Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Plenty of time to operate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

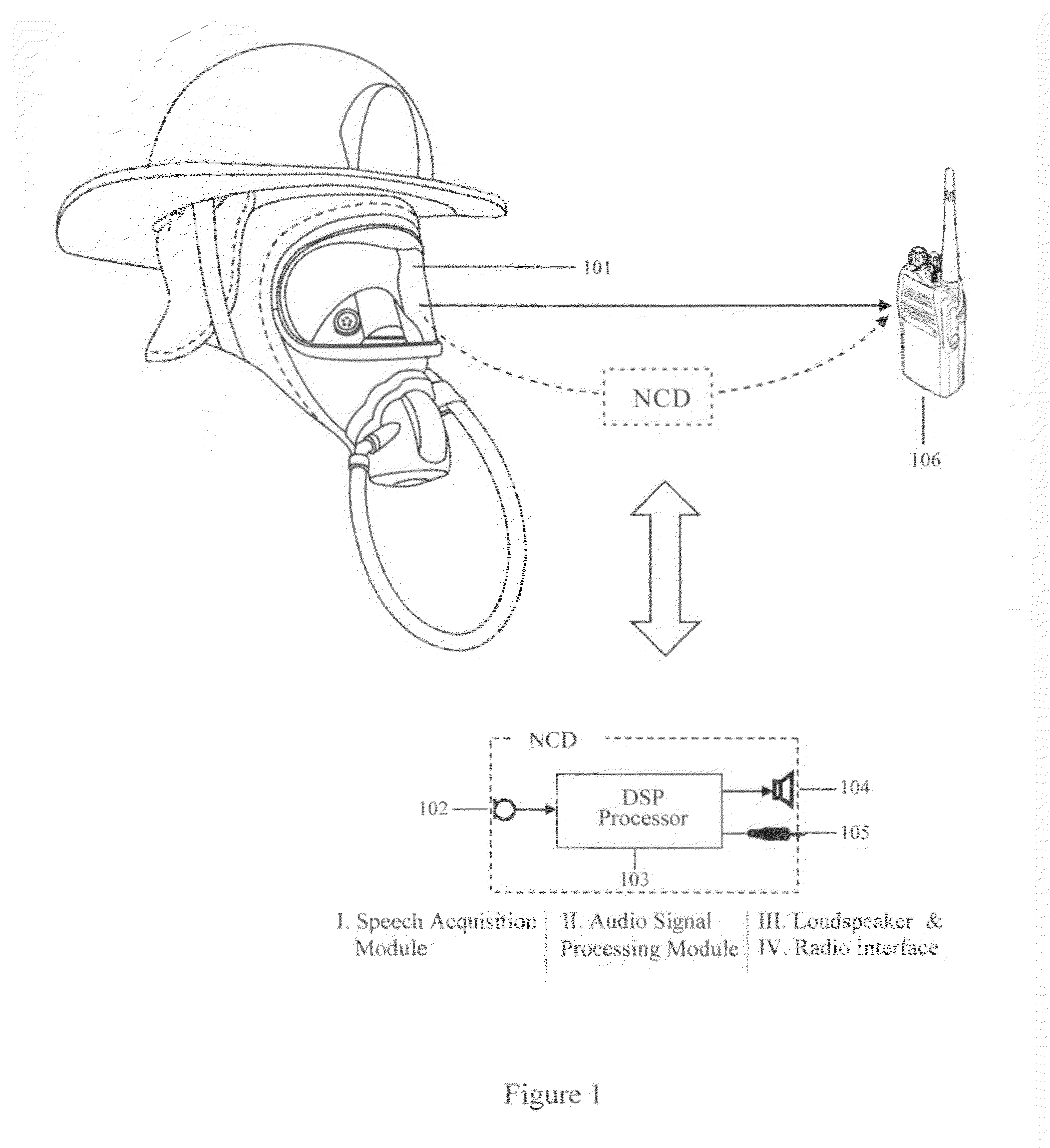

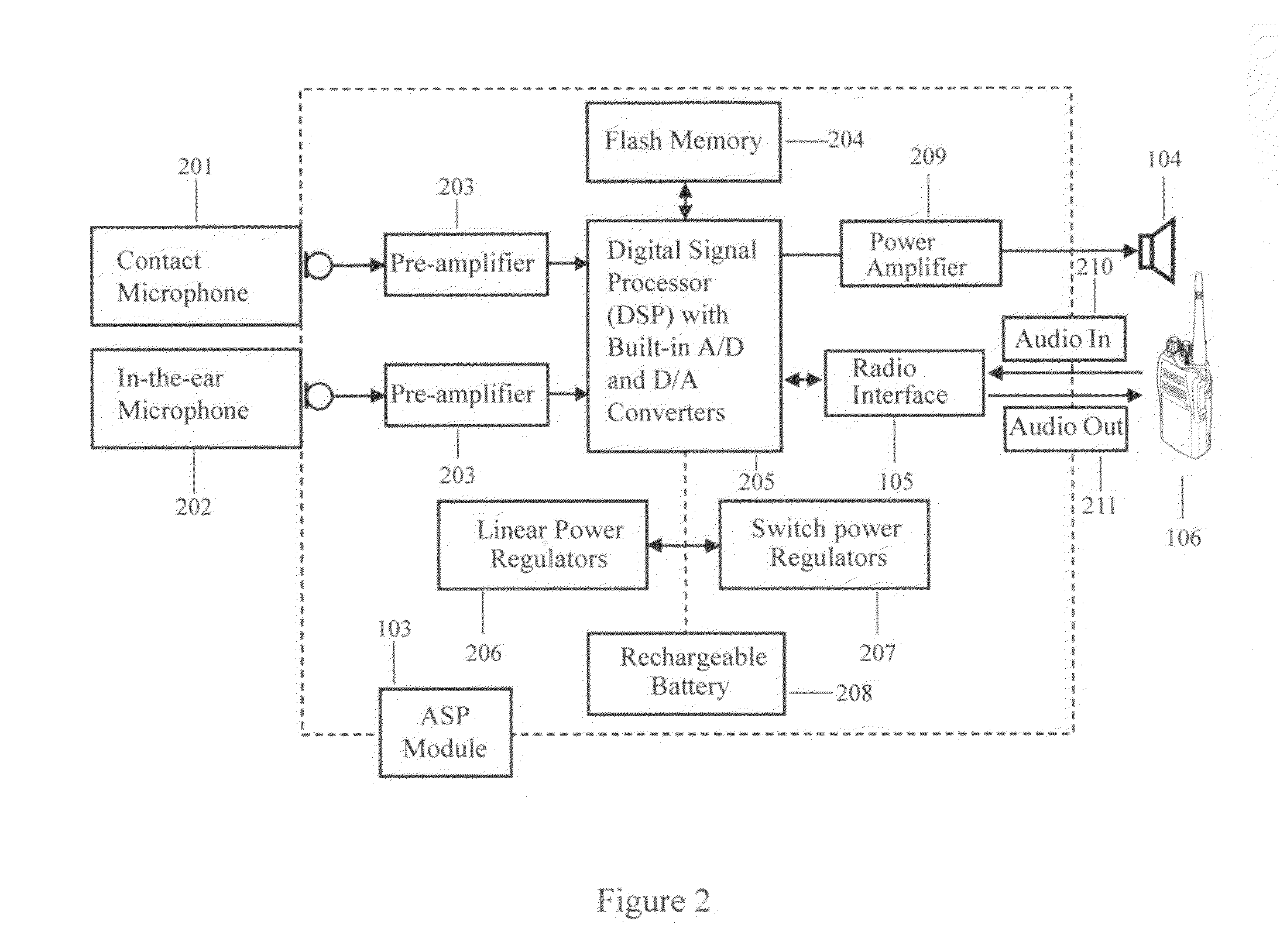

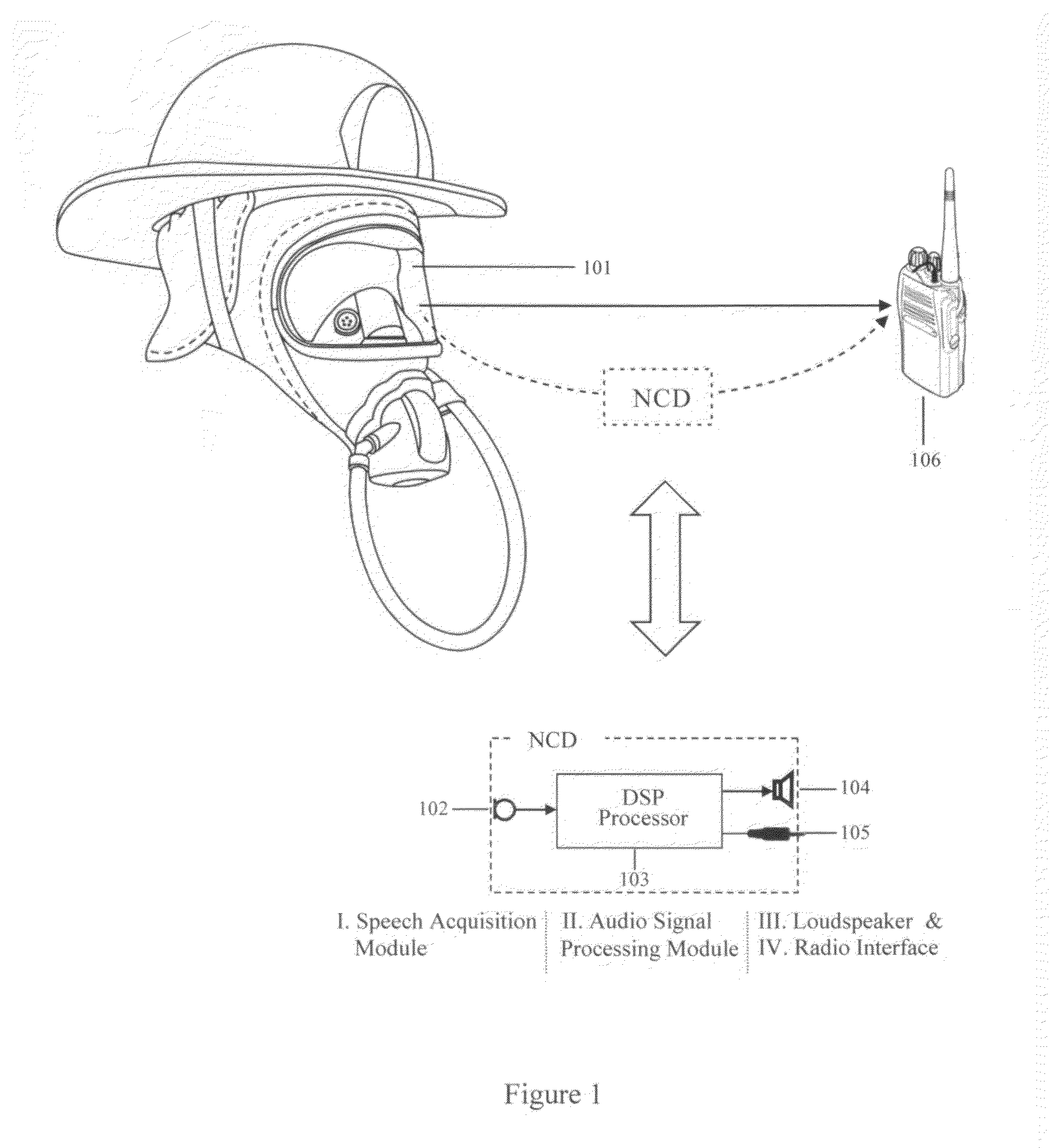

Wearable Communication System With Noise Cancellation

ActiveUS20140081631A1Efficient communicationNo impact on the first responders' abilitiesEar treatmentSpeech analysisContact microphoneEngineering

