Preparation method of MLA resin film serving as ore powder sample

A sample and resin technology, which is applied in the field of preparation of resin light sheet samples, can solve problems such as misleading inspection personnel in analysis and judgment, detection data deviation, etc., and achieves the effects of short process flow, low cost, and shortened static curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

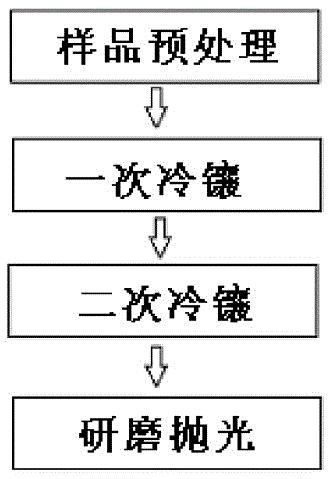

Method used

Image

Examples

Embodiment 1

[0028] 1) Crush and grind the loose massive bauxite ore sample to about 80% of -0.3mm, weigh 1g after shrinkage, put it in the oven for later use, and adjust the temperature of the oven to 60°C;

[0029] 2) Weigh 8g of Struers EpoFix resin and 0.8g of Struers EpoFix curing agent, stir for about 60s to make it evenly mixed, without filaments, inject it into the mold together with the sample to be used, stir for 95s, visually mix and then vacuum out the air bubbles, Let it stand for 4h to solidify;

[0030] 3) Cut the cured resin sample, cut two strips perpendicular to the surface of the sample, place the cross-section downwards, and place the particle-enriched side opposite in the mold, weigh 7.4g Struers EpoFix resin, 1.11g Struers EpoFix curing agent , Stir for about 1 minute and pour into the mold, vacuumize to remove air bubbles, and let it stand for about 3.5 hours to solidify.

[0031] 4) Grinding and polishing the cured product, using Struers grinding and polishing syst...

Embodiment 2

[0033] 1) Crush and grind the copper concentrate product until -0.3mm accounts for 60%, mix and shrink, weigh 1.6g, put it in an oven for later use, and adjust the oven temperature to 50°C.

[0034] 2) Weigh 5.7g of resin and 0.79g of curing agent, and stir rapidly for about 50s to make them evenly mixed without filaments. Pour it into the mold together with the sample to be used, stir for 85s, vacuumize after mixing to remove air bubbles, and let it stand for about 3.5 hours to solidify.

[0035] 3) Cut the cured resin sample, cut two strips vertically, place the cross-section down and the particle enriched side in the mold, weigh 7.8g Struers EpoFix resin, 0.78g Struers EpoFix curing agent, After stirring for 60s, pour it into the mold, vacuumize to remove air bubbles, and let it stand for 3.5 hours to solidify.

[0036] 4) Grinding and polishing the cured product, using Struers grinding and polishing system TegraSystem. Grinding uses silicon carbide sandpaper 180#, 320#, ...

Embodiment 3

[0038] 1) Crush and grind the lead-zinc ore until -0.3mm accounts for 70%, mix and shrink, weigh 2g, put it in an oven for later use, and adjust the oven temperature to 70°C.

[0039] 2) Weigh 5g of resin and 0.7g of curing agent, and stir rapidly for about 65s to make them evenly mixed without filaments. Pour it into the mold together with the sample to be used, stir for 75s, vacuumize after mixing to remove air bubbles, and let it stand for about 3 hours to solidify.

[0040] 3) Cut the cured resin sample, cut two strips vertically, place the cross-section down and the particle-enriched side in the mold, weigh 8.1g Struers EpoFix resin, 1.2g Struers EpoFix curing agent, After stirring for 65s, pour it into the mold, vacuum out the air bubbles, and let it stand for 4 hours to solidify.

[0041] 4) Grinding and polishing the cured product, using Struers grinding and polishing system TegraSystem. Grinding uses silicon carbide sandpaper 180#, 320#, 800#, 1200# for rough grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com