wax, and 1 to 5 percent of an accelerating agent. The method for preparing the epoxy resin curing agent comprises the following steps of: adding proper phenylcarbinol and isophorone diamine into a reaction kettle; uniformly stirring the phenylcarbinol and isophorone diamine, and adding the epoxy resin into the reaction kettle; stirring and heating with steam until the temperature of the reaction liquid is 60 to 75 DEG C; keeping on reaction for 2 hours, and adding the anti-scratch wax and the accelerating agent Schiff base into the reaction kettle; and uniformly dispersing, cooling and subpackaging. By the mode, the invention can provide the epoxy resin curing agent with high hardness and good weather resistance, which is excellent in self-leveling effect when being mixed with an epoxy self-leveling host, good in coating weather resistance after being cured, and high in hardness.

Owner:上海维度化工科技有限公司

Dedicated press-clip type wiring box for cadmium telluride thin film assembly

ActiveCN107911078AEasy to installPrecise positioningPhotovoltaicsPhotovoltaic energy generationDiodeCadmium

The invention discloses a dedicated press-clip type wiring box for a cadmium telluride thin film assembly. The wiring box includes a box body, a bottom board and a pedestal buckled to each other so asto form a mounting cavity. A diode is mounted in the mounting cavity. The box body is provided with a sunken mounting groove used for accommodating the diode. The mounting groove is provided with a boss protruding from the box body and formed on the back face of the box body. A plurality of radiating fins are arranged on the periphery of the boss. The box body is provided with a wire slot reaching the mounting groove from the edge of the box body. A cable is connected with the diode via the wire slot. The bottom board is in a shape corresponding to that of the mounting groove and can be nested in the mounting groove so as to form a plane with the bottom part of the box body. The middle part of the bottom board is provided with a sub box body which has a hollow bottom part. The box body with provided with a neck within the mounting groove. When the box body buckles with the bottom board, the neck is disposed in the bottom hollow part of the sub box. The edge of the bottom board is connected with a wire slot cover board capable of being spliced with the wire slot. The pedestal is provided with a pin, so that the pin is in associated connection with the neck when the pedestal is nested in the hollow part of the sub box.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