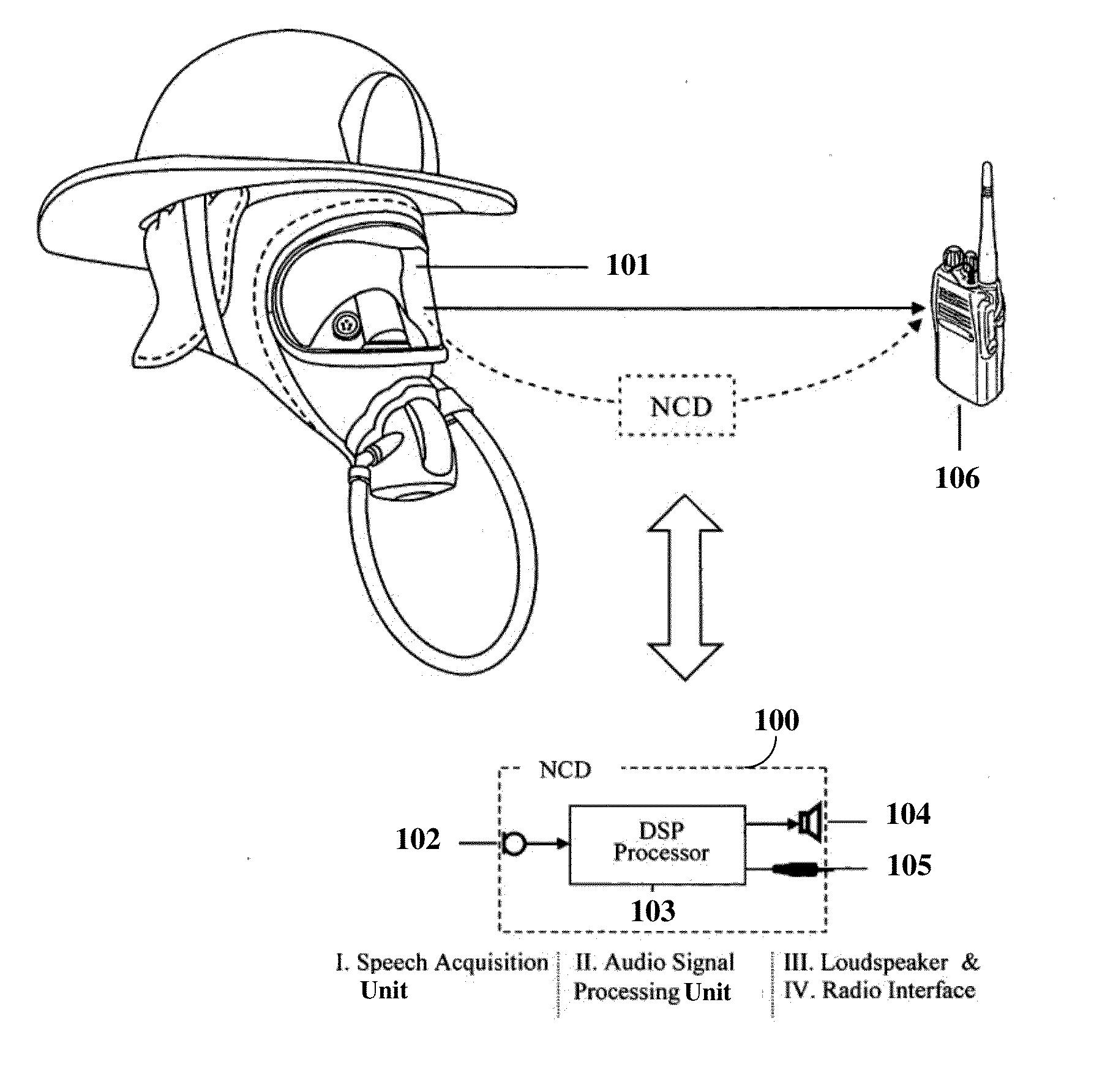

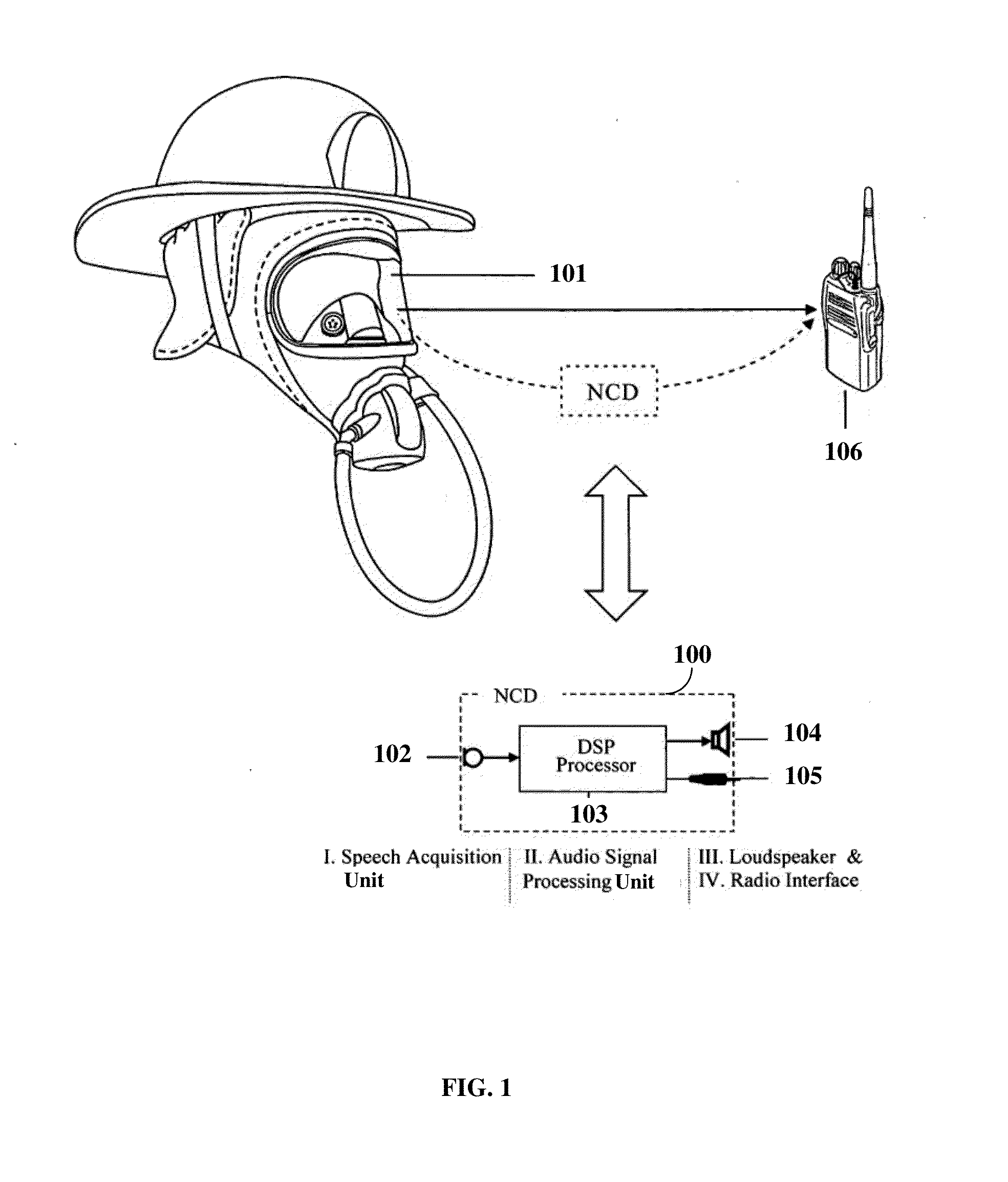

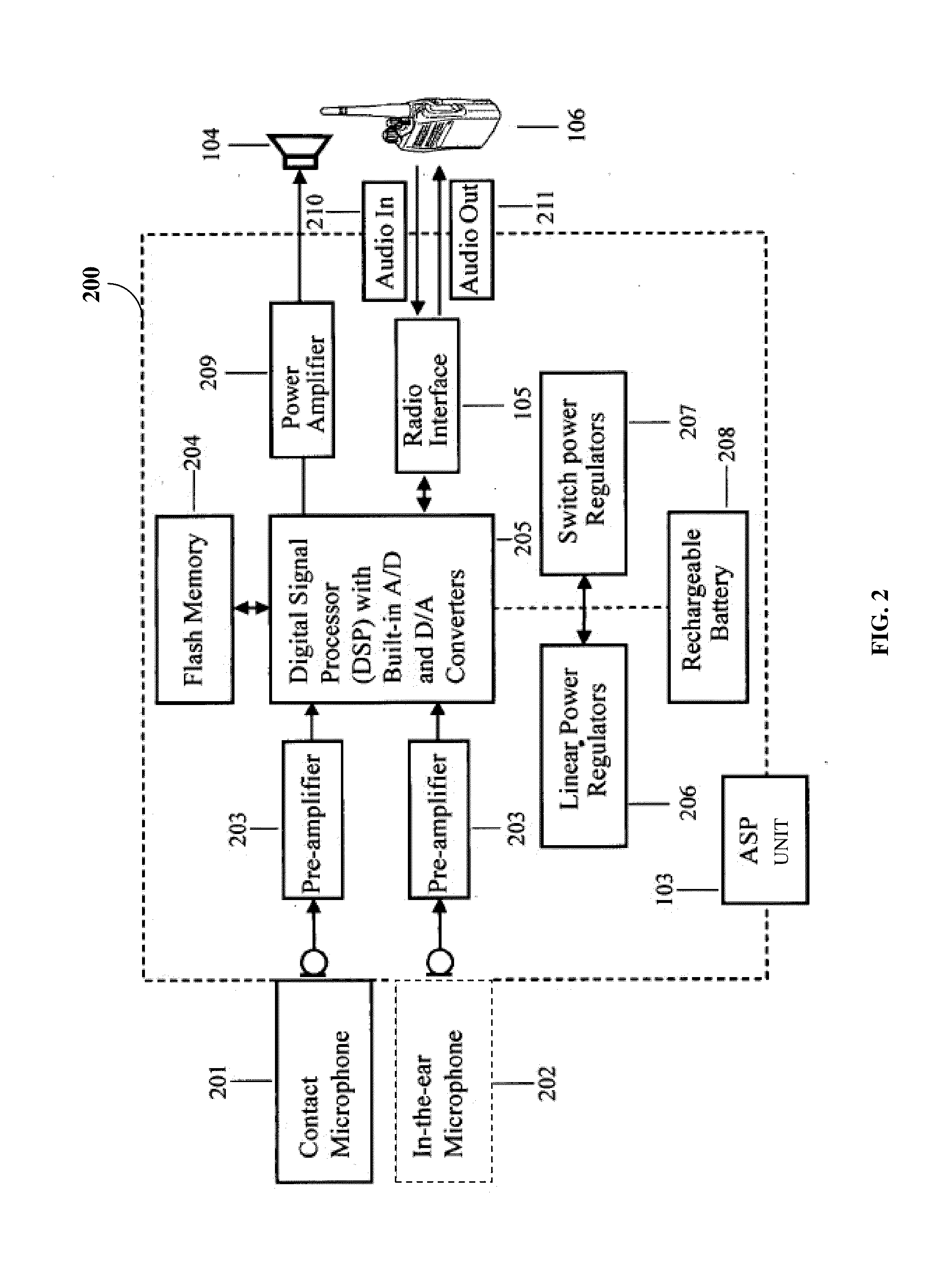

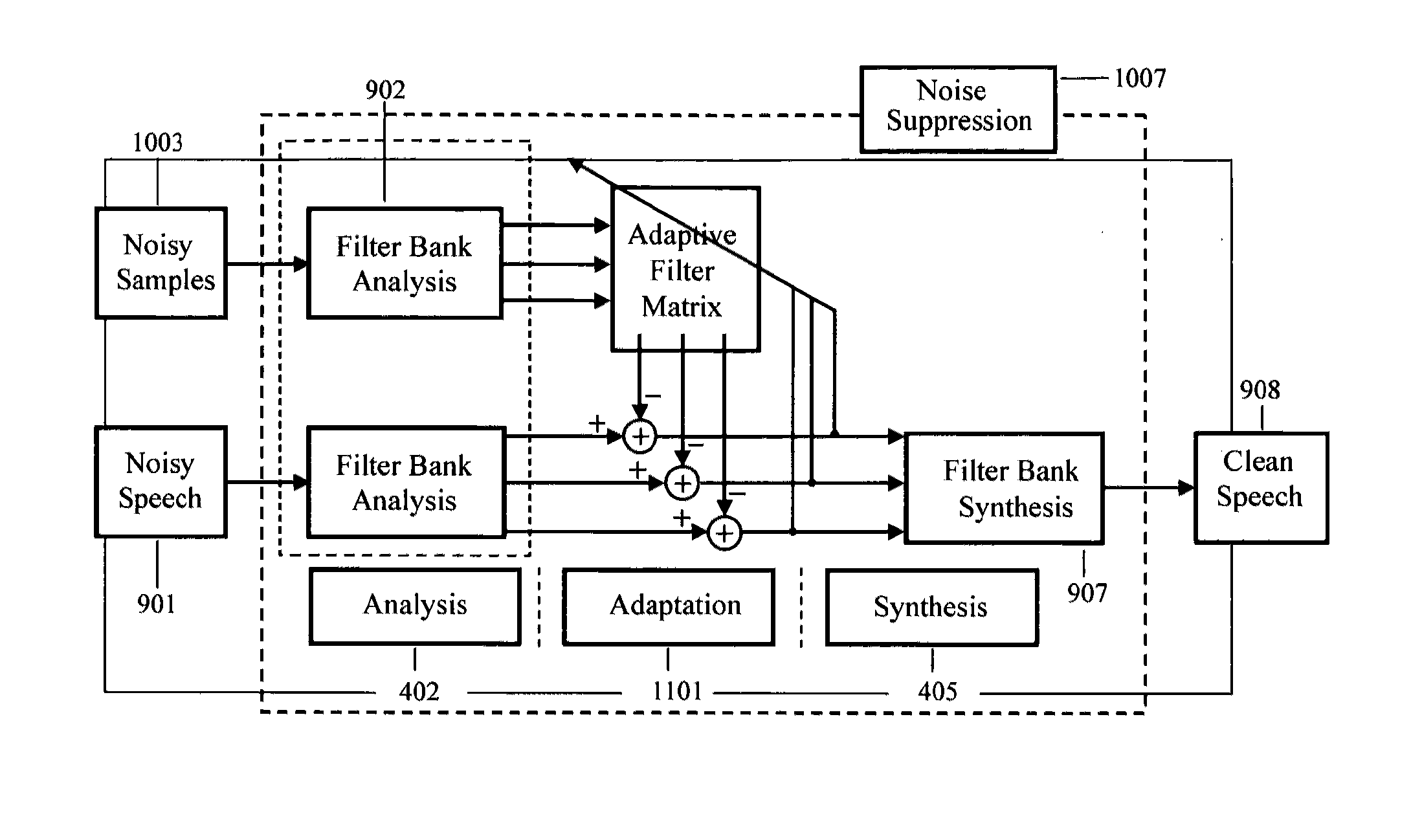

A method and a wearable communication system for personal face-to-face and wireless communications in high noise environments are provided. A noise cancellation device (NCD) operably coupled to a wireless coupling device (WCD) includes a speech acquisition unit, an audio signal processing unit, one or more loudspeakers, and a communication module. The NCD receives voice vibrations from user speech via a contact microphone and a second microphone and converts the voice vibrations into an audio signal. The NCD processes the audio signal to remove noise signals and enhance a speech signal contained in the audio signal. A loudspeaker emits the speech signal during face-to-face communication. The NCD transmits the speech signal to a communication device via the WCD and receives an external speech signal from the communication device during wireless communication. With the NCD, the signal intelligibility and signal-to-noise ratio can be improved, for example, from −10 dB to 20 dB.

Owner:LI CREATIVE TECH

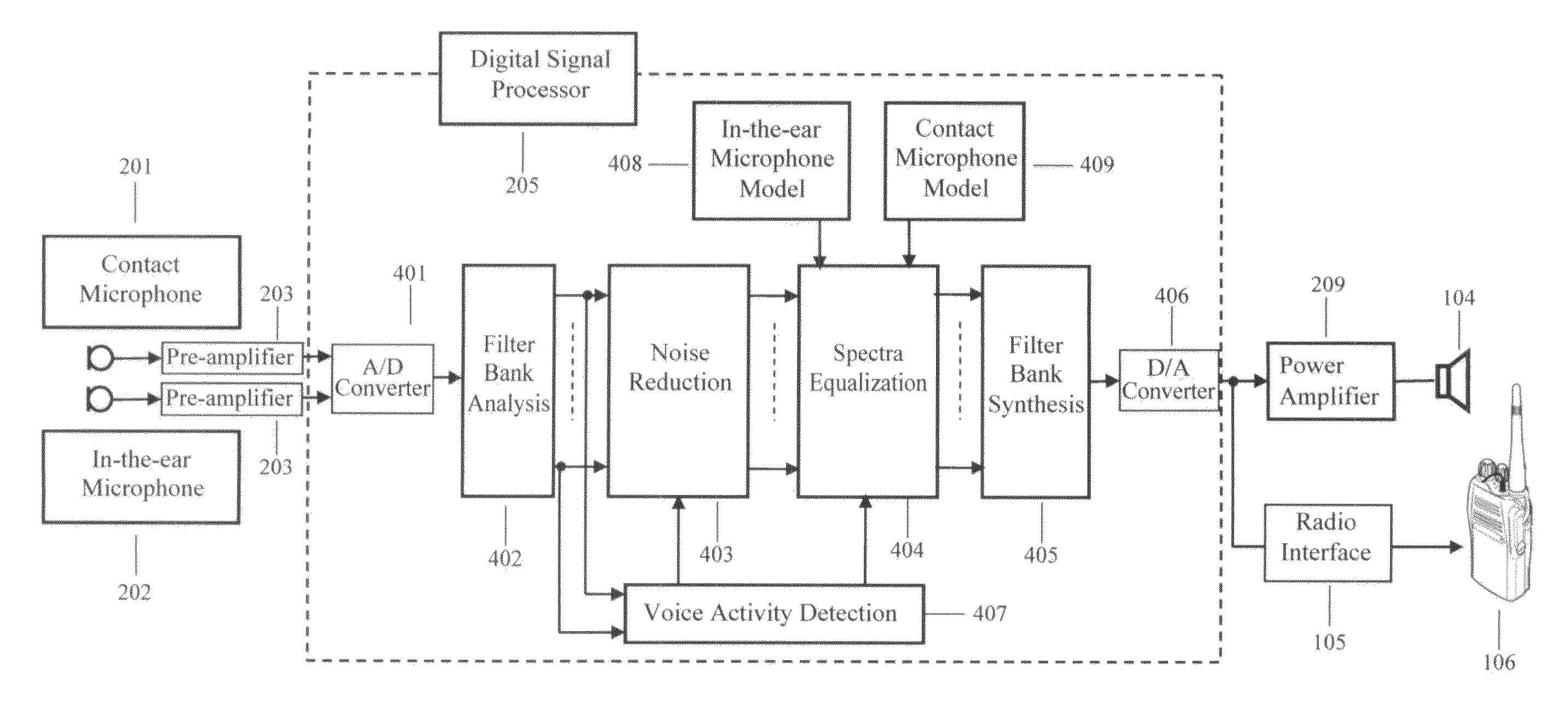

Noise cancellation device for communications in high noise environments

ActiveUS20120084084A1Novel noise cancellationEasy to useSpeech recognitionSignal-to-noise ratio (imaging)Engineering

This invention presents a noise cancellation device for improved personal face-to-face and radio communications in high noise environments. The device comprises speech acquisition components, an audio signal processing module, a loudspeaker, and a radio interface. With the noise cancellation device, the signal-to-noise ratio can be improved by as much as 30 dB.

