Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

267 results about "Residual soils" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

RESIDUAL SOIL: The soils that hold its position of their formation, without transporting, just above their parent rock are called residual or sedentary soil.

Drum cleaning program control method for full automatic washing machine

InactiveCN101413198AKeep the internal environment cleanDo not cause secondary pollutionOther washing machinesControl devices for washing apparatusLaundry washing machineControl engineering

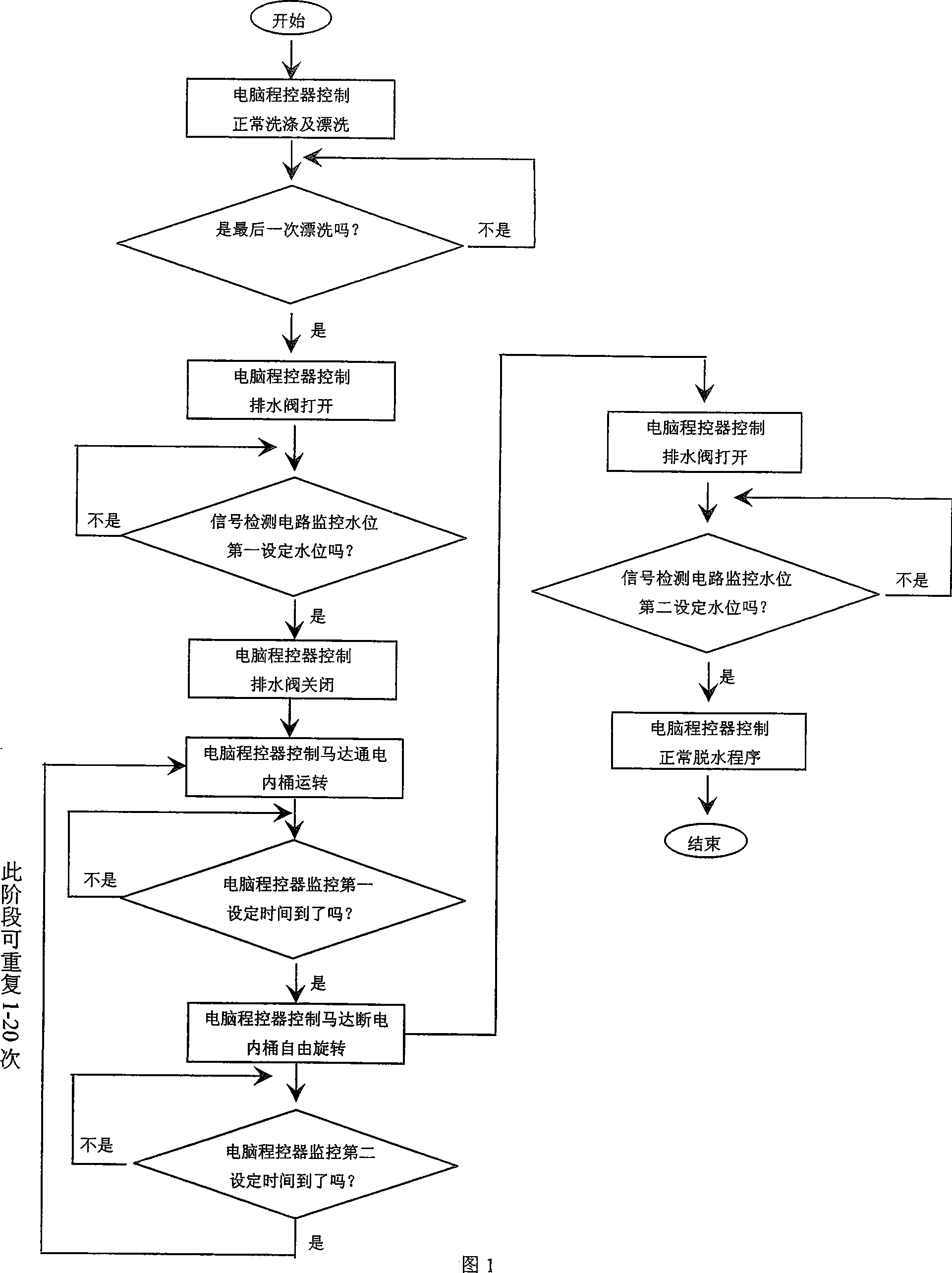

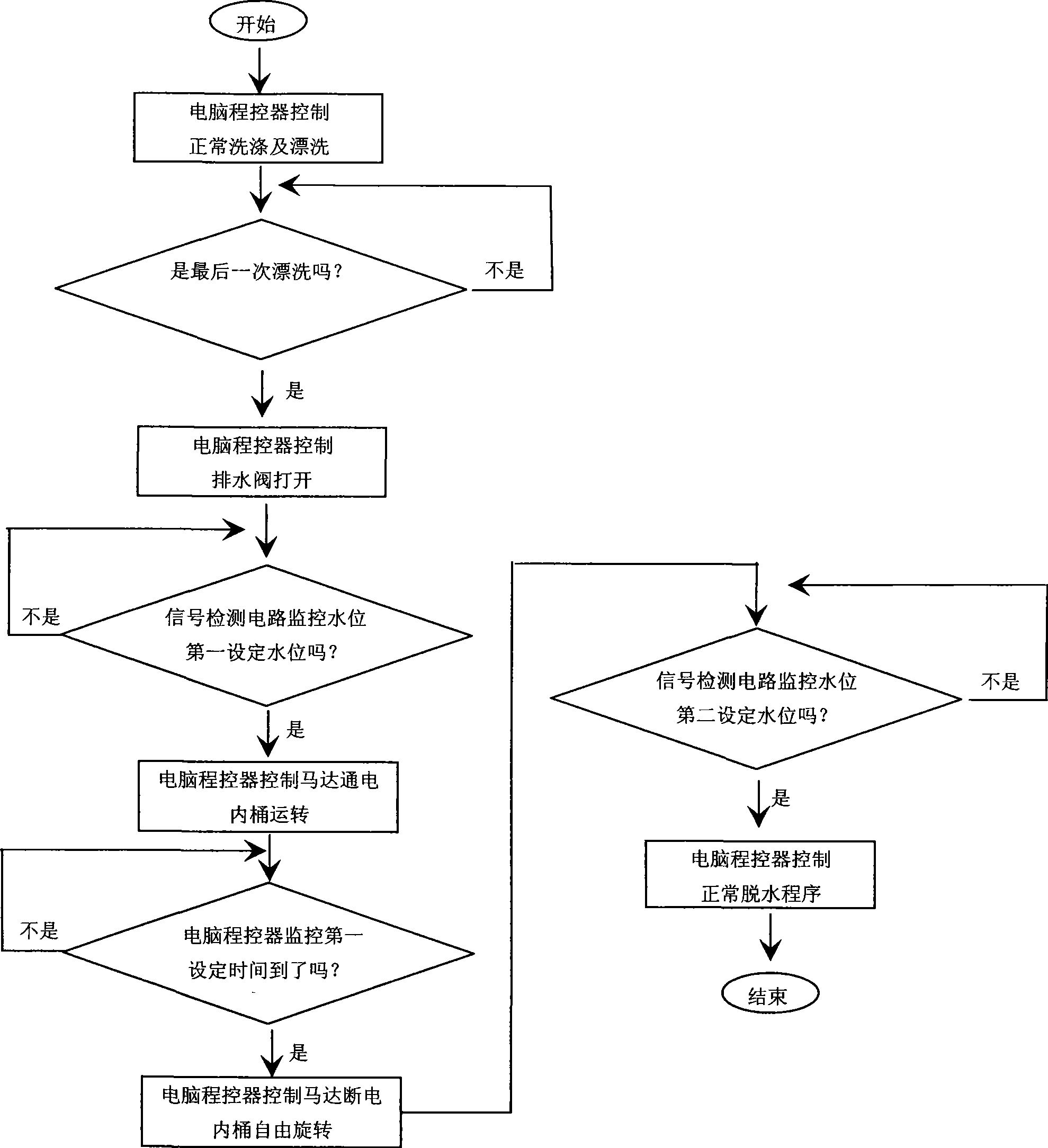

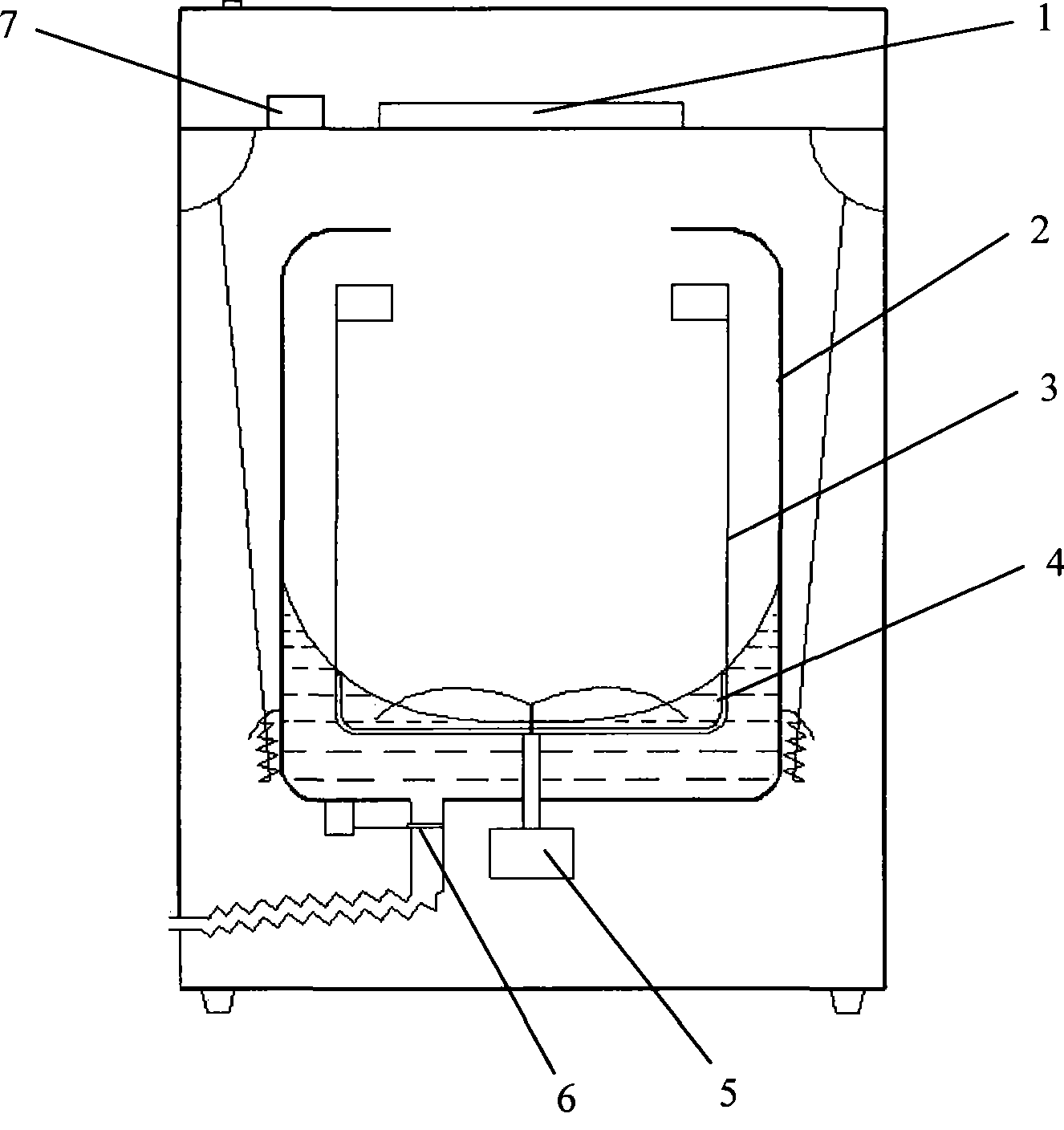

The invention discloses a method for controlling the cleaning procedure of an automatic washing machine drum, which is characterized in that drainage is begun after completion of final rinsing until the water level in a monitoring outer drum of a water level controller of a signal detection circuit reaches a first set water level; a computer programmed controller controls a drainage valve to close, and drainage stops; the computer programmed controller controls a motor to be electrified, and an inner drum rotates until a time controller of the computer programmed controller detects a first set time; the computer programmed controller controls the motor to be power-down, and the inner drum rotates freely until the time controller of the computer programmed controller detects a second set time; the computer programmed controller controls the drainage valve to open, and drainage begins until the water level in the monitoring outer drum of the water level controller of the signal detection circuit reaches a second set water level; and normal dehydration procedure is performed. The control method which changes rinsing, drainage and dehydration cleans the outside of the inner drum and the inside and the bottom surface of the outer drum of an automatic washing machine, removes residual soil, and maintains a clean internal environment for washing clothes.

Owner:PANASONIC HOME APPLIANCES R&D CENT HANGZHOU +1

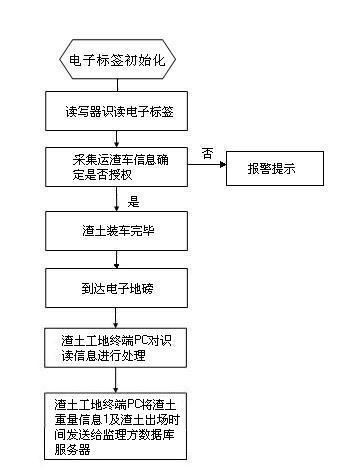

Engineering residual soil intelligent comprehensive supervision system based on RFID (radio frequency identification) technology and working method of system

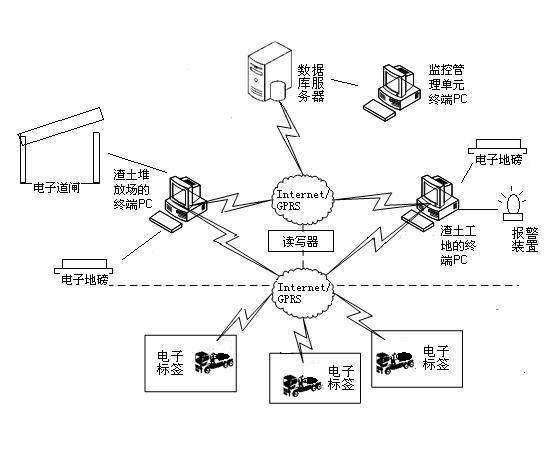

InactiveCN102156925AEasy to manageRadically eliminates the phenomenon of random throwing and dumping of dregsData processing applicationsCo-operative working arrangementsManagement unitManagement efficiency

The invention relates to the residual soil comprehensive supervision technology, provides an engineering residual soil intelligent comprehensive supervision system based on the RFID (radio frequency identification) technology and a working method of the system, wherein the system is composed of three parts, namely a supervision and management unit, a residual soil site unit and a residual soil stacking field unit. The engineering residual soil intelligent comprehensive supervision system based on the RFID technology and the working method of the system have the advantages that the residual soil site, residual soil transportation and residual soil stacking and the like can be tracked and managed intelligently in a whole course, the actual dynamic of residual soil treatment can be grasped, the system and the method are energy-saving and environmentally friendly, and the residual soil management efficiency is improved.

