Brushite-calcium silicate/chitosan composite bone cement with rapid and controllable biodegrability

A biologically active brushite technology, applied in medical science, prosthesis, etc., can solve the problems of scattering, limiting the application and research of bone cement, slow degradation rate, etc., and achieve the effect of preventing scattering and continuous rapid degradation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

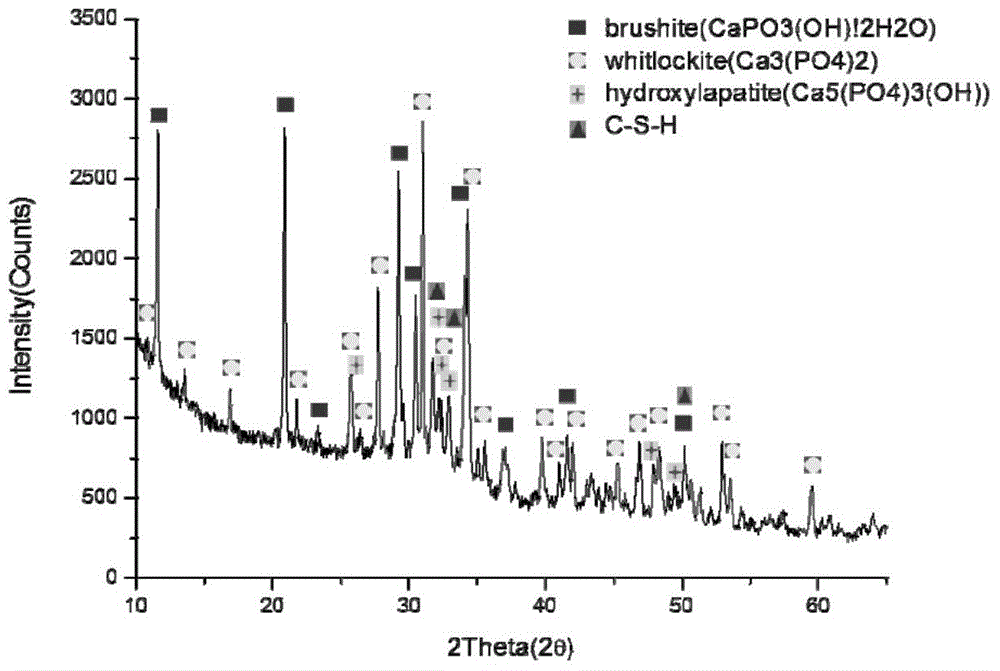

[0019] Rapidly degradable bioactive brushite-calcium silicate / chitosan composite bone cement, which is composed of composite powder 1, composite powder 2 and solidification liquid, each component is stored separately, wherein: the composite Powder one consists of MCPM1.2g, MgHPO 4 ·3H 2 O 0.2g is obtained by mixing, and the composite powder is composed of β-TCP(Ca 3 (PO 4 ) 2 )0.7g, α-TCP (Ca 3 (PO 4 ) 2 )0.7g, calcium silicate ((CaO) 7 (SiO 2 ) 3 ) 1.2g, the solidified liquid is an aqueous solution of chitosan and citric acid, the mass concentration of citric acid in the solidified liquid is 0.06g / ml, the mass concentration of chitosan is 0.05g / ml, the composite powder and the ratio of the total mass of the composite powder 2 to the volume of the solidified liquid is 1.5g / mL.

[0020] Preparation of solidified solution: Dissolve 2.4g of citric acid in 40ml of deionized water, then slowly add 2g of chitosan into the citric acid solution stirred at a constant speed, a...

Embodiment 2

[0024] Rapidly degradable bioactive brushite-calcium silicate / chitosan composite bone cement, which is composed of composite powder 1, composite powder 2 and solidification liquid, each component is stored separately, wherein: the composite Powder one consists of MCPM1.2g, MgHPO 4 ·3H 2 O 0.2g is obtained by mixing, and the composite powder is composed of β-TCP(Ca 3(PO 4 ) 2 )0.2g, α-TCP (Ca 3 (PO 4 ) 2 )1.2g, calcium silicate ((CaO) 7 (SiO 2 ) 3 ) 1.2g, the solidified liquid is a solution of chitosan and citric acid, the mass concentration of citric acid in the solidified liquid is 0.175g / ml, the mass concentration of chitosan is 0.14g / ml, the composite powder and the ratio of the total mass of the composite powder 2 to the volume of the solidified liquid is 2.0 g / ml.

[0025] The configuration of the solidified solution: Dissolve 7g of citric acid in 40ml of deionized water, then slowly add 5.6g of chitosan into the citric acid solution stirred at a constant speed,...

Embodiment 3

[0029] Rapidly degradable bioactive brushite-calcium silicate / chitosan composite bone cement, which is composed of composite powder 1, composite powder 2 and solidification liquid, each component is stored separately, wherein: the composite Powder one consists of MCPM2.09g, MgHPO 4 ·3H 2 O 0.2g is obtained by mixing, and the composite powder is composed of β-TCP(Ca 3 (PO 4 ) 2 ) 0.51g, dicalcium silicate 1.2g are mixed, and solidification liquid is the solution of chitosan and citric acid, and the mass concentration of citric acid in the solidification liquid is 0.175g / ml, and the mass concentration of chitosan is 0.14g / ml, the ratio of the total mass of composite powder 1 and composite powder 2 to the volume of solidified liquid is 2.0 g / mL.

[0030] The preparation of solidified liquid is the same as embodiment 2.

[0031] Method of use: After mechanically mixing the above-mentioned composite powder 1 and composite powder 2, add a corresponding amount of solidification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com