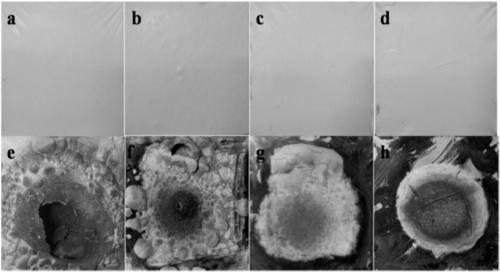

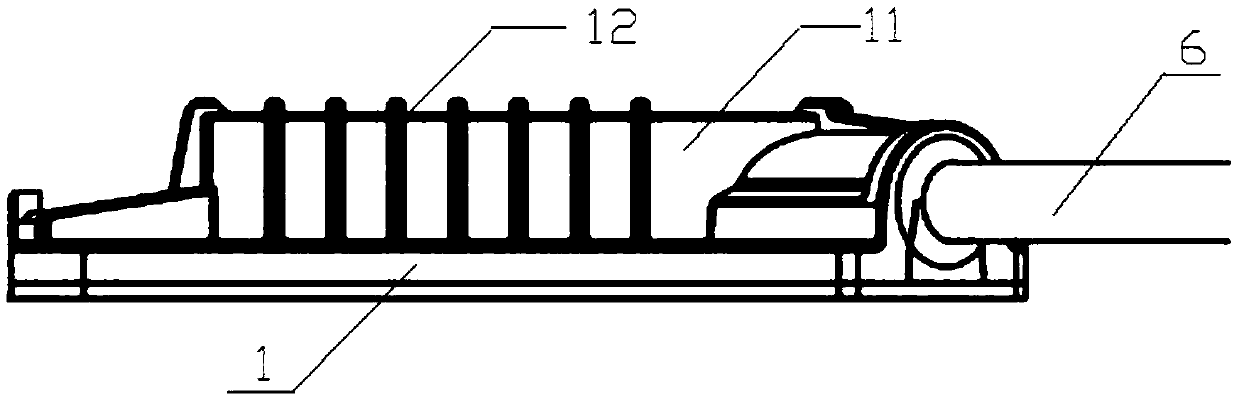

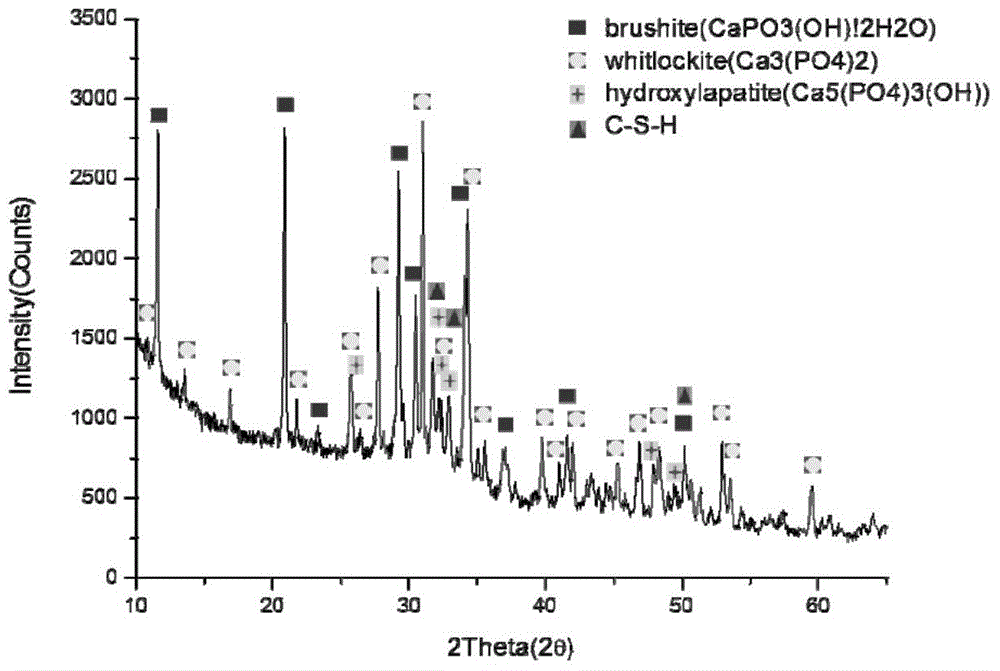

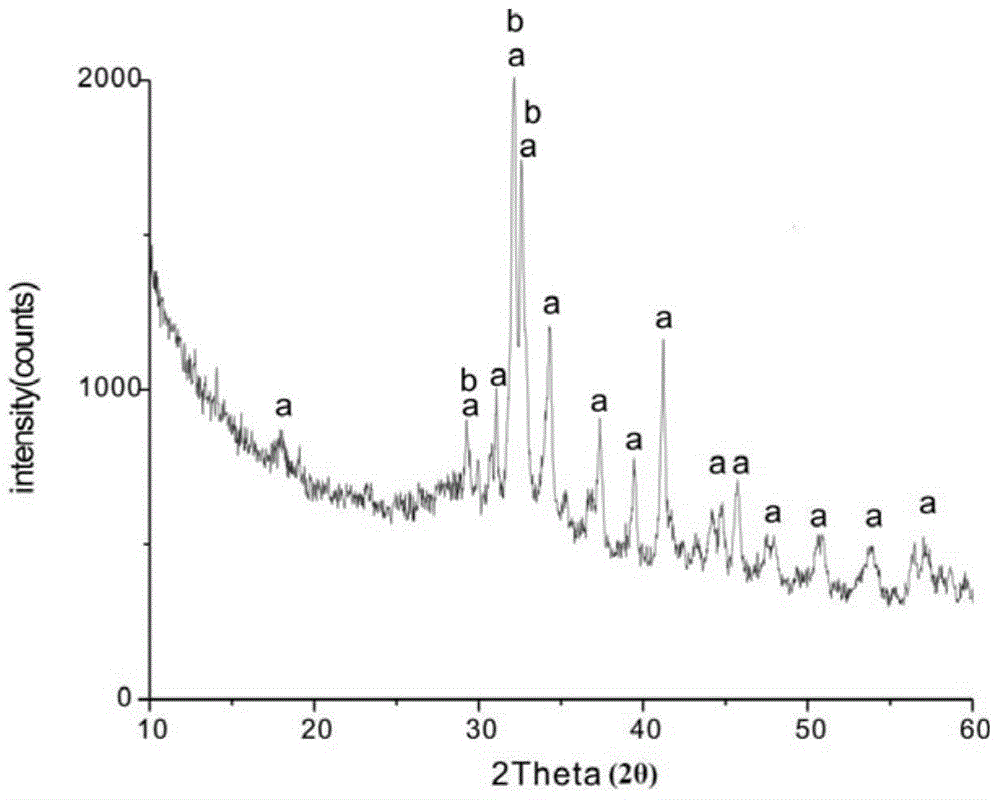

Brushite-calcium silicate/chitosan composite bone cement with rapid and controllable biodegrability