Owner:武汉启鑫物联网技术应用有限公司

Construction method of all casing precessing isolation pile

ActiveCN101638891AReduce disturbanceSave time for pilingFoundation testingRotary drillingResidual soilsBuilding construction

The invention discloses a construction method of all casing precessing isolation pile. The method comprises the following steps: downwardly and vortically placing a steel casing by a full-gyratory jacketing machine and removing various underground barriers while downward drilling of the steel casing, positively rotating an inner spiral drill pipe and reversely rotating an outer steel casing in thedrilling process to borrow soil, discharging soil carried by the rotation of the spiral drill from soil discharge port at the upper part of the steel casing, rotating and dropping a first steel casing section, positively rotating to lift up the spiral drill pipe to carry the residual soil in the steel casing, then adding another steel casing and another spiral drill pipe, repeating the steps until the design elevation is reached. In the method, the steel casing is placed downwardly by full-gyratory cutting, which causes low disturbance to the surrounding soil mass, results in higher work efficiency and has the capacity of directly removing underground barrier. The method is especially effective for removing complicated barriers and protection of periphery of structures.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

Construction residual soil sludge sintered brick doped with household garbage particles and its preparation method

InactiveCN102515835AImprove physical and mechanical propertiesImprove mechanical propertiesConstruction waste recoverySolid waste disposalBrickPrill

The invention discloses a construction residual soil sludge sintered brick doped with household garbage particles and its preparation method. The sintered brick is composed of the following raw materials by mass: 45-80% of construction residual soil, 10-35% of urban sludge, and 15-30% of an interior fuel. Specifically, with a particle size less than 3mm and a water content of 10%, the interior fuel comprises the components with the following mass percents in the raw materials of the sintered brick: 5-15% of coal slag and coal gangues, and 8-15% of household garbage particles, which are selected from combustible particles that undergo crushing, sorting, and dehydration pretreatments. The method of the invention makes fully use of urban construction residual soil, urban sludge, household garbage and other wastes, and changes waste materials into things of value. And the prepared sintered brick has superior physical and mechanical performances, low production cost, and is energy saving and environment friendly.