Owner:LI CREATIVE TECH

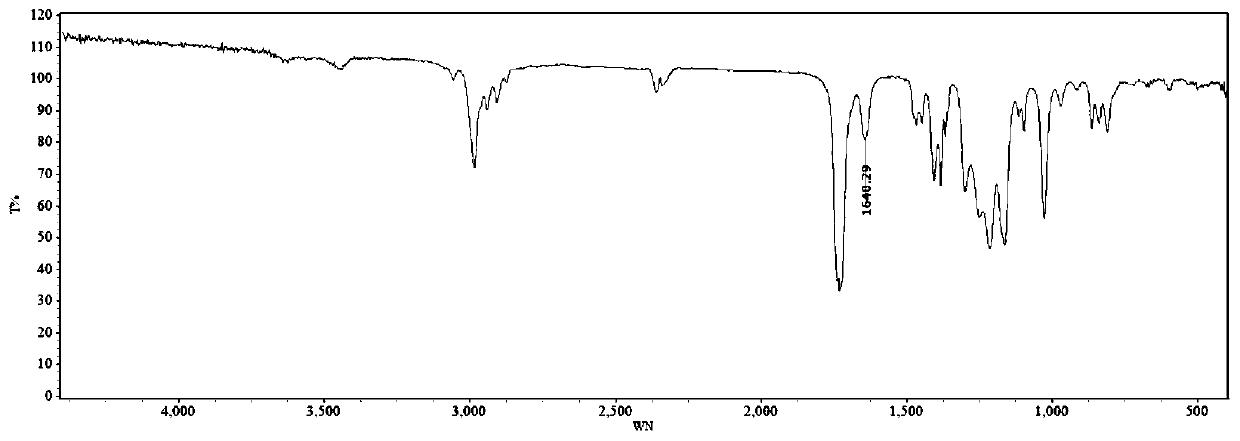

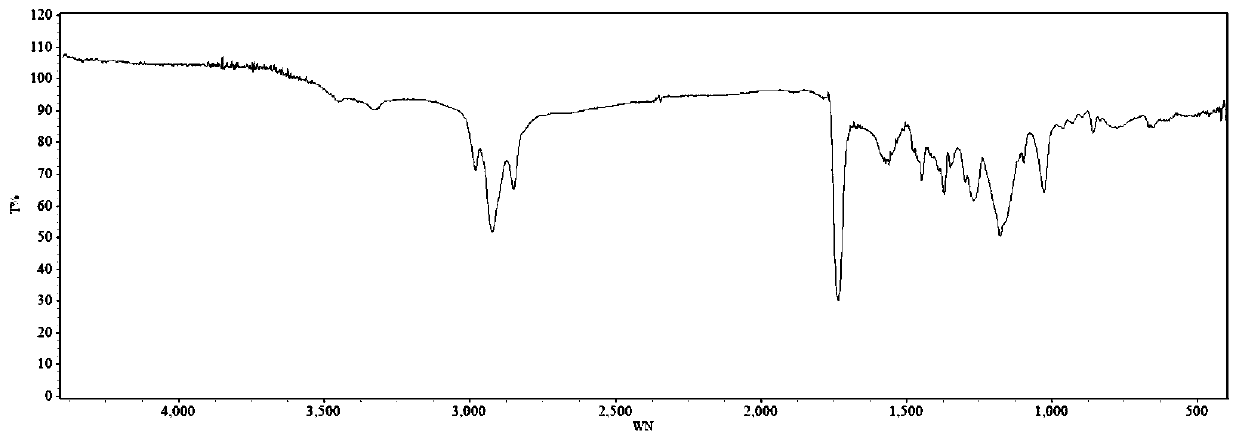

Water-dispersible polyaspartic ester resin, preparation method of waterborne polyurea coating and application

ActiveCN109761834ASmall particle sizeLow viscosityOrganic compound preparationAmino-carboxyl compound preparationWater dispersibleAging resistance

The invention relates to polyaspartic ester resin and in particular relates to water-dispersible polyaspartic ester resin, a preparation method of waterborne polyurea coating and application. Water-dispersible polyaspartic ester is obtained by carrying out Michael addition reaction on unsaturated binary carboxylate, unsaturated monocarboxylic acid and a primary amino compound under the action of acatalyst and a neutralizing agent; a coating film of the double-component waterborne polyurea coating is obtained by utilizing a water dispersion body of the water-dispersible polyaspartic ester; theperformance keeps main properties of solvent type polyurea coating, such as rapid curing at room temperature, high glossiness, high transparency, good water resistance, corrosion resistance, ultraviolet resistance and ageing resistance.

Owner:郁维铭 +1

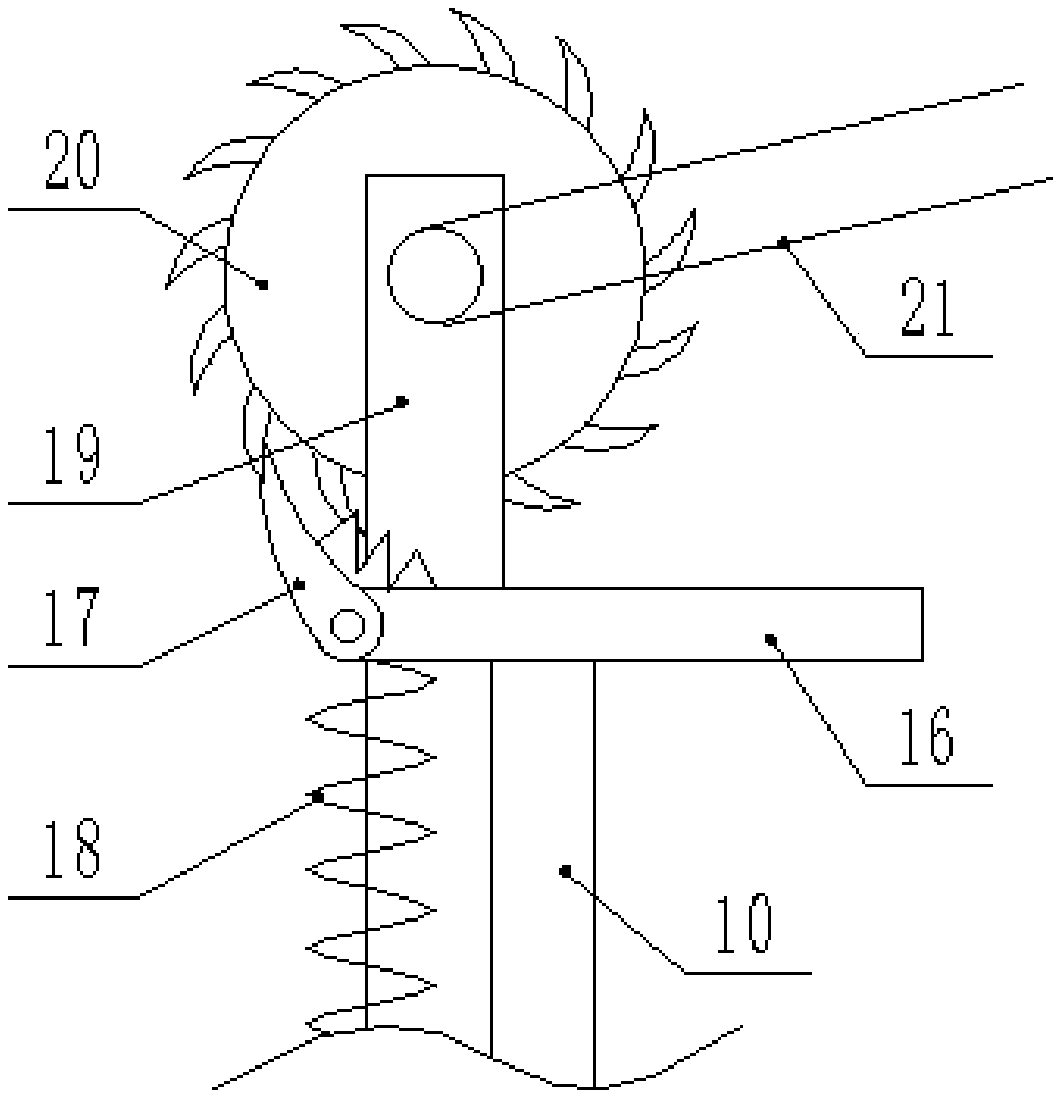

Fermented fertilizer and its production

InactiveCN1680218AEfficient use ofEliminate processing problemsBio-organic fraction processingOrganic fertiliser preparationMicroorganismYeast

The purpose of this invention is to dispose of and effectively utilize waste of the skin of a bamboo shoot, young bamboo and parent bamboo by using one or both of the skin of the bamboo which is waste in a boiling work plant of the bamboo shoot and the young bamboo which is a grown bamboo shoot as main components, adding the parent bamboo therein and composting the raw materials for a short time at a low cost. The subject fermented fertilizer is produced by adding useful microorganisms containing one or more kinds of actinomyces, photosynthetic bacteria, fungi, lactobacilli, yeast and aspergillus bacteria into the composting raw material mainly using one or both of the skin of the bamboo shoot and the young bamboo, and if need, the parent bamboo, further adding at least one of a fermentation accelerating assistant, a water control agent and a nutritious agent of the microorganisms if needed and mixing and stirring them. The fermented fertilizer containing a growth promotor contained in the bamboo shoot or the young bamboo is produced by composting the skin of the bamboo shoot or the young bamboo used as the main components and becomes the fertilizer remarkably effective for the growth promotion of plants.

Owner:KITAJIMA FOODS +1

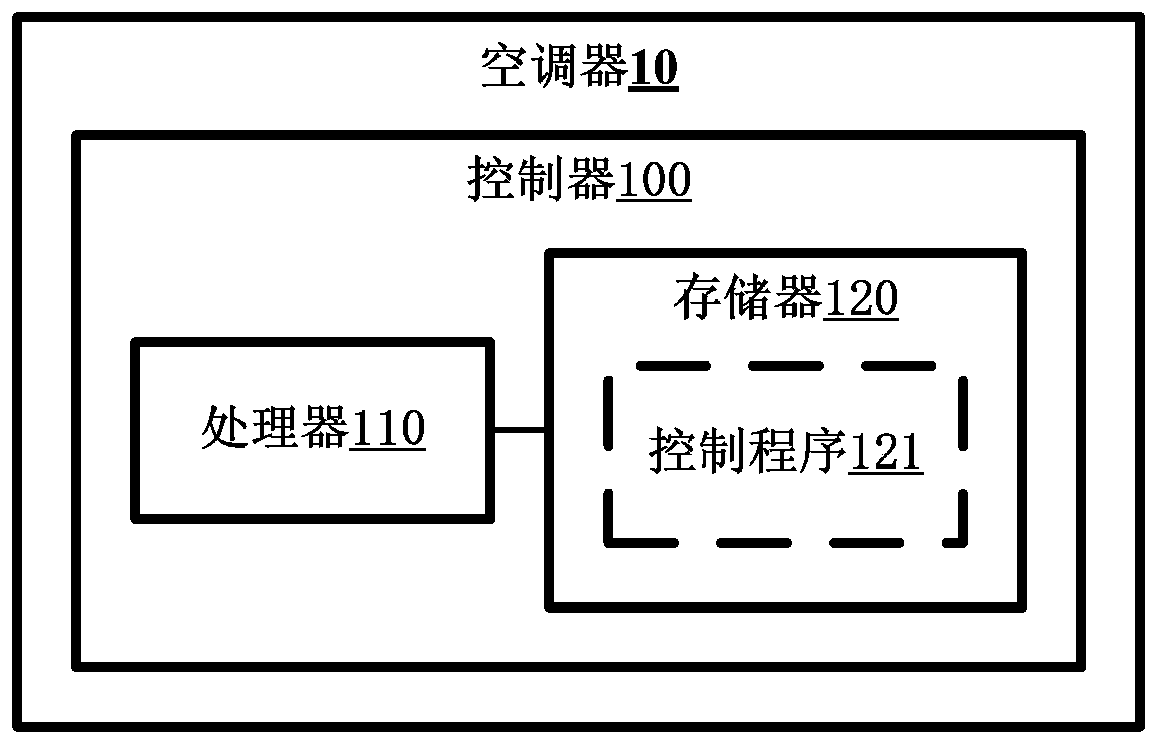

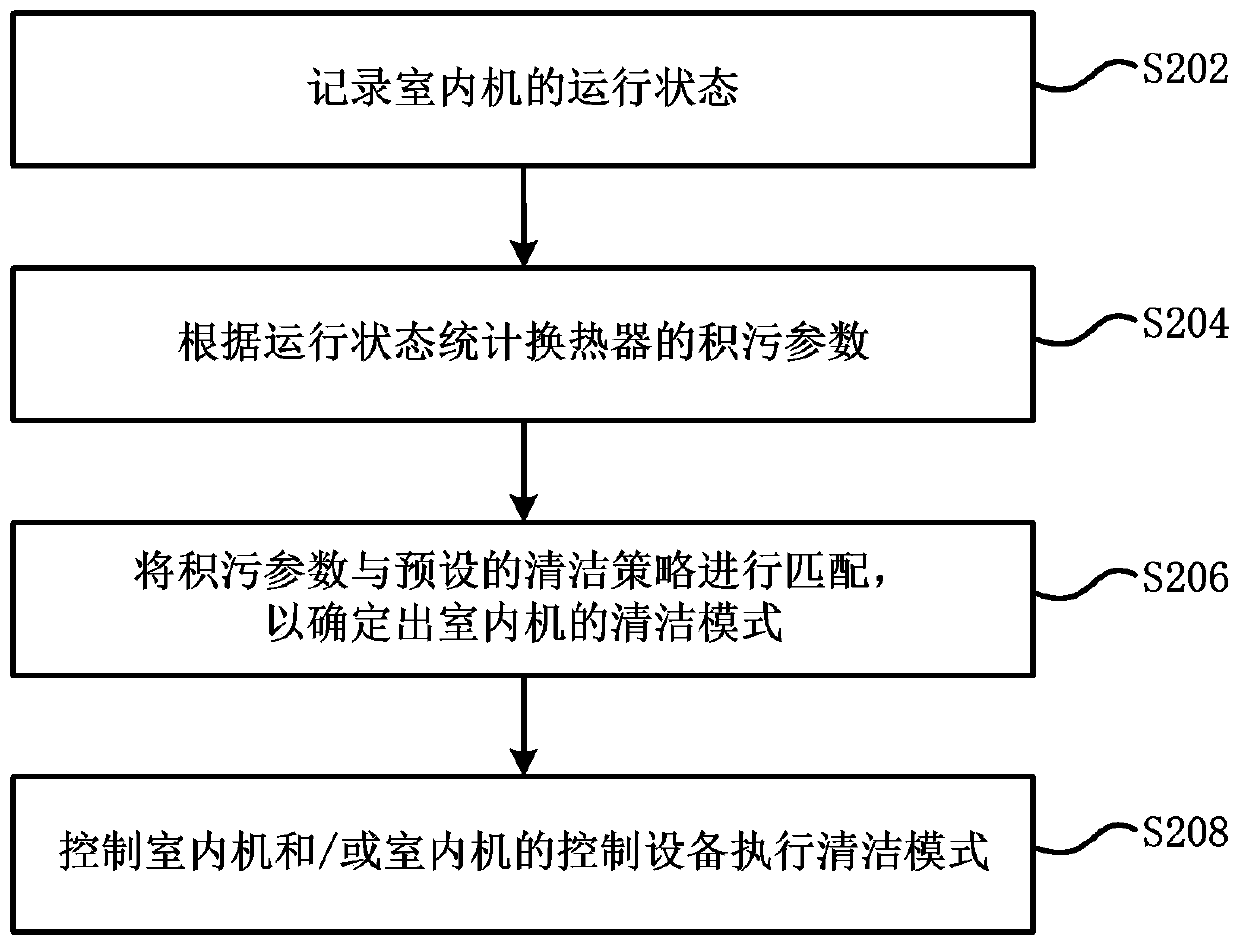

Heat exchanger self-cleaning control method of air conditioner indoor unit and air conditioner

InactiveCN110986285AAvoid cleaningSimple control methodMechanical apparatusLighting and heating apparatusProcess engineeringHeat exchanger

The invention provides a heat exchanger self-cleaning control method of an air conditioner indoor unit and an air conditioner. The self-cleaning control method comprises the steps of recording an operation state of the indoor unit; calculating dirt accumulation parameters of a heat exchanger according to the operation state; matching the dirt accumulation parameters with a preset cleaning strategyto determine a cleaning mode of the indoor unit, wherein a corresponding relation between a dirt accumulation parameter range and a cleaning mode is stipulated in the cleaning strategy; and making the indoor unit and / or control equipment of the indoor unit execute the cleaning mode. Due to a fact that the dirt accumulation parameters are obtained through operation state statistics of the indoor unit, a dirt accumulation condition of the heat exchanger is reflected, self-cleaning is ensured to be executed when the heat exchanger needs to be cleaned, self-cleaning mistaken starting or untimelystarting is avoided, an intelligent level is improved, and a requirement of a user for intelligent household appliances is met.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Noise cancellation device for communications in high noise environments

ActiveUS8606572B2Easy to useReduce power consumptionSpeech recognitionSignal-to-noise ratio (imaging)Engineering

This invention presents a noise cancellation device for improved personal face-to-face and radio communications in high noise environments. The device comprises speech acquisition components, an audio signal processing module, a loudspeaker, and a radio interface. With the noise cancellation device, the signal-to-noise ratio can be improved by as much as 30 dB.