The invention relates to brushite-calcium silicate / chitosan composite bone cement with rapid and controllable biodegrability. The brushite-calcium silicate / chitosan composite bone cement comprises three parts of composite power I, composite powder II and a curing liquid which are stored separately, wherein the composite power I is formed by mixing MCPM (monocalcium phosphate monohydrate) and MgHPO4*3H2O; the composite powder II is formed by mixing calcium phosphate and calcium silicate with a molar ratio of calcium and silicon larger than 1:1, and calcium phosphate is a mixture of one or two of beta-TPC (tertiary calcium phosphate) and alpha-TCP; the curing liquid adopts a chitosan and citric acid solution; and the mass ratio of the composite power I to the composite power II is (0.3-1.5):1, and the ratio of the total mass of the composite power I and the composite power II to the volume of the curing liquid, namely the solid-to-liquid ratio is (1.5-2.7):1 g / ml. On the basis of that appropriate curing time and certain compressive strength are guaranteed, the brushite-calcium silicate / chitosan composite bone cement has continuous, rapid and controllable biodegrability.

Owner:HUAZHONG UNIV OF SCI & TECH

A low-cost long-residence time high-performance modified asphalt and its preparation method

The invention discloses a low-cost, long-reserved time and high-performance modified asphalt and a preparation method thereof. The modified asphalt is an A and B dual-component system, wherein the component A is an epoxy resin and polyethyleneglycol diglycidylether mixture; and the component B comprises an emulsifier, matrix asphalt, a solidification agent and activated waste rubber powder. The preparation method comprises the following steps: adding the activated waste rubber powder into the matrix asphalt, adding the emulsifier and the solidification agent under a high temperature condition, carrying out shearing emulsification to obtain the component B, and fully mixing the component A and the component B of the modified asphalt to obtain the low-cost, long-reserved time and high-performance modified asphalt. Long reserved time is realized through selecting the specific epoxy resin solidification agent and regulating the solidifying rate of an epoxy system in order to meet road pavement and engineering maintenance with long reserved time requirements. The matrix asphalt and the waste rubber powder are used, so the production cost is reduced, and the low-temperature cracking resistance and stability of the modified asphalt are improved.