Owner:JIANGSU RES INST OF BUILDING SCI

Novel surface contact pipe curtain structure and construction method thereof

ActiveCN105464675AEasy splicingPrecise positioningUnderground chambersTunnel liningResidual soilsEngineering

The invention discloses a novel surface contact pipe curtain structure and a construction method thereof. The pipe curtain structure serves as the forepoling structure of a tunnel and is formed by splicing rectangular steel tubes or similar rectangular steel tubes, wherein each rectangular steel tube contains two or more contact surfaces, and surface contact is formed between each steel tube and the adjacent steel tube; each steel tube contains two or more contact surfaces, and the contact surfaces of each steel tube are in seamless attachment to the contact planes of the corresponding adjacent steel tubes; the dimensions of two contact planes which are in contact with each other are adapted to each other; a slide rail is welded to each of the two long edges of the outer wall surface of each steel tube along one of the contact planes, and every two adjacent steel tubes are fixedly connected through the corresponding slide rail. The novel surface contact pipe curtain structure is different from a traditional circular tube curtain structure, the rectangular or similar rectangular steel tubes are adopted, the novel surface contact pipe curtain structure has the advantages of being convenient to splice, great in structure stress, good in forepoling effect and the like, an extension type excavation expanding drill is used in the construction process, the cutting blind area problem of a non-circular steel tube drill bit is solved, and the difficult problem of cleaning residual soil in the tubes is effectively solved through high pressure water or high pressure blast.

Owner:BEIJING SHOUER ENG TECH

Recycling method for shield tunneling residual soil

ActiveCN109133839AReduce accumulationMeet strength requirementsSolid waste managementParticulatesSoil science

The invention provides a recycling method for shield tunneling residual soil and relates to the technical field of subway shield tunneling residual soil. The method comprises the following steps: 1, the residual soil produced by shield tunneling is subjected to innocent treatment, and mud and gravel particles are separated through stage-by-stage screening; 2, the separated mud is subjected to chemical component analysis, and the optimal water content and the maximum dry density of a soil sample are obtained by laboratory tests; 3, a proper soil stabilizer is selected according to different water content and different soil sample components for a mix ratio test; 4, the mud is cured for backfill of a foundation pit. After curing, 7d unconfined compressive strength of backfill can reach 1.5 MPa, strength requirements are met completely, the shield tunneling residual soil resources are used, and stacking of the shield tunneling residual soil is reduced.

Owner:BEIJING MUNICIPAL CONSTR +2

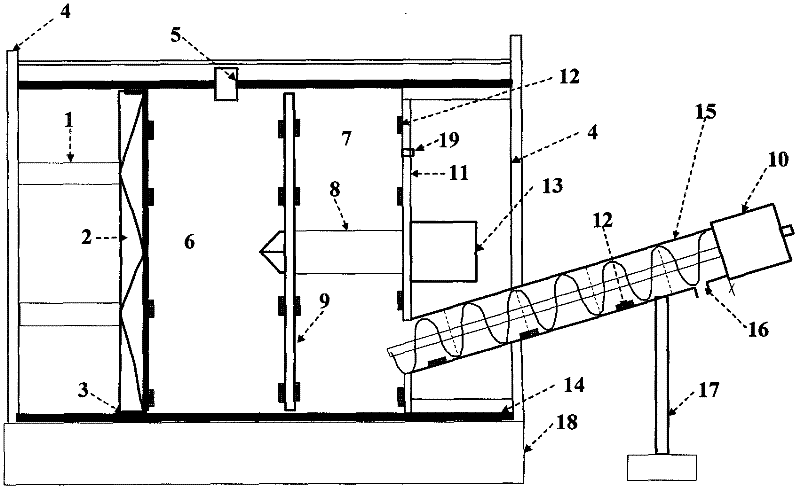

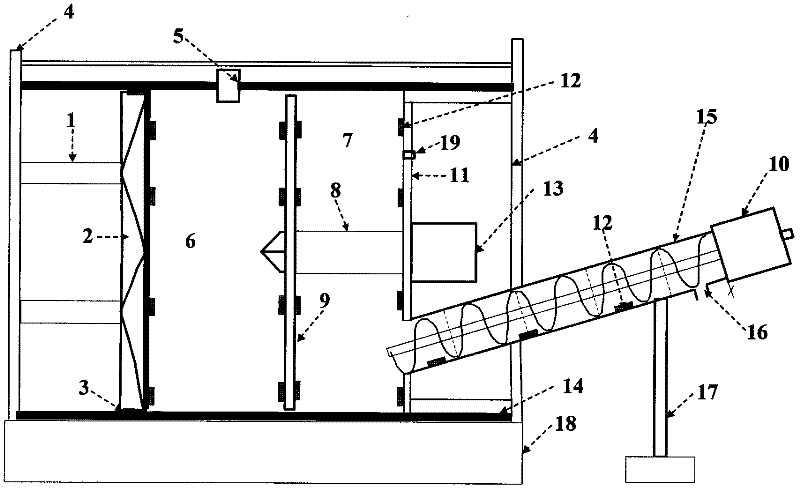

Earth pressure balance (EPB) shield residual soil pressure control model test apparatus

InactiveCN102226729AApparatus for force/torque/work measurementCompartment pressurePressure transmission

The invention discloses an earth pressure balance (EPB) shield residual soil pressure control model test apparatus. The model test apparatus mainly comprises a truss type loading system, a cutterhead, a sealed compartment, a screw conveyer and a pressure transducer system. The truss type loading system is connected with a reaction frame through a jack. Excavation surface loading can be realized by thrust of the jack. The cutterhead and the screw conveyer are driven by a motor. The pressure transducers are arranged on different positions of a sealed compartment separator plate and a screw conveyer housing. Pressure data is monitored by PC software through data an acquisition instrument. By using the apparatus, under the conditions of different modified residual soil, different sealed compartment pressure or different screw conveyer rotating speeds, and through monitoring typical position residual soil pressure of the sealed compartment separator plate and the screw conveyer, residual soil pressure transmission mechanism in the earth pressure balance (EPB) shield sealed compartment and the screw conveyer can be verified; a mapping relation between excavation surface pressure and thesealed compartment separator plate pressure and a pressure variation relation between an inlet and an outlet of the screw conveyer can be established. Therefore, an earth pressure balance (EPB) shield construction can be guided.

