Amido amine epoxy curing agent and preparation method and application thereof

A technology of epoxy curing agent and amidoamine, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of insufficient bonding strength, long curing time, inconvenient operation, etc., and achieve adhesion Strong, low process energy consumption, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

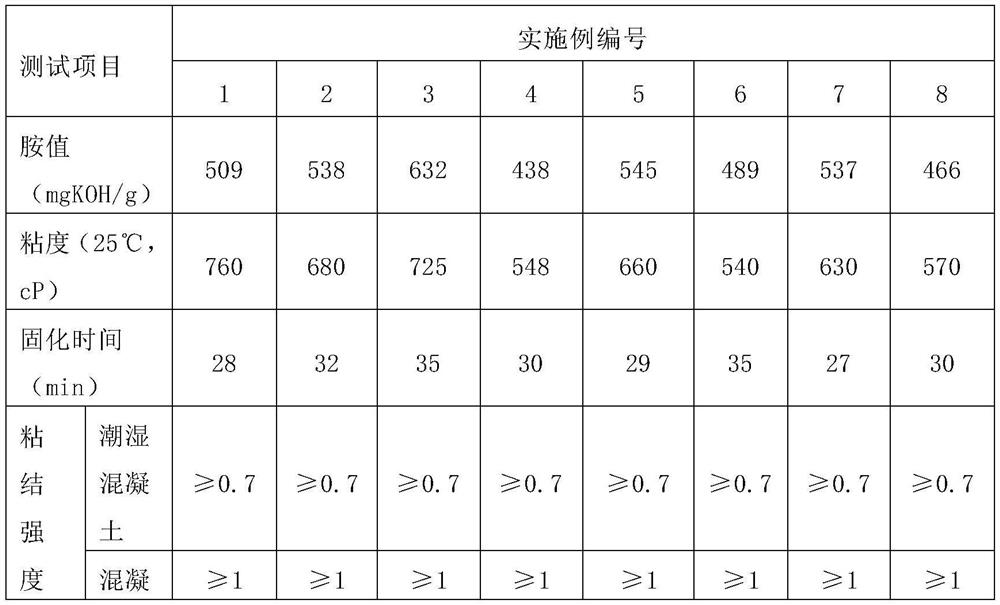

Examples

Embodiment 1

[0027] The preparation method of amidoamine epoxy curing agent comprises the steps:

[0028] S1. Weigh 46 parts of fatty acid (oleic acid and linoleic acid with a weight ratio of 1:1), 45 parts of fatty amine (triethylenetetramine), 15 parts of epoxy modifier (C12-C14 alkyl glycidyl ether ), 0.5 parts of epoxy accelerator (2,4,6 three-(dimethylaminomethyl)phenol);

[0029] S2. Mix the fatty acid and the epoxy modifier evenly, heat up to 140° C. and then stir for 2 hours;

[0030] S3, add aliphatic amine again, and heat up to 180° C., then stir for 2 hours;

[0031] S4. Cool down the temperature of the mixture in step S3 until the temperature of the mixture is ≤70° C., add an epoxy accelerator, stir evenly, and then discharge to obtain an amidoamine epoxy curing agent.

Embodiment 2

[0033] The preparation method of amidoamine epoxy curing agent comprises the steps:

[0034] S1, take by weighing 43 parts of fatty acids (C16-C20 higher fatty acid), 42 parts of fatty amines (diethylenetriamine and tetraethylenepentamine with a weight ratio of 1:1), 12 parts of epoxy modifier (trimethylol propane triglycidyl ether), 1 part epoxy accelerator (2,4,6 tris-(dimethylaminomethyl)phenol);

[0035] S2. Mix the fatty acid and the epoxy modifier evenly, heat up to 130° C. and then stir for 1 hour;

[0036] S3, add aliphatic amine again, and heat up to 170°C, then stir and react for 2 hours;

[0037] S4. Cool down the temperature of the mixture in step S3 until the temperature of the mixture is ≤70° C., add an epoxy accelerator, stir evenly, and then discharge to obtain an amidoamine epoxy curing agent.

Embodiment 3

[0039] The preparation method of amidoamine epoxy curing agent comprises the steps:

[0040] S1, take by weighing 33 parts of fatty acids (weight ratio is the C16-C20 higher fatty acid of 1:1:1, rosin acid, tall oil), 32 parts of aliphatic amines (triethylenetetramine), 10 parts of epoxy modifiers ( C12-C14 alkyl glycidyl ether), 1 part epoxy accelerator (1-aminopiperazine);

[0041] S2. Mix the fatty acid and the epoxy modifier evenly, heat up to 150° C. and then stir for 1 hour;

[0042] S3, add aliphatic amine again, and heat up to 190° C., then stir and react for 1 hour;

[0043] S4. Cool down the temperature of the mixture in step S3 until the temperature of the mixture is ≤70° C., add an epoxy accelerator, stir evenly, and then discharge to obtain an amidoamine epoxy curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com