Owner:LI CREATIVE TECH

Double-component epoxy structural adhesive and preparation method thereof

InactiveCN102408861AThixotropicImpact resistantNon-macromolecular adhesive additivesEpoxy resin adhesivesGlass fiberPolymer science

The invention provides a double-component epoxy structural adhesive and a preparation method thereof. The structural adhesive is prepared from a component A and a component B in a weight ratio of 1:1, wherein the component A comprises 100 parts by weight of modified bisphenol A epoxy resin and 40-100 parts by weight of active filler; and the component B comprises 30-40 parts by weight of modified fatty amine, 10-25 parts by weight of toughener, 1.5-5 parts by weight of coupling agent and 75-140 parts by weight of thixotropic filler. The double-component epoxy structural adhesive is curable at normal temperature, can be cured quickly at moderate temperature, and can be completely cured at 80 DEG C within 1 hour or at 100 DEG C within half an hour. The adhesive has thixotropy, and the adhesive liquid does not flow when being cured at normal temperature and raised temperature; and the double-component epoxy structural adhesive has the advantages of shock resistance, vibration resistance and high bonding strength, and has favorable effects on bonding glass fiber reinforced plastics, steel, aluminum and other metal profiles.

Owner:BEIJING QINGDA SUNKIST NEW MATERIAL TECH

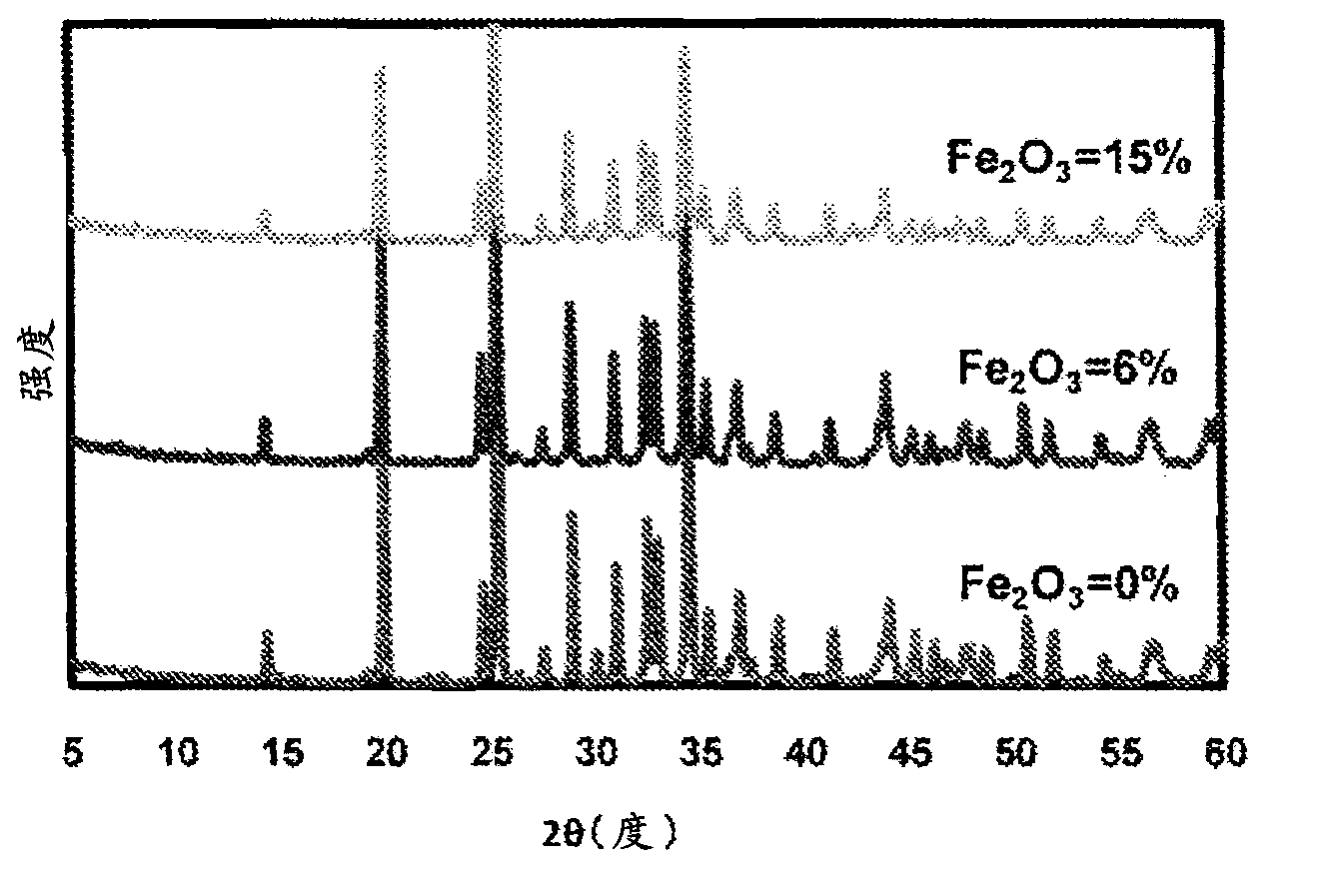

Calcium ferroaluminate compound, cement admixture and process for producing same, and cement composition

ActiveCN102869633AExcellent penetration resistancePlenty of time to operateSolid waste managementIron compoundsSelf-healingSludge

Provided is a cement admixture which gives cured cement concrete that imparts excellent non-corrodible properties to the reinforcing bars present therein, has resistance to external infiltration of chloride ions, and can be inhibited from becoming porous because Ca-ion eluviation occurs little and that has self-healing ability. Also provided is a cement composition. The cement admixture is characterized by comprising a calcium ferroaluminate compound which is based on CaO, Al2O3, and Fe2O3, has a Fe2O3 content of 0.5-15 mass%, and has a CaO2Al2O3 structure, the CaO / Al2O3 ratio being in the range of 0.15-0.7 by mole. It is preferred that the admixture have a degree of fineness of 2,000-7,000 cm2 / g in terms of Blaine specific surface area and that a latent hydraulic substance and / or a pozzolanic substance (pozzolanic substance and the like) be used in combination with the calcium ferroaluminate compound. The pozzolanic substance and the like preferably comprise one or more substances selected from a group consisting of ground granulated blast furnace slag, fly ash, silica fume, metakaolin, incineration ash of pulp sludge, incineration ash of sewage sludge, and waste glass powder. It is preferred that the ratio of the calcium ferroaluminate compound to the pozzolanic substance and the like be from 10 / 1 to 1 / 10 by mass. The cement composition comprises cement and the cement admixture.

Owner:DENKA CO LTD

Platinum catalyst used in liquid silicone rubber catalysis, and preparation method and application thereof

InactiveCN104151830AActivity can be controlledGood storage stabilityGroup 8/9/10/18 element organic compoundsCoatingsRubber materialVulcanization

The invention relates to a controllable-activity platinum catalyst used in liquid silicone rubber catalysis, and a preparation method and an application thereof. The catalyst has the general structural formula of Pt(VX)n(AY)4-n, wherein VX is one or a complex of various siloxane compounds with vinyl; AY is one or a complex of various organic compounds with alkynyl; and n is 1-3. The platinum catalyst used in liquid silicone rubber catalysis is used in the field of liquid silicone rubber. The activity of the catalyst is controllable, such that a rubber material has enough operation time during mixing and application. Also, at a late stage, silicone rubber vulcanization molding can be catalysed fast. The catalyst has good storage stability in liquid silicone rubber. The catalytic activity can maintain unchanged for a long time.

Owner:浙江恒业成有机硅有限公司

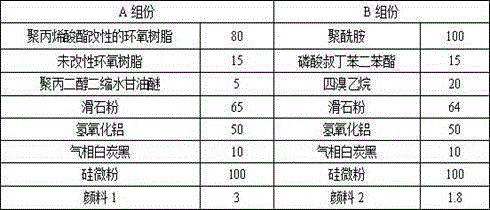

Flame-retardant epoxy grout used for joint filling and leakage stopping

InactiveCN105255420AGood bond strength and corrosion resistanceImprove toughnessNon-macromolecular adhesive additivesEpoxy resin adhesivesCarbon blackGrout

The invention discloses flame-retardant epoxy grout used for joint filling and leakage stopping. The grout is composed of a component A and a component B which are different in color. The component A comprises, by mass, 80-100 parts of epoxy resin, 4-15 parts of diluent, 50-100 parts of talcum powder, 20-50 parts of aluminum hydroxide, 5-10 parts of gas-phase white carbon black, 50-100 parts of silica powder and 0.1-3 parts of pigment. The component B comprises 40-100 parts of epoxy resin curing agents, 20-50 parts of liquid flame retardant, 50-100 parts of talcum powder, 20-50 parts of aluminum hydroxide, 5-10 parts of gas-phase white carbon black, 50-100 parts of silica powder and 0.1-3 parts of pigment. The grout is easy to prepare and convenient to construct, can be directly and manually kneaded or stirred through a machine, is moderate in operation period, quick in curing, high in strength after curing and good in toughness, and has a good flame-retardant effect.

Owner:三友(天津)高分子技术有限公司

Wearable communication system with noise cancellation

A method and a wearable communication system for personal face-to-face and wireless communications in high noise environments are provided. A noise cancellation device (NCD) operably coupled to a wireless coupling device (WCD) includes a speech acquisition unit, an audio signal processing unit, one or more loudspeakers, and a communication module. The NCD receives voice vibrations from user speech via a contact microphone and a second microphone and converts the voice vibrations into an audio signal. The NCD processes the audio signal to remove noise signals and enhance a speech signal contained in the audio signal. A loudspeaker emits the speech signal during face-to-face communication. The NCD transmits the speech signal to a communication device via the WCD and receives an external speech signal from the communication device during wireless communication. With the NCD, the signal intelligibility and signal-to-noise ratio can be improved, for example, from −10 dB to 20 dB.

Owner:LI CREATIVE TECH

Slow gel flexible polyurethane foam composition

The invention relates to a slow gel flexible polyurethane foam composition which comprises a component A and a component B with a weight ratio of 1:1, wherein the component A comprises the ingredients in percent by weight of 52.5-69.8 percent of polypropylene oxide ether polyol with a functionality degree of 2 or 3 and a number-average molecular weight of 1000-6000, 25-34 percent of aromatic hydrocarbon compound, 5-13 percent of aromatic diamine hardener, 0.05-0.2 percent of catalyst and 0.15-3 percent of water, and the ingredients are mixed and stirred uniformly to form a polymer; and the component B comprises the ingredients of 50-60 percent of polyether polyol, 15-28 percent of diisocyanate and 16-25 percent of plasticizer, and the ingredients react for 2-3h at a temperature of 70-90 DEG C to obtain a prepolymer with isocyanate with a mass content of 4.4-10 percent. When a flexible polyurethane foam material is prepared, the slow gel flexible polyurethane foam composition can generate a better foam homogenizing effect without using a silicone oil foam stabilizer; and the slow gel flexible polyurethane foam composition is long in gelation time, and ensures that enough operation time is provided when a complex product is produced.

Owner:SHANDONG INOV POLYURETHANE

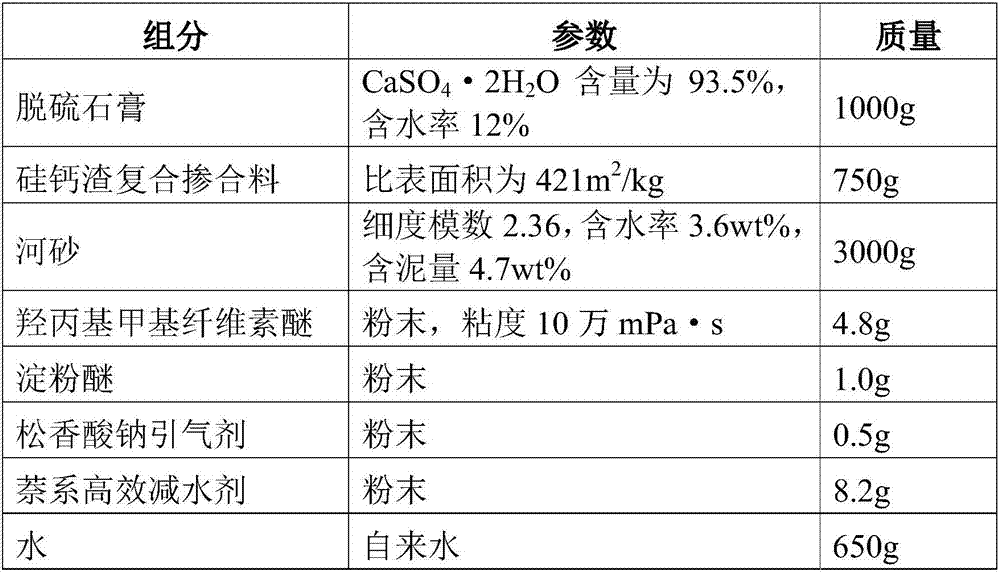

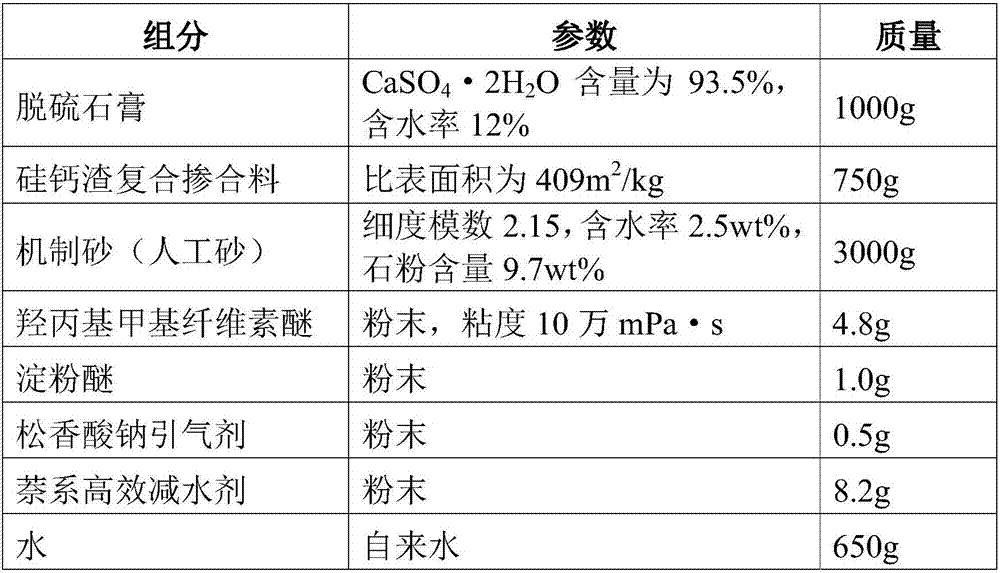

Cement-free desulfurized gypsum plastering mortar and preparation method thereof

The invention provides a cement-free desulfurized gypsum plastering mortar and a preparation method thereof. The cement-free desulfurized gypsum plastering mortar comprises the following components in parts by weight: 15-20 parts of desulfurized gypsum, 15-20 parts of silicon-calcium slag composite admixture, 60-70 parts of aggregate, 0.2-0.3 part of additive and 10-15 parts of water. The silicon-calcium slag composite admixture is composed of the following components in parts by weight: 40-50 parts of silicon-calcium slag, 1-5 parts of desulfurized gypsum, 30-35 parts of fly ash, 15-25 parts of granulated blast-furnace cinder and 0.05-0.08 part of grinding aid. The cement-free desulfurized gypsum plastering mortar is free of any cement and directly adopts the desulfurized gypsum, silicon-calcium slag and other industrial solid wastes as the basic components, so that the prepared cement-free desulfurized gypsum plastering mortar can satisfy requirements in related standards, and does not need to perform drying, calcination, milling and other processes on the desulfurized gypsum, thereby lowering the energy consumption and pollution in the desulfurized gypsum plastering mortar working process.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