Owner:GUANGSHA CONSTR GROUP +1

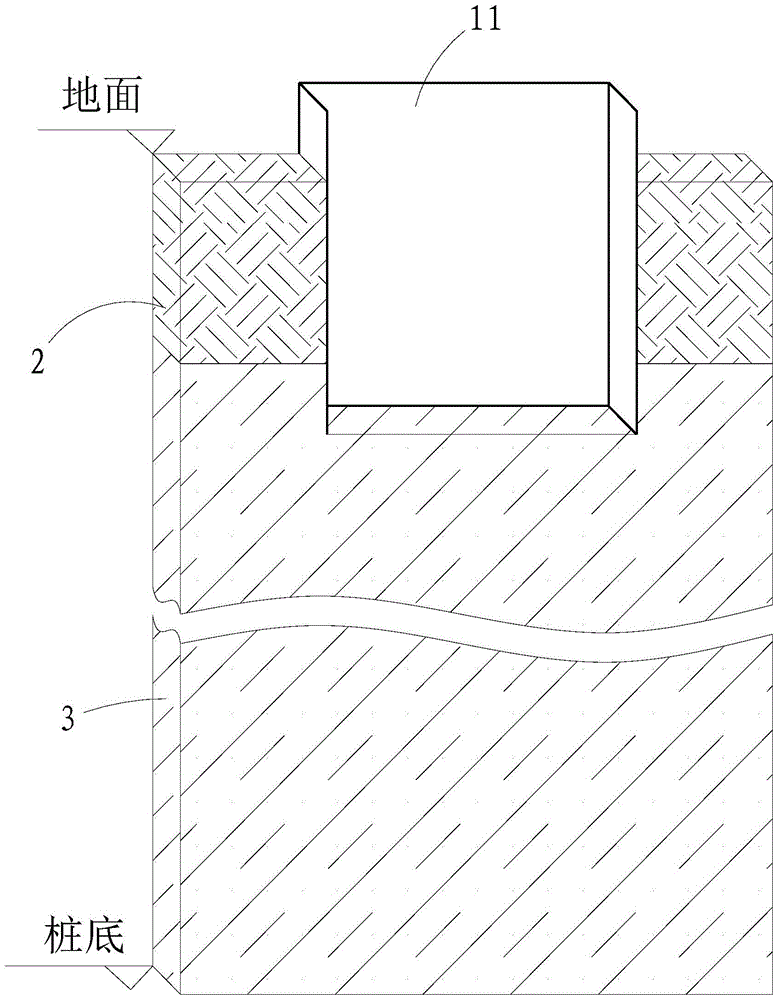

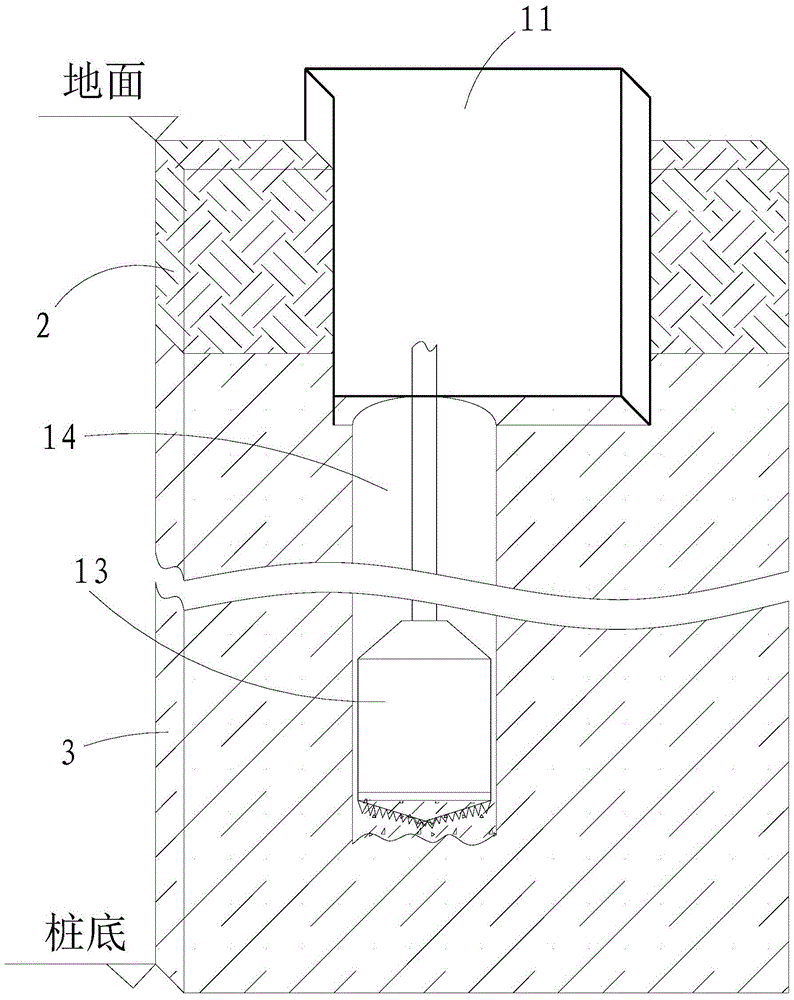

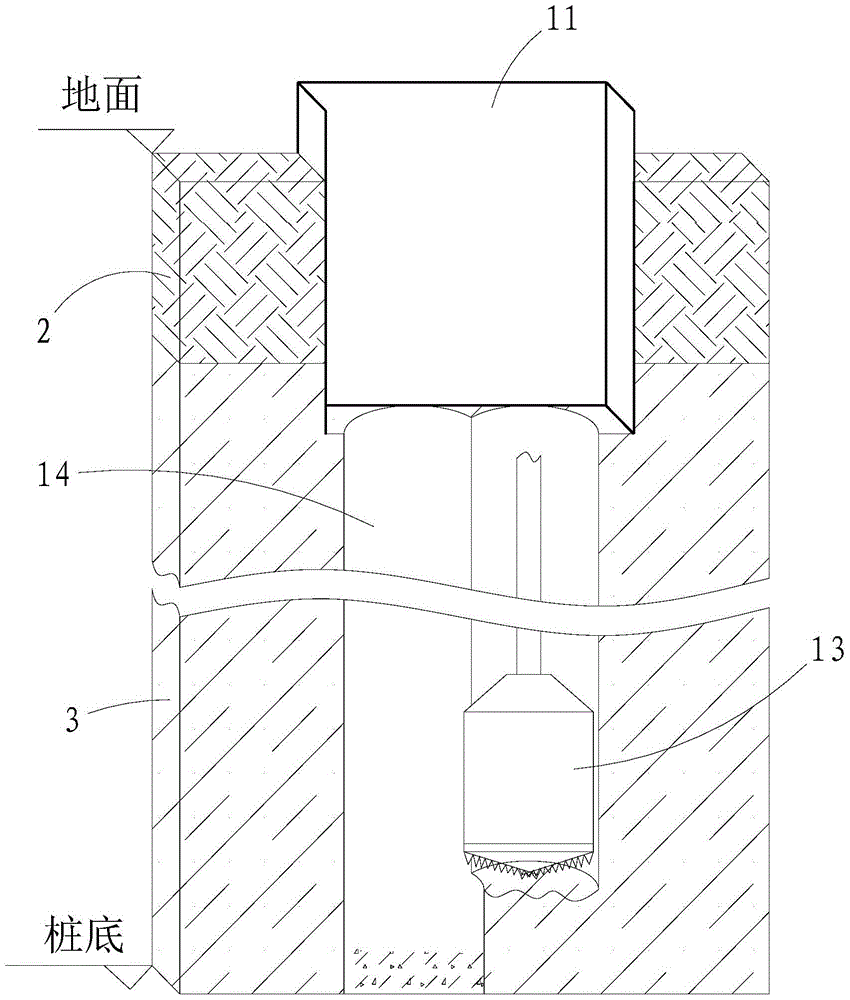

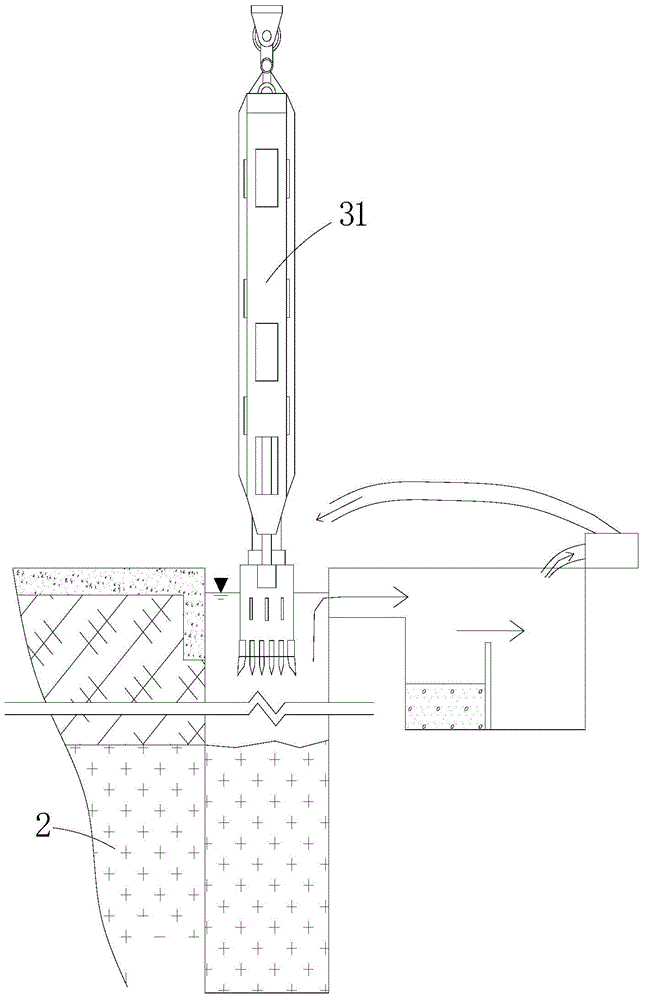

Forming method for square pile hole

InactiveCN105649011AFast molding speedQuality assuranceBulkheads/pilesDrilling machines and methodsResidual soilsDrill bit

The invention relates to the technical field of square pile holes, and discloses a forming method for a square pile hole. The forming method comprises the following construction methods that 1, trepanning is carried out, a square pile casing is put downwards, the lower end of the square pile casing penetrates a fill stratum and extends into a residual soil layer, and the upper end of the square pile casing extends out of the ground; 2, a round drill bit is utilized for carrying out hole guiding many times, a plurality of round holes are formed, the diameter of the round drill bit is consistent with the width of the square pile hole, the multiple round holes are sequentially connected in rows in the length direction of the square pile hole, and the extending length is consistent with the length of the square pile hole; and 3, a square drill bit is utilized for carrying out drilling from top to bottom, and the square pile hole is formed. The forming method for the square pile hole has the following beneficial effects that the forming speed of the square pile hole is high; the quality of the square pile hole is guaranteed; the construction cost is low, the construction speed is high, the single-machine comprehensive efficiency is high, and the mechanical construction cost is relatively low; and the construction site is clean, and field management is simplified.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

Method and apparatus for optical detection of bio-contaminants within a lumen

ActiveUS20180067051A1Lavatory sanitoryOptically investigating flaws/contaminationResidual soilsEndoscope

A method for optical detection of residual soil in lumens of lumened or cannulated devices such as surgical endoscopes, after undergoing a decontamination process (e.g., a washing or rinsing operation). A soil detection system provides an indication of the presence of residual soil within a lumen by detecting luminescent radiation emanating from the soil on the interior of the lumen in response to excitation light.