Owner:JURONG NINGWU CHEM

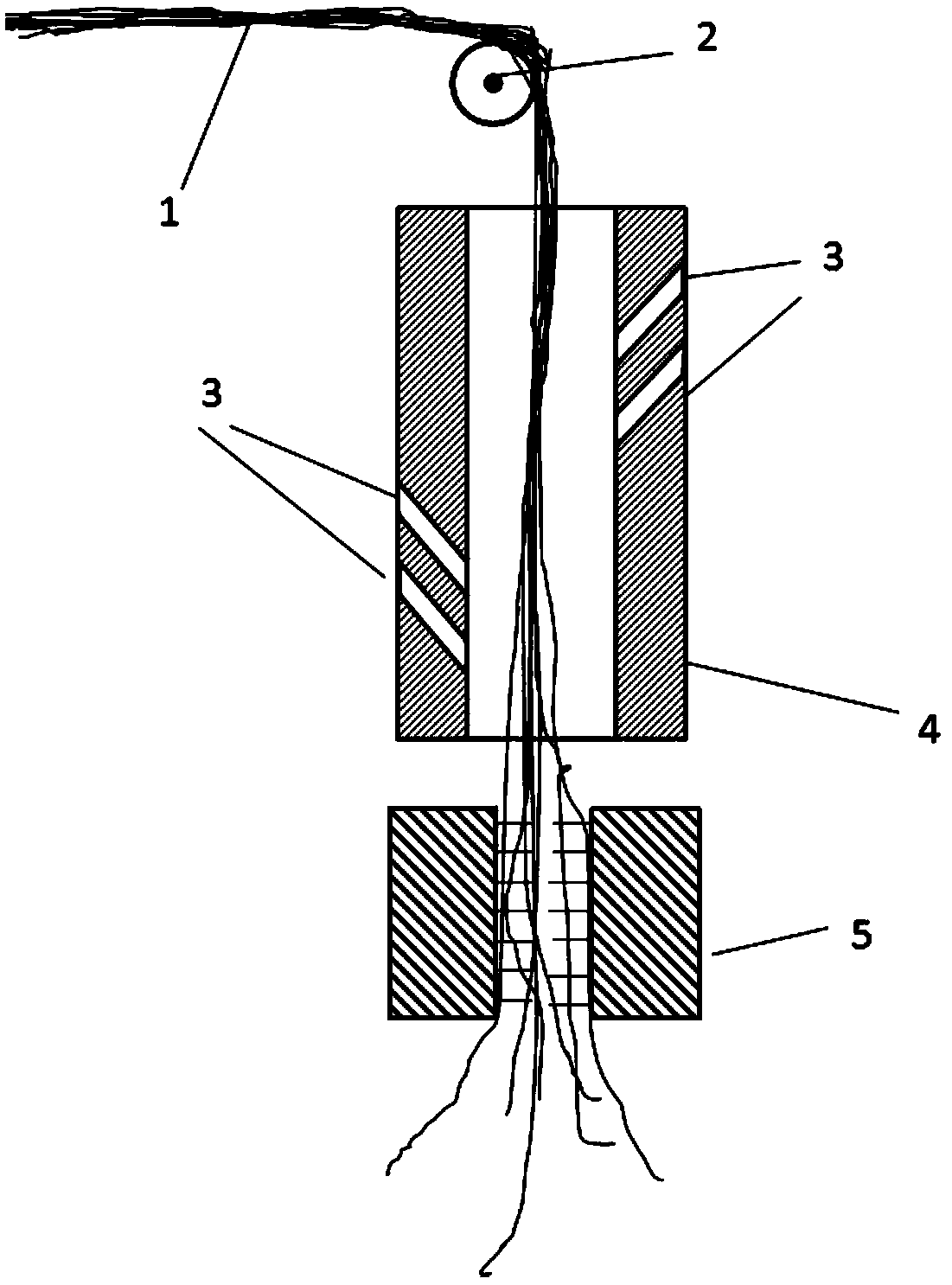

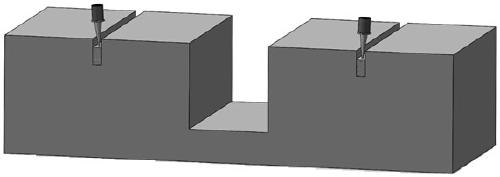

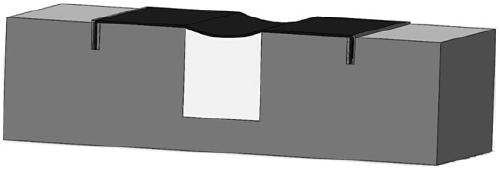

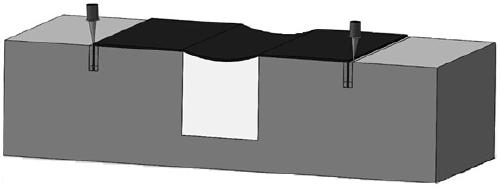

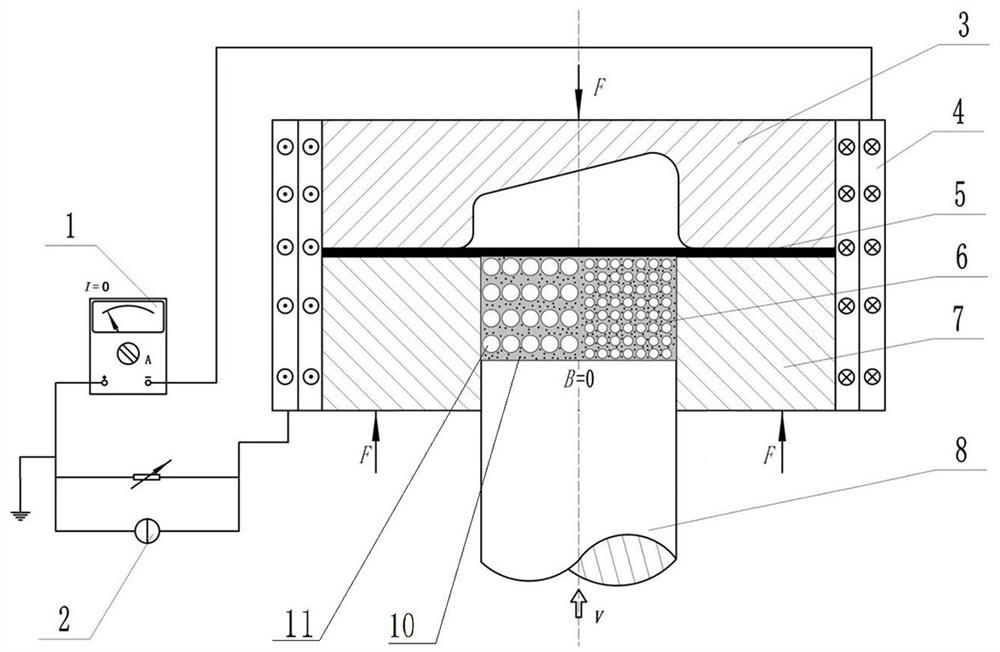

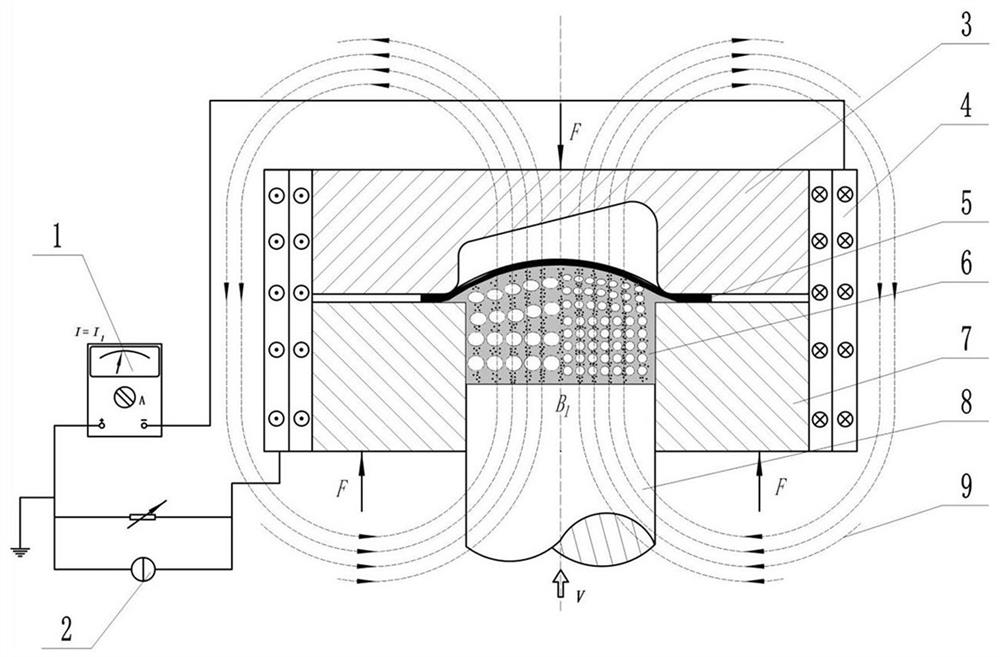

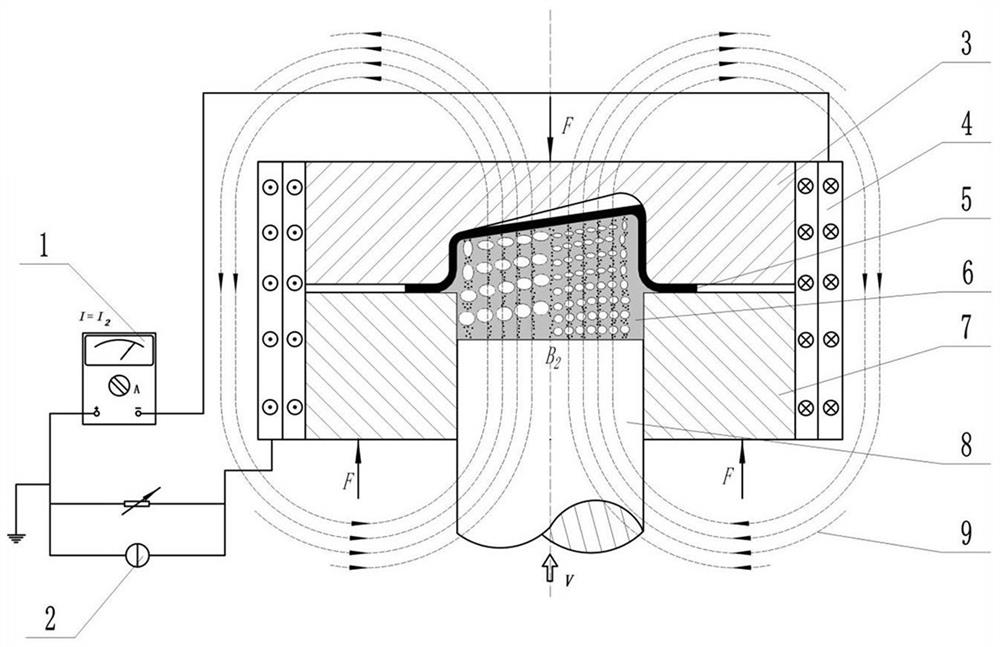

Magnetorheological porous soft mold and plate forming device

ActiveCN113510177ALarge adjustable rangeIncrease or decrease material inflowIncreasing energy efficiencyComposite materialForming force

The invention relates to a magnetorheological porous soft mold and a plate forming device. The magnetorheological porous soft mold comprises an elastic base body with pores; and magnetic particles integrally formed in the elastic base body, wherein the magnetic particles are distributed in the elastic base body in a dispersed mode and located outside the pores. The elastic base body comprises at least two forming sections; all the forming sections are internally provided with the pores, and the porosity of at least one forming section is larger than that of the other forming sections, so that the elastic modulus of the forming sections with the large porosity is smaller than that of the forming sections with the small porosity; or at least one forming section is internally provided with the pores and at least one forming section is not internally provided with the pores, so that the elastic modulus of the forming sections with the pores is smaller than that of the forming sections without the pores. Through the design of the structure, when a blank is in complete contact with a special-shaped female mold, the stress of the whole blank is uniform, and the situation that the blank is broken due to the fact that the forming force is too large when a deeper part is formed is avoided.