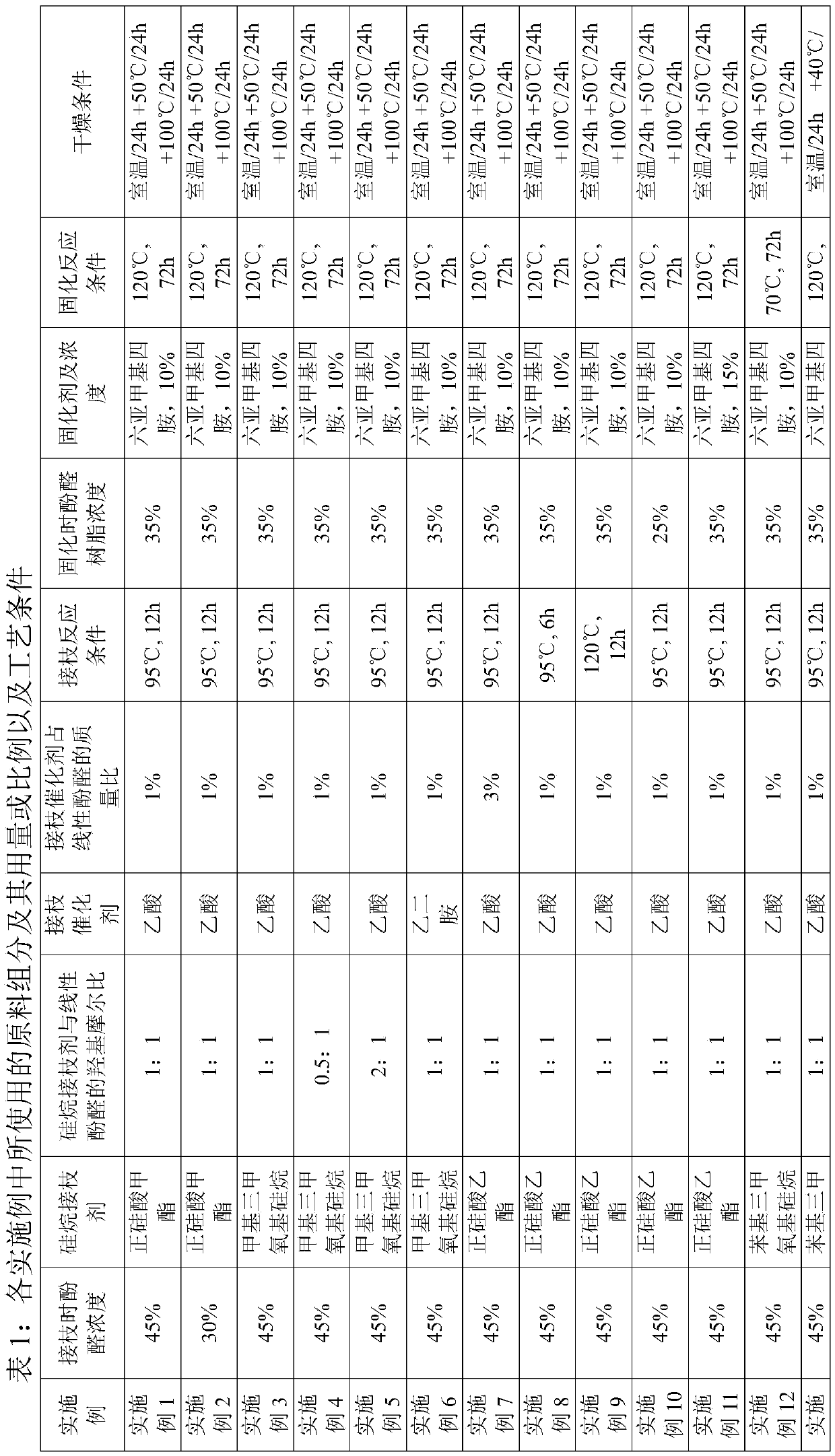

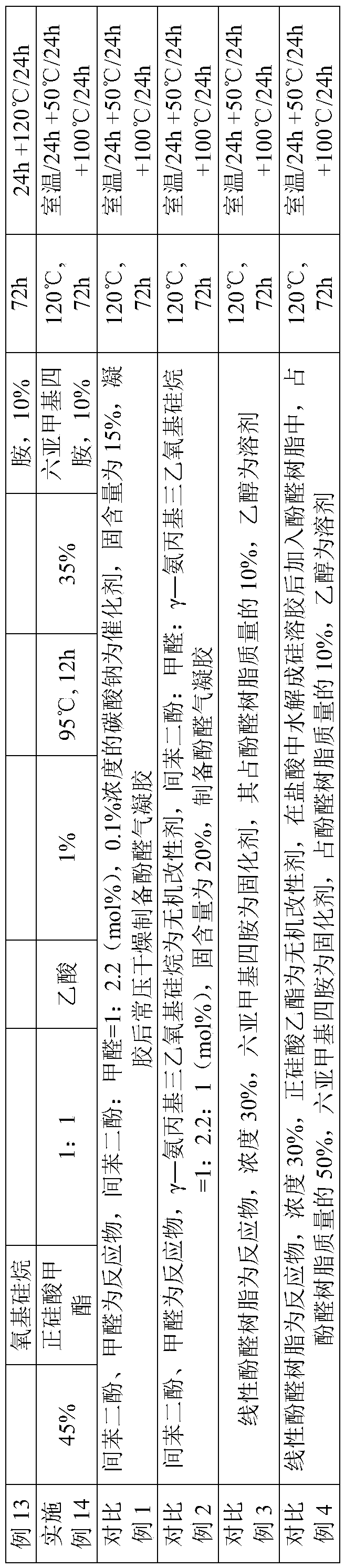

Normal pressure dried phenolic aerogel and preparation method thereof

PendingCN110408071AAtmospheric pressure dryingShorten the overall cycleOrganic solventGraft reaction

The invention provides a method for preparing a phenolic aerogel by normal pressure drying. The method comprises the following steps: preparing a graft reaction solution including a phenolic novolac resin, a silane grafting agent and a first organic solvent, and carrying out a grafting reaction the phenolic novolac resin and the silane grafting agent in the graft reaction solution to obtain a silane-grafted phenolic resin; adding a curing agent and a second organic solvent to form a curing reaction solution, and performing a curing reaction to obtain a phenolic gel; and drying the phenolic gelunder normal pressure to obtain the phenolic aerogel. The invention also provides the phenolic aerogel produced by the method. The method of the invention realizes normal pressure drying, greatly shortens the preparation cycle, reduces the preparation cost, solves the problems of microscopic phase separation and too fast gelling, and leaves sufficient operation time for practical application. Theprepared phenolic aerogel has a significantly improved framework strength, a remarkably reduced shrinkage, good oxidation resistance and good ablation resistance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

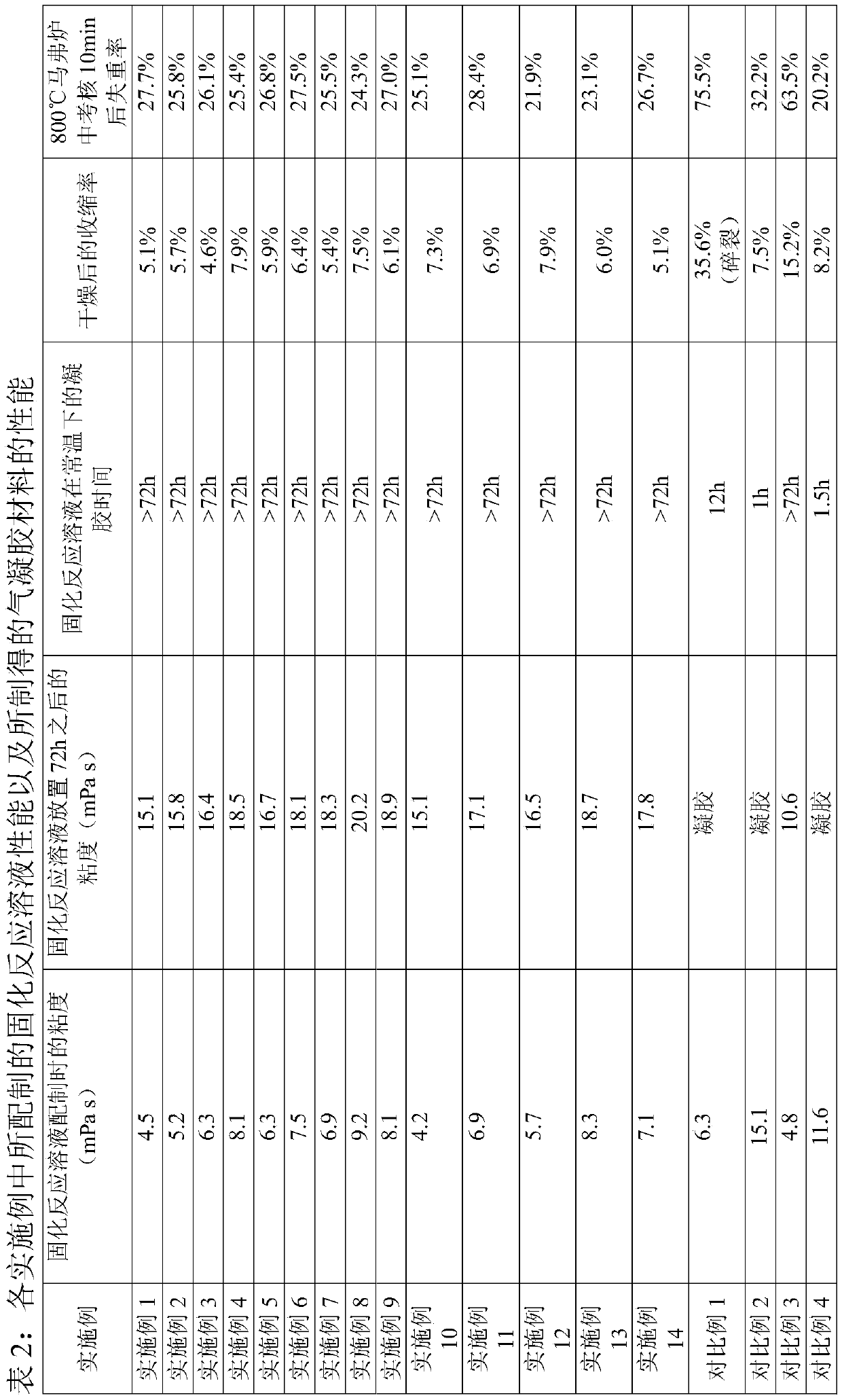

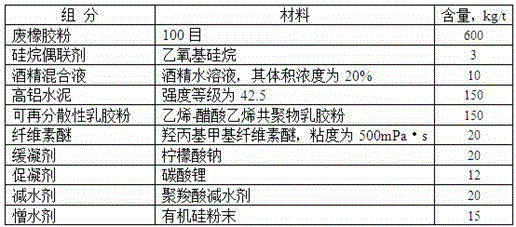

Multifunctional concentrated material used for preparing kitchen and bath cement-based waterproof material

The invention relates to a multifunctional concentrated material used for preparing a kitchen and bath cement-based waterproof material. The multifunctional concentrated material is composed of waste rubber powder, a silane coupling agent, alcohol blend, high-alumina cement, redispersible latex powder, cellulose ether, a delayed coagulant, a coagulation accelerator, a water reducer, an anti-freezing agent (added in winter), and a water repellent, and is a one-component material. The cement-based waterproof material is prepared by mixing the multifunctional concentrated material with cement and quartz powder; is used for kitchen and bath waterproof construction; possesses both excellent characteristics of waterproofing coatings and waterproof mortars, and excellent waterproof performance, so that waterproof effect can be achieved just by a thin coating layer in construction; and also possesses excellent rigidity which is convenient for paving of tiling in following procedures, and is suitable for waterproofing of waterward sides and water lee sides. Addition of waste rubber powder is capable of reducing density of the polymer cement waterproof material, increasing spreading rate of waterproof coatings, changing waste into valuables, and realizing recycling of resources.