Owner:STERIS CORP +1

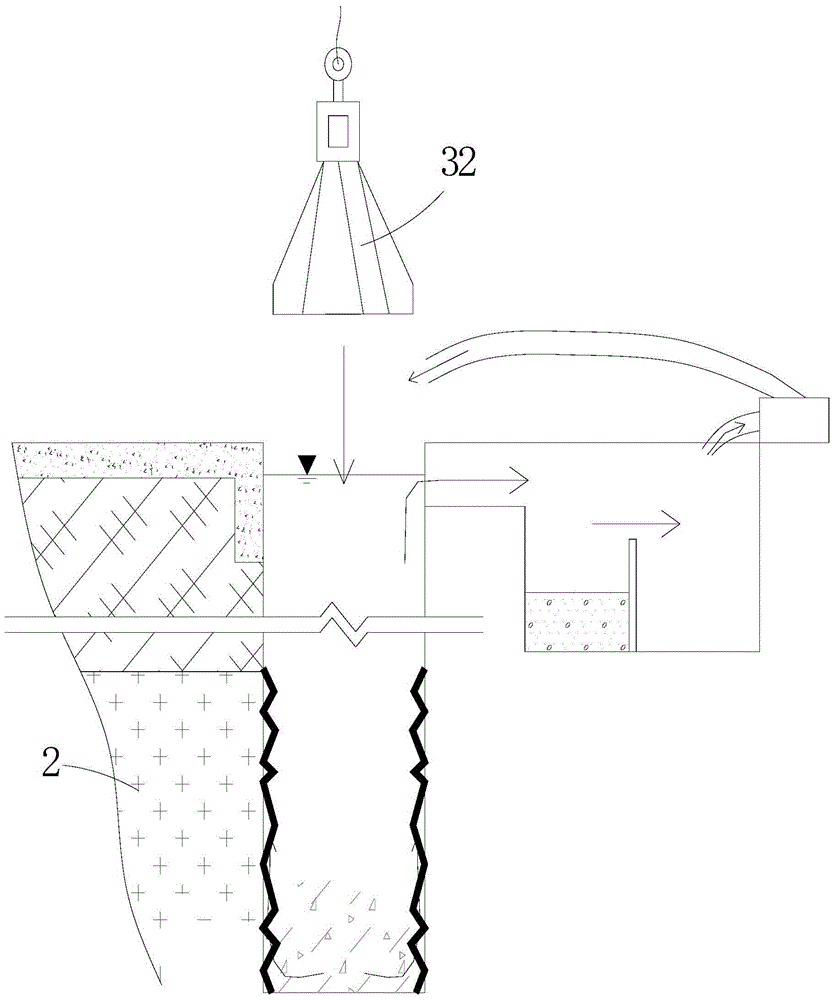

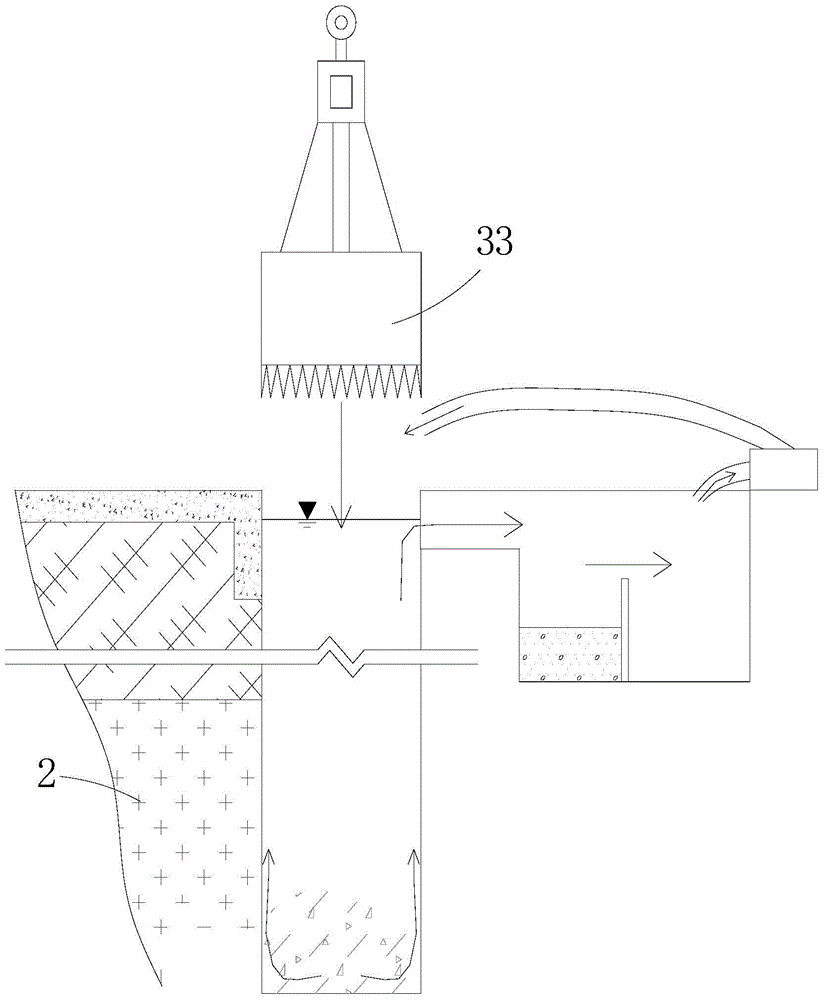

Grooving construction method for embedding underground continuous wall into rock

The invention relates to the technical field of embedding underground continuous walls into rock and grooving of the underground continuous walls and discloses a grooving construction method for embedding an underground continuous wall into rock. The method includes the steps that firstly, a grab bucket is used for excavating soil so that a groove can be formed, and a residual soil layer is reserved between the groove bottom and a rock face; secondly, a rotary excavating drilling tube is used for drilling holes in the residual soil layer and a seriously-weathered layer, a cutting-tooth drilling tube is used for drilling medium-weathered rock and micro-weathered rock, and rock entering holes in bed rock are formed; thirdly, the second step is repeated, and a plurality of rock entering holes are formed in the length extension direction of a groove segment; fourthly, a plane set-hammer is used for clearing away hard rock tooth edges. According to the construction method, the grooving speed is high, and on-site general layout and civilized construction are facilitated; meanwhile, the cutting-tooth drilling tube is used for performing rotary excavation and entering the rock to take a core, and impacting vibration is avoided; due to the fact that the grooving construction period is short, the exposing time of the groove wall is relatively short, the risk that groove wall soil collapses is reduced, the groove wall is stable, and construction cost is indirectly reduced; the residual soil layer is reserved on the rock face of the bed rock, the rotary excavating drilling tube plays a guiding role in the hole forming process, and the situation that because the inner rock face of the groove segment is inclined, hole drilling deflects is prevented.

Owner:SHENZHEN SUNHUI MECHANICAL CO LTD

Square anti-slide pile hole forming method and square drill bit for hole forming

InactiveCN108678661AImprove pore forming efficiencySimple structureConstructionsDrilling machines and methodsReinforced concreteEngineering

The invention relates to a square anti-slide pile hole forming method and a square drill bit for hole forming, which comprises the following steps: an outer contour of a lock opening is excavated manually, a template is arranged on the inner side, and the lock opening is formed by pouring the reinforced concrete; a protecting wall is arranged downwards on the bottom surface of the lock opening, and the protection wall is formed by pouring the reinforced concrete; the circular drill bit of the rotary drilling rig is sequentially connected to drill at least one row of circular guide holes alongthe length direction of the cross section of the square anti-slide pile hole, the circular guide holes of each row are also connected, and the side walls of the square anti-slide pile holes are tangent to the edges of the adjacent circular guide holes; the bit is replaced with the square drill bit, the gravity of the rotary drilling rig and the downward pressure of the power head of the rotary drilling rig is used to make the square drill bit cut the residual soil downwards along the contour line of the square anti-slide pile hole until the design requirement is met. The hole forming rectangular anti-slide pile of the rotary drilling rig is applied, so that the hole forming efficiency of the anti-slide pile can be improved, the safety risk can be reduced, and the hole forming quality can be ensured.

Owner:CHINA COMM NORTH ROAD & BRIDGE

Multicomponent compound drip washing liquid, repair method and its apparatus

InactiveCN1935968AEliminate potential hazardsSolve environmental problemsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsOil fieldResidual soils

The invention discloses aging thick oil contaminated soil grads multiple multielement compositional eluate, repairing method and the device. The detailed eluate composition, repairing method, and device can be seen in specification. It has the advantages of high residual soil cleanliness, high crude resources developing degree, simple device operation, and short repairing cycle. The produced eluate can be used to repair aging thick oil contaminated soil in oil field procedure.

