A kind of preparation method and product of high-strength marble glue

A marble glue, high-strength technology, used in adhesives, non-polymer adhesive additives, grafted polymer adhesives, etc., can solve the problem of short product storage period, low bonding strength, low molding hardness, etc. problems, to achieve the effect of reduced volatility, excellent bonding strength and moderate curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

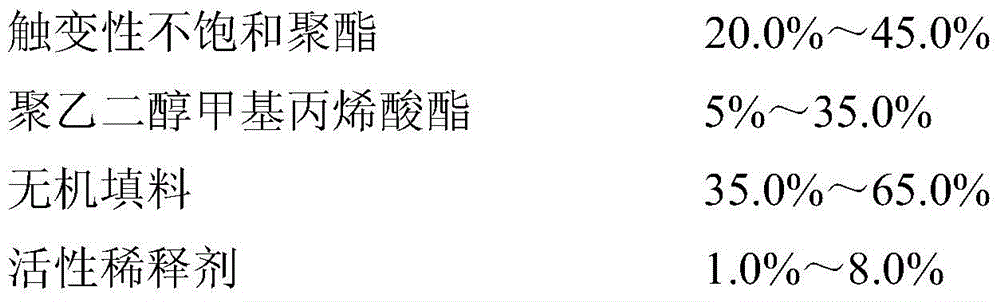

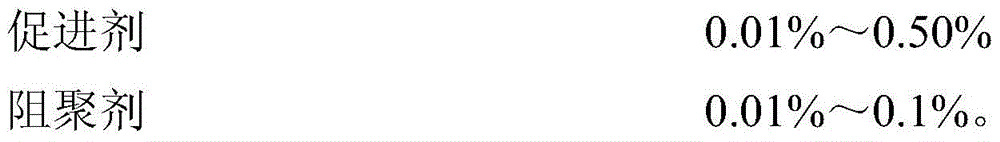

Method used

Image

Examples

Embodiment 1

[0036] First, add 98kg of maleic anhydride, 200kg of isophthalic acid, 218kg of butanediol, and 2.6kg of hydroquinone into a reaction kettle with rectification function, heat to 105°C, and start the process after all materials are dissolved. Stirrer, continue to heat up; when the temperature rises to 160°C, heat preservation reaction for about 30 minutes, then gradually heat up to 200°C, heat preservation reaction; when the theoretical water output exceeds 2 / 3, vacuum dehydration, continue to react until the acid value of the reaction system When the temperature drops to ~20°C, stop the vacuuming, end the reaction, and lower the temperature; when the temperature drops to 80°C, add 340kg of vinyl toluene and 17kg of polyamide wax, and after stirring evenly, the material can be discharged when the temperature drops below 50°C to obtain Thixotropic unsaturated polyester for use.

[0037] Then, in the reactor with water separator, add 86kg methacrylic acid, 202kg polyethylene glyc...

Embodiment 2

[0041] First, add 118kg of maleic anhydride, 166kg of isophthalic acid, 208kg of butanediol, 1.5kg of benzoquinone, and 2.0kg of tert-butylcatechol into a reaction kettle with rectification function, heat to 105°C, wait After all the materials are dissolved, start the agitator and continue to heat up; when the temperature rises to 160°C, heat preservation reaction for about 30 minutes, then gradually heat up to 200°C, heat preservation reaction; when the theoretical water output exceeds 2 / 3, vacuum dehydration, continue React until the acid value of the reaction system drops to ~20, stop vacuuming, end the reaction, and lower the temperature; when the temperature drops to 80°C, add 215kg of vinyltoluene and 21kg of hydrogenated castor oil, and stir until the temperature drops below 50°C It can be discharged to obtain thixotropic unsaturated polyester for later use.

[0042] Then, add 86kg of methacrylic acid, 220kg of polyethylene glycol 200, 1.5kg of tert-butylcatechol, 15.8k...

Embodiment 3

[0046] First, add 98kg of maleic anhydride, 166kg of isophthalic acid, 194kg of butanediol, 0.9kg of copper naphthenate, and 2.0kg of tert-butylcatechol into a reaction kettle with rectification function, and heat to 105°C After all the materials are dissolved, start the agitator and continue to heat up; when the temperature rises to 160°C, heat preservation reaction for about 30 minutes, then gradually heat up to 200°C, heat preservation reaction; when the theoretical water output exceeds 2 / 3, vacuum dehydration , continue to react until the acid value of the reaction system drops to ~20, stop vacuuming, end the reaction, and lower the temperature; when the temperature drops to 80°C, add 250kg of vinyltoluene, 18kg of fumed silica, and 1kg of organic bentonite, and stir well When the temperature drops below 50°C, the material can be discharged to obtain thixotropic unsaturated polyester for use.

[0047] Then, add 86kg of methacrylic acid, 210kg of polyethylene glycol 200, 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com