Owner:西卡德高(上海)建材有限公司

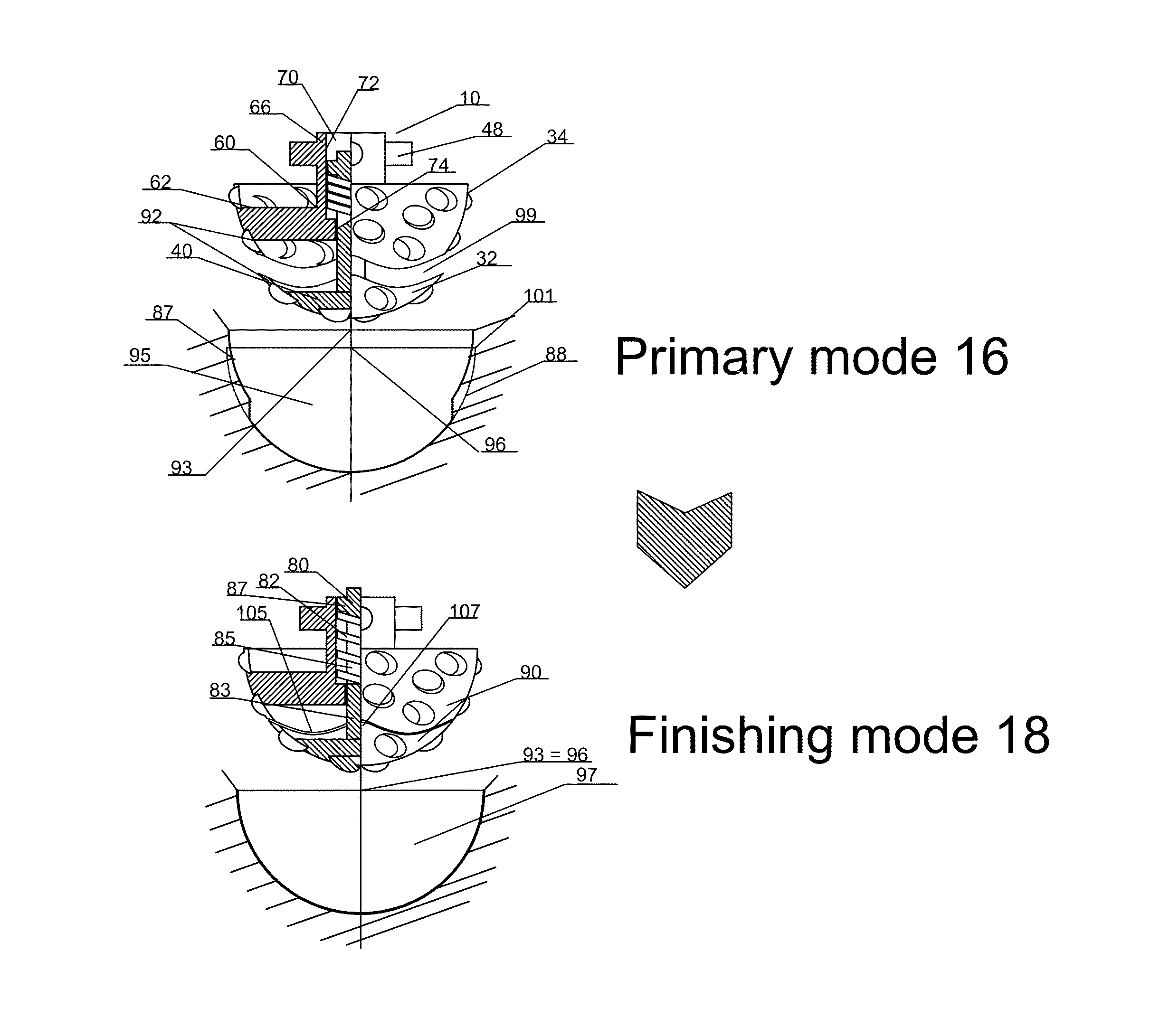

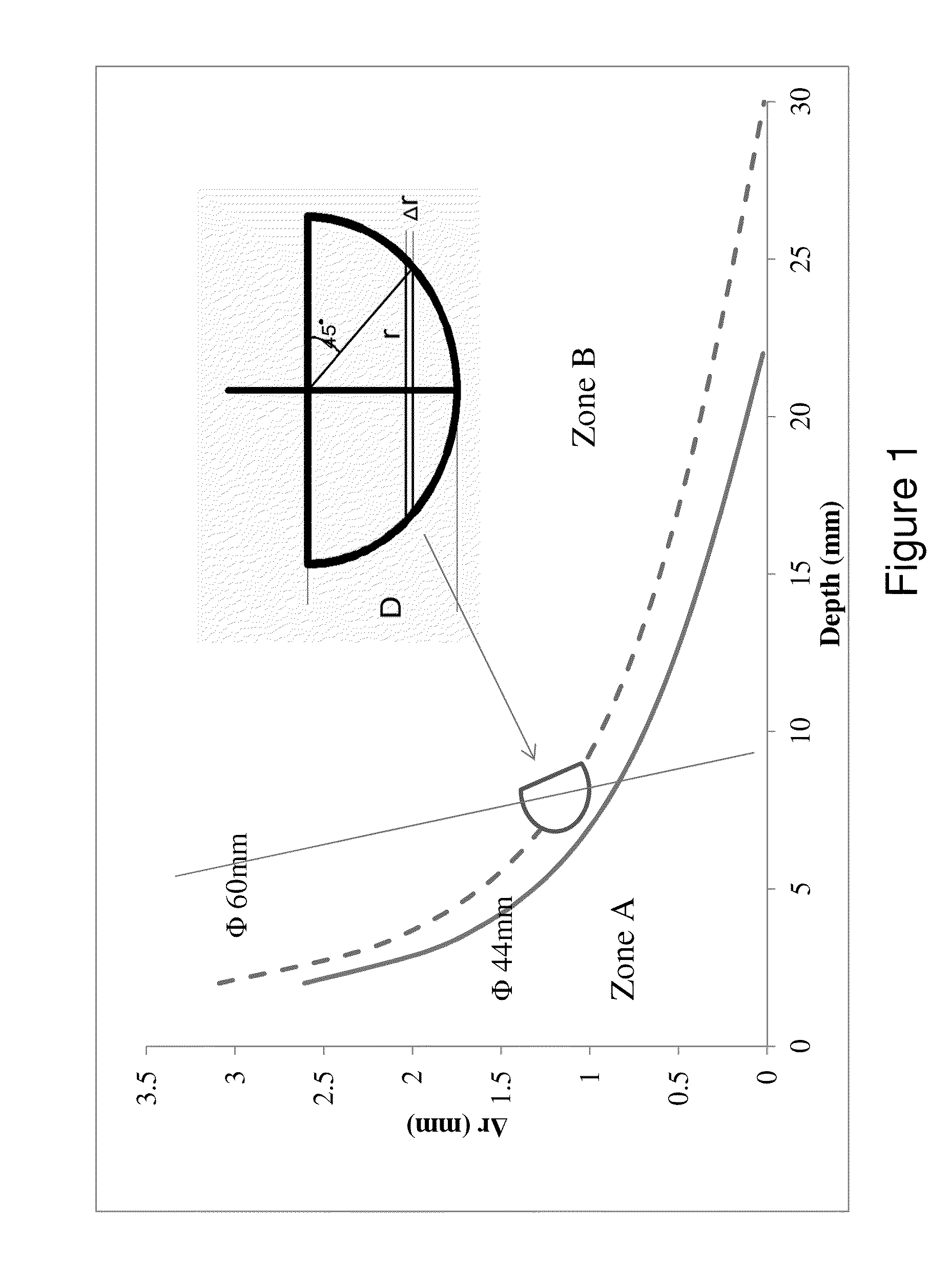

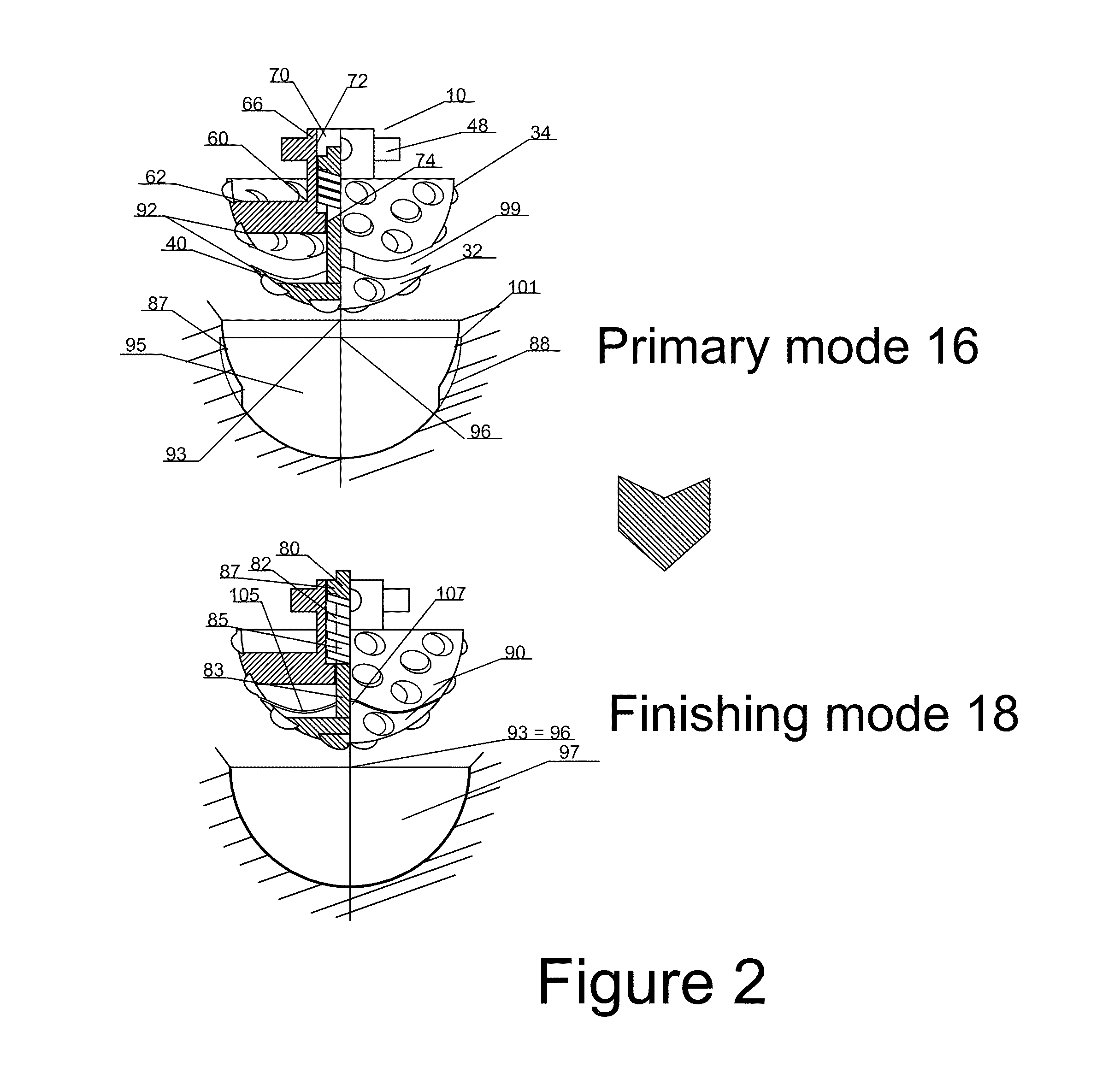

Methods and apparatus for preparing a hemispherical surface

InactiveUS20140271005A1Reduce in quantityPlenty of time to operateSurgeryReaming toolsSpherical shapedEngineering

Methods and apparatus for preparing at least a hemispherical surface with a desired dimension have been disclosed. The method includes at least two steps: a primary cutting mode for mostly reaming a lower portion of the target site, which enveloped area from the pole to intermediate latitude and a finishing cutting mode for reaming either an upper portion or an entire area of the site by less number of times of rotation, respectively. The intermediate latitude locates between the pole and the equator of hemisphere.

Owner:XIE PING +1

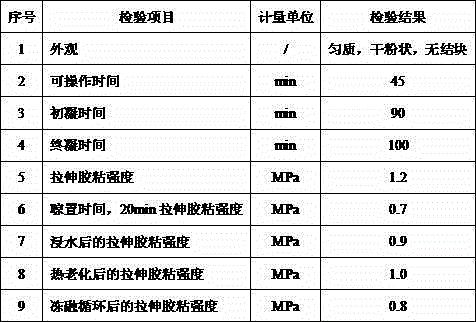

High-performance rapid-hardening ceramic tile adhesive

The invention discloses a high-performance rapid-hardening ceramic tile adhesive which is prepared from the following components in parts by weight: 30- 40 parts of cement, 8-10 parts of gypsum, 50-65parts of quartz sand, 2-3 parts of re-dispersible latex powder, 0.2-0.3 part of water retaining agent, 0.15-0.3 part of early strength agent and 0.04-0.09 part of retarder. Compared with the prior art, the high-performance rapid-hardening ceramic tile adhesive disclosed by the invention has the characteristics of rapid hardening and high strength and can be set and hardened rapidly; through 6 hours of stretching, the adhesive strength can reach the industrial standard 0.5MPa, and the operable time is not less than 40min, enough for operation; meanwhile, the high-performance rapid-hardening ceramic tile adhesive is green and environmentally friendly.

Owner:ZHEJIANG ZHONGXIN NEW BUILDING MATERIALS

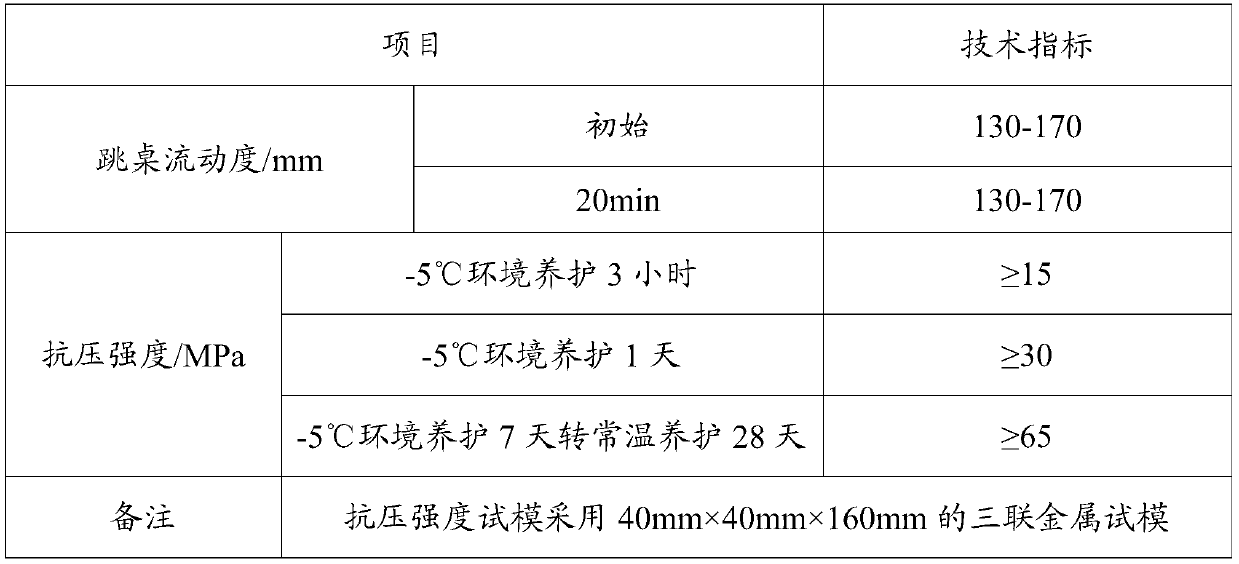

Sealing slurry for low-temperature environment as well as preparation method and application thereof

The invention discloses sealing slurry for a low-temperature environment as well as a preparation method and an application of the sealing slurry. The sealing slurry comprises: 30-50 parts of cement,0-10 parts of a mineral admixture; 0-15 parts of early strength component, 40-60 parts of aggregate, 0-0.1 part of a water reducing agent, 0.01-0.03 part of a plastic expanding agent, 0.1 part of a defoaming agent, 0-1 part of a corrosion inhibitor, 0.003-0.2 part of a water retaining agent, 0.01-0.05 part of an air entraining agent, 0-0.4 part of retarder and 0-0.05 part of coagulant. All the rawmaterials are uniformly mixed according to the proportion to obtain the product. The sealing slurry can be used after being uniformly stirred with water according to a water-ash weight ratio of 0.13-0.15. The sealing slurry disclosed by the invention has the advantages that 1) the plasticity and the softness are excellent; and 2) the adhesive has good adhesive property at low temperature; 3) low-temperature expansion performance is good; 4) good negative-temperature hydration hardening characteristic is good, the product is suitable for sealing the bottom of a component in an environment of-10 DEG C or above and sealing seams around a communicating cavity, and solving the problem of slurry sealing construction at the temperature of 5 DEG C or below, especially 0 DEG C; 5) after mixing, the operation time is 20 minutes, and 6) no chlorine salt and other early-strength components having a corrosion effect on reinforcing steel bars or sleeves are contained.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

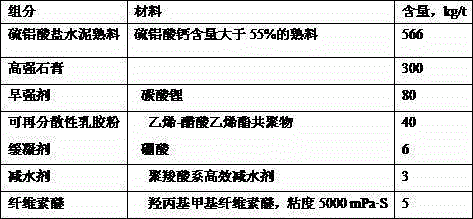

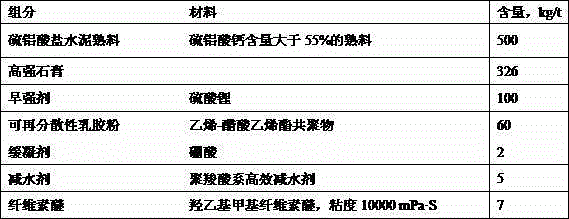

Novel early-strength and quick-drying tile adhesive concentrate

The invention relates to novel early-strength and quick-drying tile adhesive concentrate.The tile adhesive concentrate at least comprises, by weight, 500-800 parts of sulphoaluminate cement clinker, 200-500 parts of high-strength gypsum, 1-100 parts of early strength agent, 40-120 parts of dispersible latex powder, 1-10 parts of retarder, 1-40 parts of water reducer and 5-20 parts of cellulose ether.The novel early-strength and quick-drying tile adhesive concentrate has the advantages that the sulphoaluminate cement clinker and Portland cement are used as the composite cement base materials, the composite cement base materials are coordinated with the additives such as the early strength agent and retarder, tile glue coagulation time is regulated, sufficient operation time is guaranteed, early strength and quick drying are achieved, the next joint filling can be performed immediately after tile adhering, construction time can be shortened, and the construction period can be shortened.

Owner:西卡德高(上海)建材有限公司

One-component epoxy resin adhesive capable of delaying curing

InactiveCN106753139ASolve problems that cannot be curedSimple production requirementsNon-macromolecular adhesive additivesEpoxy resin adhesivesUltraviolet lightsRoom temperature

The invention discloses a one-component epoxy resin adhesive capable of delaying curing. The epoxy resin adhesive is prepared from the following components in parts by mass: 40.0-85.0 parts of epoxy resin, 0.1-30.0 parts of a reactive diluent, 0.5-8.0 parts of a photoinitiator and 0.1-10 parts of an adhesion promoter. The epoxy resin adhesive capable of delaying curing can be applied onto the surface of a base material to be adhered in advance, and is activated by ultraviolet irradiation; then, a base material to be adhered is stuck on the other side of the epoxy resin adhesive, and the activated adhesive can be cured at the room temperature; therefore, the two base materials to be adhered are stuck together. The ultraviolet activation stage of the adhesive is before the sticking of the base materials, so that the problem that the base materials to be adhered can not be crude due to being not transparent to ultraviolet light can be solved; furthermore, the adhesive is activated by relying on the ultraviolet light, thus being stored at the conventional storage temperature and the conventional humidity.