Owner:PEKING UNIV

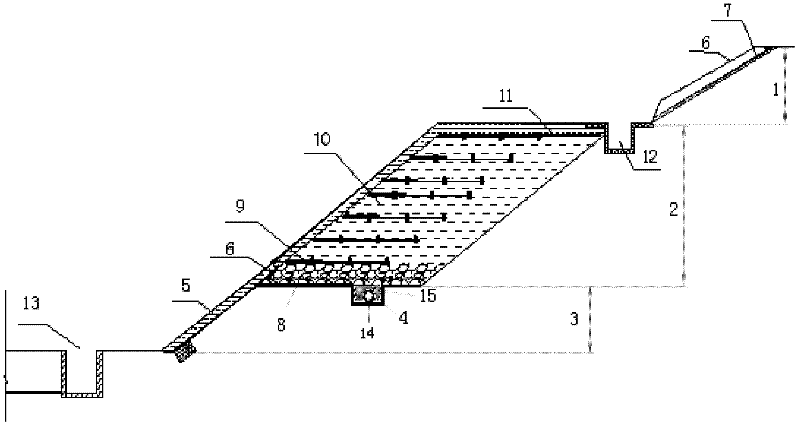

Flexible reinforcement combination protection structure for controlling humidification and damage for soft rock strong weathering zone

InactiveCN102518136AStrong targetingEnsure slope stabilityExcavationsEnvironmental resistanceResidual soils

The invention discloses a flexible reinforcement combination protection structure for controlling humidification and damage for a soft rock strong weathering zone. In the invention, in a residual soil layer (1) arranged at the upper part of a side slope, an excavated surface is laid with a first layer of geotextile (7) and spread plant loam (6), and is planted with grass; a soft rock of a strong weathering rock zone (2) arranged at the middle part of the side slope is reinforced by a flexible reinforcement retaining structure; and a weak weathering soft rock (3) arranged at the lower part of the side slope is protected by three-dimensional planting grass (5). The flexible reinforcement retaining combination protection structure is capable of stabilizing the side slope and greatly reducing the work amount, is simple and convenient in technology, rapid in construction speed, economical and environment-friendly, and can be used for resisting humidification and damage for the soft rock side slope strong weathering zone.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Remediation method of heavy metal-polluted soil

InactiveCN104307861AAvoid pollutionRealize the screening effectContaminated soil reclamationSoil sciencePollution soil

The invention discloses a remediation method of heavy metal-polluted soil, wherein the remediation method comprises the following steps: Step a, primary screening of soil: spraying water to polluted soil, performing primary screening on polluted soil by a screening device under the action of hydraulic flushing, separating and removing soil particles with the particle size less than 0.05 mm after screening, and collecting residual soil slurry; Step b, sand-water separation: performing sand-water separation on the soil slurry obtained in the step a, removing supernatant, and collecting precipitate; Step c, elution: fully contacting and reacting an eluting agent with the precipitate obtained in the step b, migrating heavy metals from soil solid phase into eluting liquid phase; Step d, dehydration: dehydrating the eluted soil obtained in the step c. The remediation method of heavy metal-polluted soil can perform effective remediation on heavy metal-polluted soil.

Owner:BEIJING GEOENVIRON ENG & TECH +1

Comprehensive repair method for residual quinclorac herbicide in tobacco field

InactiveCN104871777AResidue reductionPromote improvementPlant cultivationCultivating equipmentsNicotiana tabacumMonopotassium phosphate

The invention provides a comprehensive repair method for residual quinclorac herbicide in a tobacco field, and belongs to the technical field of herbicide residual soil treatment and repair. The method comprises the steps of detecting quinclorac in the soil after harvesting grains; deeply harrowing to sun the upturned soil in case of soil exceeding the standard (more than 0.05mg / kg); irrigating water to promote discharging one month before transplanting tobacco seedlings; applying quick lime or dolomite powder to the field surface under proper soil moisture content in order to achieve acid-base neutralization; applying straw biochar or carbon based organic fertilizer to the bottom of the ridge while ridging and fertilizing the flue-cured tobacco in order to physically absorb; spraying the leaf surfaces through a mixed solution of gibberellin (920), monopotassium phosphate and mancozeb or zineb in case of quinclorac chemical injury (the leaves are deformed in rat-tail shape) occurring on the flue-cured tobacco in the resettling stage or vigorous growing stage of the flue-cured tobacco so as to relieve or remove chemical injury. With the adoption of the method, the residual quinclorac in the soil of the tobacco field can be removed; in addition, the acidity of the soil can be reduced; the tobacco soil-borne disease can be prevented; the soil health can be promoted; the tobacco output and quality can be increased.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +2

Chemical eluting agent for repairing mercury polluted soil and application method of chemical eluting agent

InactiveCN106433649AReduce pollutantsShorten the timeContaminated soil reclamationOrganic fertilisersSodium hypochlorite solutionResidual soils

The invention discloses a chemical eluting agent for repairing mercury polluted soil and an application method of the chemical eluting agent, and belongs to the technical field of polluted soil repairing. The eluting agent is composed of an independent agent A and an independent agent B. The agent A comprises a hydrochloric acid solution, a potassium iodide solution and a sodium thiosulfate solution. The agent B comprises a sodium hydroxide solution and a sodium hypochlorite solution. The application method of the chemical eluting agent includes the following steps of firstly, preprocessing and smashing the soil and picking out impurities, stones and the like; secondly, adding the eluting agent A and the mercury polluted soil according to the ratio of the polluted soil to the eluting agent being 1:10-1:20 for continuous or intermittent stirring for 4-8 h; thirdly, adding water to residual soil after solid-liquid separation for cleaning and eluting; fourthly, adding the eluting agent B to the soil obtained after cleaning and eluting in the third step for continuous or intermittent stirring for 4-8 h; fifthly, conducting direct backfilling after adding water to residual soil for cleaning and eluting after solid-liquid separation. The method mainly includes the two steps of eluting, and the mercury content in the soil is effectively reduced by means of the different eluting agent A and eluting agent B.

Owner:BEIJING XINYUAN ENVIRONMENT CO LTD

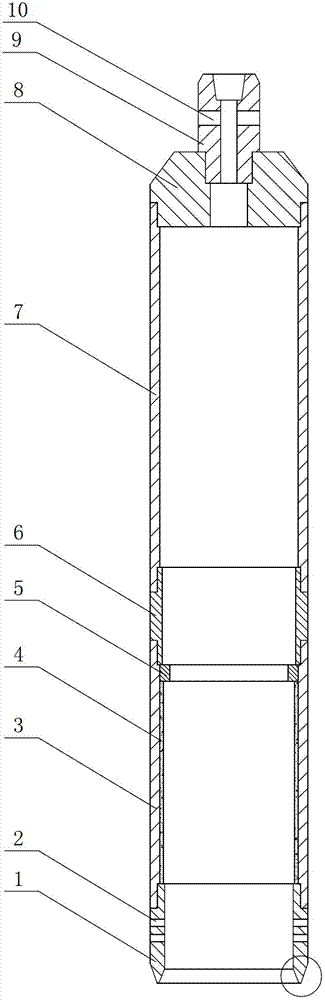

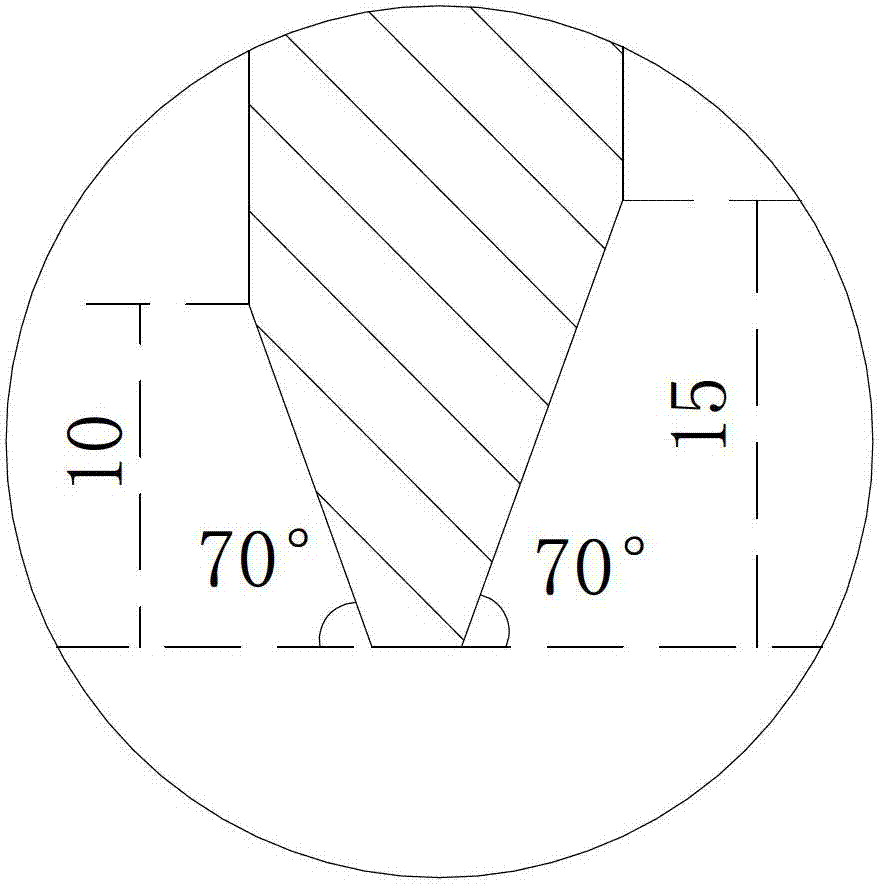

Covering layer sampling device

The invention relates to a covering layer sampling device, which comprises a sampling drill (1) on the end part, a sampler outer pipe (3), a residual soil pipe (7), an outer pipe joint (6) positioned between the sampler outer pipe (3) and the residual soil pipe (7), and a core-like inner cylinder (4) positioned on the inner wall of the sampler outer pipe (3), wherein a position stopping ring (5) is positioned on the inner wall of the sampler outer pipe (3) and between the outer pipe joint (6) and the core-like inner cylinder (4), the upper end of the residual soil pipe (7) is fixed with a cover head (8), the upper end of the cover head (8) is provided with a reducing joint (9), and the sampling drill (1) is an alloy drill with a quenching treatment or a normalizing treatment. The covering layer sampling device of the present invention has the following advantages that: adaptability on stratum is wide, no disturbance is generated to the rock sample, layer mixing of the upper layer and the lower layer is not generated, the original gradation and the original structure are maintained, representativeness of the rock sample is strong, requirements of geological description and rock sample tests can be met, and the sampler has characteristics of simple and reasonable structure, easy operation, and high sampling success rate.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES +1

