Earth pressure balance (EPB) shield residual soil pressure control model test apparatus

A model test device, the technology of earth pressure balance shield, applied in the direction of measuring device, force/torque/work measuring instrument, instrument, etc., can solve the problems of difficult to obtain general laws and many influencing factors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

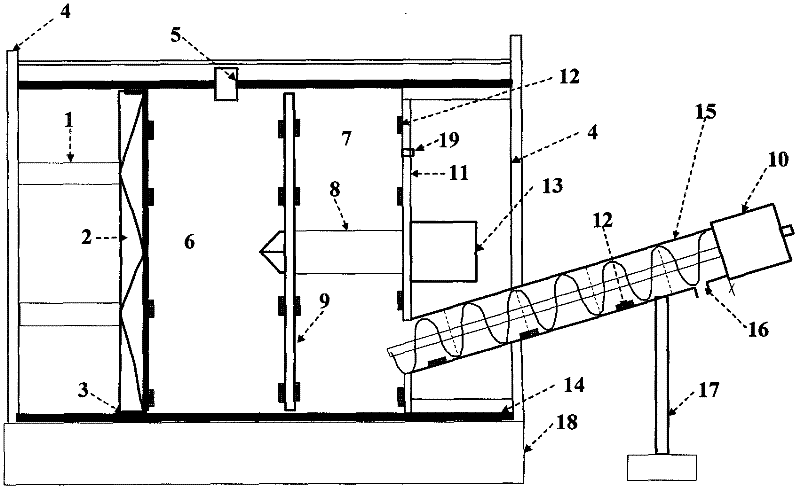

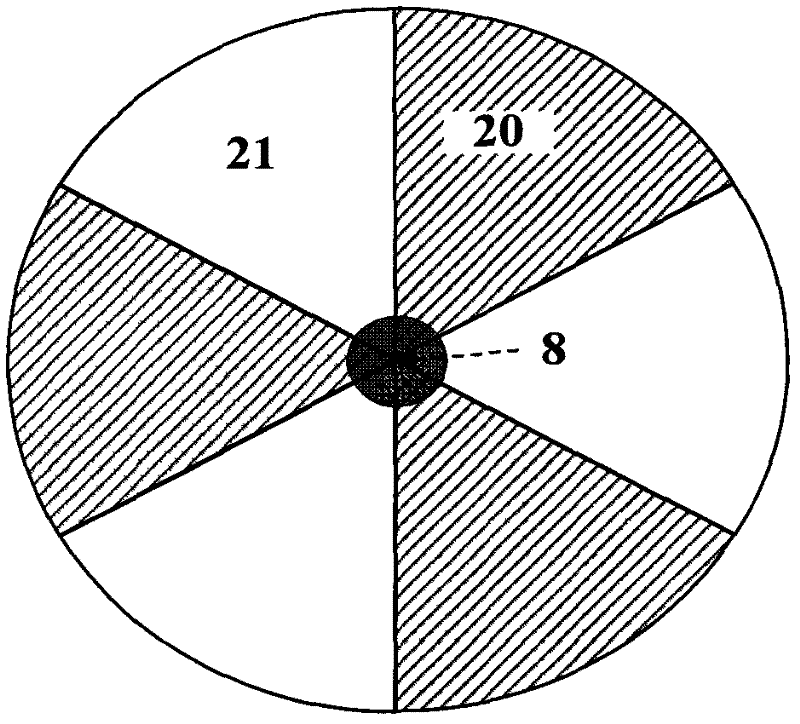

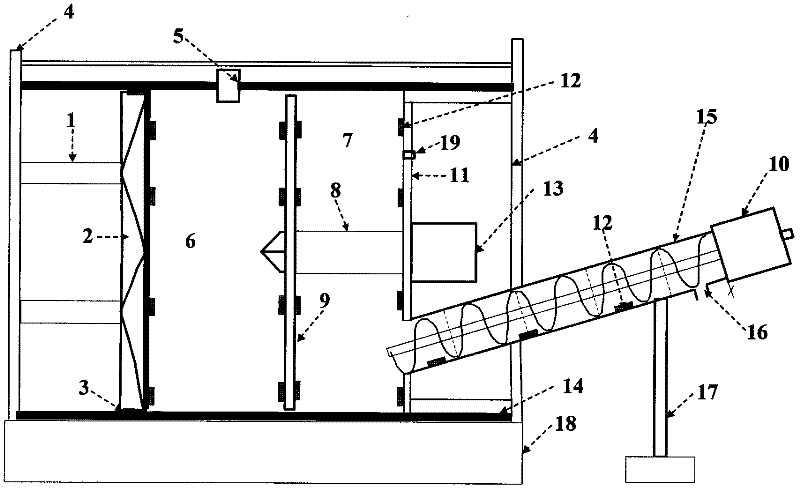

[0015] Such as figure 1 , figure 2 As shown, the present invention supports reaction frames at both ends of the circular shield shell 14 respectively, and the reaction force frames on both sides are connected by connecting rods 10, and a truss type loading system 2 is sealed and installed on one side of the hole of the circular shield shell 14, The other side of the circular shield shell 14 holes is equipped with a partition, and a drive motor 13 is installed on the outside of the partition 11. A cutter head 9 with an opening is installed towards the rotating shaft 8 of the drive motor 13 of the truss type loading system 2, and the partition 11 Consists of the airtight cabin 7 of the simulated shield with the cutter head 9, on the side of the truss type loading system 2 facing the cutter head 9, on the two sides of the cutter head 9, and on the partition 11 facing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com