Owner:HENAN UNIV OF SCI & TECH

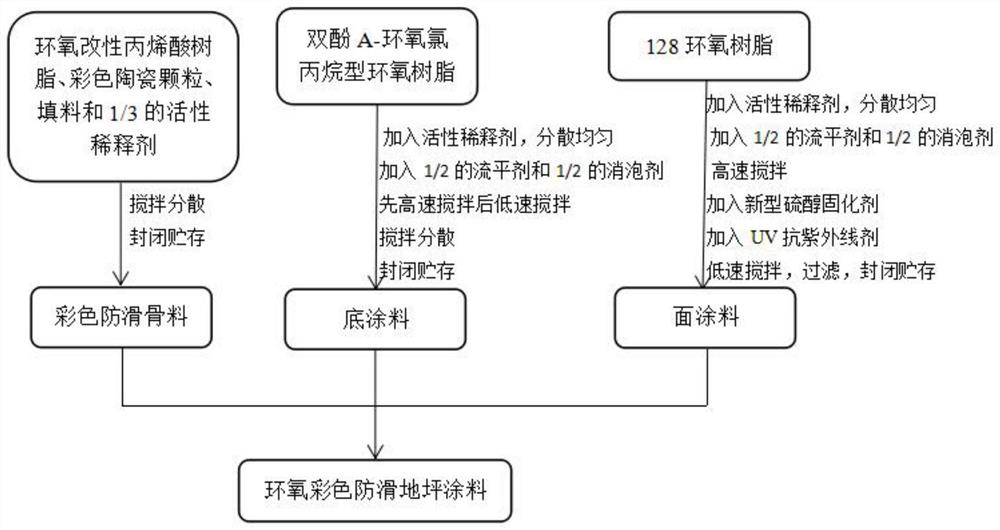

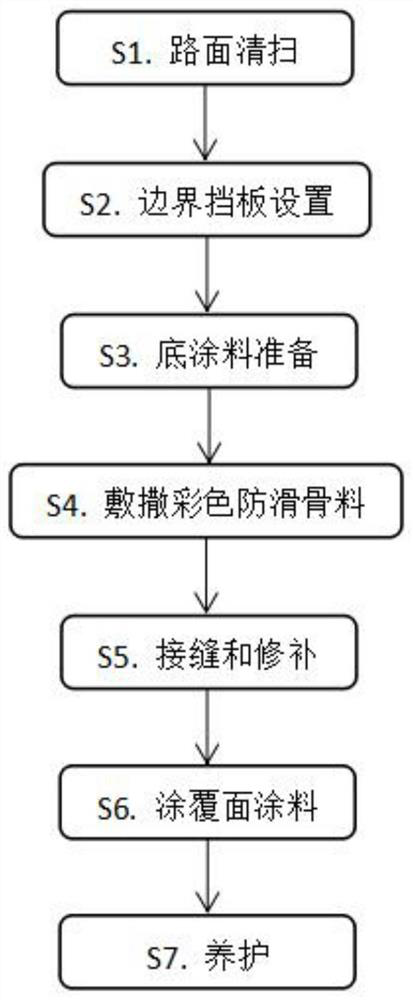

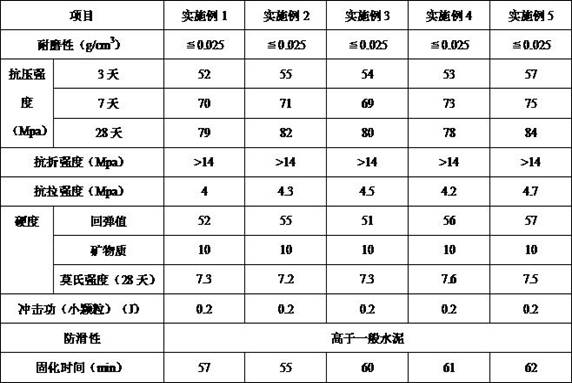

A kind of epoxy colored non-slip floor coating and its preparation and construction method

ActiveCN109593428BImprove ductilityGood anti-aging performanceIn situ pavingsEpoxy resin coatingsPolymer scienceAcrylic resin