Cabbage harvester

The invention discloses a cabbage harvester capable of completing the processes of cassava digging, conveying, cassava stem separation, soil removing and collecting and the like at one time. The harvester mainly comprises a suspension frame, a guide depth limiting device, a soil cutting and leakage prevention disc, a digging shovel, a rod type shaking lifting device, a digging shovel angle adjusting mechanism, supporting road wheels, a rack and a transmission system, wherein during operation, guide depth limiting wheel rolls, and exert the effects of guiding and crushing soil blocks; the digging shovel is used for scooping up the soil containing the potatoes, and a part of broken soil is leaked from the gaps of shovel pieces and the gaps of extending sieve bars; the soil cutting and leakage prevention disc cuts soil in a longitudinal direction of the cutting edge, and blocks the potato blocks leaked from the side; the cassava-containing soil falls on a lifting chain, and most of soil is shaken off when moves to the tail end of the lifting chain; the potato blocks are floated to the upper part of the residual soil layer, and finally, the potato blocks fall to the back floppy soil layer which is just turned over and shaken to break. The harvesting process is completed on the broken soft soil layer; and the single-row potato harvester has the advantages of high production efficiency, low labor intensity, compact structure, convenient movement and the like.

Owner:姜丹宁

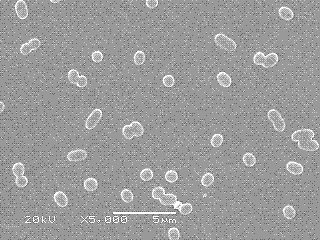

Enterobacter cloacae having phosphorus solubilizing function and used for degrading imazethapyr

The invention discloses enterobacter cloacae having a phosphorus solubilizing function and used for degrading imazethapyr and relates to enterobacter cloacae. The enterobacter cloacae have the functions of degrading imazethapyr and degrading indissolvable phosphorus into soluble phosphorus, thereby laying a foundation for solving the problem of soil pollution caused by residues of a herbicide imazethapyr by means of micro-biological degradation. The enterobacter cloacae T02 are preserved in CGMCC with the preserving address: #3, Yard 1, Beichen West Road, Chaoyang District, Beijing on Jule 9, 2014 and have a preservation number: CGMCC No. 9287. The enterobacter cloacae T02 not only have the function of degrading imazethapyr, but also have the function of degrading indissolvable phosphorus into soluble phosphorus. The enterobacter cloacae are used for degrading residual herbicide imazethapyr in soil.

Owner:INST OF MICROBIOLOGY HEILONGJIANG ACADEMY OF SCI

Potato harvesting and residual film recycling combine machine

PendingCN108293400AReduce labor intensityPlay the role of overload protectionDiggersGatherer machinesPlastic mulchResidual soils

The invention relates to a potato harvesting and residual film recycling combine machine. A two-stage conveying structure is adopted, potatoes move on a lower layer of a primary conveying shaking mechanism, and straw and a mulching film move on an upper layer of the primary conveying shaking mechanism; through the conveying of the primary conveying shaking mechanism, the potatoes fall down after the primary conveying is over, and the straw and the mulching film move upwards along a secondary conveying mechanism. Since a bow-shaped supporting rod of the secondary residual film conveying mechanism diffuses a mixture of residual soil and the potatoes towards the two sides, the mixture is gathered into lines in fields under the effect of a potato collecting sieve, the mulching film is collected by a wound film collecting device, and the straw is thrown out and returns to the fields or is wound around a residual film collecting barrel. As the place where the straw falls to is located at therear of the place where the potatoes fall to, the interference with picking up the potatoes caused by the burying of the straw underground is avoided. The potato harvesting and residual film recycling combine machine is light in weight, simple and ingenious in hierarchical structure, convenient and flexible, workers' labor intensity is alleviated, and the working efficiency is improved.

Owner:GANSU AGRI UNIV

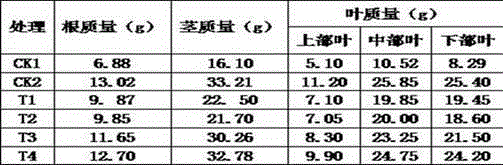

Indoor testing device and method for solidified residual soil by virtue of microorganism grouting technique

PendingCN107356463AReduce gapImprove accuracyPreparing sample for investigationEarth material testingStanding framePeristaltic pump

The invention relates to an indoor testing device and method for solidified residual soil by virtue of a microorganism grouting technique. The device is characterized by comprising an iron stand frame and a stainless steel splitting mold fixedly clamped on the iron stand frame, wherein the stainless steel splitting mold is filled with residual soil particles, a coarse sand pad layer and a gauze pad layer are sequentially arranged on and under the residual soil particles in the stainless steel splitting mold, ports of the stainless steel splitting mold are respectively plugged with an upper single-hole rubber plug and a lower single-hole rubber plug, a lower drainage tube penetrates into the lower single-hole rubber plug, a water stop clamp is arranged on the lower drainage tube, the upper single-hole rubber plug is sequentially connected with a flow guide pipe and a liquid storage device, and a peristaltic pump is connected to a middle section of the flow guide pipe. The indoor testing device is simple in structure and reasonable in design, resources are saved, and the difference between experiment data and actual soil property is reduced.

Owner:FUZHOU UNIV

Method for improving drought resistance of alfalfa

ActiveCN105027931AMeet growth needsTimely collectionGeneral water supply conservationAlkali orthophosphate fertiliserDrought resistanceResidual soils

The invention discloses a method for improving the drought resistance of alfalfa. The method comprises following steps: an alfalfa plot is deeply ploughed for 42-45 cm; the soil is deeply dug for 30-35 cm, the residual soil layer is leveled, and boxes are placed on the soil layer, wherein the side wall and the bottom portion of each box are provided with through holes, and the upper portion of each box is provided with an opening; 40-50% of the dug soil and a water-retaining agent are mixed to achieve the mixing soil, and the mixing soil is loaded into the boxes, wherein the loading volume of the mixing soil accounts for 2 / 3 of the volume of each box; a cover plate provided with meshes covers the mixing soil; the residual soil covers the cover plate to form a planting layer; ribs are made on the planting layer, furrows are arranged between the ribs, and alfalfa seeds are planted in the ribs; and furthermore, a headrace and a water storage well are arranged on one side of the alfalfa plot, one end of each furrow is enclosed, and the other end of each furrow is communicated with the headrace, so that rain water can flow into the water storage well along the furrows through the headrace, and water can be taken out from the water storage well when irrigation is required to be carried out.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

Construction muck regenerated soil treatment technology

InactiveCN107971325ASolve sortingResolve separabilityConstruction waste recoverySolid waste disposalSoil treatmentEngineering

The invention provides a construction muck regenerated soil treatment technology. Before construction mucks are fed into a preliminary crushing device I to be subjected to primary crushing treatment,blocky sundries are picked out by operators. After being preliminarily crushed into to-be-treated materials with the diameter not exceeding the main crushing feed upper limit, the construction mucks fall onto a belt conveyor 2, the sundries are picked out manually, and steel bars are attracted out through an iron separator; then the materials are conveyed into a roller stone scrubber 3 through thebelt conveyor 2, water is added into the materials, and the materials are stirred, struck, ground and washed; in the stirring and washing process, blocky construction waste are struck and ground, hardened soil blocks can be crashed and pulverized, all residual soil and dust and water on the sundries are combined into slurry, and then the slurry and the blocky materials together are fed into a screening and treating device 4; after solid particles and the sundries are filtered out, the slurry goes into a sand washer to remove sand; the sand-removed slurry overflows and goes into a sedimentation tank 6, soil particles start to precipitate slowly along with slowdown of water flow; after a period of time, the soil precipitates and solidifies; through a slurry pump or other devices, the slurryis charged into a stirring machine 7 and is stirred together with organic materials and additives; after being stirred uniformly, the mixture is dehydrated and solidified through a dehydrating device8 to form finished planting soil.