Owner:HANGZHOU BAOMING NEW MATERIAL TECH CO LTD

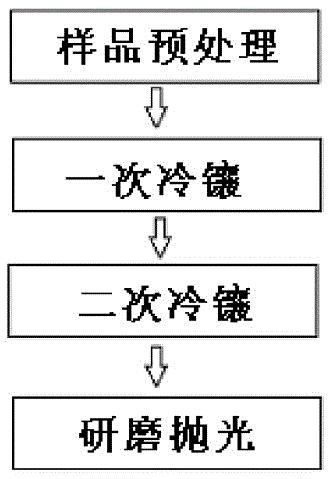

Preparation method of MLA resin film serving as ore powder sample

InactiveCN106769311AStrong representativeIncreased dispersionPreparing sample for investigationMaterials scienceCuring time

The invention discloses a preparation method of an MLA resin film serving as an ore powder sample. The preparation method comprises the following steps: sample pretreatment, first-time cold inlaying, second-time cold inlaying, and grinding and polishing. According to the preparation method disclosed by the invention, by adopting a process of the sample pretreatment, the first-time cold inlaying, the second-time cold inlaying, and the grinding and polishing and two inlaying of the powder sample in sequence, high representativeness and high dispersion degree of sample granules are guaranteed; according to the ratios of resin and a curing agent, enough operation time can be guaranteed; meanwhile, standing and curing time of a resin sample is shortened; the whole flow has the advantages of short process flow, obvious effect, high practicality and low cost.

Owner:KUNMING METALLURGY INST

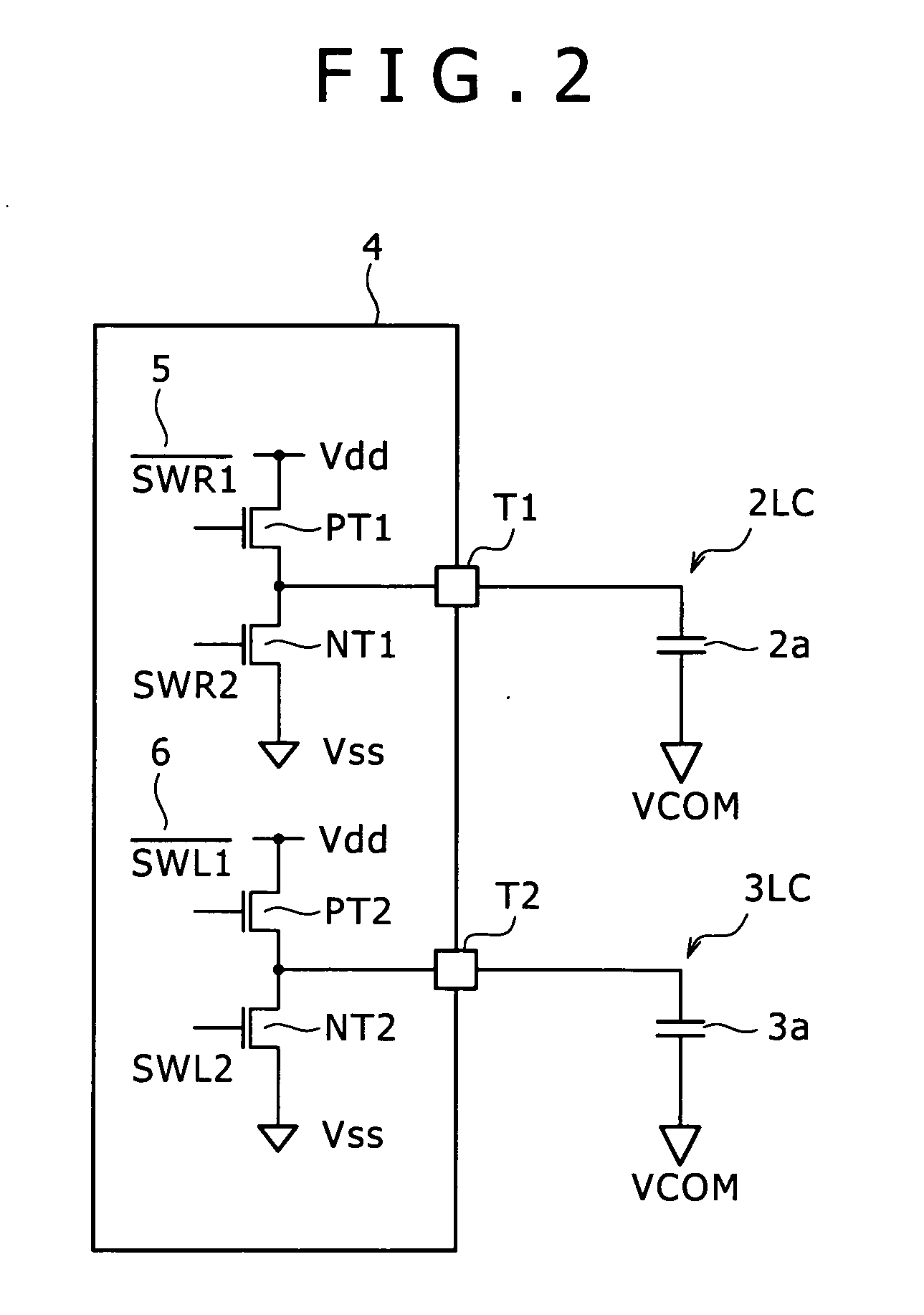

Shutter drive unit and three dimensional image display system

InactiveUS20110050868A1Reduce power consumptionPlenty of time to operateTelevision system detailsPower reduction by energy recoveryCapacitanceInductor

Disclosed herein is a shutter drive unit, including: at least one inductor; first and second drive paths; first and second shutter including first and second drive object capacitive loads, respectively; first and second clamping circuits adapted to clamp the first and second drive object capacitive loads either to a power source potential or to a reference potential through the first and second drive paths, respectively; a first switch adapted to switch connection and non-connection between the inductor and the first drive object capacitive load over to each other; a second switch adapted to switch connection and non-connection between the inductor and the second drive object capacitive load over to each other; and a power collecting portion having a function of applying an intermediate voltage between the power source potential and the reference potential to the inductor, and a power collecting function of collecting a power by the inductor.

Owner:SATURN LICENSING LLC

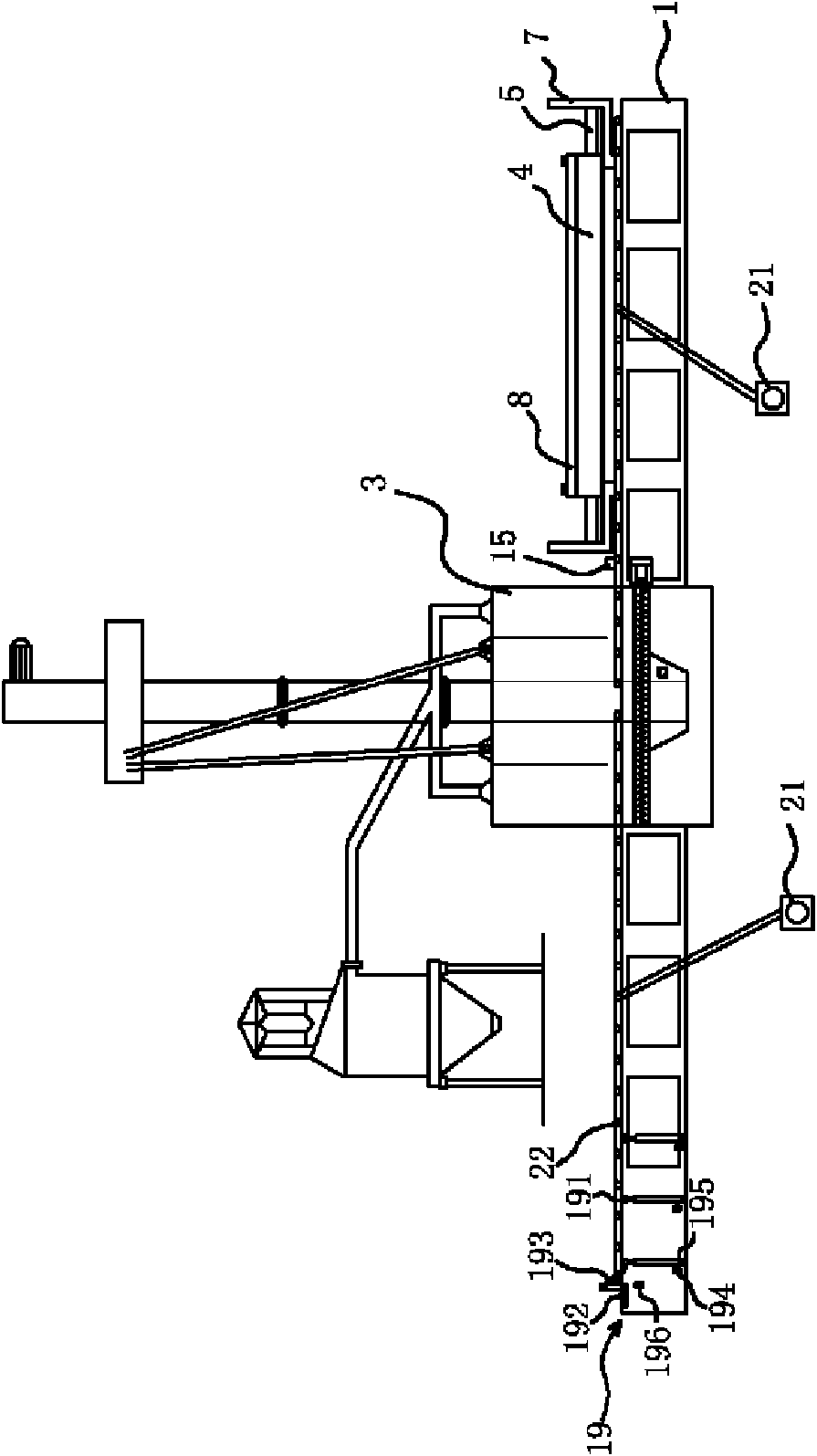

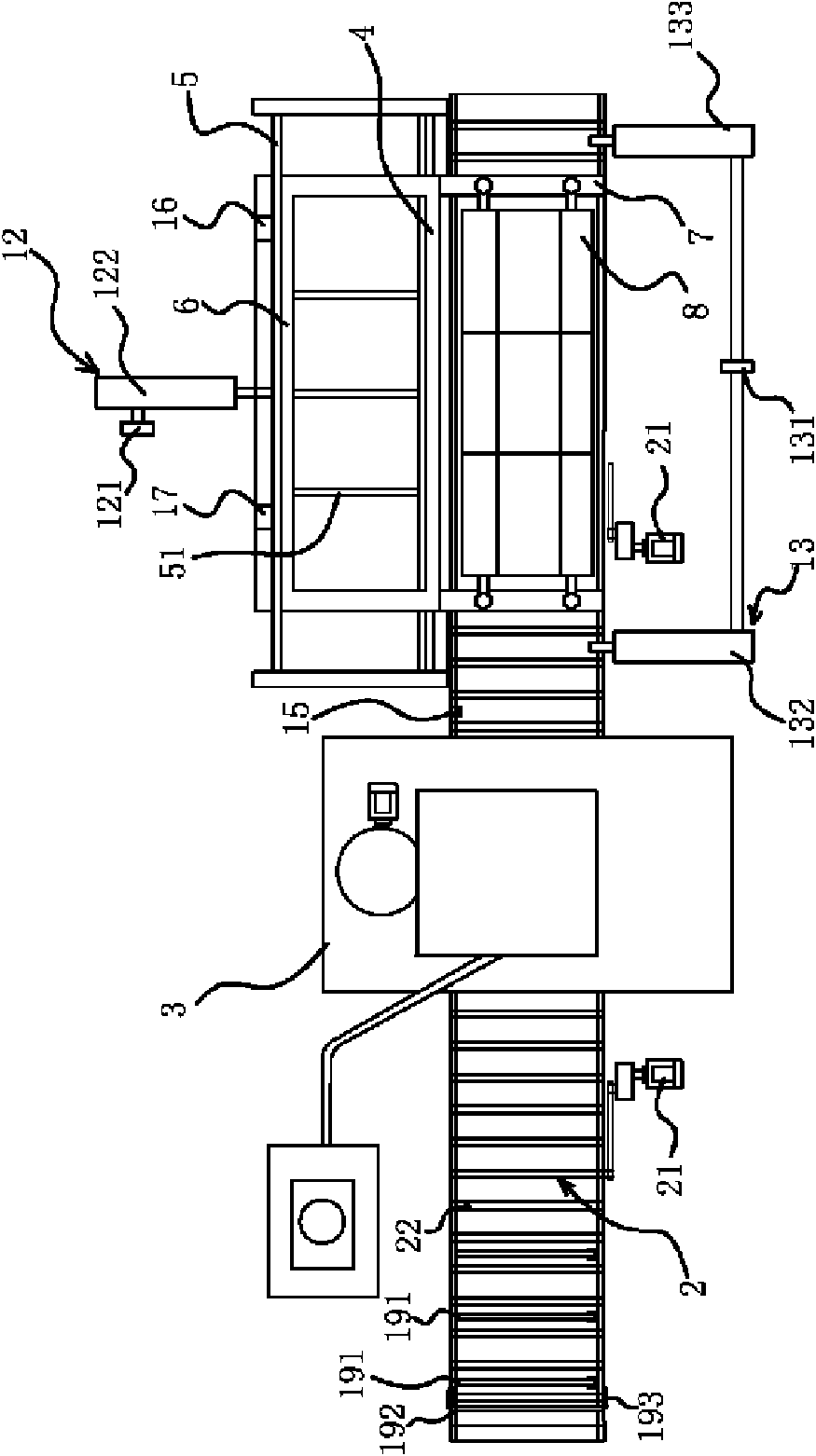

Feeding device in steel processing device

InactiveCN101659018ASave operating timeEliminates the need to stop the operation of the conveying mechanismMetal working apparatusEngineeringSmall footprint

The invention provides a feeding device in a steel processing device, belonging to the mechanical technical field. The feeding device solves the problems that the existing steel processing device discontinuously loads materials, has low processing efficiency and the like. The feeding device in the steel processing device is characterized in that the steel processing device comprises a frame, a conveying mechanism which is arranged on the frame and can convey steel to be processed, the feeding device is arranged in a feeding part of the conveying mechanism, a feeding bracket is arranged above the conveying mechanism, a platy material carrying part for putting the steel to be processed is arranged in the feeding bracket and moves back and forth along the horizontal direction, and a blockingpart which blocks the steel to be processed and brings down the steel to be processed is arranged above the material carrying part. The feeding device has the advantages of simple and safe operation,high processing efficiency, small occupied area, low manufacture cost and the like.