Owner:天华交通建设集团有限公司

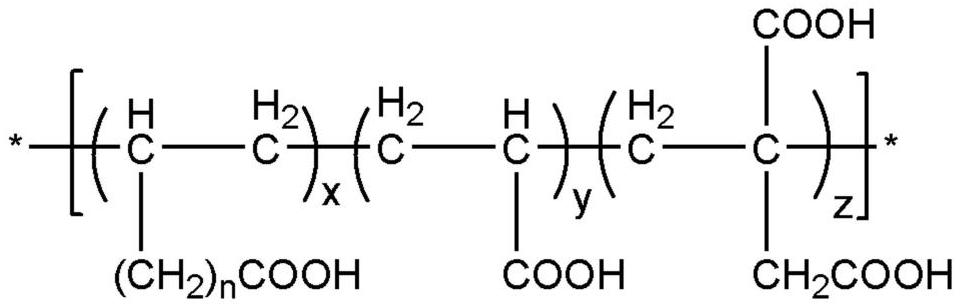

Glass ionomer cement compound used for dental department

ActiveCN113367995AAppropriate viscosityEasy to operateImpression capsDentistry preparationsGlass ionomersPolymer science

The invention discloses a glass ionomer cement compound used for the dental department the matrix component of the glass ionomer cement compound comprises silicon-aluminum-fluorine glass powder and polycarboxylic acid liquor, wherein the polymerizable monomer of the polycarboxylic acid comprises 55-70 parts by weight of acrylic acids, 25-30 parts by weight of itaconic acids and 5-15 parts by weight of alkyl olefine acids. The invention prepares a tricarboxylic acid copolymer, the tricarboxylic acid copolymer is dissolved in water to prepare the polycarboxylic acid liquor used for the glass ionomer cement, the polycarboxylic acid liquor and the commercially available silicon-aluminum-fluorine glass powder are mixed and cured, and therefore, the prepared glass ionomer cement has the characteristic of high mechanical strength. Compared with the prior art, the glass ionomer cement compound can effectively improve the bending strength and the compressive strength of the glass ionomer cement, and the application range of the glass ionomer cement in the field of dental department restoration is expanded.

Owner:SOUTH CHINA UNIV OF TECH

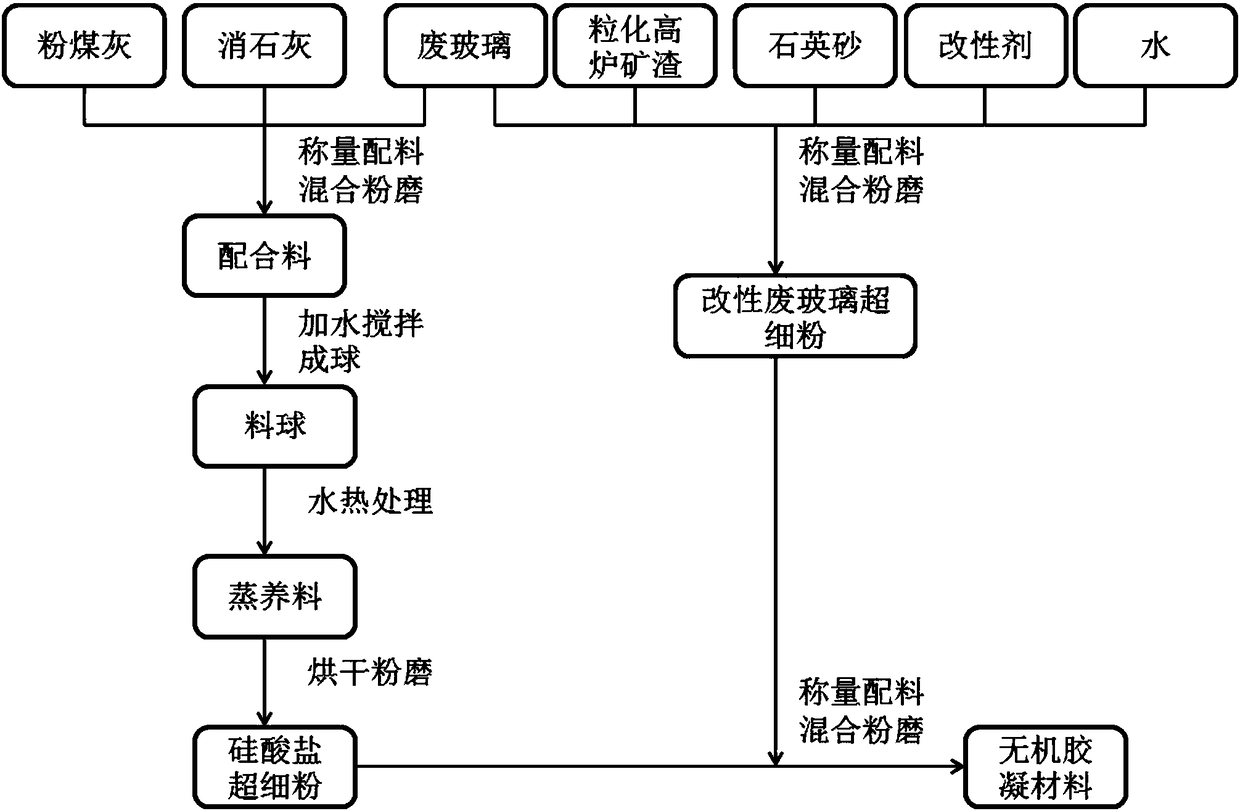

A kind of inorganic cementitious material with fly ash and waste glass as raw materials and preparation method thereof