Owner:张宗楼

Dregs tipping device

The invention discloses a residual soil tipping device for a gantry crane used in construction of underground. The residual soil tipping device mainly comprises a tipping hook, a sliding seat, a bearing seat, a screw rod, a guide sleeve, a tooth-type coupler, a speed reducer, a motor, a fixed guide rail, a moving guide rail, a connecting rod, position switches and a pin shaft and is mainly characterized in that: a discharge mechanism is installed on a trolley of the crane to realize output of residual soil at arbitrary position; the motor and the speed reducer are used for directly driving the sliding seat to move on the fixed guide rail through the screw rod, so automatic hanging and discharge of the tipping hook is realized; and during working of the residual soil tipping device, a determined position for hanging and discharging of the tipping hook is controlled by the position switches installed at the two ends of the fixed guide rail. The residual soil tipping device adopts pure mechanical transmission, is simple in structure, low in manufacturing cost, low in fault rate, convenient and easy for maintenance, safety, reliable, and high in working efficiency.

Owner:湖南中铁五新重工有限公司

Slurry shield main engine for upper-soft lower-hard ground

ActiveCN104775824ASolve the problem that the pressure balance is not easy to controlSettlement controlTunnelsGratingAgricultural engineering

The invention discloses a slurry shield main engine for upper-soft lower-hard ground. The slurry shield main engine comprises a composite cutter-head, a main driver and a shield body, wherein the composite cutter-head is arranged at the forefront of the slurry shield main engine, the rear part of the composite cutter-head is connected with the main driver in a bolting way, and the main driver is arranged on the shield body; the back of the composite cutter-head is provided with a conical box body, the middle part of the shield body is provided with a central hopper, and the bottom of the shield body is provided with a bottom pulp sucking pipe; the rear end of the central hopper is provided with a central pulp sucking pipe, and the front end of the bottom of pulp sucking pipe is provided with a grid matched with the conical tank body. According to the slurry shield main engine provided by the invention, a tunnel face can be balanced by the pressure of muddy water, rocks can be broken by the excavation of the composite cutter-head and the relative rotation between the conical tank body and a grating plate, residual soil at the lower part of the slurry shield main engine can be lifted to the central hopper by using a scum board and a mucking plate and then can be discharged by the central pulp sucking pipe, so as to realize the function of synchronously discharging residues up and down, and prevent the accumulation of the rocks; furthermore, the problems that the pressure balance of the tunnel face is unlikely to be controlled in the construction of the upper-soft lower-hard ground and the hard rocks at the lower part of the tunnel face are difficult to cut can be effectively solved, and the construction efficiency and reliability of equipment can be improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

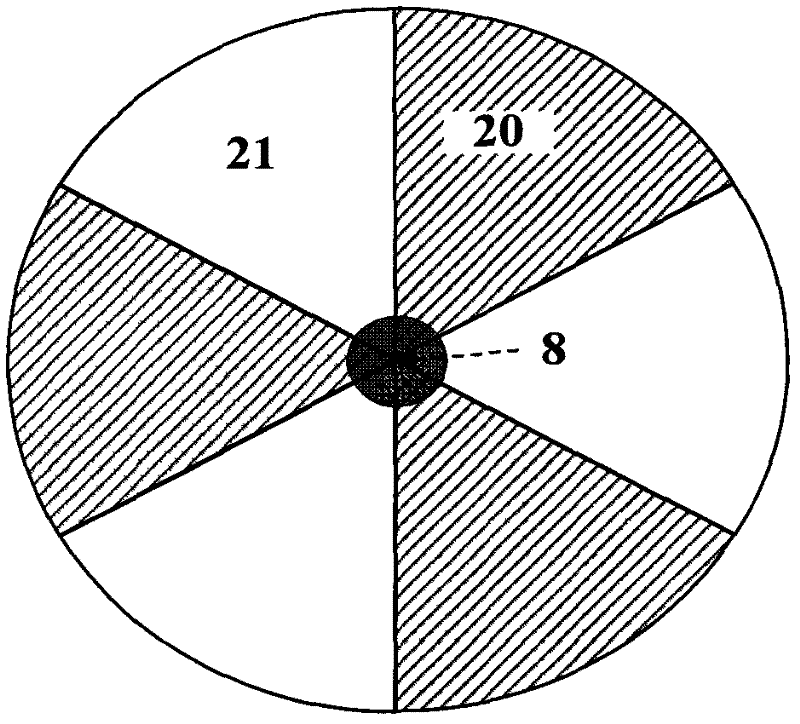

Hole cleaning drilling tool

InactiveCN102312660ASimple and fast operationImprove work efficiencyBorehole/well accessoriesResidual soilsPetroleum engineering

The invention discloses a hole cleaning drilling tool, which relates to a device for collecting deposited residual soil at the hole bottom and aims at providing the hole cleaning drilling tool with the advantages that the structure is simple, the cost is low, the operation is simple and convenient, and the work efficiency is high. The hole cleaning drilling tool comprises a drilling tube, wherein the upper end of the drilling tube is provided with a connecting component connected with a drilling rod, the lower end of the drilling tube is connected with an arc-shaped side plate, the arc-shaped side plate has the same radius as the drilling tube and is concentric with the drilling tube, the lower end of the arc-shaped side plate is connected with a corresponding fan-shaped bottom plate, a center shaft is arranged in the drilling tube, the lower end of the center shaft is fixedly connected onto the fan-shaped bottom plate, a baffle plate is fixedly connected between one side edges of the center shaft and the arc-shaped side plate, the lower edge of the baffle plate is fixed and connected with the fan-shaped bottom plate, a soil collecting plate capable of rotating around the center shaft is arranged on the center shaft, the lower edge of the soil collecting plate is slightly lower than the plane of the fan-shaped bottom plate, a downwards inclined support leg is arranged on one side surface of the soil collecting plate facing the baffle plate, and the lower end of the support leg is a little lower than the lower edge of the soil collecting plate.

Owner:BEIJING SANY HEAVY MASCH CO LTD

Method for optical detection of bio-contaminants

A method and apparatus for optical detection of residual soil on articles (such as medical instruments and equipment), after completion of a washing or a rinsing operation by a washer. A soil detection system provides an indication of soil on the articles by detecting luminescent radiation emanating from the soil in the presence of ambient light.

Owner:STERIS CORP +1

Intelligent soil sampling humidity analysis detector

InactiveCN111912657AHigh humidity detection accuracyHigh efficiency water recovery effectWithdrawing sample devicesUsing mechanical meansSoil scienceMoisture capacity

The intelligent soil sampling humidity analysis and detector comprises an analysis and detection machine body, a falling cavity with an upward opening is formed in the analysis and detection machine body, the upper end of the falling cavity communicates with a loading cavity with an upward opening, and a rotating switching wheel is rotationally arranged in the loading cavity; a switching plate capable of switching the opening and closing states in a rotating mode is arranged in the rotating switching wheel, the right wall of the loading cavity is provided with a meshing cavity in a communicating mode, and a rack capable of moving front and back is arranged in the meshing cavity.After soil is grabbed and stored, most of soil moisture is extruded and recycled through extrusion; According tothe invention, residual soil moisture in recovered soil is separated through high-speed shaking and then continues to be recovered, the high-efficiency soil moisture recovery effect is achieved, thenafter residual soil and moisture are discharged at the same time, the effect of cleaning the interior of the device is achieved, and the next soil moisture detection precision is higher.

Owner:磐安斯元智能装备科技有限公司

Compound stratum shield residual soil improvement construction system and method

The invention relates to the technical field of building construction, in particular to a compound stratum shield residual improvement construction system and method. The compound stratum shield residual improvement construction system comprises a bentonite system and a foam injection system, and further comprises a soil bin replacement tool changing system; the soil bin replacement tool changingsystem is combined with the bentonite system and the foam injection system, after a foam injection solution and bentonite slurry are stirred and mixed, a tool can be replaced, the replacement time isshortened, and the tunneling speed is effectively guaranteed. A foaming agent, P1 polymer and coal ash are mixed to enable shield cutting residual soil to have good flow plasticity, consistence, low water permeability and small frictional resistance.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Klebsiella inoculum capable of biodegrading residual chlorpyrifos pesticide on surfaces of garden stuffs and soil

A microbial strain capable of degrading chlorpyrifos pesticide residue in soil with the chlorpyrifos pesticide residue is isolated. The microbial strain is klebsiella sp. dsp-B by identification, Genbank accession number is HQ836365, and the strain preservation number is CCTCC: NO: M2012477. The characteristic of chlorpyrifos pesticide degradation of klebsiella is utilized for development of biodegrading inoculum applicable to the surfaces of garden stuffs and soil. The klebsiella inoculum belongs to the field of microbial environment modification, and the process flow comprises: purified strain preserving, shaking culture, seeding tank enlargement culture, fermentation tank secondary enlargement, and product split charging. The inoculum is simple in preparation technology, low in production cost and easy to popularize and apply, and the application characteristic is direct spraying. The klebsiella inoculum is capable of fast effectively degrading residual chlorpyrifos pesticide on the surfaces of garden stuffs and soil, so that the exceeding standard problem of the residue is solved; and the klebsiella inoculum has direct economical value for production nontoxic nuisance-free greed agricultural products.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com