Owner:刘传玲

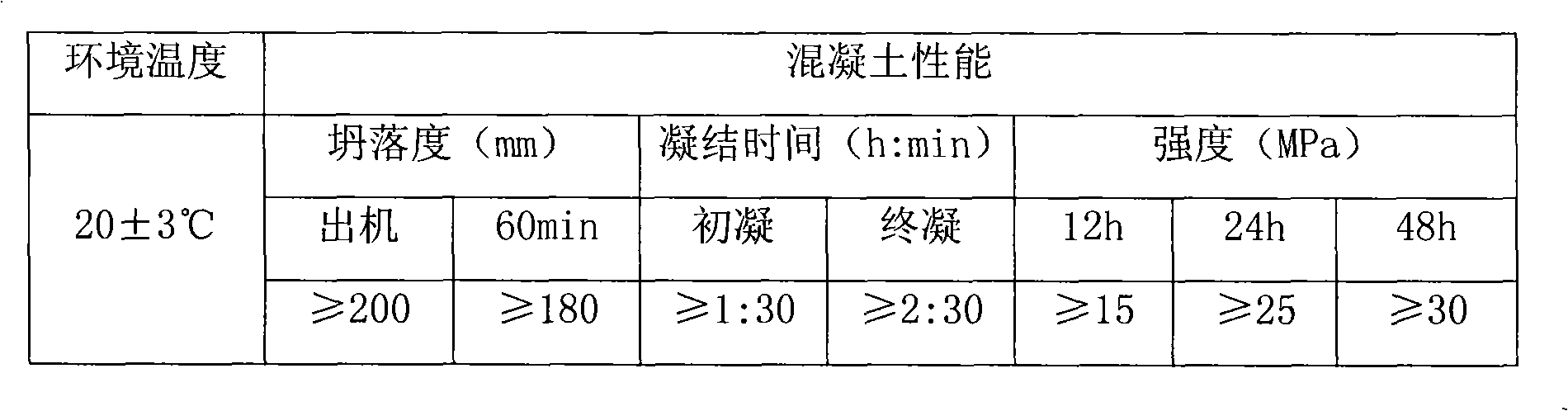

High-early premixed concrete of sulfoaluminate salts

InactiveCN101306939AImprove early strengthMeet Quick Fix EngineeringSolid waste managementAluminiumWater reducer

The invention relates to sulphate aluminium cement early strength premixed concrete, which is formed by 10 to 14 percent (weight) of sulphate aluminium cement with the strength grade equal to 42.5, 70 to 75 percent (weight) of sandstone, 0.2 to 0.25 percent (weight) of high-efficiency water reducing agent, 5 to 8 percent (weight) of water and the balance being admixture which are stirred and mixed. Under the condition of a certain ambient temperature, the coagulation and the hardening of the sulphate aluminium cement early strength premixed concrete ensure enough operation time during transportation and construction; meanwhile, higher early strength can be obtained after the coagulation and the hardening of the concrete, and can meet the requirements of quick repair engineering; moreover, the concrete has remarkable economic benefit and social benefit.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD

Foamed silica gel with water used as foaming agent and production method of foamed silica gel with water used as foaming agent

The invention relates to the technical field of foamed silica gel, in particular to foamed silica gel with water used as a foaming agent and a production method of the foamed silica gel with the waterused as the foaming agent. The foamed silica gel with the water used as the foaming agent comprises an A component and a B component, wherein the A component and the B component are mixed according to a mass ratio of 1:1, the A component comprises the following raw materials in parts by weight: 180-220 parts of gas-phase method base rubber, 130-160 parts of vinyl silicone oil, 20-40 parts of water and 1-2 parts of a platinum complex; and the B component comprises the following raw materials in parts by weight: 200-250 parts of gas-phase method base rubber, 20-40 parts of vinyl silicone oil, 150-200 parts of hydrogen-containing silicone oil, 0.5-2 parts of 2,4,6,8-tetravinyl-2,4,6,8-tetramethylcyclotetrasiloxane and 0.1-0.3 part of 1-ethynyl-1-cyclohexanol. According to the foamed silica gel, the water is adopted as a source of main hydroxyl groups, the water and a hydrosiloxane component are subjected to a reaction to generate foaming gas, using the water as the foaming agent is non-toxic and pollution-free for both a production environment and a final product, and especially, by using the water as the foaming agent, silicone rubber foam with super low density (0.05-0.10 g / cm<3>)can be produced.

Owner:深圳市红叶杰科技有限公司

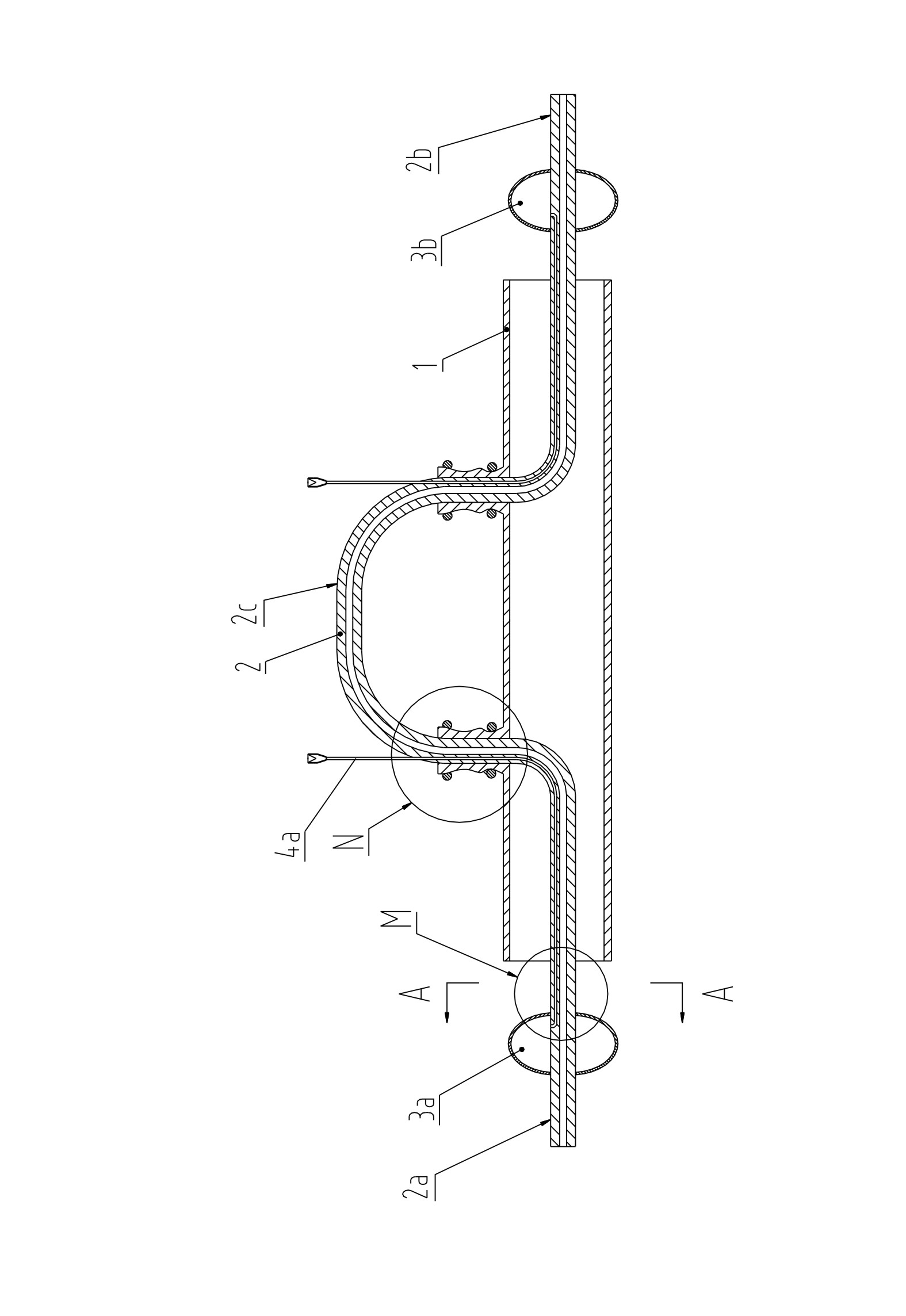

Artificial blood vessel

The invention provides an artificial blood vessel which comprises an artificial blood vessel main body, a shunt vessel, two air bags and two air filled vessels, wherein the side wall of the artificial blood vessel main body is provided with two through holes, each through hole is provided with an outward extending skirt edge, and each skirt edge is provided with a tightening line; both ends of the shunt vessel respectively pass through the artificial blood vessel main body from the two through holes and the skirt edges and extends our of both ends of the artificial blood vessel main body, and each extension section of both ends of the shunt vessel passes through one air bag and is hermetically connected with the air bag; and both air filled vessels are arranged in the vessel wall of the shunt vessel, one end of each air filled vessel extends out from the middle section of the shunt vessel, and the other end is communicated with one air bag. Surgeries can be performed without blocking the blood flow in the human blood vessel by using the shunt vessel and the two air bags, the anastomosis between the artificial blood vessel and the human blood vessel is completed, organ ischemia is avoided, the success ratio of surgeries and the convenience of surgery operations are increased, and the pain of patients in surgeries is relieved.

Owner:THE THIRD AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIV OF PLA

Human body canal cast filler and preparation method thereof

InactiveCN102391617AEasy to prepareSimple and fast operationDead animal preservationEducational modelsHuman bodyPolymer science

The invention provides a human body canal cast filler and a preparation method of the human body canal cast filler; and the human body canal cast filler is good in physicochemical performance, strong in acid-base resistance, good in flexibility and stronger in support force. The human body canal cast filler is prepared by the components according to the volume ratio: 100ml of cyclodextrin (CYD)-128 type epoxy resin, 20-24ml of liquid-state nitrile rubber, 35-40ml of polypropylene glycol diglycidyl ether, 15ml of 2, 4, 6-tri-(dimethylamino methyl) phenol (DMP-30), 45ml of modified polyether amine epoxy resin curing agent ZY-1784 and 40-45ml of high-performance epoxy resin toughening modifier (RF-400). The human body canal cast filler is easy in preparation as well as simple and convenient in operation, can be completed by once injection without after-teeming, and can be immediately prepared when injection is not sufficient. The invention has the characteristics of being good in fluidity, low in injection resistance, full in molding, fin and attractive, low in contractibility rate, environment-friendly and the like.

Owner:黄海龙

Preparation method for improving production security of tire curing bladder

The invention provides a preparation method for improving production security of a tire curing bladder, and relates to the technical field of the curing bladder. The curing bladder takes butyl rubberand chloroprene rubber as the basic rubber; compared with the prior art, an anti-scorching agent is added, the adding of the anti-scorching agent can prolong the scorching time, thereby ensuring thatthe mold filling is incomplete and a nozzle cannot be blocked in the injection; and meanwhile, the optimum curing time is prolonged, the production efficiency is reduced, other process is appropriately adjusted, such as the adding amount of the curing temperature of the active agent zinc oxide and promoter DM; the prepared tire curing bladder can realize the appropriate total curing time when reaching a basic performance requirement, the scorching time is prolonged, and the production security is improved.

Owner:YONGYI RUBBER CO LTD

Low-density high-strength solid buoyancy material in shallow water and preparation method of solid buoyancy material

The invention provides a low-density high-strength solid buoyancy material in shallow water and a preparation method of the solid buoyancy material. The solid buoyancy material comprises the followingraw materials: 100 parts of epoxy resin, 35-60 parts of a curing agent, 10-20 parts of a toughening curing agent, 0.5-2 parts of a catalyst, 2-4 parts of a coupling agent, and 45-75 parts of hollow glass microbeads. The method comprises the following steps: mixing the above raw materials, performing mixing under stirring in certain temperature and humidity environmental conditions, performing kneading, filling a steel mold with the mixture, and performing curing molding in a certain pressure and temperature range to obtain the low-density high-strength solid buoyancy material. According to the method provided by the invention, the steel mold is used for direct molding, the raw material reaction speed is slow, the operating time is sufficient, the heat release is small, the expansion rateis small, and the production costs of the product are reduced.

Owner:北京大敖海洋科技有限公司

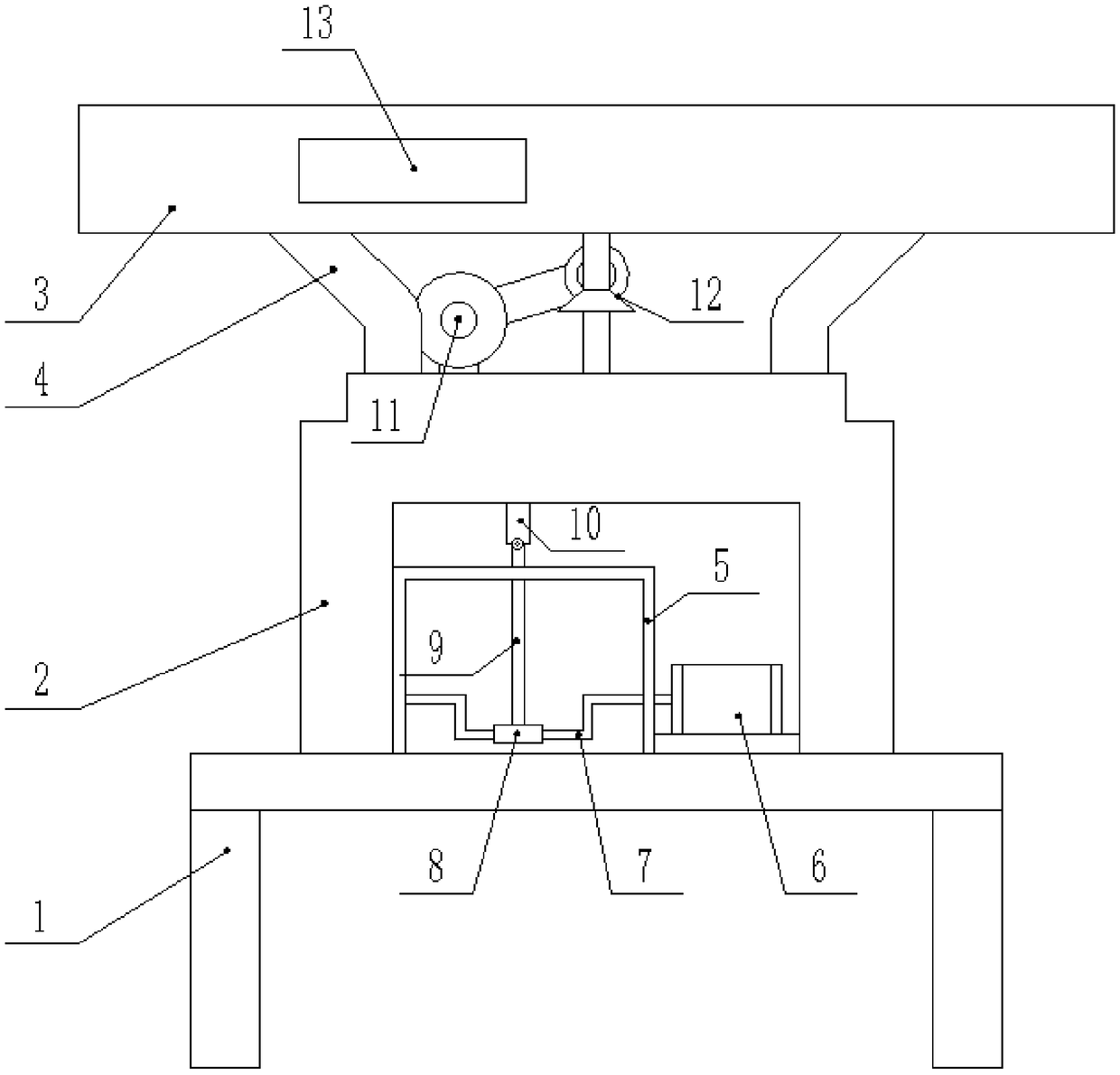

Mechatronics counter and use method thereof

InactiveCN109063813APlenty of time to operateSimple structureCounting mechanisms/objectsTime delaysDrive motor

The invention discloses a mechatronics counter and a use method thereof, the counter includes a device body, A base is arranged at the bottom of the device body, A bracket is arranged above the base,A rotating casing is arranged above the bracket, a supporting column is arranged at the bottom of the rotating casing, a receiving cavity is arranged in the device body, a crank is arranged inside thereceiving cavity, a driving motor is arranged outside the receiving cavity, a time delay structure is arranged above the bracket, and a bevel gear is arranged at the middle position of the bracket, wherein, a rotating casing is arranged above the bracket, a supporting column is arranged at the bottom of the rotating casing, a crank is arranged inside the receiving cavity, a driving motor is arranged outside the receiving cavity. The invention has simple structure, realizes the function of circulating counting through the intermittent movement mode, does not need manual control in counting process, directly and automatically counts, and the counting time interval is accurate, and provides sufficient operation time for the working staff, and is convenient to use and has strong practicability.

Owner:WUXI NANLIGONG TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com