The invention provides an inorganic gelling material made from coal ash and waste glass and a preparation method of the inorganic gelling material. The inorganic gelling material comprises, by weight, 65-75 parts of silicate superfine powder and 25-35 parts of modified waste glass superfine powder. The preparation method includes mixing and grinding the coal ash, slaked lime and the waste glass, adding water, evenly stirring the mixture into a material ball, drying and cooling the material ball after hydrothermal treatment, and grinding the material ball into the silicate superfine powder; mixing and grinding the waste glass, granulated blast-furnace slag, silica sand, modifying agent and water to obtain the modified waste glass superfine powder; mixing the silicate superfine powder with the modified waste glass superfine powder, and grinding the mixture to obtain the inorganic gelling material. High-temperature calcination is not needed and heat consumption is low in the preparing process of the inorganic gelling material, utilization rates of the coal dust and the waste glass are high, curing time of the obtained material is proper, and the obtained material has high curing strength and high sulphate attack resistance.

Owner:HOHAI UNIV

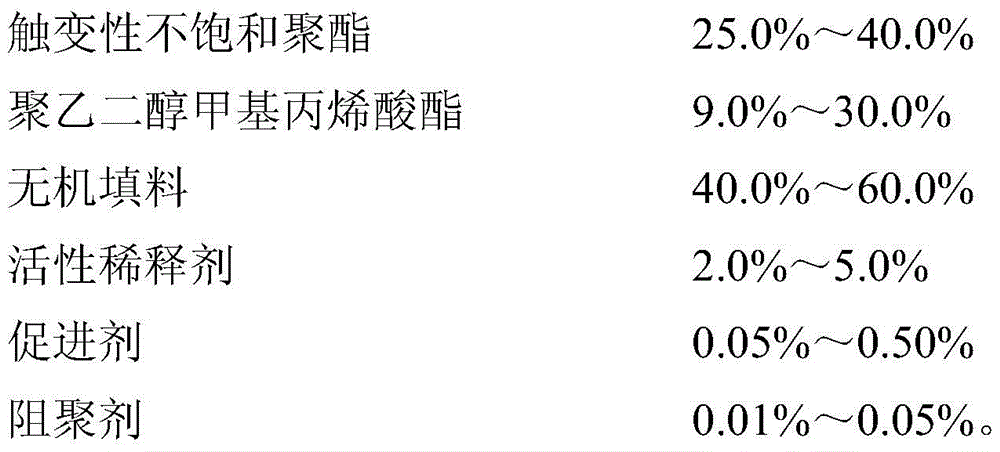

A kind of preparation method and product of high-strength marble glue

ActiveCN105255412BImprove toughnessGood compatibilityNon-macromolecular adhesive additivesGraft polymer adhesivesAdhesiveHardness

The invention discloses a high-strength marble adhesive and a preparation method thereof. The preparation method comprises the following steps: preparing thixotropic unsaturated polyester and polyglycol methacrylate ester as matrix resin at first; and then performing compounding with a polymerization inhibitor, an inorganic filler, a reactive diluent and an accelerant to prepare a marble adhesive product. The marble adhesive product disclosed by the invention is convenient in raw material source and simple in preparation process, and the obtained product has the advantages of being moderate in curing time, stable in storage, small in smell, high in hardness, good in toughness, good in adhesive strength and the like.

Owner:杭州得力科技股份有限公司

Amido amine epoxy curing agent and preparation method and application thereof

PendingCN114057993AImprove toughnessStrong adhesionEpoxy resin adhesivesPolymer scienceDiethylenetriamine

The invention discloses an amido amine epoxy curing agent which comprises the following components in parts by weight: 30-55 parts of fatty acid, 30-60 parts of fatty amine, 5-20 parts of an epoxy modifier and 0.2-4 parts of an accelerant, the fatty acid is one or a mixture of more of C16-C20 higher fatty acid, oleic acid, linoleic acid, abietic acid and tall oil; the fatty amine is one or a mixture of more of diethylenetriamine, triethylene tetramine, tetraethylenepentamine and pentaethylenehexamine; the epoxy modifier is one or a mixture of more of C12-C14 alkyl glycidyl ether, 1, 4-butanediol diglycidyl ether, o-cresol glycidyl ether and trimethylolpropane triglycidyl ether. The amido amine epoxy curing agent is moderate in curing reaction time, low in viscosity and convenient to operate, has excellent adhesive force on a humid surface, and is particularly suitable for the field of civil engineering in a humid environment.

Owner:潼灏(上海)材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com